Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Epson N Series

- Page 1 6-Axis Robots N series MANUAL Rev.2 EM221R5137F...

- Page 3 6-Axis Robots N series Manual Rev.2 Copyright 2021-2022 SEIKO EPSON CORPORATION. All rights reserved. N series Rev.2...

- Page 4 Please notify us if you should find any errors in this manual or if you have any comments regarding its contents. MANUFACTURER CONTACT INFORMATION Contact information is described in “SUPPLIERS” in the first pages of the following manual: Robot System Safety Manual Read this manual first N series Rev.2...

- Page 5 Please separate used batteries from other waste streams to ensure that it can be recycled in an environmentally sound manner. For more details on available collection facilities please contact your local government office or the retailer where you purchased this product. N series Rev.2...

- Page 6 Directive 91/157/EEC and legislation transposing and implementing it into the various national legal systems. For other countries, please contact your local government to investigate the possibility of recycling your product. The battery removal/replacement procedure is described in the following manuals: Maintenance Manual N series Rev.2...

- Page 7 N2 series Manipulators can be used with the following combinations of Controllers and software. Controller : RC700-A Software : EPSON RC+ 7.0 Ver.7.2.0 or later N6 series Manipulators can be used with the following combinations of Controllers and software. Controller : RC700-A Software : EPSON RC+ 7.0 Ver.7.3.4 or later...

- Page 8 The manual is primarily intended for people who design robot systems or do programming. RC700 series Maintenance Manual (PDF) N series Maintenance Manual (PDF) This manual describes the details of maintenance etc. The manual is intended for people who perform maintenance.

- Page 9 EPSON RC+ 7.0 SPEL+ Language Reference (PDF) This manual describes the robot programming language “SPEL+”. Other Manual (PDF) Manuals for each option are available. N series Rev.2...

- Page 10 N series Rev.2...

-

Page 11: Table Of Contents

3.8 Checking the Basic Orientation ............35 4. End Effectors 4.1 Attaching an End Effector..............36 4.2 Attaching Camera and Air Valves ............37 4.3 WEIGHT and INERTIA Settings ............38 4.3.1 WEIGHT setting ................39 4.3.2 INERTIA setting ................42 4.4 Precautions for Auto Acceleration/Deceleration ........46 N series Rev.2... - Page 12 6.2 Camera Plate Unit ................61 6.3 Tool Adapter (ISO Flange) ..............64 6.4 User Wires.................... 65 Included items ..................65 6.5 Wiring Guide ..................66 6.6 Table Top Mount Bracket..............67 6.7 Calibration Plate ................... 69 N series Rev.2...

- Page 13 3.6 Connecting the Cables ............... 117 3.7 User Wires and Pneumatic Tubes............119 Electrical wires .................. 120 Pneumatic tubes ................120 3.8 Checking the Basic Orientation ............121 4. End Effectors 4.1 Attaching an End Effector..............123 N series Rev.2...

- Page 14 Remove the brake release unit ............155 How to use the brake release unit ............. 156 6.2 Camera Plate Unit ................157 6.3 Tool Adapter (ISO Flange) ..............160 6.4 User Wiring..................161 6.5 M/C Cable ..................161 N series Rev.2...

- Page 15 N6-A1000**: J3 (Table Top mounting, Ceiling mounting) ....185 N6-A1000**: J4 (Table Top mounting, Ceiling mounting) ....186 N6-A1000**: J5 (Table Top mounting, Ceiling mounting) ....186 N6-A1000**: J6 (Table Top mounting, Ceiling mounting) ....186 N series Rev.2 xiii...

- Page 16 N6-A1000**: J2 (Table Top mounting, Ceiling mounting) ....192 N6-A1000**: J3 (Table Top mounting, Ceiling mounting) ....192 N6-A1000**: J4 (Table Top mounting, Ceiling mounting) ....193 N6-A1000**: J5 (Table Top mounting, Ceiling mounting) ....193 N6-A1000**: J6 (Table Top mounting, Ceiling mounting) ....193 N series Rev.2...

-

Page 17: N2 Manipulator

N2 Manipulator This volume contains information for setup and operation of the Manipulators. Please read this volume thoroughly before setting up and operating the Manipulators. -

Page 19: Safety

WARNING not followed properly. This symbol indicates that a danger of possible harm to people or physical damage to equipment and facilities exists if the CAUTION associated instructions are not followed properly. N series Rev.2... -

Page 20: Design And Installation Safety

To ensure safety, a safeguard must be installed for the robot system. For details on the safeguard, refer to the Installation and Design Precautions in the Safety chapter of the EPSON RC+ User’s Guide. The following items are safety precautions for design personnel: ■... -

Page 21: Operation Safety

ON. Connecting or disconnecting the motor connectors with the power ON is extremely hazardous and may result in serious bodily injury as the Manipulator may move abnormally, and also may result in electric shock and/or malfunction of the robot system. N series Rev.2... - Page 22 (Speed: approx. 5 to 20%) depending on combination of Arm orientation and end effector load. Oscillation arises from natural oscillation frequency of the Arm and can be controlled by following measures. Changing Manipulator speed Changing the teach points Changing the end effector load N series Rev.2...

-

Page 23: Emergency Stop

Whether or not the reduction gear is damaged Whether or not the joints are in their proper positions If there is a position gap, perform calibration by referring to “N series Maintenance Manual- N2 Maintenance 8. Calibration”. Before using the Emergency Stop switch, be aware of the followings. - Page 24 In addition, time and distance of the free running vary by following factors: Hand weight WEIGHT Setting ACCEL Setting Workpiece weight SPEED Setting Posture etc. For time and distance of the Manipulator free running, refer to “Appendix B: Time and Distance of Free Running in Emergency”. N series Rev.2...

-

Page 25: Safeguard

Hand weight WEIGHT Setting ACCEL Setting Workpiece weight SPEED Setting Posture etc. For time and distance of the Manipulator free running, refer to “Appendix C: Time and Distance of Free Running When the Safeguard is Opened”. N series Rev.2... -

Page 26: How To Move Arms With The Solenoid Brake

>Brake On,[The number (from 2 to 6) corresponding to the arm whose brake will be turned ON] While the Solenoid brakes are ON (such as in emergency mode), you cannot move any arms except for Arm #1 by pushing manually. N series Rev.2... -

Page 27: Precaution For Operation In Low Power Status

■ Carefully operate the Manipulator in the low power status. A comparatively high joint torque may be generated. It may cause your hands and fingers caught and/or cause equipment damage to or malfunction of the Manipulator as it may collide CAUTION with peripheral equipment. N series Rev.2... -

Page 28: Warning Labels

When releasing the brakes, be careful of the arm falling due to its own weight. This warning label is attached on the Manipulator and optional brake release unit. Be careful not to burn yourself. N series Rev.2... - Page 29 The product name, model name, serial number, information which laws and regulations are supported, product specifications, manufacturer, importer, date of manufacture, country of manufacture, etc. are listed. For details, see the label affixed to the product. Location of Labels: N series Rev.2...

