Table of Contents

Advertisement

Quick Links

Ridder – Drive Systems

Lorentzstraat 38

3846 AX Harderwijk

PO Box 360

3840 AJ Harderwijk

the Netherlands

RW1000-SD

RW1200-SD

RW1400-SD

RW1600-SD

RW2000-SD

T +31 (0)85 237 3000

E info@ridder.com

I ridder.com

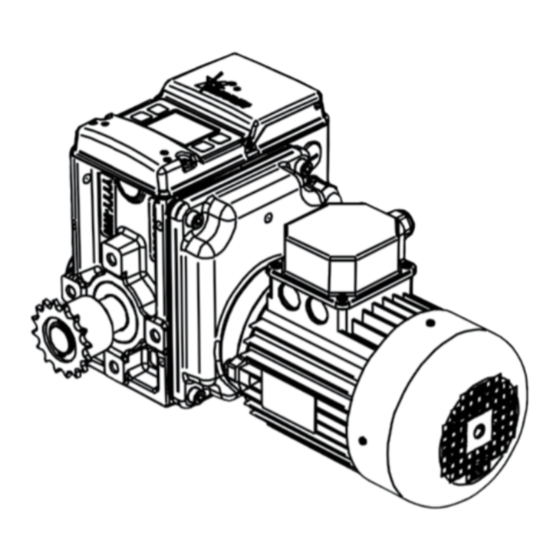

RW-SD Motor Gearboxes 3-phase

RW70-SD

RW100-SD

RW140-SD

RW200-SD

RW240-SD

RW400-SD

RW600-SD

RW45-SD

Product Manual

Ridder SmartDrive

Original product-manual

265004EN - 2024.05 - V01

RW800-SD

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ridder SmartDrive RW70-SD

- Page 1 Ridder – Drive Systems Lorentzstraat 38 3846 AX Harderwijk T +31 (0)85 237 3000 PO Box 360 E info@ridder.com 3840 AJ Harderwijk I ridder.com the Netherlands Product Manual Ridder SmartDrive RW-SD Motor Gearboxes 3-phase Original product-manual 265004EN - 2024.05 - V01...

-

Page 2: Table Of Contents

7.3 Commissioning - Basic Settings [❶] 7.4 Commissioning - End Positions Setting [❷] 7.5 Installation-Closing covers 8. MAIN MENU 9. MOTOR CONTROL 10. CHANGE THE END POSITIONS 11. BLUETOOTH Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 3: Guidelines, Standards And Conditions

However, there is no guarantee that interference will not occur in a particular installation. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 4: Approved Personnel

1.2 Approved personnel This product manual contains important information for installers about the installation and commissioning of a Ridder SmartDrive RW-SD Motor-Gearbox. Read this product manual and instructions first before the work starts. Approved mechanical and/or electrical installers, with professional competence, must do all work safely and responsibly. -

Page 5: Special Tools And Equipment

To use Bluetooth the special tools and equipment that follow are necessary: ① A mobile device with SmartPhone functionality ② The Ridder SmartDrive App. Go to Google Play Store or Apple App Store for download and setup. Use the app (after commissioning) to: • Copy range-of-travel configuratons to other Ridder SmartDrive SD Basic Units (SD-BU) -

Page 6: Safety, Precautions And Symbols

Refer to the permitted Ê mounting positions in the product manual.* * Not applicable to motor gearboxes filled with grease! Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 7: Precautions And Safety Instructions

SD basic unit) during all work. There is a risk of short circuit, fire and corrosion. • Take sufficient precautions to prevent ElectroStatic Discharge (ESD). • Ridder is not responsible for injury, material damage or consequential damage if accessories are used that Ridder did not make. -

Page 8: Residual Risks

Persons can be in danger of life if they touch a system that is in operation. Forces Ridder cannot be sure that there will be no injury to persons or damage to the system because of the forces in the systems (in which the drive unit is installed). Ridder – Drive Systems... -

