Table of Contents

Advertisement

Quick Links

Ridder – Drive Systems

Lorentzstraat 38

3846 AX Harderwijk

PO Box 360

3840 AJ Harderwijk

the Netherlands

RW1000-SD

RW1200-SD

RW1400-SD

RW1600-SD

RW2000-SD

T +31 (0)341 416 854

E info@ridder.com

I ridder.com

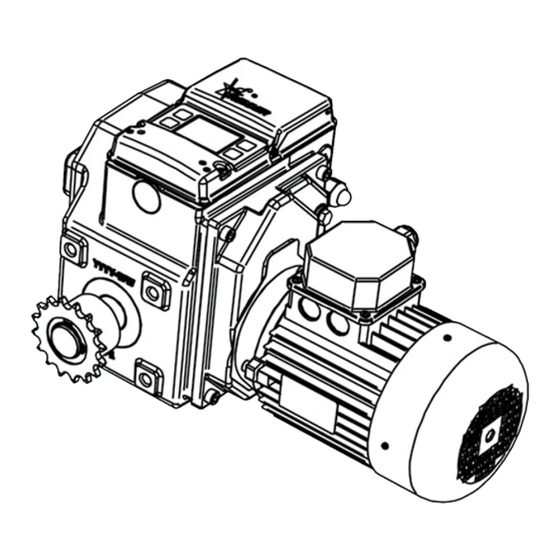

RW-SD Motor Gearboxes 3-phase

RW70-SD

RW100-SD

RW140-SD

RW200-SD

RW240-SD

RW400-SD

RW600-SD

RW45-SD

Product Manual

Ridder SmartDrive

Original product-manual

265004EN - 2023.07 - V00

RW800-SD

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ridder RW-SD Series

- Page 1 Ridder – Drive Systems Lorentzstraat 38 3846 AX Harderwijk T +31 (0)341 416 854 PO Box 360 E info@ridder.com 3840 AJ Harderwijk I ridder.com the Netherlands Product Manual Ridder SmartDrive RW-SD Motor Gearboxes 3-phase Original product-manual 265004EN - 2023.07 - V00...

-

Page 2: Table Of Contents

7.3 Commissioning - Basic Settings [❶] 7.4 Commissioning - End Positions Setting [❷] 7.5 Installation-Closing covers 8. MAIN MENU 9. MOTOR CONTROL 10. CHANGE THE END POSITIONS 11. BLUETOOTH Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com... -

Page 3: Guidelines, Standards And Conditions

However, there is no guarantee that interference will not occur in a particular installation. Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com... -

Page 4: Approved Personnel

1.2 Approved personnel This product manual contains important information for installers about the installation and commissioning of a Ridder SmartDrive RW-SD Motor-Gearbox. Read this product manual and instructions first before the work starts. Approved mechanical and/or electrical installers, with professional competence, must do all work safely and responsibly. -

Page 5: Special Tools And Equipment

To use Bluetooth the special tools and equipment that follow are necessary: ① A mobile device with SmartPhone functionality ② The Ridder SD app. Go to Google Play Store or Apple App Store for download and setup. Use the app (after commissioning) to: • Copy range-of-travel configuratons to other SD units... - Page 6 HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER LIABILITY, WHETHER IN AN ACTION OF CONTRACT, TORT OR OTHERWISE, ARISING FROM, OUT OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR OTHER DEALINGS IN THE SOFTWARE. Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com...

-

Page 7: Safety, Precautions And Symbols

May result in minor injury if the hazard is not avoided. Significant injury, possible death, if the hazard is not avoided. Severe injury and possible death if the hazard is not avoided. Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com... -

Page 8: Precautions And Safety Instructions

SD unit) during all work. There is a risk of short circuit, fire and corrosion. • Take sufficient precautions to prevent ElectroStatic Discharge (ESD). • Ridder is not responsible for injury, material damage or consequential damage if accessories are used that Ridder did not make. - Page 9 • Stay away from or safety areas where there is a risk to become caught in a system that moves. • The torque and the duty cycle of the system must be in the range of the motor gearbox parameters. Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com...

-

Page 10: Residual Risks

Persons can be in danger of life if they touch a system that is in operation. Forces Ridder cannot be sure that there will be no injury to persons or damage to the system because of the forces in the systems (in which the drive unit is installed). 2.4 Symbols and abbreviations This section tells about used symbols and abbreviations in this manual. - Page 11 Safety transformer (EN 61558) Motor connection MPCB/ Motor-Protection Circuit-Breaker Motor connection Neutral wire Motor connection “normally closed” Terminal strip (1–10) “normally open” Terminal strip (11–16) Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com...

-

Page 12: Product Details

NOTE: Possibly the sequence of symbols is different and/or other symbols are included in the identification. Not all symbols and assembled configurations (such as LK, LD, ...) are included in the explanation. * K = Sprocket in an assembled configuration. Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com... -

Page 13: Description

• RW45-SD: 12-tooth 1⁄2”x5⁄16” zinc-plated sprockets for chain couplings are installed. Optionally 16-tooth 1⁄2”x5⁄16” sprockets are installed to compensate for larger angle differences (to a maximum of 6°). Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com... - Page 14 • RW70/100/140/200-SD: 16-tooth 1⁄2”x5⁄16” zinc-plated sprockets for chain couplings are installed. The switching range of the end position system is 1100 revolutions of the drive shaft. Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com...

-

Page 15: Application

This section tells about usual configurations of motor gearboxes and operated systems. Possibly other configurations (or applications) are applicable. For other (different) applications, approval from Ridder is necessary. Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com... -

Page 16: Dimensions

RW45-SD: RW-SD-L/(SD-LK) Ø15 H1 = 55–56 mm RW-SD-TRA H2=144–158mm L1 = 166–170 mm RW-SD-D L2 = 108–112 mm 70.5 Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com... - Page 17 L1 = 156–246 mm 72.5 L2 = 115–195 mm RW800-SD: H1 = 72.5–89 mm 62.5 H2 = 190–213 mm L1 = 217–246 mm L2 = 160–215 mm Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com...

- Page 18 L1 = 248–315 mm L2 = 130–210 mm RW70/100/140/200-34\68SD: 188.5 77.5 Ø25 H1 = 75–88 mm H2 = 179–230 mm L1 = 215–246 mm L2 = 112–153 mm Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com...

-

Page 19: Technical Specifications

IP54* Ambient temperature [°C (°F)] 0–60 °C (32–140 °F) Maximum relative humidity A not-condensed relative humidity is necessary. * IP55 only applicable if in identification. Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com... - Page 20 * The illustration shows two sensor units (SU), but SD motor gearboxes have only one sensor unit. Only the RW45-SD and RW240–600-SD series have the mounting location SU*. Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com...

- Page 21 The Flash Memory has a maximum number of times to erase or write without faults. You can erase or write (without faults) approximately 10,000 times. The lifespan of the flash memory extends when the erase/write cycles are kept to a minimum. Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com...

-

Page 22: Installation

• §4.5 for TRA models with TRA drive-unit (installation options G, H, I) • §4.6 for L models with belt drum (installation option J) • §4.7 for L models with cable drum (installation option K). Ridder – Drive Systems T +31 (0)341 416 854 - E info@ridder.com - I ridder.com...

Need help?

Do you have a question about the RW-SD Series and is the answer not in the manual?

Questions and answers