Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Rockwell Automation Allen-Bradley J Series

- Page 1 Industrial Computers and Thin Clients for Hazardous Locations, Series J Catalog Numbers 6181X-000NWNNDNB-3xNNNNxG-xxx(x), 6181X-000NWNNDNB-3xxxxxxG-xxx(x), 6181X-121PPMXDNB-3xNNNNxG-xxx(x), and 6181X-121PPMXDNB-3xxxxxxG-xxx(x) User Manual Original Instructions...

- Page 2 If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

-

Page 3: Table Of Contents

Add External Component Accessories ........28 Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... - Page 4 Install a Book Mount Bracket ..........55 Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

- Page 5 Technical Data ............69 Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

- Page 6 Table of Contents Notes: Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 7: Preface

Describes basic Ethernet concepts, infrastructure components, and infrastructure features. Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation® industrial system. Provides product-related downloads including firmware, release notes, associated software, Product Compatibility and Download Center (PCDC) website, rok.auto/pcdc... - Page 8 Preface Notes: Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 9: Overview

Multi-touch screen settings for thick or thin gloves for dry to damp operation Non-display models are designed for two mounting options, either: • wall mount design or • book mount when attached to the 6189V-BOOKBRKT book mount bracket. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 10: Initial Preferred Catalog Numbers

(2) For non-hazardous locations: The USB 3.0 ports are hot swappable. See Mounting Requirements on page 23 for more information. Only connect a high-quality, shielded USB 3.0 cable with a retention feature. For hazardous locations: The USB 3.0 ports are not hot swappable. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 11: Accessories

Figure 2 - Nameplate Catalog No. WIN No. Certifications Date Code Record your model-specific information here for future reference. Catalog Number 6181X- Series J WIN Number Date Code Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... - Page 12 Chapter 1 Overview Notes: Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 13: Installation Precautions And Requirements

• les normes ABNT NBR CEI 60529, NEMA 250, UL 50 et provided by enclosures CEI 60529, selon le cas, pour des explications sur les niveaux de protection assurés par les différents types d’armoire. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 14: European Union Directive/United Kingdom Regulations

Required Attribute Shielded or unshielded Shielded USB 3.0 Serial RS-232 Shielded Shielded DisplayPort Shielded DC Power Unshielded (1) For hazardous locations: Only connect a high-quality, shielded USB 3.0 cable with a retention feature. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 15: Hazardous Location Information

Installation Precautions and Requirements Hazardous Location Information This equipment meets the following certifications. For the most current information on all certifications, visit the Rockwell Automation Product Certifications website at rok.auto/certifications and use ‘6181X-CT’ as the search term. North American Hazardous Location Approval The following information applies when operating this Informations sur l’utilisation de cet équipement en... - Page 16 RoHS Disclosure Table See Restriction of Hazardous Substances (RoHS), PEC-TD003. IMPORTANT All 6181X Series J industrial computers and thin clients for hazardous locations can only be used in non-hazardous locations in any Eurasian Conformity region. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 17: Outdoor Installation - Integrated Display Models

Avoiding long-term exposure to direct sunlight helps protect the front of your product from direct exposure to UV radiation, and greatly increase its field life. IMPORTANT The Rockwell Automation approved sun shield, Cat. No. 6189X-SUNSHIELD, must be used if your integrated display model is exposed to direct sunlight. -

Page 18: Conditions For Safe Use Apply In Atex, Ukex, Iecex, Inmetro, And Ccc

PCIe and PCI add-in cards must be rated Zone 2 CCC (Ex)/ATEX/UKEX/IECEx/INMETRO, T4 (maximum), 4 W (maximum), 90 °C (194 °F) (minimum) surrounding ambient temperature. • The internal enclosure ambient temperature range is -20…+70 °C (-4…+158 °F) Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 19: Conditions For Safe Use In North American Hazardous Locations

4 W (maximum) et de Classe I, Division 2, T4 Division 2, T4 (max), 4 W (max), 90 °C (194 °F) (min) (maximum), 90 °C (194 °F) (minimum) à la température surrounding ambient temperature. ambiante environnante. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 20: Installation Requirements

Maximum Heat Dissipation Peripheral Loading PCIe Card, Maximum USB Ports, Maximum per Port 900 mA, 10 W max for all ports (2 A) (1) Add-in cards and peripherals are included in the heat dissipation value. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 21: Installation Site Requirements

0.012 in p-p (10…57 Hz); 2 g peak (57…640 Hz) Vibration (1) See Installation Guidelines on page 8 for more information about temperature guidelines. (2) Applies to panel-mounted integrated display models and wall-mounted non-display models. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... - Page 22 Table 6 on page 21 and must avoid condensation. • If your industrial computer or thin client is exposed to direct sunlight, the Rockwell Automation approved sun shield, Cat. No. 6189X-SUNSHIELD, must be installed. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