-

Page 30: Response For Emergency Or Malfunction

CAUTION While the brake is being released, the Manipulator’s arm falls by its own weight. The arm falling may cause hands and fingers to be caught and/or may cause equipment damage to or malfunction of the Manipulator. N series Rev.2... - Page 31 >Brake Off,[ the Arm (#2 to #6) whose brake will be turned OFF] Execute the following command to turn ON the brake again. >Brake On,[ the Arm (#2 to #6) whose brake will be turned ON] Using “Brake release unit (option)”: Refer to “6.1 Brake Release Unit”. N series Rev.2...

-

Page 32: Specifications

Manipulators are set to “Ceiling mounting” at shipment. To use the Manipulators as “Table Top mounting”, you need to change the model settings. For details on how to change the model settings, refer to “5.4 Changing the Robot”, and “EPSON RC+ User’s Guide Robot Configuration”. N series Rev.2... -

Page 33: Part Names

Be very careful.) Performing any work with the power ON is extremely hazardous and it may result in electric shock and/or improper function of the robot system. Make sure to turn OFF the Controller power before the maintenance work. N series Rev.2... -

Page 34: Outer Dimensions

N2 Manipulator 2. Specifications 2.3 Outer Dimensions [Unit: mm] 2.3.1 S/N: N201000001~N201010000 N series Rev.2... -

Page 35: S/N: N201010001 Or Later

N2 Manipulator 2. Specifications 2.3.2 S/N: N201010001 or later : Difference from “2.4.1 S/N: N201000001~N201010000” N series Rev.2... -

Page 36: Standard Motion Range

Manipulator. Arm #5 moves keeping a constant angle regardless of the arm pose. Depending on the arm pose of the basic arms, the wrist may collide with the Manipulator. The collision may cause equipment damage to and/or CAUTION malfunction of the Manipulator. N series Rev.2... -

Page 37: Specifications

It is also possible to install the Manipulator on the base table by making an installation hole like ceiling mounting. Calibration plate The option used for calibration. It helps to perform calibration with higher accuracy than calibration using the origin position marks (0 pulse position) on the exterior of the Manipulator. N series Rev.2... -

Page 38: How To Set The Model

The custom specifications may require a different configuration procedure; check the custom specifications number (MT***) and contact the supplier of your region when necessary. The Manipulator model can be set from software. Refer to the chapter Robot Configuration in the EPSON RC+ User’s Guide. N series Rev.2... -

Page 39: Environment And Installation

Manipulator will damage the food or not. The Manipulator cannot be used in corrosive environments where acid or alkaline is used. In a salty environment where the rust is likely to gather, the Manipulator is susceptible to rust. N series Rev.2... -

Page 40: Unpacking, Transportation, And Relocation

CAUTION Manipulator weight: 19 kg: 42 lbs. ■ Avoid excessive vibration or shock during Manipulator transporting. Excessive vibration or shock may cause equipment damage to and/or malfunction of the Manipulator. N series Rev.2... - Page 41 Controller. Do not unplug the M/C cable (power cable and signal cable) from the Manipulator. (M/C cable 3 m: 2 kg) (4) Unscrew the anchor bolts. Then, remove the Manipulator from the base table. N series Rev.2...

- Page 42 > Pulse 0, 0, 0, 0, 0, 0 NOTE The Joint #1 is not equipped with the brake. When installing the Manipulator, be careful not to rotate the Joint #1. The cable may break when exceeding Max. motion range. Be careful when operating. N series Rev.2...

-

Page 43: Mounting Dimensions

The maximum ranges in the above figure are the case when the end effector is 50 mm. If the end effector is longer than 50 mm, or the camera or the electromagnetic valve attached on the Arm is large, define the max motion ranges by considering the area where these tools may reach. N series Rev.2... -

Page 44: Installation

■ To ensure safety, a safeguard must be installed for the robot system. For details on the safeguard, refer to the Installation and Design Precautions in the Safety chapter of the EPSON RC+ User’s Guide. ■ Install the Manipulator in a location with sufficient space so that a tool or a work piece does not touch a wall or a safeguard when the Manipulator extends its arm fully while holding a work piece. - Page 45 Removing the base cover Leave about 200 mm from the base cover. Removal and installation procedures of the base cover are described in the following section. 200 mm N series Maintenance Manual N2 Manipulator- 3.15 Base Cover N series Rev.2...

-

Page 46: Base Table

If you are passing cables through the holes on the base table, see the figures below. [unit : mm] Power Cable Signal Cable M/C Cables Connector (Straight) Connector Power Cable Connector (L-shaped) Do not remove the M/C cables from the Manipulator. N series Rev.2... - Page 47 refer to the Controller manual. ■ To ensure safety, a safeguard must be installed for the robot system. For details on the safeguard, refer to the EPSON RC+ User’s Guide. WARNING Base Table – Design Example The following is an example for designing the base table of the N2 Manipulator.

-

Page 48: Connecting The Cables

After using the brake release unit, be sure to connect the external short connector to the Manipulator, or check connection of the connector for the brake release unit. N series Rev.2... -

Page 49: User Wires And Pneumatic Tubes

The user cable connector and the brake release connector have the same shape. Be careful not to connect the wrong connector. NOTE The Ethernet cable connectors Ether 1 and Ether 2 have the same shape. Be careful not to connect the wrong connector. N series Rev.2... -

Page 50: Electrical Wires

The commercially available Ethernet cables can be used. For details, refer to “6. Option”. Pneumatic tubes Max. Usable Pneumatic Pressure Pneumatic Tubes Outer Diameter × Inner Diameter 0.59 MPa (6 kgf/cm : 86 psi) ø6 mm × ø4 mm N series Rev.2... -

Page 51: Checking The Basic Orientation

The process to compensate the position gap is called “Calibration”. If the gap still exists and the Manipulator cannot be in the basic orientation after the calibration, please contact the supplier of your region. N series Rev.2... -

Page 52: End Effectors

Compatibility with ISO flange: For installing the end effector whose mounting dimensions are designed for the ISO flange, the optional tool adapter (ISO flange) is available. For details, refer to “6. Options”. N series Rev.2... -

Page 53: Attaching Camera And Air Valves

The decks are equipped to the Arms #3 and #5 for easy installation of the air valves. To mount the camera, the camera plate unit is necessary. The optional Camera Plate Unit is available. For details, refer to “6. Options”. N2-A450S* [Unit: mm] N series Rev.2... -

Page 54: Weight And Inertia Settings

Manipulator joint starts to rotate (amount of inertia). The inertia moment increases as weight of the load and amount of eccentricity increase. As this also increase the load applied on the joint, make sure to keep the inertia moment within the allowable value. N series Rev.2... -

Page 55: Weight Setting

WEIGHT command according to the load. Setting a value that CAUTION is smaller than the actual load may cause errors, excessive shock, insufficient function of the Manipulator, and/or shorten the life cycle of parts/mechanisms. N series Rev.2... - Page 56 Load on the Manipulator Mounting location of the load Arm #3 Deck Arm #5 Deck Load on the fore end of Arm #6 Details of the deck 2×M4 depth8 6×M4 depth6 Arm #5 Deck Arm #3 Deck [Unit: mm] N series Rev.2...

