Table of Contents

Advertisement

Quick Links

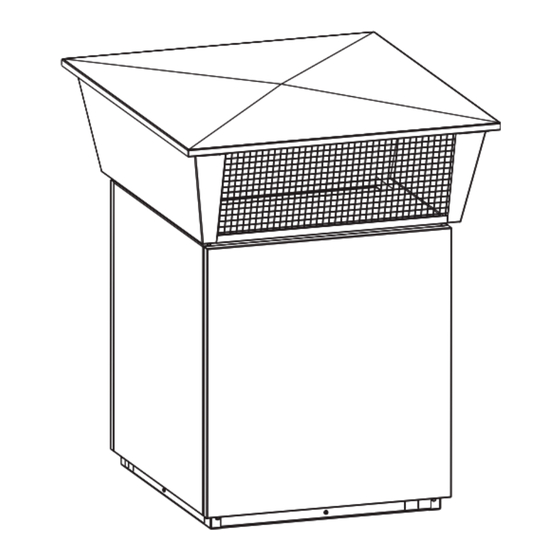

WPL 10 A, WPL 10 I, WPL 10 IK

WPL 7 AS, WPL 7 IKS, WPL 10 AS, WPL 10 IKS

Compact air/water heat pump

The installation (water and electrical work) and commissioning, as well as the maintenance of

this equipment, must only be carried out by an authorised qualified contractor in accordance with

these instructions.

Content

1.1

1.2

1.3

1.4

1.5

1.6

2

2.1

2.2

2.3

2.4

3

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

4

5

6

7

8

Information for the owner of the heat pump

heating system

Keep these operating instructions safely and

pass them on to any new user, should the

equipment change hands. Let your contractor

check their content in conjunction with any

maintenance or repair work.

Risk of injury

Where children or persons with

limited physical, sensory or mental capa-

bilities are to be allowed to control this

appliance, ensure that this will only happen

under supervision or after appropriate in-

structions by a person responsible for their

safety.

Children should be supervised to ensure

that they do not play with the appliance.

Page

2

2

2

2

2

2

2

3

3

4

5

6

7

7

7

7

9

10

10

12

12

12

13

22

22

22

23

24

27

27

Advertisement

Table of Contents

Summary of Contents for STIEBEL ELTRON WPL 10 A

-

Page 1: Table Of Contents

WPL 10 A, WPL 10 I, WPL 10 IK WPL 7 AS, WPL 7 IKS, WPL 10 AS, WPL 10 IKS Compact air/water heat pump installation instructions Content Page 1 General information Equipment description Function Correct operation Incorrect operation Regulations and standards Standard delivery and accessories Specification... -

Page 2: Installation Instructions

Installation instructions for contractors 1 General information Special features for the WPL..IK / IKS DIN 1988: Technical rules for DHW installations These installation instructions are for The WPL..IK/IKS includes the heat pump TRD 721: Safety equipment to prevent excess contractors. The heat pump installation also manager WPM II as standard. -

Page 3: Specification

2 Specification (check details on the type plate) 2.1 Specification triplephase(equipment information) Heat pump Type WPL 10 A WPL 10 I WPL 10 IK Part no. 22 08 12 22 08 11 22 08 26 Design and operating mode compact... -

Page 4: Performance Diagram Triplephase

2.2 Output diagram for heat pump WPL 10 A / I / IK, WPL 10 AS / IKS Inlet temperature of the WQA - medium Fig. 1a... -

Page 5: Specification Singlephase

2.3 Specification singlephase (equipment information) Heat pump Type WPL 7 AS WPL 7 IKS WPL 10 AS WPL 10 IKS Part no. 22 20 49 22 21 38 22 20 48 22 21 37 Design and operating mode compact compact compact compact Design: compact / split / open version... -

Page 6: Performance Diagram Singlephase

2.4 Output diagram for heat pump WPL 7 AS / IKS Inlet temperature of the WQA - medium Fig. 1b... -

Page 7: Installation, Connection And Sound Emissions

3 Installation, connection and Where the heat pump is installed on strip Protect all pipe fixings and wall transitions foundations, seal off the open sides of the with anti-vibration insulation. sound emissions foundation. Never direct the air inlet and outlet apertures in external walls towards neighbouring 3.1 Transport 3.2.2 Internal installation... - Page 8 Internal installation External installation Air outlet Air inlet Ø 1122 Air inlet Air outlet Schlauchanschlussplatte Fig. 2 Fig. 3 Internal installation Ø max 800 min 300 Air outlet Air inlet Fig. 4...