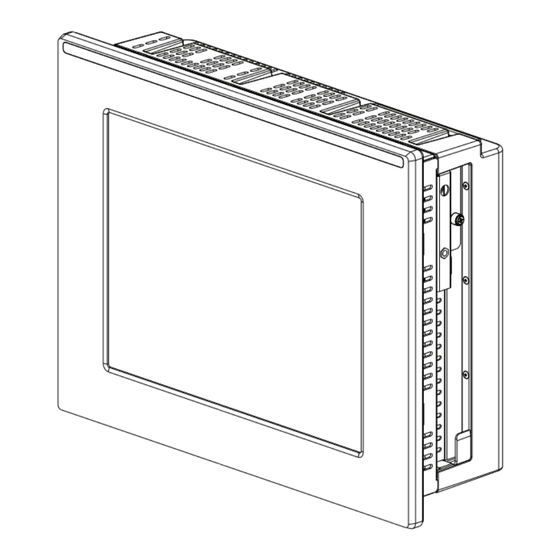

Page 23: Integrated Display Models

Your non-display model can be mounted vertically at a 0°tilt either: a. directly to a wall, such as a steel panel in an enclosure or equipment room, or b. to a book mount bracket, cat. no. 6189V-BOOKBRKT. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... - Page 24 • Make sure that the area around the panel cutout is clear. See the approximate dimensions in Figure 4 to plan the position of your non-display model. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 25: Cable Requirements

IMPORTANT The USB ports will continue to draw power from the power supply of your industrial computer if the power supply is connected to an electrical outlet. Be sure to disconnect the DC power supply before performing maintenance and lockout operations. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... - Page 26 Chapter 2 Installation Precautions and Requirements Notes: Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 27: Installation

Otherwise, continue to unpack the product. Keep the original packing material including the inner and outer packing cartons, in case you must return your product for service (such as Rockwell Automation for RTC battery replacement) or transport to another location. -

Page 28: Add Internal Component Accessories

3. Slide the mounting clips (provided) into the holes on the top, bottom, and sides of your industrial computer or thin client. 4. Hand-tighten the mounting clips around the bezel in the following sequence: Rear View Hand-tighten and Torque Sequence Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 29: For Non-Display Models

ATTENTION: Tighten the mounting clips to the specified torque to provide a proper seal to help prevent water or chemical damage to your industrial computer or thin client. Rockwell Automation assumes no responsibility for water or chemical damage to your industrial computer, thin client, or other equipment within the enclosure because of improper installation. -

Page 30: Add External Component Accessories

Insert a CFast SSD Card — Cat. No. 6189X-64GCFAST on page 3. If a solid-state drive (SSD) is required for your installation: a. Follow the Voltage Precautions on page b. Follow the installation instructions within Install a Solid-state Drive (SSD) on page Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 31: Operation And Connection

IMPORTANT Access to components behind the panel where the industrial computer or thin client is installed is restricted to authorized and properly trained personnel. Rockwell Automation Publication 6181X-UM003-EN-P - April 2024... -

Page 32: Connect Peripheral Cables

2. Attach all other peripheral cables to your industrial PC or thin client. Table 8 for I/O port locations. 3. Attach the unattached end of the peripheral cables to the appropriate component in your schema. Rockwell Automation Publication 6181X-UM003-EN-P - April 2024... -

Page 33: Connect Dc Power

LTSC (64 bit): Read and accept the end-user setup procedure. WARNING: Do not disconnect power from the system until the setup procedure is complete. If power is disconnected, your system image can become corrupt. Rockwell Automation Publication 6181X-UM003-EN-P - April 2024... -

Page 34: Restart

2. Press the power button on the underside of the industrial computer or thin client. See Note No. 8 within Table 8 on page 30 for the location of the power button on the chassis. Rockwell Automation Publication 6181X-UM003-EN-P - April 2024... -

Page 35: Configure The Uefi Setup Utility

3. Immediately press the ‘F2’ key on your keyboard to access the UEFI setup utility. The initial UEFI setup utility screen appears as shown in UEFI Screen Layout and Navigation on page Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 36: Uefi Screen Layout And Navigation

9. Repeat steps 2...7 to change other values within the active menu. 10. Repeat steps 1…9 to change values in other menus. 11. Press the ‘F4’ key to save your changes and exit the UEFI. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 37: Menu Details

Memory Frequency Frequency of the installed memory [value] MT/s Runtime Hours Records the total hours of computer runtime [value] Rockwell Automation / Manufacturer System manufacturer Allen-Bradley Catalog Number Allen-Bradley® catalog number with series letter 6181X-xxxxxxxxxx H Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 38: Advanced Menu