Page 9: Symbols And Abbreviations

Model with winch shaft Motor connection L1, L2, L3 Voltage source Motor connection Manual Control Motor connection Terminal strip (1–10) MPCB/ Motor-Protection Circuit-Breaker Terminal strip (11–16) Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 10: Product Details

NOTE: Possibly the sequence of symbols is different and/or other symbols are included in the identification. Not all symbols and assembled configurations (such as LK, LD, ...) are included in the explanation. * K = Sprocket in an assembled configuration. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 11: Description

The digital end positions are used to enable these contacts. If a Ridder SmartDrive SD Panel Unit (SD-PU) is connected, the control contacts (motor control) and a safety contact of the panel unit are used. Then the duty contacts and the safety contact of the BU circuitboard become disabled. - Page 12 • RW1000/1200/1400/1600/2000-SD: 16-tooth 3/4”x7/16” zinc-plated sprockets for chain couplings are installed. The switching range of the end position system is 110 revolutions of the drive shaft. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

-

Page 13: Application

This section tells about usual configurations of motor gearboxes and operated systems. Possibly other configurations (or applications) are applicable. For other (different) applications, approval from Ridder is necessary. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 14: Dimensions

RW45-SD: RW-SD-L/(SD-LK) Ø15 H1 = 55–56 mm RW-SD-TRA H2=144–158mm L1 = 166–170 mm RW-SD-D L2 = 108–112 mm 70.5 Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... - Page 15 L1 = 156–246 mm 72.5 L2 = 115–195 mm RW800-SD: H1 = 72.5–89 mm 62.5 H2 = 190–213 mm L1 = 217–246 mm L2 = 160–215 mm Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

- Page 16 L1 = 248–315 mm L2 = 130–210 mm RW70/100/140/200-34\68-SD: 188.5 77.5 Ø25 H1 = 75–88 mm H2 = 179–230 mm L1 = 215–246 mm L2 = 112–153 mm Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

-

Page 17: Technical Specifications

IP54* Ambient temperature [°C (°F)] 0–60 °C (32–140 °F) A not-condensed relative humidity is necessary. Maximum relative humidity * IP55 only applicable if in identification. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... - Page 18 Ground: enabled* feedback signal Interface A Communication channel A Interface B Communication channel B 24 V AC/DC IN Input: power supply 24 V AC/DC GND Ground: power supply Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

- Page 19 The Flash Memory has a maximum number of times to erase or write without faults. You can erase or write (without faults) approximately 10,000 times. The lifespan of the flash memory extends when the erase/write cycles are kept to a minimum. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

-

Page 20: Install Instructions

• §4.5 for TRA models with TRA drive-unit (installation options G, H, I) • §4.6 for L models with belt drum (installation option J) • §4.7 for L models with cable drum (installation option K). Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 21: Mounting Positions

• After installation interchange the plug in the highest position with the vent plug! This is not applicable to motor gearboxes that are filled with grease! RW45-SD [grease lubrication]: RW240/400/600-SD [oil lubrication]: Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... - Page 22 RW240-SD [grease lubrication]: RW800-SD [oil lubrication]: Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

- Page 23 RW1000/1200/1400/1600/2000-SD [oil lubrication]: RW70/100/140/200-34\68SD [oil lubrication]: Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

-

Page 24: Sprockets

Refer to the illustration (step ❶ and ❷) that follows for the configuration of shaft keys (a, b), retaining rings (c) and ring (d). For more information on item numbers and models refer to the Ridder catalog or website at ridder.com. -

Page 25: Installation

• In the factory the reductor is filled with the necessary quantity of grease (usually only RW45-SD) or oil. After installation interchange (of reductors filled with oil) the plug in the highest position with the vent plug! Refer to §4.1. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... - Page 26 C3. Do clamp mounting on lattices (different lattice widths and lattice heights possible). In this product manual shown illustrations can be different than the components and/or systems. For more information on item numbers and models refer to the Ridder catalog or website at ridder.com.