- Page 57 Load on the Arm #5 deck is 0.5 kg (M The deck is 290 mm (L ) away from the Joint #3. =0.8×0 /347 =0.5×290 /347 =0.35 → 0.4 (round up) =1.0+0+0.4=1.4 Enter “1.4” for the Weight parameter. N series Rev.2...

-

Page 58: Inertia Setting

The inertia moment of the load (weight of the end effector and work piece) on the Arm #6 can be set by the “inertia moment (INERTIA)” parameter of the INERTIA command. Select [Tools]-[Robot Manager]-[Inertia] panel and enter the value in [Load inertia:]. EPSON You may also execute the Inertia command from [Command Window]. N series Rev.2... - Page 59 #6 can be set by the “eccentric quantity” parameter of the INERTIA command. Enter the larger value of either “a” or “b” in the figure above to [Eccentricity]. Select [Tools]–[Robot Manager]-[Inertia] panel and enter the value into [Eccentricity:]. EPSON You may also execute the Inertia command from [Command Window]. N series Rev.2...

- Page 60 * The percentage in the graph is based on the acceleration / deceleration at rated eccentricity (0.005 kg·m ) as 100%. Automatic setting by eccentricity setting [mm] Eccentricity * The percentage in the graph is based on the acceleration / deceleration at rated eccentricity (30 mm) as 100%. N series Rev.2...

- Page 61 Figure out the whole inertia moment using the basic formulas below. (a) Inertia moment of a rectangular parallelepiped Rotation Center Rectangular Parallelepiped’s Center of Gravity + m × L (b) Inertia moment of a cylinder Cylinder’s Center of Gravity Rotation Center + m × L N series Rev.2...

-

Page 62: Precautions For Auto Acceleration/Deceleration

The acceleration/deceleration are controlled according to the Manipulator’s posture. When the Manipulator extends its arms or when the movement of the Manipulator produces vibration frequently, the acceleration/deceleration are reduced. Set appropriate values for WEIGHT and INERTIA so that the Manipulator operation is optimized. N series Rev.2... -

Page 63: Motion Range

Manipulator does not move. The pulse range can be set in [Tools]-[Robot manager]-[Range] panel. EPSON You may also execute the Range command from the [Command Window]. N series Rev.2... -

Page 64: Max. Pulse Range Of Joint #1

When viewing from the outside of the Arm #1, pulse values in counterclockwise direction are positive (+) and values in clockwise direction are negative (-). Arm #2 0 pulse position - direction + direction - direction + direction Angle (°) : ±180 Pulse (pulse) : ±7929856 N series Rev.2... -

Page 65: Max. Pulse Range Of Joint #3

From the angle of arm end, clockwise pulse values are positive (+) and counterclockwise pulse values are negative (-). - direction + direction + direction - direction Arm #4 0 pulse position Angle (°) : ±195 Pulse (pulse) : ±7170731 N series Rev.2... -

Page 66: Max. Pulse Range Of Joint #5

From the angle of arm end, clockwise pulse values are positive (+) and counterclockwise pulse values are negative (-). Arm #6 0 pulse position - direction + direction - direction + direction Angle (°) : ±360 Pulse (pulse) : ±13107200 N series Rev.2... -

Page 67: Restriction Of Manipulator Operation

The Manipulator cannot have the following orientation except in Jog motion. - When the angles of both Joint #2 and #3 are positive values with Righty, Below Elbow orientation. - When the angles of both Joint #2 and #3 are negative values with Lefty, Below Elbow orientation. N series Rev.2... - Page 68 Manipulator cannot move to the blue frame area. Similarly, the Manipulator cannot move to the red frame area when the tip of the arm is in the blue frame area. 580 mm (Red frame: rectangular of 110 mm × 580 mm × 332 mm) N series Rev.2...

-

Page 69: Coordinate System

5.3 Coordinate System The origin point is where the Manipulator’s installation face intersects with the rotation axis of Joint #1. For details on the coordinate system, refer to the EPSON RC+ Users Guide manual. Ceiling mounting Table Top mounting The “Table Top mount bracket” for Table Top mounting is available as an option. -

Page 70: Changing The Robot

N2 Manipulator 5. Motion Range 5.4 Changing the Robot This section describes how to change the Manipulator model on EPSON RC+. (Default setting is “Ceiling mounting”.) ■ Changing the Manipulator should be done with great caution. It initializes the robot calibration parameters (Hofs, CalPls), additional axis information, and PG parameter data. -

Page 71: Setting The Cartesian (Rectangular) Range In The Xy Coordinate System Of The Manipulator

These settings are disabled during a joint jogging operation. Therefore, be careful not to allow the end effector to collide with the Manipulator or peripheral equipment. Set the XYLim setting in [Tools]-[Robot manager]-[XYZ Limits] panel. EPSON You may also execute the XYLim command from the [Command Window]. N series Rev.2... -

Page 72: Options

87 mm Weight (Cables are not included.) 1.7 kg Cable to the Manipulator M/C Short connector For M/C power cable short-circuit View from A Power switch Power cable* Power lamp Brake release switches * Item you should provide N series Rev.2... -

Page 73: Power Cable

- Standard Sheet C13: AC250V / 10A For Japan Item Specification Plug PSE qualified Class I (2P+PE), AC125V, 7A or higher Code PSE qualified 0.75mm or larger Connector PSE qualified IEC 60320-1 Standard Sheet C13:AC125V/10A or higher N series Rev.2... -

Page 74: Mount The Brake Release Unit

If the M/C power cable is already connected to the Controller: Go to the step (3). (3) Remove the external short connector. External short connector (4) Connect the brake release unit to the connector of the connection cable. N series Rev.2... -

Page 75: Remove The Brake Release Unit

While the brake is being released, the Manipulator’s arm falls by its own weight. The arm falling may cause hands and fingers to be caught and/or may cause CAUTION equipment damage to or malfunction of the Manipulator. N series Rev.2... - Page 76 The brake will be enabled by pressing the switch once again. NOTE Move the arm the brake is released by two persons or more (one presses the switch and one moves the arm). The arm can be very heavy and needs the significant force to move. N series Rev.2...

-

Page 77: Camera Plate Unit

Mounting holes for the camera base plate on the N2 series Manipulator Camera base plate mounting hole For the installation steps, refer to the following manual: EPSON RC+ Option Vision Guide 7.0 Hardware & Setup Hardware 6.4.1 6-Axis Robot N series Rev.2... - Page 78 Joint #5 motion range that will be limited in this case. (°=degree) USB camera, −135° to −135° to −135° to −135° to 93 mm GigE camera +70° +53° +33° +13° 38 mm 18 mm -2 mm -22 mm N series Rev.2...

- Page 79 N2 Manipulator 6. Options Direction of the Joint #5 motion N series Rev.2...

