Advertisement

Quick Links

MC160 Series PLC User Quick Start Manual

Thank you for using MC160 series PLC. Before using the product, please

carefully read this manual so as to better understand it, fully use it, and ensure

safety. This quick start manual is to offer you a quick guide to the design,

installation, connection and maintenance of MC160 series PLC, convenient for

on-site reference.

This manual is for the following series members:

MC160-0806BTD1

MC160-1206BTD1

MC160-0806BTD7

MC160-1214BMD1

Version:2.1

Revision Date:2019-05-17

BOM Code:R33010423

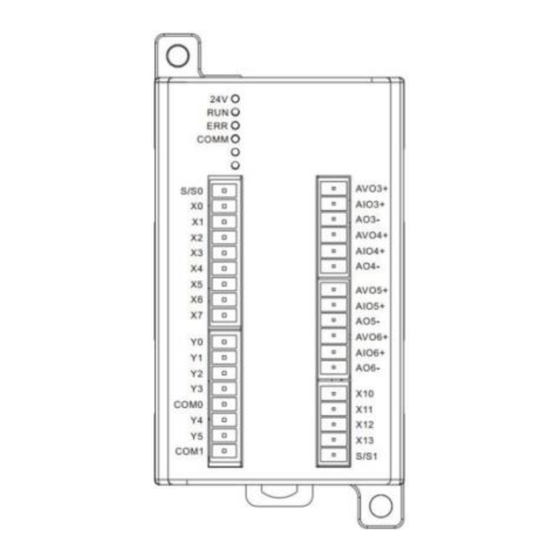

1. Appearance and Part Name

MC160-0806BTD1

MC160-0806BTD7

2. Model

3. Installation Description

3.1 Environmental Temperature

temperature exceeds 55° C for a long time.

3.2 Installation Site

3.3 Installation Method

cabinet, and maintain a distance of more than 20cm from the peripheral

equipment or cabinet wall. The installation in other directions is not conducive

to the PLC heat dissipation, and there can be no heating equipment under the

PLC. As shown in the picture below:

3.4 Installation Method

DIN rail mounting

MC160-1206BTD1

the DIN snap-fit at the bottom of the module and lock the bottom of the

module onto the DIN rail;

a double-checking, as the following figure:

Screw fixing

mounting. M3 screws can be chosen to fix the PLC onto the backboard of the

electric cabinet through the mounting holes on PLC enclosure, as the following

figure.

MC160-1214BMD1

Temperature range for PLC usage:-5℃~55℃.

Humidity: <85%RH, no condensation

A well-ventilated place should be selected when the ambient

◆ Place without corrosion, flammable and explosive gas and liquid.

◆

Solid place without vibration.

◆

This controller is designed for II standard installation environment and

2-level pollution occasions.

The PLC must be installed horizontally on the backplane of the electrical

Generally, you can mount the PLC onto a 35mm-wide rail (DIN). Open

Rotate module close to the DIN guide rail and close the DIN snap-fit with

Fixing the PLC with screws can stand greater shock than DIN rail

1

Advertisement

Summary of Contents for Megmeet MC160 Series

- Page 1 2. Model MC160 Series PLC User Quick Start Manual Thank you for using MC160 series PLC. Before using the product, please carefully read this manual so as to better understand it, fully use it, and ensure safety. This quick start manual is to offer you a quick guide to the design, installation, connection and maintenance of MC160 series PLC, convenient for on-site reference.

-

Page 2: Terminal Description

3.5 Cable connection and specification It is recommended to use stranded copper cables and prefabricate insulated ends to ensure connection quality. The following table lists the sectional areas and models of the recommended cables. Recommended Installation Cable Position Allowed NO. length method Power terminal(3PIN) - Page 3 L1+, L1-, LR1- PT100 thermal resistance input channel 1 L2+, L2-, LR2- PT100 thermal resistance input channel 2 L3+, L3-, LR3- PT100 thermal resistance input channel 3 L4+, L4-, LR4- PT100 thermal resistance input channel 4 Temperature control output channel 1~4, output OUT1~OUT4, COM2 common port 2 Y6, Y7, COM2...

- Page 4 Transistor output 3. It is recommended to use a connection cable with a length of less than The output terminals of MC160 series PLC are composed of several 100m to reduce measurement errors and noise interference. groups, which are electrically isolated each other, and the output contacts of different groups are connected to different power circuits;...

- Page 5 Poor cable connection, or 1. The warranty range is confined to the PLC only. incorrect signal property of 2. Warranty period is 18 months, within which period Megmeet conducts free Correct the signal circuit, such as reverse the maintenance and repairing to the PLC that has any fault or damage under the...

Need help?

Do you have a question about the MC160 Series and is the answer not in the manual?

Questions and answers