-

Page 9: Circulation Pump

3.3.4 Flushing the heating system Foundation for external installation when using pressure hoses Thoroughly flush the pipework before connecting the heat pump. Debris, such as Hauptwindrichtung welding pearls, rust, sand, sealant etc. can impair the operational reliability of the heat pump, and can lead to a blocking of the condenser. -

Page 10: Condensate Drain

pressure drop values for the interconnecting line, the heat pump and the WPKI 5. Base the sizing of the circulation pump on the nominal volume flow and the total pressure drop. Heat meter For the installation of a heat meter observe, that most heat meters cause a substantial pressure drop;... -

Page 11: Buffer Cylinder

10 (B-PUMP CONST) to ON. Minimum volume flow Stiebel Eltron recommends that one or several heating circuits in the heating system are left open. The open heating circuit(s) should be installed in the lead room (living room or bathroom). -

Page 12: Second Heat Source

(see Fig. 3). connected. For optimum function of the WPL 10 A/I/ Always cover the air inlet and outlet IK connect all three stages (8.8 kW) and for... -

Page 13: Electrical Connection

4 Electrical connection The IWS (abbreviation for integrated heat pump control) is a PCB fitted as standard into the heat pump control panel. The IWS controls Notify your local power supply company of the the contactors of the compressors and the electrical connection. - Page 14 Electrical connection WPL 10 IK 3/N/PE~400/50 1/N/PE~230/50 3/N/PE~400/50 Control Mains X26 (earth) 1/N/PE~230/50 3/N/PE~400/50 WPL 10 A WPL 10 I 3/N/PE~400/50 Control Mains Control terminals Mains supply: L, N, PE Outputs: KOKP Collector circuit pump and N, PE Mains Mixer circuit pump and N, PE...

- Page 15 Fig. 13...

- Page 16 Fig. 14...

- Page 17 Electrical connection diagram for heat pumps WPL 10 A and WPL 10 I with heat pump manager WPM II Heat pump manager WPM II max. 2 A gl 1/N/PE ~ 50Hz 230 V 16 A gl Supply from the domestic meter...

- Page 18 Electrical connection WPL 7 IKS 1/N/PE~230/50 1/N/PE~230/50 WPL 10 IKS 1/N/PE~230/50 Control Mains X26 (earth) 1/N/PE~230/50 1/N/PE~230/50 WPL 7 AS WPL 10 AS 1/N/PE~230/50 Control Mains Control terminals Mains supply: L, N, PE Outputs: KOKP Collector circuit pump and N, PE Mains Mixer circuit pump and N, PE Pump...

- Page 19 Fig. 17...

- Page 20 Fig. 18...

- Page 21 Electrical connection diagram for heat pumps WPL 7 AS, WPL 10 AS with heat pump manager WPM II Heat pump manager WPM II max. 2 A gl 1/N/PE ~ 50Hz 230 V 16 A gl Supply from the domestic meter Time switch for POWER OFF periods Control phase L without off-period...

-

Page 22: Commissioning

5 Commissioning 7 Maintenance and cleaning Maintenance See the operating instructions for the heat pump manager WPM II. WPM II The heat pump operates under automatic Since the WPL..A / AS, I and IK / control and requires no specific maintenance. IKS are heat pumps with internal HS 2, please If heat meters are installed, frequently clean observe the WP type 2 when reading the... -

Page 23: Troubleshooting

50 °C and stops at 55 °C. The at the factory, subject to the heat pump type, frost protection sensor connected to the IWS for the WPL 10 A/I/IK to 1. at terminals sensor 1,2 is used to sense the 1 Single compressor with internal HS 2 control magnitude, i.e. -

Page 24: Commissioning Report

Installation conditions according to tecalor Commissioning report installation and operating instructions: Customer’s address: Installation room volume: m³ Operating mode mono mode dual-mode - parallel - part parallel Installer: - alternative Dual-mode heat source Gas fired boiler Oil fired boiler Solid fuel boiler Building type: District heating Electric heating... - Page 25 10. Heat source: 12. System periphery: Outside air Circulation pump source Extract air Manufacture / type Temperature min: °C Circulation pump heating Manufacture / type max: °C Ground Circulation pump Ground probe Heat pump/heat exchanger Manufacture / type Internal pipe diameter: Distributor: yes Circulation pump Heat exchanger / cylinder...

- Page 26 15. Actual data: 16. Tested to VDE 0701 Actual at the heat pump after 10 min. operation: Implemented: Brine inlet/water/air: °C Values OK: Brine outlet/water/air: °C Heat pump flow temp.: °C Heat pump return temp: °C 17. System layout...

-

Page 27: Guarantee

Place, date Installer’s signature...

Need help?

Do you have a question about the WPL 10 A and is the answer not in the manual?

Questions and answers