-

Page 80: Tool Adapter (Iso Flange)

(1) Press-fit the pin to the Arm #6 end flange. Pin projection : 10.5 mm from the flange (2) Align the pin and the pin hole on the flange, and then Flange mount the flange. Hexagon socket head cap bolts: 4-M4×12 4-M4×12 N series Rev.2... -

Page 81: User Wires

Standard fittings kit for customer use (ø6 elbow) Item Qty. Manufacturer Standard ø6 elbow fitting KQ2L06-M5N Standard user connector kit (D-sub): Option Item Qty. Manufacturer Standard Connector DA-15PF-N (Solder type) (Connector setscrew: Clamp hood HDA-CTH(4-40)(10) #4-40 UNC) N series Rev.2... -

Page 82: Wiring Guide

Fix the cables and tubes along the wiring guide using the wire ties, and then install wiring to the end effector while leaving marginal length. Installation of Wiring Guide Reference: Example of wiring Wiring Guide M4×8 Wiring Guide Cables and tubes End effector N series Rev.2... - Page 83 Table top mount plate 3 Pin (ø6×15) Pin (ø6×25) Hexagon socket head cap bolts (M4×15) Table Top Mount Bracket Rough dimensions N2 side Table top mount plate 3 Table fixing side Table top mount plate 1 Table top mount plate 2 N series Rev.2...

- Page 84 Hexagon socket head cap bolts for M8 (4 bolts) (3) Fix the Manipulator on the table top mount bracket. Adjust position between the bracket and the Manipulator by the attached pin (ø 6×25). Fix the bracket and the Manipulator. Hexagon socket head cap bolts (4-M6×20) N series Rev.2...

-

Page 85: Calibration Plate

Using the origin position marks (0 pulse position) Using the calibration plate helps to perform calibration with higher accuracy than calibration using the origin position marks. For details of calibration, refer to N series Maintenance Manual “N2 Maintenance - 8. Calibration”. Calibration Plate Parts List Item Qty. - Page 86 N2 Manipulator 6. Options N series Rev.2...

-

Page 87: N6 Manipulator

N6 Manipulator This volume contains information for setup and operation of the Manipulators. Please read this volume thoroughly before setting up and operating the Manipulators. -

Page 89: Safety

WARNING not followed properly. This symbol indicates that a danger of possible harm to people or physical damage to equipment and facilities exists if the CAUTION associated instructions are not followed properly. N series Rev.2... -

Page 90: Design And Installation Safety

To ensure safety, a safeguard must be installed for the robot system. For details on the safeguard, refer to the Installation and Design Precautions in the Safety chapter of the EPSON RC+ User’s Guide. The following items are safety precautions for design personnel: ■... -

Page 91: Operation Safety

ON. Connecting or disconnecting the motor connectors with the power ON is extremely hazardous and may result in serious bodily injury as the Manipulator may move abnormally, and also may result in electric shock and/or malfunction of the robot system. N series Rev.2... - Page 92 Arm orientation, and end effector load. Oscillation arises from natural oscillation frequency of the Arm and can be controlled by following measures. Changing Manipulator speed Changing the teach points Changing the end effector load N series Rev.2...

-

Page 93: Emergency Stop

Whether or not the reduction gear is damaged Whether or not the joints are in their proper positions If there is a position gap, perform calibration by referring to “N series Maintenance Manual- N6 Maintenance 8. Calibration”. Before using the Emergency Stop switch, be aware of the followings. - Page 94 In addition, time and distance of the free running vary by following factors: Hand weight WEIGHT Setting ACCEL Setting Workpiece weight SPEED Setting Posture etc. For time and distance of the Manipulator free running, refer to “Appendix B: Time and Distance of Free Running in Emergency”. N series Rev.2...

-

Page 95: Safeguard

Hand weight WEIGHT Setting ACCEL Setting Workpiece weight SPEED Setting Posture etc. For time and distance of the Manipulator free running, refer to “Appendix C: Time and Distance of Free Running When the Safeguard is Opened”. N series Rev.2... -

Page 96: How To Move Arms With The Electromagnetic Brake

>Brake On,[The number (from 2 to 6) corresponding to the arm whose brake will be turned ON] While the Electromagnetic brakes are ON (such as in emergency mode), you cannot move any arms except for Arm #1 by pushing manually. N series Rev.2... -

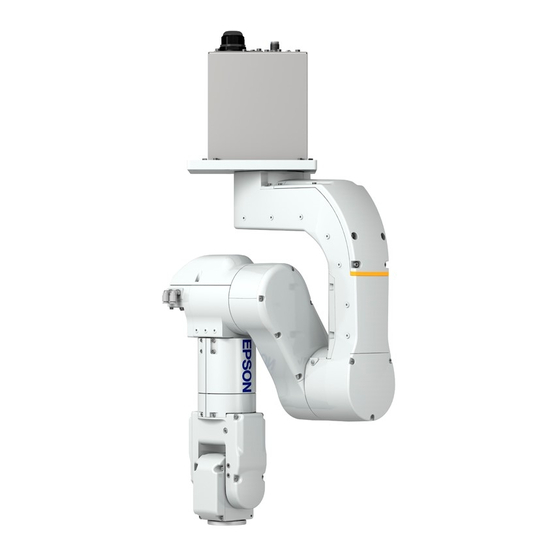

Page 97: Arm Motion

N6 Manipulator 1. Safety Arm Motion N6-A1000** Arm #2 Arm #3 Arm #1 Arm #5 Arm #4 Arm #6 Base N series Rev.2... -

Page 98: Precaution For Operation In Low Power Status

■ Carefully operate the Manipulator in the low power status. A comparatively high joint torque may be generated. It may cause your hands and fingers caught and/or cause equipment damage to or malfunction of the Manipulator as it may collide CAUTION with peripheral equipment. N series Rev.2... -

Page 99: Warning Labels

Only authorized personnel should perform sling work and operate a crane and a forklift. If unauthorized personnel perform these operations, it is extremely hazardous and may result in serious bodily injury and/or severe equipment damage to the robot system. N series Rev.2... -

Page 100: Location Of Labels

The product name, model name, serial number, information which laws and regulations are supported, product specifications, manufacturer, importer, date of manufacture, country of manufacture, etc. are listed. For details, see the label affixed to the product. Location of Labels: N6-A850*** N series Rev.2... - Page 101 N6 Manipulator 1. Safety N6-A1000** N series Rev.2...

-

Page 102: Response For Emergency Or Malfunction

Move the arm by hand. The Arm with brake (Arm #2 to #6): Release the brake on the subject arm, and then move the arm by hand. Arm #2 Arm #3 Arm #1 Arm #5 Arm #4 Arm #6 Base N series Rev.2... - Page 103 CAUTION While the brake is being released, the Manipulator’s arm falls by its own weight. The arm falling may cause hands and fingers to be caught and/or may cause equipment damage to or malfunction of the Manipulator. N series Rev.2...

- Page 104 >Brake Off,[ the Arm (#2 to #6) whose brake will be turned OFF] Execute the following command to turn ON the brake again. >Brake On,[ the Arm (#2 to #6) whose brake will be turned ON] Using “Brake release unit (option)”: Refer to “6.1 Brake Release Unit”. N series Rev.2...

-

Page 105: Specifications

N6-A850**R is for “Ceiling mounting” only. “Table Top mounting” is not available. For details on how to change the model settings, refer to “5.5 Changing the Robot”, and “EPSON RC+ User’s Guide Robot Configuration”. N series Rev.2... -

Page 106: Part Names

Be very careful.) Performing any work with the power ON is extremely hazardous and it may result in electric shock and/or improper function of the robot system. Make sure to turn OFF the Controller power before the maintenance work. N series Rev.2... - Page 107 Performing any work with the power ON is extremely hazardous and it may result in electric shock and/or improper function of the robot system. Make sure to turn OFF the Controller power before maintenance work. N series Rev.2...