- Page 27 SID (4x): ≥ 16 mm! ≥ 14 mm! M12 (4x) M10 (3x) M10 x 25 (3x) - 45 Nm M12 x 25 (4x) - 80 Nm Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

- Page 28 Do the check of the minimum screw-in depth/free thread-length (SID/FTL) of the configuration that follows: SHEET THICKNESS and fixing-bolt LENGTH. This prevents damage or injury (breakage risk). Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

-

Page 29: Installation Options A-F For Output Shafts

** D is supplied as two parts (chain, chain connector). In this product manual shown illustrations can be different than the components and/or systems. For more information on item numbers and models refer to the Ridder catalog or website at ridder.com. -

Page 30: Installation Chain (For A-D)

❻ Put the chain onto the sprockets with the chain ends at the top. Install the chain ❶–❽ Install the chain connector and chain (on the sprockets). Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 31: Tra Drive-Unit Onto Rw45\240-Sd-Tra Motor Gearbox

❻/❼ Drill two holes of Ø13mm for foot mounting (j) or top mounting (k) in the structure. Use M12 fasteners (l or m) to install the TRA system onto the structure. Obey the instructions for installation of M12 fasteners (l or m). Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... - Page 32 In this product manual shown illustrations can be different than the components and/or systems. For more information on item numbers and models refer to the Ridder catalog or website at ridder.com. Ridder – Drive Systems...

-

Page 33: Belt Drum Onto Rw45\240/400-Sd-L Motor Gearbox

HEX 3 mm - 10 Nm In this manual shown illustrations can be different than the components and/or systems. For more information on item numbers and models refer to the Ridder catalog or website at ridder.com. Ridder – Drive Systems... -

Page 34: Cable Drum Onto Rw45\240/400-Sd-L Motor Gearbox

In this manual shown illustrations can be different than the components and/or systems. For more information on item numbers and models refer to the Ridder catalog or website at ridder.com. NOTE: Ridder does not supply steel cables and steel cable clamps. -

Page 35: Removal-Opening Covers

• Install and close the covers (2x) again after the work! Refer to the end of chapter 7. PH/PZ (4x) In this product manual shown illustrations can be different than the components and/or systems. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 36: Electrical Material

• 50 mA–500 mA at 24 V AC/DC • A maximum of 100 mA at 115–240 V. The SD end position system is NOT applicable for motor-current connection through the switching contacts. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... - Page 37 * If your decision is not to use this cable gland, make sure to put the sealing plug back. Tighten the cable gland with the correct tool and tightening torque! - 5 Nm Ø6.0–12.0 mm - 2.5 Nm Ø5.0–10.0 mm M20x1.5/M16x1.5 Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

-

Page 38: Protection - Conditions And Starting Points

Always make sure that the protections comply with the, local or national, laws and regulations of the country. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 39: Tightening-Torque Motor-Connections

• Make sure that the shields do not divide when the length of shielded cables is increased. 5.4 Tightening-torque motor-connections Tighten the motor connections with the correct tightening torque! 2 Nm! • M4 connections: 2 Nm • M5 connections: 3 Nm. 3 Nm! Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 40: Control-Circuit Connection

§5.7 §5.6 Always connect the safety contact (Safety stop) and all duty contacts (0%\100%). This is necessary for safety and correct functional operation. Connections: 1–6 Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 41: Automatic Control (Acs)

Obey the diagram that follows to connect two or more SD basic units (SD-BU). Alarm (AL) Circuit board A2 Circuit board A2 Circuit board A2 Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 42: Change Direction-Of-Rotation

5.8 Change direction-of-rotation If necessary, it is possible to change the direction-of-rotation. Change direction-of-rotation (diagram §5.5): Interchange U1 and V1 on the terminal block (EM). Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 43: User Instructions

NOTE: Motor control and copy function only enabled after commissioning (“in operation”) and when SD panel unit (SD-PU) is connected. Refer to the SD-PU product manual. Refer to the Ridder catalog or website ridder.com for more information. Always refer to the related information and manuals (automatic control-systems and control components). -

Page 44: Operation Structure - Sd Control Screen (Cs)

More settings Setpoint: enabled Change screen auxiliary contact orientation §12.2.2 §12.3.1 Change Back to Frequency limiter Fault contact language factory settings §12.2.3 §12.2.1 §12.3.2 §12.3.3 Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 45: Operating Options: Commissioning - Normal Operation

