Summary of Contents for Sime Super 4 W. M.

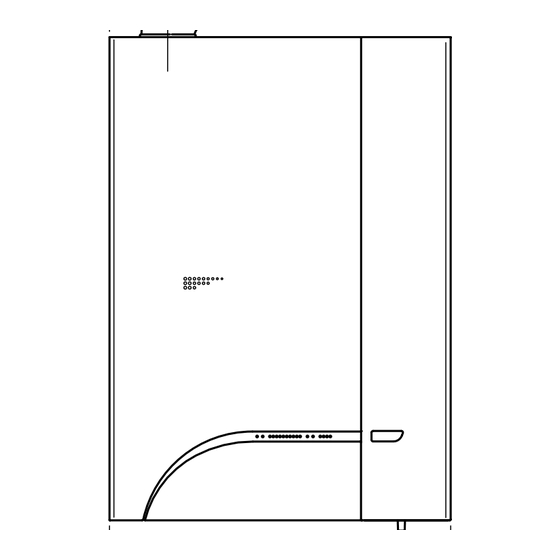

- Page 1 PLEASE LEAVE THIS INSTRUCTION WITH THE USER Planet Sup er 4 W . M. Installation & Servicing Instructions...

-

Page 2: Table Of Contents

Note: All CORGI registered installers carry a CORGI ID Card. You can check your installer is CORGI Registered by calling 01256 372300 SIME COMBINATION BOILERS Installer checklist Please remember to carry out the following checks after installation. This will achieve complete customer satis- faction, and avoid unnecessary service calls. -

Page 3: Description Of The Boiler

DESCRIPTION OF THE BOILER 1. 1 INTRODUCTION tion, see fig. xx) makes available and thanks They may be fuelled by natural gas (metha- also to an electronic management and con- ne) and butane gas (G30) or propane The “PLANET SUPER 4 W.M.” wall hung trol system via a microprocessor. - Page 4 FUNCTIONAL DIAGRAM 1 Fan 2 Heat exchanger 3 Combustion chamber 4 Gas valve 5 D.H.W. tank 6 C.H. sensor (SM) 7 100°C safety stat 8 Air relief valve 9 C.H. pump 10 D.H.W. pump 11 Expansion vessel 12 D.H.W. safety valve 13 C.H.

-

Page 5: General Requirements For Installation

GENERAL REQUIREMENTS FOR INSTALLATION 2. 1 STATUTORY REQUIREMENTS may be used provided it is modified bustion products will not cause nui- accordingly. sance and that the terminal will not GAS SAFETY (INSTALLATION AND USE) – Where installation will be in an unusual obstruct the passageway. - Page 6 GAS SUPPLY – The gas installation should be in accor- dance with BS6891. The gas required for the boiler is specified in section 1.3. – Ensure that the pipework from the meter to the appliance is of adequate 30/60 4 W.M. size.

-

Page 7: Installation

temperature with all radiators in circula- Company should be obtained before the 2.9. 1 Optional secondary circulation tion an extra expansion vessel is required. appliance is connected to the cold water mains supply. Check that the mains sup- The boiler is equipped with a secondary ply pressure is within the prescribed lim- return to be used for recirculation purposes 2.8.3... - Page 8 Fig. 8 duct kits required. Z Dimension greater than 3,000 mm. NOT PERMITTED. Fig. 9 – If no extension ducts are required, pro- cede to 3.5.2. – If an extension duct or ducts is/are to be TABLE 3 - Maximum flue lengths (measured from appliance casing to outside wall face) used, the flue and air ducts should be Rear outlet R.H.

- Page 9 Fit the quarter bend (2) to the hot water outlet (E) using the gasket supplied (1). – GAS CONNECTION (C) 1a-b Coaxial duct kit code 8084808 Fit the gas cock (7) to the gas connection. Extension L.855 code 8084804 Vertical extension L.590 with take-off points code 8086902 Supplementary 90°...

- Page 10 duct is greater than 1 m in length, insu- lation is recommended in order to avoid, 105 120 in particularly cold periods, the formation of condensation on the outside of the tubing. – With discharge duct positioned on the outside of the building, or in cold environ- ments, insulation is necessary to avoid starting failures of the burner.

- Page 11 Should this require replacement, it must be terminals of board TA-CR-SE-SB will the terminals CR (6-7) . purchased exclusively from SIME. irreparably damage the control board. The electric power supply to the boiler Make sure that any connections to be...