- Page 108 Power cable : User Ether 1 Signal cable Signal cable Ether 2 Brake release connector : B-release Brake release connector : B-release User cable connector Ether 1 Ether 2 : User Ethernet cable connector N series Rev.2...

-

Page 109: Outer Dimensions

N6 Manipulator 2. Specifications 2.3 Outer Dimensions [Unit: mm] 2.3.1 Basic Orientation N6-A1000*: Cable direction: Standard (backward) N series Rev.2... - Page 110 N6 Manipulator 2. Specifications N6-A1000*B: Cable direction: Upward and Downward N6-A850*R: Cable direction: Standard (backward) N series Rev.2...

- Page 111 N6 Manipulator 2. Specifications N6-A850*BR: Cable direction: Upward N series Rev.2...

-

Page 112: Orientation With The Maximum Arm Length

N6 Manipulator 2. Specifications 2.3.2 Orientation with the Maximum Arm Length N6-A1000** N6-A850**R N series Rev.2... -

Page 113: Standard Motion Range

Manipulator. The collision may cause equipment damage to and/or CAUTION malfunction of the Manipulator. N6-A1000** [Unit: mm] (deg.= °) * P point : Intersection of the rotation centers for Joint #4, #5, and #6 A: No entry range (Reference: 5.2 Coordinate System) N series Rev.2... - Page 114 Joints #3, 5 0 pulse position Lateral View Lateral View Robot Robot installation face installation face * P point : Intersection of the rotation centers for Joint #4, #5, and #6 A: No entry range (Reference: 5.2 Coordinate System) N series Rev.2...

-

Page 115: Specifications

The option for mounting the end effector whose dimensions are designed for the ISO flange to the N6 series Manipulators. User wires The option for using the internal wiring for the end effector drive. Standard user connector kit: Standard D-sub 15-pin × 2 N series Rev.2... -

Page 116: How To Set The Model

(MT***) and contact the supplier of your region when necessary. The Manipulator model can be set from software. Refer to the chapter Robot Configuration in the EPSON RC+ User’s Guide. N series Rev.2... -

Page 117: Environment And Installation

Manipulator will damage the food or not. The Manipulator cannot be used in corrosive environments where acid or alkaline is used. In a salty environment where the rust is likely to gather, the Manipulator is susceptible to rust. N series Rev.2... - Page 118 Controller you are using. For details, refer to the Controller manual. WARNING ■ When cleaning the Manipulator, do not rub it strongly with alcohol or benzene. It may lose luster on the coated face. CAUTION N series Rev.2...

-

Page 119: Unpacking, Transportation, And Relocation

N6-A1000** N6-A850**R CAUTION Weight: 69 kg: 152 lbs. Weight: 64 kg: 141 lbs. ■ Avoid excessive vibration or shock during Manipulator transporting. Excessive vibration or shock may cause equipment damage to and/or malfunction of the Manipulator. N series Rev.2... - Page 120 > Pulse 0, 0, 0, 0, 0, 0 N6-A1000** N6-A850**R Center of Center of gravity gravity (3) Turn OFF the power for all devices and disconnect the power cable connector and signal cable connector from the Controller. N series Rev.2...

- Page 121 (5) Secure the Manipulator to the delivery equipment or have at least 2 people to carry the Manipulator. (6) After installing the Manipulator, turn ON the Controller. (7) Return the Manipulator to the basic orientation. Command EPSON > Pulse 0, 0, 0, 0, 0, 0 N series Rev.2...

- Page 122 ■ Remove the eyebolts from the Manipulator after transportation/relocation is completed. If the Manipulator is operated with the eyebolts left on it, the arm may collide with the eyebolts and it may cause equipment damage to and/or CAUTION malfunction of the Manipulator. N series Rev.2...

-

Page 123: Mounting Dimensions

To prevent the power cable from bending, make sure to leave space for 150mm When NOTE installing the cable, be sure to maintain sufficient distance from obstacles. In addition, leave enough space for other cables to prevent them from bending. [Unit: mm] 3.3.2 Mounting dimensions N6-A1000**: Cable direction: Standard (backward) N series Rev.2... - Page 124 N6-A1000**: Cable direction: Upward and Downward Cleanroom model Standard model *: Example of space for Manipulator base for “Cable direction: Upward and Downward”: Design the base table as shown above considering not interfering with the positioning holes and the installation holes. N series Rev.2...

-

Page 125: Motion Range

When operating in narrow space with the basic orientation, make sure to consider the radius of the arm rotation as shown the figure below. The Manipulator must be installed to avoid interference with peripherals during operation. N series Rev.2... - Page 126 N6 Manipulator 3. Environment and Installation N6-A1000**: Maximum motion range N series Rev.2...

- Page 127 N6-A1000**: Radius of arm rotation (Basic orientation) Motion range (CP motion) P point* 310 R510 (Motion position) * When the P point is 310mm apart from the center, upward and downward distance in CP motion will be the maximum. N series Rev.2...

- Page 128 N6 Manipulator 3. Environment and Installation N6-A850**R: Maximum motion range N series Rev.2...

-

Page 129: Installation

■ To ensure safety, a safeguard must be installed for the robot system. For details on the safeguard, refer to the Installation and Design Precautions in the Safety chapter of the EPSON RC+ User’s Guide. ■ Anchor the Manipulator before turning ON the power to or operating the Manipulator. - Page 130 Tap hole position for transportation N6-A1000** 3-M10 depth 18 depth 20* * Same for the other side N6-A850**R 3-M10 depth 18 depth * Same for the other side N series Rev.2...

- Page 131 When operating the Manipulator after installing it, exhaust from the exhaust port is 60L/min. Cable direction: Standard (backward) Cable direction: Upward and Downward Cleanroom model:Exhaust port (One-touch fittings for ø10 mm pneumatic tubes) Cleanroom model:Exhaust port (One-touch fittings for ø10 mm pneumatic tubes) N series Rev.2...

-

Page 132: Base Table

3.3.2 Mounting dimensions Connector [unit : mm] If you are passing cables through the holes on the base table, see the figures below. Power Cable Signal Cable M/C Cables Connector (Straight) Connector Power Cable Connector (L-shaped) N series Rev.2... -

Page 133: Connecting The Cables

refer to the Controller manual. ■ To ensure safety, a safeguard must be installed for the robot system. For details on the safeguard, refer to the EPSON RC+ User’s Guide. WARNING 3.6 Connecting the Cables ■ Before performing any replacement procedure, turn OFF the Controller and related equipment, and then disconnect the power plug from the power source. - Page 134 Follow local regulations for grounding. It is recommended that the core size of the grounding wire be 5.5 mm or more. Directly connect the ground line to the Manipulator as shown in the figure below. N6-A1000** Bolt hole M5 (for grounding) N6-A850**R Bolt hole M5 (for grounding) N series Rev.2...

