Summary of Contents for nVent RAYCHEM C910-485

- Page 1 C910-485 Heat Trace Controller Installation, Operation and Maintenance Manual Firmware versions up to V4.0X...

-

Page 2: Table Of Contents

Section 3 – Operator Console ..........................12 Alphanumeric Display ............................... 12 Keypad ..................................... 12 LED Indicators .................................. 13 Section 4 – C910-485 Operation ..........................14 Operating Modes ................................14 4.1.1 Four Modes on Console ....................................14 Console Mode Menus ............................... 15 4.2.1 Alphanumeric Tag Assignment ................................16 4.2.2 Setting Units ....................................... - Page 3 4.2.29 Acknowledging and Resetting Alarms ..............................46 4.2.30 Alarm Output Normal State ...................................47 Section 5 – Troubleshooting ...........................48 Section 6 – Appendix A: Proportional Ambient Sensing Control (PASC) ..............49 Section 7 – Appendix B: C910-485 wiring diagram to fire alarm panel ..............50 nVent.com/RAYCHEM RAYCHEM-OM-H58415-C910series-EN-2403...

-

Page 4: Section 1 - Overview

Additional copies of this user manual may be ordered separately through your nVent representative or online at nVent.com/RAYCHEM This document covers the C910-485 Heat Trace Controller and its available options. To ensure that you are using the correct documentation for your particular version of controller, please check the firmware version number of your C910-485 against the version number listed on the front of this manual. -

Page 5: Product Specification

Buyer. However, the Buyer shall pay all shipping charges, duties, and taxes for products returned to nVent from another country. nVent warrants that the software and firmware designated by nVent for use with the C910-485 Controller will execute its programming instructions properly. - Page 6 Enclosure Protection NEMA 4X Materials FRP/Polycarbonate Ambient operating temperature range –40°F to 140°F (–40°C to 60°C) Ambient storage temperature range –40°F to 185°F (–40°C to 85°C) Relative humidity 0% to 90%, noncondensing Control Relay type Double-pole, mechanical Voltage, maximum 277 V nominal, 50/60 Hz Current, maximum 30 A @ 104°F (40°C) derated to 20 A @ 140°F (60°C) Control algorithms...

- Page 7 Mounting FRP/Poly carbonate enclosure Surface mounting with four fixing holes on 7.25 in x 11.7 in (184 mm x 297 mm) centers Hole diameter: 0.31 in (8 mm) Communications Protocol Modbus RTU / ASCII Topology Multidrop, daisy chain Cable Single shielded twisted pair, 26 AWG or larger Length 4,000 ft.

-

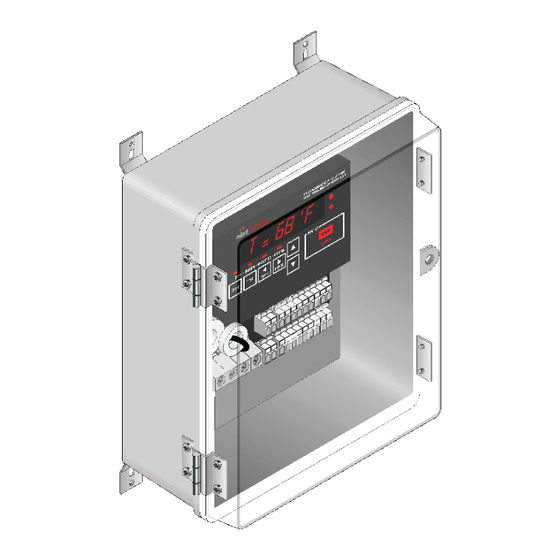

Page 8: Section 2 - Installation And Wiring

Fig. 2.1 – Mounting Hole Template 2.5 Wiring The following drawings provide sample wiring diagrams for the C910-485 control products and optional accessories. Refer to Fig. 2.2 for wiring terminal locations. Please contact your local nVent representative for information regarding other available options. -

