Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for ITT HABONIM 26 Series

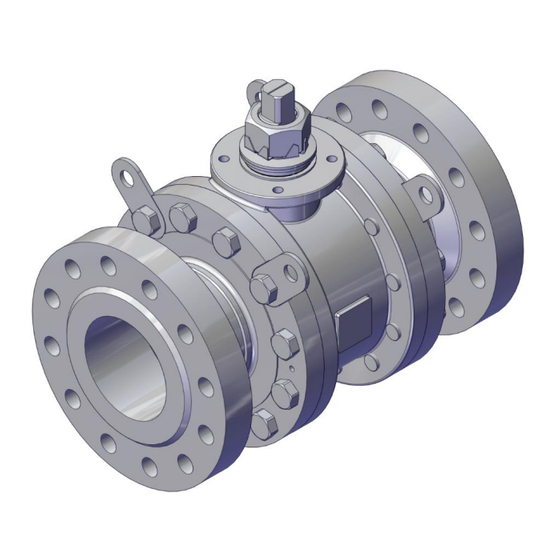

- Page 1 Installation, Operating & Maintenance Guide Installation, Operating & Maintenance Three-Piece Full - Bore Class #600 Ball Valves 26 Valves Series Importer for European Union: Habonim Europe B.V. (EROI NL861781491B0) Item number: YP0005356 REV00-05/24...

- Page 2 Installation, Operating & Maintenance Guide Habonim cannot anticipate all the situations user may encounter while installing and using Habonim valves. The user MUST know and follow all applicable industry specifications on the safe installation and use of these valves. Misapplication of the product may result in injuries or property damage. Refer to Habonim product catalogues, product brochures and installation, operating and maintenance manuals for additional product safety information or contact Habonim.

-

Page 3: Table Of Contents

Installation, Operating & Maintenance Guide Contents General ..........................3 SIL ............................ 3 ATEX – Explosive environment ..................3 Valves marking and labeling .................... 4 Storage ..........................5 Limitations ........................6 6.1. Erosion allowance ..................... 6 6.2. Lubrication and greasing ................... 7 Installation ........................ -

Page 4: General

Installation, Operating & Maintenance Guide 1. General This Installation, Operating & Maintenance manual represents the instructions required for safe use of Habonim ball valve. The manual relates to reduce and full-bore valves. Before using any of these series valves, read the entire IOM carefully and make sure everything is clear. -

Page 5: Valves Marking And Labeling

Installation, Operating & Maintenance Guide 4. Valves marking and labeling 4.1. All valves marking is on a nameplate which is spot welded to the valve body. 4.2. Valves for the European market and above 1” carry the CE mark with the information required by the PED. -

Page 6: Storage

Installation, Operating & Maintenance Guide Standard API-6D Tag Standard Habonim Tag 5. Storage Prior to storage, inspect the valve for shipping damage. Keep all protective packaging, flange covers, and end caps attached to the valves during storage. It is recommended to keep the valves in a clean and dry environment until they are ready for use. -

Page 7: Limitations

Installation, Operating & Maintenance Guide 6. Limitations The correct selection of materials of construction, seats and seals, internal valve components and pressure/temperature ratings determines the safe use of the valves and the performance requirements for the application. This information can be found on the name plate welded to the valve body. DO NOT EXCEED THE VALVE PERFORMANCE LIMITATIONS! EXCEEDING THE PRESSURE OR TEMPERATURE LIMITATIONS MARKED ON THE VALVE LABEL PLATE MAY CAUSE DAMAGE AND LEAD TO... -

Page 8: Lubrication And Greasing

Installation, Operating & Maintenance Guide 6.2. Lubrication and greasing A lubricant is applied to assist valve torque break in on all Habonim valves as a standard unless specified otherwise! The lubricant, if unacceptable, may be removed by disassembling the valve, a solvent wash and assembling it back. -

Page 9: Flanged Valves

Installation, Operating & Maintenance Guide 7.4. Flanged Valves 7.4.1. Before installing the valves, make sure the flanges and the pipe are free from grit, dirt or burrs. 7.4.2. The flanges must be aligned and parallel with the correct distance to allow the valve face-to-face dimension and gaskets to fit between. -

Page 10: Weld End Valves In-Line - Extended Ends

Installation, Operating & Maintenance Guide 7.7. Weld End Valves in-line - Extended Ends 7.7.1. Welding of valves shall be performed by a qualified person according to the ASME Boiler Construction Code Section IX. For valves to be welded within the EEA, refer to the requirements of ESR 3.1.2 of the Pressure Equipment Directive 97/23/EC. -

Page 11: Maintenance

Installation, Operating & Maintenance Guide 9. Maintenance HABONIM valves have a long and reliable life, and maintenance is seldom required. When maintenance is necessary, valves can be refurbished on site. Habonim recommend replacing all bearings, seals, seats, and soft parts every 500,000 cycles or 5 years, whichever comes first. -

Page 12: Disassembly & Assembly Manual

Installation, Operating & Maintenance Guide 10. Disassembly & Assembly Manual 10.1. General 10.1.1. It is strongly recommended to review both the disassembly and assembly chapters before getting started. 10.1.2. For full bore valves, use one size up to your valve size when using the torque tables. 10.1.3. -

Page 13: Assembly

Installation, Operating & Maintenance Guide 10.3. Assembly The following instructions are for valves of all sizes. Fig.2: 10.3.1. Lubricate the stem thrust seal (7) and the stem seal (9) with appropriate lubricant. 10.3.2. Place the stem thrust seal (7) on the stem (4). WARNING: Make sure that the Thrust seal chamfer faces down (Fig.2). - Page 14 Installation, Operating & Maintenance Guide The following instructions are for off-line assembly of valves all sizes 3.21. Bring the valve to the close position and insert the ball (3). 3.22. Place the ball in the valve body (1) until the stem tongue is engaged and turn the stem so the valve is at an open position to prevent the ball from falling out.

- Page 15 Installation, Operating & Maintenance Guide Three-Piece Full-Bore Class #600 Ball Valves - 26 Valves Series...

Need help?

Do you have a question about the HABONIM 26 Series and is the answer not in the manual?

Questions and answers