-

Page 135: User Wires And Pneumatic Tubes

Air 1 Air 2 Ethernet cable connectors One-touch fittings for ø6 mm pneumatic tubes N6-A850**R User cable connector USER Air 1 Air 2 Ether 2 Ether 1 Ethernet cable connectors One-touch fittings for ø6 mm pneumatic tubes N series Rev.2... -

Page 136: Electrical Wires

The commercially available Ethernet cables can be used. For details, refer to “6. Option”. Pneumatic tubes Max. Usable Pneumatic Pressure Pneumatic Tubes Outer Diameter × Inner Diameter 0.59 MPa (6 kgf/cm : 86 psi) ø6 mm × ø4 mm N series Rev.2... -

Page 137: Checking The Basic Orientation

How to return to the origin position Turn ON the Controller. Turn ON the Manipulator motors. Command EPSON > Motor On Move the joints to the origin position. Command EPSON > Pulse 0, 0, 0, 0, 0, 0 Basic Orientation N6-A1000** N series Rev.2... - Page 138 The process to compensate the position gap is called “Calibration”. If the gap still exists and the Manipulator cannot be in the basic orientation after calibration, please contact the supplier of your region. N series Rev.2...

-

Page 139: End Effectors

Manipulator body depending on the outer diameter of the end effector, the size of the work piece, or the position of the arms. When designing your system layout, pay close attention to the interference area of the end effector. N series Rev.2... -

Page 140: Attaching Camera And Air Valves

The decks are equipped to the Arms #3, #4 and #5 for easy installation of the air valves. To mount the camera, the camera plate unit is necessary. The optional Camera Plate Unit is available. For details, refer to “6. Options”. N6-A1000** [Unit: mm] N series Rev.2... - Page 141 N6 Manipulator 4. End Effectors N6-A850**R [Unit: mm] N series Rev.2...

-

Page 142: Weight And Inertia Settings

Manipulator joint starts to rotate (amount of inertia). The inertia moment increases as weight of the load and amount of eccentricity increase. As this also increase the load applied on the joint, make sure to keep the inertia moment within the allowable value. N series Rev.2... -

Page 143: Weight Setting

Manipulator, and/or shorten the life cycle of parts/mechanisms. The acceptable weight capacity (end effector and work piece) for N6 series Manipulators is as follows: Rated Maximum 3 kg 6 kg N series Rev.2... - Page 144 Load on the Arm #3 deck is 1.0 kg (M The deck is 120 mm (L ) away from Joint #3. Load on the Arm #5 deck is 0.5 kg (M The deck is 550 mm (L ) away from the Joint #3. N series Rev.2...

- Page 145 Acceleration / Deceleration [%] Speed [%] 6 (kg) Weight Parameter N6-A850**R Acceleration / Deceleration [%] Speed [%] 6 (kg) Weight Parameter The percentages in the graphs are based on the speed at rated weight (3 kg) as 100%. N series Rev.2...

-

Page 146: Inertia Setting

The inertia moment of the load (weight of the end effector and work piece) on the Arm #6 can be set by the “inertia moment (INERTIA)” parameter of the INERTIA setting. Select [Tools]–[Robot Manager]-[Inertia] panel and enter the value in [Load inertia:]. EPSON You may also execute the INERTIA setting from [Command Window]. N series Rev.2... - Page 147 #6 can be set by the “eccentric quantity” parameter of the INERTIA setting. Enter the larger value of either “a” or “b” in the figure above to [Eccentricity]. Select [Tools]-[Robot Manager]-[Inertia] panel and enter the value into [Eccentricity:]. EPSON You may also execute the INERTIA setting from [Command Window]. N series Rev.2...

- Page 148 * The percentage in the graph is based on the acceleration / deceleration at rated eccentricity (0.03 kg·m ) as 100%. Automatic setting by eccentricity setting 150 160 Eccentricity [mm] * The percentage in the graph is based on the acceleration / deceleration at rated eccentricity (50 mm) as 100%. N series Rev.2...

- Page 149 Figure out the whole inertia moment using the basic formulas below. (a) Inertia moment of a rectangular parallelepiped Rotation Center Rectangular Parallelepiped’s Center of Gravity + m × L (b) Inertia moment of a cylinder Cylinder’s Center of Gravity Rotation Center + m × L N series Rev.2...

-

Page 150: Precautions For Auto Acceleration/Deceleration

The acceleration/deceleration are controlled according to the Manipulator’s posture. When the Manipulator extends its arms or when the movement of the Manipulator produces vibration frequently, the acceleration/deceleration are reduced. Set appropriate values for WEIGHT and INERTIA so that the Manipulator operation is optimized. N series Rev.2... -

Page 151: Motion Range

Manipulator does not move. The pulse range can be set in [Tools]-[Robot manager]-[Range] panel. EPSON You may also execute the Range command from the [Command Window]. N series Rev.2... -

Page 152: Max. Pulse Range: N6-A1000

When viewing from the arrow on the right figure, pulse values in counterclockwise direction are positive (+) and values in clockwise direction are negative (-). + direction + direction Arm #2 0 pulse position − direction − direction Angle (°) : ±180 Pulse (pulse) : ±6619136 N series Rev.2... - Page 153 When viewing from the arrow on the right figure, pulse values in counterclockwise direction are positive (+) and values in clockwise direction are negative (-). Arm #4 0 pulse position + direction − direction + direction − direction Angle (°) : ±200 Pulse (pulse) : ±5898240 N series Rev.2...

- Page 154 When viewing from the arrow on the right figure, pulse values in counterclockwise direction are positive (+) and values in clockwise direction are negative (-). Arm #6 0 pulse position + direction − direction + direction − direction Angle (°) : ±360 Pulse (pulse) : ±8773632 N series Rev.2...

-

Page 155: Max. Pulse Range: N6-A850**R

When viewing from the arrow on the right figure, pulse values in counterclockwise direction are positive (+) and values in clockwise direction are negative (-). Arm #2 0 pulse position − direction + direction − direction + direction Angle (°) : ±180 Pulse (pulse) : ±6619136 N series Rev.2... - Page 156 When viewing from the arrow on the right figure, pulse values in counterclockwise direction are positive (+) and values in clockwise direction are negative (-). Arm #4 0 pulse position + direction − direction − direction + direction Angle (°) : ±200 Pulse (pulse) : ±5898240 N series Rev.2...

- Page 157 When viewing from the arrow on the right figure, pulse values in counterclockwise direction are positive (+) and values in clockwise direction are negative (-). + direction − direction Arm #6 0 pulse position + direction − direction Angle (°) : ±360 Pulse (pulse) : ±8773632 N series Rev.2...

-

Page 158: Restriction Of Manipulator Operation

The motion ranges of the Joints #2 and #3 are defined according to the combinations of their angles. If the combination of the joint angles falls the painted areas in the below figure, the Manipulator motion will be restricted. N series Rev.2... - Page 159 When the target position is inside the combination restriction area of joint angle (Fig. 1: Green, Blue). [Remedy] Change the target position and avoid “Error: 4066”. N6-A1000** Joint #2 angle ° [Unit: N6-A850**R ° Joint #2 angle [Unit: Fig. 1: Combination restriction of joint angle N series Rev.2...