PCI Bus Driver Version Displays the PCI bus driver version information. read-only [Disabled] PERR# Generation Enables or disables PCI Device to Generate PERR#. Disabled by default. [Enabled] [Disabled] SERR# Generation Enables or disables PCI Device to Generate SERR#. Disabled by default. [Enabled] Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... - Page 39 Device Settings Displays the Base I/O address and IRQ setting of serial port 1 IO=3F8H; IRQ=4 Serial Port 1 [Auto] Configuration [IO=3F8h; IRQ=4] Select an optimal setting for the super I/O device Change Settings [IO=2F8h; IRQ=4] Auto by default [IO=3E8h; IRQ=4] [IO=2E8h; IRQ=4] Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 40: Chipset

TIP: Increasing the brightness from the default setting reduces the life of the LED backlight, particularly at high temperatures. LAN 1 Enables or disables onboard LAN 1 controller [Enabled] LAN Configuration Enabled by default [Disabled] LAN 2 Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 41: Boot Menu

TIP: Follow instructions in the dialog box to change the boot order, Boot Option #4 and to enable or disable options. TIP: Press the arrow keys to reorder the boot order. Boot Option #5 Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 42: Security Menu

TIP: To reset an administrator password, perform one of the following steps: setting Clear the UEFI; see Clear the CMOS on page User Password Ship the industrial computer to Rockwell Automation for RTC battery replacement. See Shipment and Transport on page 61 for instructions. TPM Support... - Page 43 Authorized Signatures Pop-up window appears [Update] {Append] [Details] [Export] Forbidden Signatures Pop-up window appears [Update] [Append] [Delete] Authorized Time Stamps Pop-up window appears [Update] {Append] OS Recovery Signatures Pop-up window appears [Update] {Append] Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 44: Save And Exit

4. On the ‘Find Downloads’ page, type your industrial computer model in the ‘Search’ field. 5. Click the search icon to return results. 6. Follow the instructions on the Rockwell Automation PCDC site to find your UEFI (BIOS). 7. Download the UEFI (BIOS) file to your USB drive. - Page 45 The POST initiates. 14. Press the ‘F2’ key. 15. On the ‘Main’ tab, verify that the system time and date are accurate. 16. Press ‘F10 ‘to save your changes and exit the UEFI setup utility. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

- Page 46 Chapter 5 Configure the UEFI Setup Utility Notes: Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 47: Touch Screen Use - Integrated Display Models

Brightness that is increased above the 70% default setting reduces the life of the backlight, particularly at high temperatures. 5. Exit the BIOS setup utility. 6. Disconnect the keyboard from the USB connection. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 48: Calibrate The Resistive Touch Screen

1. Click the Windows icon at the bottom left of your touch screen. 2. Navigate to Settings. 3. Select ‘Display. 4. Start the calibration routine that is offered within the utility. 5. Follow the calibration instructions on the touch screen. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 49: Install Accessories

#2 cross-head screwdriver • Anti-static wriststrap Prepare for Accessory Back Up Data Installation IMPORTANT Before you install internal components, we recommend that you first back up all data to avoid possible data loss. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 50: Shut Down The System

With your industrial computer or thin client properly shut down and all power and peripheral cables disconnected, perform the following steps to remove the cover from the chassis. Figure 12 - Remove the Rear Cover Rear View Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 51: Install A Pci Riser Card - Cat. No. 6189X-Pciriser

Screw 6. Tighten the three retained screws to the add-in card tray in the sequence shown in Figure 13 to secure it to the motherboard. 7. Proceed to Reattach the Cover on page Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 52: Add Memory Modules

The keyed surface is off center to assist the correct alignment. 4. Press each memory module fully into the slot to engage the lock levers. Figure 14 for guidance. 5. Proceed to Reattach the Cover. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 53: Reattach The Cover

180°, and reinsert. Do not force the card into the slot or you can damage the connector pins. 5. Close the CFast card slot cover (D in Figure 16). Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 54: Install A Solid-State Drive (Ssd)

9. Tighten the screw that secures the slot cover of the drive bay (H in Figure 17). IMPORTANT For ATEX, UKEX, and IECEx applications, the CFast card slot cover screw must be hand-tightened and verified as secure. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 55: Attach Mounting Clips

ATTENTION: Tighten the mounting clips to 1.35 N•m (12 lb•in) to provide a proper seal to help prevent water or chemical damage to your industrial computer or thin client. Rockwell Automation assumes no responsibility for water or chemical damage to your industrial computer or thin client and other equipment because of improper installation. -