Page 9: Power Connections

The C910-485 has two (2) RTD inputs. Use only 3-wire 100 Ω Platinum RTDs (DIN 43760, α= 0.00385 Ω/ Ω/°C) Note: The C910-485 default is set for one RTD in position one. If a second RTD is installed in position two, the controller must be power cycled to recognize the RTD. -

Page 10: Alarm Relay Connections

Note: Both alarm relays are controlled by the C910-485 using the same signal. Note: The dry contact alarm relay is intended to be used for switching low-voltage, low-current signals. Do not use this relay to directly switch line voltages. -

Page 11: Communication Signal Connections

Fig. 2.9 – Used as a Powered AC Alarm Relay 2.6.1 Communication Signal Connections The C910-485 controller includes a RS-485 communications interface. Use twisted pair, shielded cable communication wiring. Ground the shield on communications wiring at one end only, using the terminals provided. -

Page 12: Section 3 - Operator Console

SECTION 3 – OPERATOR CONSOLE 3.1 Alphanumeric Display The console incorporates a six characters, fourteen segment, plus decimal LED display. Messages and prompts that are greater than six characters long are scrolled, allowing more meaningful, non-cryptic messages to be used. 3.2 Keypad The local keypad consists of six keys that allow you to select the console mode function that you are interested in. -

Page 13: Led Indicators

• The ALARM LED will flash (approximately once per second) when the controller has detected an alarm condition Two additional LEDs are used to indicate external communications activity and are only used with the C910-485 with the optional RS-485 communications interface. -

Page 14: Section 4 - C910-485 Operation

SECTION 4 – C910-485 OPERATION 4.1 Operating Modes 4.1.1 Four Modes on Console Scan This is the default mode displayed during normal operation. In this mode, the console sequentially displays load current, temperature, and setpoint readings. Alarm This mode allows you to examine or reset any alarms that may exist. The LED above the ALARM key is illuminated while in this mode. -

Page 15: Console Mode Menus

4.2 Console Mode Menus The Console Mode Menu Index below shows all user interface parameters. This menu shows the Factory Default along with the associated range. The section column refers to the section in this manual that illustrates the actual keystrokes required to input the parameters. -

Page 16: Alphanumeric Tag Assignment

4.2.1 Alphanumeric Tag Assignment Purpose A 19 character alphanumeric TAG may be assigned to a control point to allow it to be easily associated with a pipe, vessel, process, circuit, drawing name, or number Setting Any combination of 19 characters from A–Z, 0–9, /, -, ., (, ), or # Keystrokes for Changing TAG Start Press the [ENTER] again to... -

Page 17: Setting Units

4.2.2 Setting Units Purpose This allows selection of the type units (temperature or size) to display on the operator Setting Metric or Imperial Factory Default Imperial Keystrokes for Changing Units Start Press the [DOWN] arrow Press [SHIFT] Press [ENTER] key until you see CONFIG ALARM MONITOR... -

Page 18: Switch Control Mode

4.2.3 Switch Control Mode Purpose This allows selection of the type of algorithm to be used to maintain the control setpoint temperature. Reference Fig. 2.5 for the External Direct wiring schematic. Setting On/Off or Proportional Ambient Sensing Control (PASC), External Direct Factory Default On/off Keystrokes for changing Switch Control Mode... -

Page 19: Control Setpoint

4.2.4 Control Setpoint Purpose This is the temperature that the controller uses to determine whether its output switch should be on or off Setting/Range 0°F to 200°F (–18°C to 93°C) Factory Default 40°F (4°C) Keystrokes for Changing the Control Setpoint Start Press the [DOWN] arrow Press [SHIFT] Press [ENTER]... -

Page 20: Deadband = Xx

4.2.5 Deadband Purpose The deadband is a window of difference between the measured control temperature and the desired control setpoint temperature and provides the decision to turn the output off or on Setting/Range 1°F to 10°F (1°C to 6°C) Factory Default 5°F (3°C) Keystrokes for Changing Deadband Start... -