- Page 160 If “Error: 4066” occurs when the motion command “Go Pulse(0,0,0,0,0,0)” is executed, refer to the following remedy to avoid “Error: 4066”. [Remedy] Move the Manipulator by Jog motion. Release a brake and move the Manipulator by hand. N series Rev.2...

- Page 161 (Fig. 2). Move the Manipulator from the area by moving the Joint #2 or #3 by Jog motion in Joint mode. If the Manipulator moves at high speed, it will collide with itself after detecting “Error: NOTE 4248”. Make sure to check the motion by simulator or motion in low power mode. N series Rev.2...

-

Page 162: Coordinate System

N6 Manipulator 5. Motion Range 5.3 Coordinate System The origin point is where the Manipulator’s installation face intersects with the rotation axis of Joint #1. For details on the coordinate system, refer to the EPSON RC+ Users Guide manual. N6-A1000** N6-A1000**R N6-A850**R... -

Page 163: How To Use Orientation Flag

When you cannot select the orientation flag for N6-A1000**, use the command: “AutoOrientationFlag”. Orientation flag is automatically changed to the orientation which the robot does not collide with the equipment. N series Rev.2... -

Page 164: Command: "Autoorientationflag

When setting the AutoOrientationFlag to Above “ON”: Flag is changed as follows due to the Below position of point P and the red line. Point P is above the red line: Above Point P is below the red line: Below N series Rev.2... -

Page 165: Changing The Robot

N6 Manipulator 5. Motion Range 5.5 Changing the Robot This section describes how to change the Manipulator model on EPSON RC+. (N6-A1000** is set to “Table top mounting” by default. If you want to change the mounting type to “Ceiling mounting”, follow the steps below to change the model. -

Page 166: Setting The Cartesian (Rectangular) Range In The Xy Coordinate System Of The Manipulator

These settings are disabled during a joint jogging operation. Therefore, be careful not to allow the end effector to collide with the Manipulator or peripheral equipment. Set the XYLim setting in [Tools]-[Robot manager]-[XYZ Limits] panel. EPSON You may also execute the XYLim command from the [Command Window]. N series Rev.2... -

Page 167: Options

87 mm Weight (Cables are not included.) 1.7 kg Cable to the Manipulator M/C Short connector For M/C power cable short-circuit View from A Power switch Power lamp Power cable* Brake release switches * Item you should provide N series Rev.2... -

Page 168: Power Cable

- Standard Sheet C13: AC250V / 10A For Japan Item Specification Plug PSE qualified Class I (2P+PE), AC125V, 7A or higher Code PSE qualified 0.75mm or larger Connector PSE qualified IEC 60320-1 Standard Sheet C13:AC125V/10A or higher N series Rev.2... - Page 169 ■ If you turn ON the brake release unit without the connector, it may lead to the short for the male pin used in the connector. Before turning ON the brake release unit, make sure that the connector is connected. N series Rev.2...

-

Page 170: Mount The Brake Release Unit

The connection cable connector and the adjacent user cable connector have the same shape. Be careful not to connect the wrong connector. M/C cable direction: Standard (backward) Upward and downward Connector of connection cable Connector of connection cable N series Rev.2... -

Page 171: Remove The Brake Release Unit

The connection cable connector and the adjacent user cable connector have the same shape. Be careful not to connect the wrong connector. M/C cable direction: Standard (backward) Upward and downward External short connector External short connector N series Rev.2... -

Page 172: How To Use The Brake Release Unit

The brake will be enabled by pressing the switch once again. NOTE Move the arm the brake is released by two persons or more (one presses the switch and one moves the arm). The arm can be very heavy and needs the significant force to move. N series Rev.2... -

Page 173: Camera Plate Unit

For details of tightening the hexagon socket head screws, refer to “Regular Inspection for NOTE N6 Manipulator”-“2.4 Tightening Hexagon Socket Head Bolts”. Mounting holes for the camera base plate on the N6 series Manipulator Camera base plate mounting hole 2×M4×8 N series Rev.2... - Page 174 N6 Manipulator 6. Options For the installation steps, refer to the following manual: EPSON RC+ Option Vision Guide 7.0 Hardware & Setup Hardware 6.4.1 6-Axis Robot Dimension of the camera plate unit Dimensions X and Y vary depending on the position of the camera mid plate and camera size.

- Page 175 The table below shows the motion range (reference values) based on the available cameras for this option and the mounting positions of the camera mid plate. The values in the table may vary depending on how to secure the cables. Direction of the Joint #5 motion N series Rev.2...

-

Page 176: Tool Adapter (Iso Flange)

(1) Insert the two pins into ISO flange. Pin projection : 4 mm from the flange (2) Align the pin and the pin hole on the arm, and then mount the flange. 4-M4×8 Hexagon socket head cap bolts: 4-M4×8 N series Rev.2... -

Page 177: User Wiring

Straight R12NZ900YU L-shaped R12NZ900YZ Straight R12NZ900YV Flexible L-shaped R12NZ900Z1 Straight R12NZ900YW L-shaped R12NZ900Z2 Straight R12NZ900YX L-shaped R12NZ900Z3 For the replacement of M/C cable, refer to N series Maintenance Manual “N6 Maintenance - 4.6 Replacing the M/C Cable” N series Rev.2... - Page 178 N6 Manipulator 6. Options N series Rev.2...

-

Page 179: Regular Inspection

Regular Inspection Performing inspection properly is essential to prevent trouble and ensure safety. This volume describes the inspection schedule and contents. Inspect according to the schedule. -

Page 181: Regular Inspection For N2 Manipulator

9 months (2250 h) √ √ 10 months (2500 h) √ 11 months (2750 h) √ 12 months (3000 h) √ √ √ √ 13 months (3250 h) √ √ 20000 h h = hour *Overhaul (parts replacement) N series Rev.2... -

Page 182: Inspection Point

If the arm falls when in MOTOR OFF and the brake is not released, contact the supplier. Check that there is no unusual sound or vibration when operating. Check whether unusual sound or vibration occurs. If there is something wrong, contact the supplier. N series Rev.2... - Page 183 Check that either the external short Check either the external short connector or the brake release unit connector or the brake release unit connector is connected. connector is connected. When it is not connected, connect it. N series Rev.2...

-

Page 184: Overhaul (Parts Replacement)

Overhaul timing training. Joint #1, 2, 3, 4, 5, 6 Reduction gear unit For details, “N series Maintenance Manual” 1.4 Tightening Hexagon Socket Head Bolts Hexagon socket head cap bolts (hereinafter, “bolts”) are used in places where mechanical strength is required. These bolts are fastened with the tightening torque shown in the following tables. -

Page 185: Regular Inspection For N6 Manipulator

9 months (2250 h) √ √ 10 months (2500 h) √ 11 months (2750 h) √ 12 months (3000 h) √ √ √ √ 13 months (3250 h) √ √ 20000 h h = hour *Overhaul (parts replacement) N series Rev.2... -

Page 186: Inspection Point

If the arm falls when in MOTOR OFF and the brake is not released, contact the supplier. Check that there is no unusual sound or vibration when operating. Check whether unusual sound or vibration occurs. If there is something wrong, contact the supplier. N series Rev.2... - Page 187 Check that either the external short connector or the brake release unit connector is connected. When it is not connected, connect it. M/C cable direction: M/C cable direction: Backward (standard) Upward and Downward Check either the external short connector or the brake release unit connector is connected. N series Rev.2...