- Page 12 ROOM STAT TERMOSTATO AMBIENTE 1 Control panel 2 Terminal connector block “Logica Remote Control ” 3 Connector J2 TA Room stat (not supplied) CR Logica Remote Control (optional) SE External temperature sensor (optional) SB D.H.W. sensor LOGICA REMOTE CONTROL LOGICA REMOTE CONTROL EXTERNAL SONDA...

- Page 13 3. 1 0 LOGICA REMOTE CONTROL – Holiday programme: the programme is through a window contact. interrupted for the holiday period and – Anti-bacterial. All the boiler's functions can be managed by automatically restarted on returning a optional digital multifunctional device code home.

- Page 14 With the activation of the adaptation, the pre-set value transmitted to the Activation of adaptation boiler regulator is adapted to the effective heat need. The adaptation functions with both the atmospheric guide with ambient influence and with pure ambient control. If the "Logica Remote Control"...

- Page 15 Operating mode of external contact If the entrance (terminals 3 and 4 of the socket) is connected to a zero potential external contact (parameter 64 = 2 or 3), the operating mode of the contact can be determined (remote telephone switch or window contact). The operating mode specifies the status of the contact in which the required function is active.

-

Page 16: Characteristics

CHARACTERISTICS 4. 1 ELECTRONIC PANEL pressure level (STEP) of the gas valve. return to the set value of heating pres- According to the type of gas for which sure. With the insertion of the bridge Made in accordance with the Low Voltage the boiler is predisposed, the trimmer both the technical pause programmed EEC directive 73/23, supplied with 230... - Page 17 1 Ignition electrode earth faston, 3 Fuse (1.6 AT) 5 Connector “ANN. RIT.” 6 Trimmer “POT. ACC.” 7 Connector “MET-GPL” 8 D.H.W. potentiometer 9 Detection electrode faston 10 Trimmer “POT. RISC.” 11 C.H. potentiometer 12 Selector CR/OFF/EST/INV/UNBLOCK 13 DIP SWITCH 14 Connector “Modureg Sel.”...

-

Page 18: Use And Maintenance

P-P1 Zone pump Fig. 23 USE AND MAINTENANCE SIME SUPPORT THE BENCHMARK INITIATIVE All relevant sections of the logbook must be filled in at the time of installation and there- after service information on the back page of the logbook. - Page 19 SIME: variations are dis- couraged. Only in the passing from one type of gas supply (methane) to another (butane or propane) is a change in the working pressure allowed. It is essential that this operation is car- ried out by authorised personnel.

- Page 20 Pressure/heat output diagram for natural gas (methane) 1 Plastic cap 8, 1 (7.000) 11,6 (10.000) 8, 1 (27.600) 11,6 (39.600) 17,4 (15.000) 17,4 (59.350) 23,2 (20.000) 23,2 (79. 1 50) 29,0 (25.000) 29,0 (98.950) 2 Minimum pressure adjusting nut 3 Maximum pressure adjusting nut HEAT OUTPUT kW (Btu/h) POTENZA TERMICA kW (kcal/h) 4 Modulator...

- Page 21 cover, with the label supplied, the gas pre-setting data on the data tag. NOTE: After assembly the sealing capaci- ty of all the gas connections must be test- ed, using special products, and avoiding the use of naked flames. The conversion must be carried out only by authorised personnel.

-

Page 22: Standard Settings Of The "Logica Remote Control

STANDARD SETTINGS OF THE “LOGICA REMOTE CONTROL” C.H. WITHOUT ZONE MULTI-ZONE C.H. WITH EXTERNAL WITHOUT EXTERNAL WITH EXTERNAL WITHOUT EXTERNAL TEMPERAT. SENSOR TEMPERAT. SENSOR TEMPERAT. SENSOR TEMPERAT. SENSOR Function Value Function Value Function Value Function Value 20 - 25°C 20 - 22°C –... -

Page 23: Short List Of Parts

SHORT LIST OF PARTS 16-17 Fig. 29 DESCRIPTION MAKER’S PT NO DESCRIPTION MAKER’S PT NO Water/gas heat exchanger 6174225 D.H.W. tank 5167705 Burner 5172720 Water pressure transducer 6273601 Main injector ø 1.30 6154402 Safety valve 3 bar C.H. 6042201 6225615 Safety valve 7 bar D.H.W. - Page 24 Sime Ltd Unit D2 Enterprise Way, Bradford Road, Idle, Bradford BD10 8EW Tel. 0870 9911114 - Fax 0870 9911115 www.sime.ltd.uk - e-mail: enquiries@sime.ltd.uk...

Need help?

Do you have a question about the Super 4 W. M. and is the answer not in the manual?

Questions and answers