Page 21: Proportional Ambient Sensing Control (Pasc)

4.2.6 Proportional Ambient Sensing Control (PASC) Purpose This control mode sets Proportional Ambient Sensing Control (PASC). See Appendix A for more details. Setting Range Factory Default Pipe Size (inch): ½, 1 or, ≥ 2 ½- Control Setpoint: 0 to 200°F (–18 to 92°C) 40°F (4°C) Min. -

Page 22: Low Temperature Alarm: Enable (Lo Ts 1 And Lo Ts 2)

4.2.7 Low Temperature Alarm: Enable (Lo TS 1 and Lo TS 2) Purpose This allows the user to enable or disable the low temperature alarm for temperature sensor number 1 and 2. Alarm time delay filter is factory set at 15 minutes. Setting/Range Enable or disable Factory Default... -

Page 23: Low Temperature Alarm: Setting (Lo Ts 1 And Lo Ts 2)

4.2.8 Low Temperature Alarm: Setting (Lo TS 1 and Lo TS 2) Purpose This allows the user to set the low temperature alarm setting for temperature sensor number 1 and 2. Alarm time delay filter is factory set at 15 minutes. Setting/Range 0°F to 180°F (–18 to 82°C) Factory Default... -

Page 24: High Temperature Alarm: Enable (Hi Ts 1 And Hi Ts 2)

4.2.9 High Temperature Alarm: Enable (Hi TS 1 and Hi TS 2) Purpose This allows the user to enable or disable the high temperature alarm for temperature sensor number 1 and 2. When enabled, high limit cutout feature will force the controller output off if the temperature reading exceeds the HIGH ALARM temperature setting. -

Page 25: High Temperature Alarm: Setting (Hi Ts 1 And Hi Ts 2)

4.2.10 High Temperature Alarm: Setting (Hi TS 1 and Hi TS 2) Purpose This allows the user to set the high temperature alarm Setting for temperature sensor number 1 and 2. Alarm time delay filter is factory set at 15 minutes. Setting/Range 0°F to 200°F (–18°... -

Page 26: Temperature Sensor Failure Alarm

4.2.11 Temperature Sensor Failure Alarm Purpose This allows the user to enable or disable the temperature sensor failure alarm. Alarm time delay filter is factory set < 2 minutes. Setting/Range Enable or disable Factory Default Disable Keystrokes for Enabling and Disabling TS 2 Start Press the [DOWN] arrow Press [SHIFT]... -

Page 27: High Temperature Cut-Out, Setpoint And Alarm (Hi Limit Ts1/Hi Limit Ts2)

4.2.12 High Temperature Cut-out, Setpoint and Alarm (HI Limit TS1/HI limit TS2) Purpose Set high temperature alarm and cut-out values. Setting/Range Enable/Disable HI Limit Factory Default Disable Set point: 0°F (-18°C) to 200°F (93°C) 200°F (93°C) Enable/Disable Alarm Disable Keystrokes for Selecting TS HI Limit (ENA/DIS) Setpoint and Alarm Note: these steps can apply to TS 2 (ENA/DIS), Setpoint and Alarm Start Press the [DOWN]... -

Page 28: Low Load Current Alarm: Enable (Lo Load)

4.2.13 Low Load Current Alarm: Enable (Lo Load) Purpose This allows the user to enable or disable the low load current alarm to detect current levels which are lower than a preset limit for the application. Alarm time delay filter is factory set at < 2 minutes. Setting/Range Enable or disable Factory Default... -

Page 29: Low Load Current Alarm: Setting (Lo Load)

4.2.14 Low Load Current Alarm: Setting (Lo Load) Purpose This allows the user to set the low load current alarm level. Alarm time delay filter is factory set at < 2 minutes. Setting/Range 0.3 A to 30 A or off Factory Default Keystrokes for Entering the LO Load Current Setpoint Start Press the [DOWN] arrow... -

Page 30: Factory Default Settings (Load Defaults)