Selection/Control with related button (S1–S4) Menu/Text field selection with related button (S1–S4) ...TEXT... Other symbols (no selection) “Home”: Locked screen Canceled Main Menu Unlocked screen Confirmed (OK) Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 46: Safety Functions And Stop Functions

Do not go across the limits of the system. This prevents damage or injury. Before the system is put into operation, the installer must always make sure that the end position system is correctly set. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 47: End Position System

There is no function set (or enabled) for the auxiliary contacts. • Connection of the safety contact and all duty contacts is mandatory. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 48: Commissioning - Basic Settings [❶]

PU* Applicable screen when an SD panel unit (SD-PU) is Select how to set connected. the end positions Use this screen Use the app and buttons Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 49: Commissioning - End Positions Setting [❷]

Do not go across set end positions when the motor gearbox is operated manually or with electric tools (externally with the hexagon socket in the electric-motor shaft). This prevents damage to the operated system. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 50: Installation-Closing Covers

Metal cover - 1.0 Nm Plastic cover - 0.5 Nm PH/PZ (4x) Click Click In this product manual shown illustrations can be different than the components and/or systems. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 51: Main Menu

• When an SD panel unit is connected, motor control is possible with the SmartDrive App on a Smartphone. Refer to the app for instructions. • When no SD panel unit is connected an external manual control (MC) is necessary. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 52: Change The End Positions

Configuration download is completed 4. App: Copy range-of-travel configurations of the first set SD basic unit to other units. To copy range-of-travel configurations is only permitted to approved personnel. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 53: Settings

2. Select the wanted percentage of the setpoint. 3. Wanted position setting Motor control: 1. 2. Control to the wanted position. 3. Wanted position setting Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 54: Reversed Feedback

1. Select the wanted feedback type (linear 12.2 Auxiliary contacts settings Main menu: Settings\ Auxiliary contacts settings\ Changes to auxiliary contacts settings are only permitted to approved personnel. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 55: Fault Contact

2. Select the wanted percentage of the setpoint. 3. Wanted position setting Motor control: 1. 2. Control to the wanted position. 3. Wanted position setting Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 56: Frequency Limiter

“Can you read this?” is shown two times. Obey the steps on the control screen (CS). Can you read this? Procedure 1. Select the wanted screen orientation. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 57: Change Language

This change makes basic settings and a full setting procedure (commissioning) necessary again. When factory settings are set again it is necessary and mandatory to do the procedure “End Positions Setting” again. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 58: Maintenance Instructions

• A problem is found with no solution. Refer to chapter 14 first. Refer to the Ridder catalog or the website at ridder.com for more information about spare parts (or accessories) that are available. Also refer to available documentation (maintenance instructions) at ridder.com of the Ridder products in the operated system. -

Page 59: Service

#3 Incorrect range-of-travel configuration #4 Incorrect range-of-travel configuration Observation 4 Cause 1 Bluetooth transmits range-of-travel configuration incorrectly. Solution 1 Do the download and upload procedures again. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 60: Technical Support

14.2 Technical support For technical support contact your local After Sales contact person. You can find your local After Sales contact person on our website at ridder.com. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 61: Environment

5. Make the product unserviceable and make a mark on the product. This prevents that the product is (accidentally) used again. 6. The permanent decommissioning is completed. Refer to §15.2 “Waste disposal”. Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com... -

Page 62: Waste Disposal

15.2 Waste disposal Discard products of Ridder after their lifespan and obey the applicable national and/or local regulations. This product has built-in semiconductor circuits (PCBs, different electronic components, capacitors and such). Incorrect waste disposal can increase the risk that poisonous gases have an effect on the environment or cause injury (burn chemically or such). - Page 63 Ridder – Drive Systems T +31 (0)85 237 3000 - E info@ridder.com - I ridder.com...

Need help?

Do you have a question about the SmartDrive RW70-SD and is the answer not in the manual?

Questions and answers