-

Page 188: Overhaul (Parts Replacement)

Joint #1, 2, 3, 4, 5, 6 personnel who has taken a proper Reduction gear unit Overhaul timing training. For details, “N series Maintenance Bevel gear Joint #6 Manual” 2.4 Tightening Hexagon Socket Head Bolts Hexagon socket head cap bolts (hereinafter, “bolts”) are used in places where mechanical strength is required. -

Page 189: Appendix

Appendix This volume describes the specifications table for each model and detailed data of time and distance of free running. -

Page 191: Appendix A: Specifications

Joint #4 5.4 N·m (0.55 kgf·m) Allowable moment Joint #5 5.4 N·m (0.55 kgf·m) Joint #6 2.4 N·m (0.24 kgf·m) Joint #4 0.2 kg·m Allowable moment of Joint #5 0.2 kg·m inertia (GD2/4) Joint #6 0.08 kg·m N series Rev.2... - Page 192 Mounting types other than “Ceiling mounting” and “Table Top mounting” are out of specification. For details on how to change the model settings, refer to “ N2 Manipulator 5.4 Changing the Robot”, and “EPSON RC+ User’s Guide Robot Configuration”. *2: In case of PTP control *3: Do not apply the load exceeding the maximum payload.

-

Page 193: N6 Specifications

6 kg Joint #4 15.2 N·m (1.55kgf·m) Allowable moment Joint #5 15.2 N·m (1.55kgf·m) Joint #6 9.4 N·m (0.96 kgf·m) Joint #4 0.42 kg·m Allowable moment of Joint #5 0.42 kg·m inertia (GD2/4) Joint #6 0.14 kg·m N series Rev.2... - Page 194 Mounting types other than “Table Top mounting” and “Ceiling mounting” are out of the specification. For details on how to change the model settings, refer to “ N6 Manipulator 5.5 Changing the Robot”, and “EPSON RC+ User’s Guide Robot Configuration”. *2: In case of PTP control *3: Do not apply the load exceeding the maximum payload.

- Page 195 Although values larger than 100 can be set to Accel, it is recommended to minimize the use of large values to necessary motions since operating the Manipulator continuously with the large Accel setting may shorten the product life remarkably. N series Rev.2...

-

Page 196: Appendix B: Time And Distance Of Free Running In Emergency

Horizontal axis : Weight setting value Vertical axis : Time and distance of free running in each Weight setting value Weight [kg] : Weight setting value Time [sec] : Free running time Distance [degrees] : Free running distance N series Rev.2... -

Page 197: N2 Time And Distance Of Free Running In Emergency

0.00 Weight [kg] Weight [kg] N2-A450S*: J3 (Table Top mounting, Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.60 80.0 70.0 0.50 60.0 0.40 50.0 0.30 40.0 30.0 0.20 20.0 0.10 10.0 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 198: N2-A450S*: J4 (Table Top Mounting, Ceiling Mounting)

0.10 0.05 0.00 Weight [kg] Weight [kg] N2-A450S*: J6 (Table Top mounting, Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.35 50.0 0.30 40.0 0.25 30.0 0.20 0.15 20.0 0.10 10.0 0.05 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 199: N6 Time And Distance Of Free Running In Emergency

0.40 0.30 20.0 0.20 10.0 0.10 0.00 Weight [kg] Weight [kg] N6-A850**R: J3 (Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.60 100.0 0.50 80.0 0.40 60.0 0.30 40.0 0.20 20.0 0.10 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 200: N6-A850**R: J4 (Ceiling Mounting)

0.20 30.0 20.0 0.10 10.0 0.00 Weight [kg] Weight [kg] N6-A850**R: J6 (Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.60 120.0 0.50 100.0 0.40 80.0 0.30 60.0 0.20 40.0 0.10 20.0 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 201: N6-A1000**: J1 (Table Top Mounting, Ceiling Mounting)

Weight [kg] Weight [kg] N6-A1000**: J3 (Table Top mounting, Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.70 80.0 70.0 0.60 60.0 0.50 50.0 0.40 40.0 0.30 30.0 0.20 20.0 0.10 10.0 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 202: N6-A1000**: J4 (Table Top Mounting, Ceiling Mounting)

0.10 10.0 0.00 Weight [kg] Weight [kg] N6-A1000**: J6 (Table Top mounting, Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.60 120.0 0.50 100.0 0.40 80.0 0.30 60.0 0.20 40.0 0.10 20.0 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 203: Appendix C: Time And Distance Of Free Running When Safeguard Is Opened

Horizontal axis : Weight setting value Vertical axis : Time and distance of free running in each Weight setting value Weight [kg] : Weight setting value Time [sec] : Free running time Distance [degrees] : Free running distance N series Rev.2... -

Page 204: N2 Time And Distance Of Free Running When Safeguard Is Opened

0.20 20.0 0.00 Weight [kg] Weight [kg] N2-A450S*: J3 (Table Top mounting, Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.70 100.0 0.60 80.0 0.50 60.0 0.40 0.30 40.0 0.20 20.0 0.10 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 205: N2-A450S*: J4 (Table Top Mounting, Ceiling Mounting)

0.20 10.0 0.10 0.00 Weight [kg] Weight [kg] N2-A450S*: J6 (Table Top mounting, Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.50 60.0 50.0 0.40 40.0 0.30 30.0 0.20 20.0 0.10 10.0 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 206: N6 Time And Distance Of Free Running When Safeguard Is Opened

80.0 0.40 60.0 0.30 40.0 0.20 20.0 0.10 0.00 Weight [kg] Weight [kg] N6-A850**R: J3 (Ceiling mounting) 100% Speed [%] 100% Speed [%] 1.00 200.0 0.80 150.0 0.60 100.0 0.40 50.0 0.20 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 207: N6-A850**R: J4 (Ceiling Mounting)

0.20 20.0 0.10 0.00 Weight [kg] Weight [kg] N6-A850**R: J6 (Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.70 140.0 0.60 120.0 0.50 100.0 0.40 80.0 0.30 60.0 0.20 40.0 0.10 20.0 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 208: N6-A1000**: J1 (Table Top Mounting, Ceiling Mounting)

20.0 0.10 0.00 Weight [kg] Weight [kg] N6-A1000**: J3 (Table Top mounting, Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.80 200.0 0.70 0.60 150.0 0.50 0.40 100.0 0.30 0.20 50.0 0.10 0.00 Weight [kg] Weight [kg] N series Rev.2... -

Page 209: N6-A1000**: J4 (Table Top Mounting, Ceiling Mounting)

0.00 Weight [kg] Weight [kg] N6-A1000**: J6 (Table Top mounting, Ceiling mounting) 100% Speed [%] 100% Speed [%] 0.70 140.0 0.60 120.0 0.50 100.0 0.40 80.0 0.30 60.0 0.20 40.0 0.10 20.0 0.00 Weight [kg] Weight [kg] N series Rev.2... - Page 210 Appendix C: Time and Distance of Free Running When Safeguard Is Opened N series Rev.2...

Need help?

Do you have a question about the N Series and is the answer not in the manual?

Questions and answers