4.2.15 Factory Default Settings (Load Defaults) Purpose To provide a quick method of re-Setting the controller’s configuration parameters to the Factory Default parameters. Setting Factory Default Keystrokes for Loading Defaults Start Press the [DOWN] arrow Press [SHIFT] Press [ENTER] key until you see CONFIG ALARM MONITOR... -

Page 31: Ground-Fault Current Alarm Level (Hi Gf Alarm)

4.2.16 Ground-fault Current Alarm Level (Hi GF Alarm) Purpose This allows the user to set the ground-fault current alarm level. Exceeding this limit will trigger the alarm to indicate that a ground-fault condition exists in the heating cable circuit. To protect against the risk of fire or shock, ground-fault level should be set at the lowest level possible to allow normal operation of the cable. -

Page 32: Ground-Fault Current Trip Level (Hi Gf Trip)

4.2.17 Ground-fault Current Trip Level (Hi GF Trip) Purpose This allows the user to set the ground-fault current trip level. Exceeding this limit will result in the output switch being latched off and the Ground-fault Level Trip Alarm activated to indicate a ground fault condition. Warning: Fire Hazard. -

Page 33: Temperature Sensor Failure Mode

4.2.18 Temperature Sensor Failure Mode Purpose This mode sets the controller to turn the output switch ON or OFF if all selected temperature sensors fail Setting/Range On or off Factory Default Keystrokes for configuring TS FAIL Mode ON or OFF Temperature Sensor Mode Start Press the [DOWN] arrow Press [SHIFT]... -

Page 34: Temperature Sensor Control Mode (Ts Clt Mode)

4.2.19 Temperature Sensor Control Mode (TS CLT Mode) Purpose The TS CONTROL MODE allows the selection of one of eight possible temperature control modes for the controller. The different modes allow redundant fail-safe temperature sensing. Setting/Range 1. TS1-Fail ON 5. Average Fail ON 2. -

Page 35: External Input: Inhibit Or Force On

4.2.20 External Input: Inhibit or Force on Purpose Using an external input device to override sensor inputs: Force on or force off. Reference Fig. 2.5 for the wiring connection schematic. Setting/Range Factory Default Ext Input: Not used, Force on or Inhibit Not used Override: Remote or External input Remote... -

Page 36: Firmware Version

4.2.21 Firmware Version Purpose This menu displays the revision level of the firmware programmed into the controller. Setting/Range Factory Default Keystrokes for Viewing the Software Version Start Press the [DOWN] arrow Press [SHIFT] Press [ENTER] key until you see ALARM MONITOR CONFIG MONITOR CONFIG... -

Page 37: Passcode

4.2.22 Passcode Purpose The four digit numeric PASSWORD stops unauthorized users from modifying the controller’s configuration parameters using the Operator Console. Setting/Range 0000 to 9999 Factory Default 0000 Keystrokes for Entering a Password Start Press the [DOWN] arrow key until you see CONFIG MONITOR CONFIG... -

Page 38: Communications Setup

4.2.23 Communications Setup Purpose Defines the communications language used by the controller to communicate with other devices. The C910-485 only communicates using Modbus Protocol. The C910-485 automatically detects when it is connected to the ACS-30 network. Setting/Range See C910-485 Communication Parameters Table... - Page 39 If you are communicating directly with the controller using a different device, select the MODBUS protocol. Modbus RTU For a detailed description of the controller’s MODBUS mapping please refer to C910-485 Modbus ASCII Heat Trace Controller. Note: HTCBus is for factory use only.