Page 56: Install A Sun Shield

2. Use a 50:50 cleaning solvent and clean cloth to wipe the perimeter of the integrated display where the sun shield will be installed. 3. Align the six mounting holes on the sun shield with the six mounting holes on your industrial computer or thin client. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 57: Install A Book Mount Bracket

Install a Book Mount Bracket The book mount bracket, Cat. No. 6189V-BOOKBRKT, allows for a book mount installation for all non-display industrial computers. For Book Mount Bracket Mounting on page 28 for installation instructions. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... - Page 58 Chapter 7 Install Accessories Notes: Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 59: Maintenance

• We recommend that you use only Allen-Bradley® approved internal components that are listed in Accessories for Industrial Computers for Hazardous Locations 6181X Series J Product Information, publication 6181X-PC002. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 60: Prepare For Maintenance

2. Press the power switch on the underside of the industrial computer or thin client. See Note No. 8, Table 2 on page 10 for the location of the power button on the chassis. ATTENTION: Do not reapply power until shutdown is complete. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 61: Step C: Disconnect Cables And Power

Gently wipe away the paint or grease from the exterior surfaces except for the equipment labels. c. Dampen a clean, damp cloth with water. d. Gently wipe over the exterior surfaces where the isopropyl alcohol came in contact with the exterior surfaces. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 62: For Internal Component Replacement

For Internal Components on page 48 replacement instructions. IMPORTANT The RTC (real time clock) lithium battery must be replaced by Rockwell Automation only. For return information, contact your local distributor or Rockwell Automation representative, or visit Product and Application Support. For proper shipment... -

Page 63: For Externally Accessible Replacement

Perform the following steps to ship or transport your industrial computer or thin client to Shipment and Transport another location for maintenance (such as Rockwell Automation for RTC battery replacement). ATTENTION: Do not ship or transport your industrial computer or thin client when it is installed in an enclosure, machine, panel, or rack. - Page 64 Chapter 8 Maintenance Notes: Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

-

Page 65: Troubleshoot

Adjust Brightness on page The system date and time is The RTC lithium battery must be replaced by Rockwell Automation only. incorrect or real time clock (RTC) Complete Maintenance on page 61 then for proper shipment procedures. -

Page 66: Diagnostics

Remove the Rear Cover on page SHOCK HAZARD: Do not operate the industrial computer while the rear cover is removed. The rear cover must be attached to maintain EMI shield. 3. Locate the CMOS header on the motherboard. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 67: Hardware Monitoring

4. Select the ‘Advanced’ menu. 5. Select the ‘Hardware Monitor’ menu. 6. Review the data within the Hardware Monitor menu to determine if there is an issue with internal voltages or component temperatures. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 68: Load The System Defaults

3. Select the system defaults. 4. Exit the UEFI set-up utility. Shipment and Transport on page 61 for instruction. Ship or Transport the Computer End-of-Life Disposal on page 61 for instruction. End-of-Life Disposal Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 69: Technical Data

12.1 inch integrated display panel thin client, PCAP multi-touch touch screen, aluminum bezel, Intel Core i3 processor, 6181X-121PPMXDNB-3ANNNNFG-N1S Integrated Display 16 GB RAM, fTPM, DC power, without SSD, without OS, without Rockwell Automation software bundle Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 70: General Specifications

For hazardous locations: The USB 3.0 ports are not hot swappable. Only connect a high-quality, shielded USB 3.0 cable with a retention feature. For non-hazardous locations: The USB 3.0 ports are hot swappable. See Installation Precautions on page 13 for more information. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... -

Page 71: Technical Data

30 g’s (1/2 sine, 11 ms) Non-display — -30…+80 (-22…+176) Applies to panel-mounted integrated display and wall-mounted non-display industrial computers and thin clients. Installation Guidelines on page 8 for more information about temperature guidelines. Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024... - Page 72 2 LAN ports (RJ45), 1 GB each Lithium RTC battery IMPORTANT: The lithium battery can only be replaced by Rockwell Automation. Return your product in its original inner and outer Real-time clock (RTC) Battery packaging to Rockwell Automation for battery replacement. For return information, contact your local distributor or...

- Page 73 Industrial Computers and Thin Clients for Hazardous Locations, Series J User Manual Notes: Rockwell Automation Publication 6181X-UM003A-EN-P - April 2024...

- Page 74 At the end of life, this equipment should be collected separately from any unsorted municipal waste. Rockwell Automation maintains current product environmental compliance information on its website at rok.auto/pec. Allen-Bradley, expanding human possibility, Rockwell Automation, and ThinManager are trademarks of Rockwell Automation, Inc. American Megatrends, AMI, and APTIO are trademarks of American Megatrends, Inc.

Need help?

Do you have a question about the Allen-Bradley J Series and is the answer not in the manual?

Questions and answers