-

Page 40: Auto-Cycle: Enabling

4.2.24 Auto-Cycle: Enabling Purpose The autocycle function applies power to the heating cable circuit for approximate 10 seconds at the selected interval. It is used to test the integrity of the heating cable circuit. Note: Although the autocycle function helps monitor the functionality of the heating cable circuits it does not eliminate the need for preventive maintenance as detailed in the heating cable operating manuals. -

Page 41: Auto-Cycle: Interval

4.2.25 Auto-Cycle: Interval Purpose Set the interval for running the autocycle procedure Setting/Range 1 to 240 [minutes or hours, selected in the Auto-cycle units menu.] Factory Default Keystrokes for Entering Auto Cycling Interval Start Press the [DOWN] arrow Press [SHIFT] Press [ENTER] key until you see CONFIG ALARM... -

Page 42: Auto-Cycle: Units

4.2.26 Auto-Cycle: Units Purpose Select the Autocycle interval time units Setting/Range Minutes or hours Factory Default Hours Keystrokes for Changing Auto-Cycle Units Start Press the [DOWN] arrow Press [SHIFT] Press [ENTER] key until you see ALARM MONITOR CONFIG MONITOR CONFIG ALARM ALARM MONITOR CONFIG... -

Page 43: Contactor Count

4.2.27 Contactor Count Purpose Generates an alarm if the number of off-to-on transitions of a contactor reaches or exceeds the Contactor Count Alarm Setting. This serves as a method to perform preventative maintenance on the contactor before a failure is likely to occur. Setting/Range 0 to 999,999 Factory Default... -

Page 44: Monitor And Maintenance Menus

4.2.28 Monitor and Maintenance Menus Purpose The Monitor menu displays the measured and stored readings. You can also reset counters from this menu. Setting/Range See C910-485 Monitoring and Maintenance Parameters table. Factory Default Keystrokes for Entering Monitor and Maintenance Menus START... - Page 45 LEDs of the Operator Console to ensure that they are functioning properly. Recorded Values Temperature values This feature indicates the maximum and minimum temperatures recorded by the C910-485 since the last time the values were reset: • Max Control temp •...

-

Page 46: Acknowledging And Resetting Alarms

4.2.29 Acknowledging and Resetting Alarms Purpose To acknowledge and reset any alarm conditions that may exist. Use the Up / Down Arrow keys to examine the next/previous active alarms. Setting/Range See Alarm Filter Times Factory Default Keystrokes for Acknowledging and RESETING Alarms Start Press [SHIFT] Press [TEST]... -

Page 47: Alarm Output Normal State

4.2.30 Alarm Output Normal State Purpose ConFig.s both the alarm output relays (dry contact and AC alarm) for normally open or normally closed operation. The normal condition is assumed to be when the HTC is powered and no alarms exist. Setting/Range Normally Open (N.O.) or Normally Closed (N.C.) Factory Default Normally closed... -

Page 48: Section 5 - Troubleshooting

SECTION 5 – TROUBLESHOOTING The C910-485 may be used as an effective troubleshooting tool to pinpoint problem areas of heating cable circuits. Described below are a few of the more common problem areas, their symptoms, and parameters to check to determine the actual faulty portion of the heating cable circuit. -

Page 49: Section 6 - Appendix A: Proportional Ambient Sensing Control (Pasc)

The C910-485 has a control algorithm that uses the measured ambient temperature, desired maintain temperature, minimum ambient temperature assumption used during design, and size of the smallest pipe diameter to calculate how long the heating cable should be on or off to maintain a near-constant pipe temperature. -

Page 50: Section 7 - Appendix B: C910-485 Wiring Diagram To Fire Alarm Panel

SECTION 7 – APPENDIX B: C910-485 WIRING DIAGRAM TO FIRE ALARM PANEL nVent.com/RAYCHEM RAYCHEM-OM-H58415-C910series-EN-2403... - Page 51 nVent.com/RAYCHEM RAYCHEM-OM-H58415-C910series-EN-2403...

- Page 52 Our powerful portfolio of brands: ©2024 nVent. All nVent marks and logos are owned or licensed by nVent Services GmbH or its affiliates. All other trademarks are the property of their respective owners. nVent reserves the right to change specifications without notice. nVent.com/RAYCHEM RAYCHEM-OM-H58415-C910series-EN-2403...

Need help?

Do you have a question about the C910-485 and is the answer not in the manual?

Questions and answers