Advertisement

Quick Links

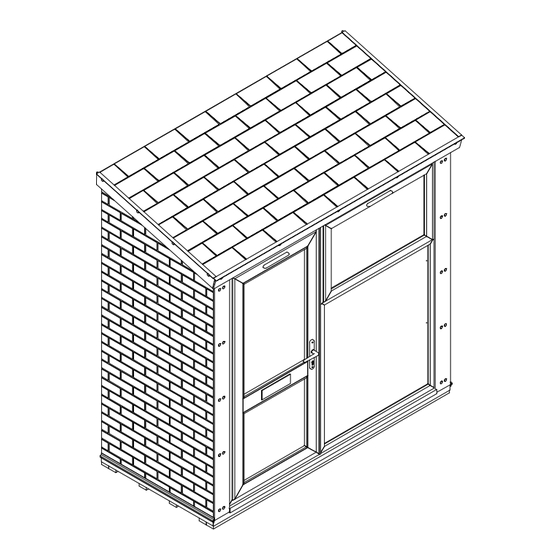

G3-2412PCH-LG-G (Brick Effect/Light Grey/Grey Windows)

G3-2412PCH-UP-G (Brick Effect/Un-Painted/Grey Windows)

Brick effect side panels

G3-2412PCH

Option of brick effect side panels have been illustrated in this installation manual.

The door & window can be positioned on the left or right hand side.

In this manual, the door has been illustrated on the left & the window on the right.

All dimensions are approximate and subject to the limitations of the materials used and the methods of manufacture

Manufacturer:

Dunster House Ltd.

Caxton Road

Bedford

Bedfordshire

England

MK41 0LF

ADDROOM PORCH 2.4m x 1.2m

G3-2412GPCH-G (Grooved/Grey Windows)

G3-2412PCH-G (Brick Effect/Red/Grey Windows)

Installation Manual

Please read this installation manual carefully

before proceeding with the construction of your Addroom Porch.

Unique Porch Reference Number

Groove effect side panels

G3-2412GPCH

Important!

_____________________________

V3

Customer Service:

cs@dunsterhouse.co.uk

www.dunsterhouse.co.uk

Advertisement

Summary of Contents for Dunster House ADDROOM G3-2412GPCH-G

- Page 1 In this manual, the door has been illustrated on the left & the window on the right. Important! All dimensions are approximate and subject to the limitations of the materials used and the methods of manufacture Manufacturer: Unique Porch Reference Number Dunster House Ltd. _____________________________ Caxton Road Bedford Bedfordshire...

- Page 2 In the unlikely event that you need to contact us, please do so in writing to: Email: cs@dunsterhouse.co.uk Post: FAO Customer Services, Dunster House Ltd - Factory 1, Caxton Road, Bedford, MK41 0LF Our Customer Services department is open 9:00 - 17:00, Monday to Friday. Please include your Sales Order number starting with SO or your postcode so we can locate your order.

- Page 3 PORCH 2.4m x 1.2m Components BEARER WHITE WPC (Side Roof Fascia) RH (Step 1) WHITE WPC (Side Roof Fascia) LH (Step18) (Step 18) 1210 1210 6x P-35x70 - L = 2320mm 1x P-White WPC-1210x100x10.A LH 1x P-White WPC-1210x100x10.A RH WHITE WPC (Front Vertical Sides) (Step 13) 2005 2x P-White WPC-2005x150x10.B...

- Page 4 PORCH 2.4m x 1.2m Components WHITE WPC (Front Fascia) (Step 14) 2320 1x P-White WPC-2320x85x10.A WHITE WPC (Front Roof Fascia) (Step 18) 2420 1x P-White WPC-2420x100x10.A L PROFILE L PROFILE (Step 3) (Step 3) 1x L Profile 50x50x2 (0200PW) - 1100mm.A LH 1x L Profile 50x50x2 (0200PW) - 1100mm.A RH L PROFILE DRIP TRAY...

- Page 5 PORCH 2.4m x 1.2m Components SUPPORT BEAM H COUPLER - 2000mm (Step 23) (Step 11) 1x P-70x70.A - L = 990mm uPVC DOOR / WINDOW CILL - 2032mm (Step 9) 2032 uPVC SEALED SINGLE DOOR UNIT uPVC SEALED WINDOW UNIT (Step 10) (Step 12) (outward opening) with uPVC glazing beads...

- Page 6 PORCH 2.4m x 1.2m Fixings & Accessories 35mm C/sk Screw 60mm Drywall Screw (Steps 6, 18 to 21 & 23) (Step 5) 70mm C/sk Screw 30mm White Polytop Pins (Steps 2, 10 & 12 to 15) (Step 22) 90mm C/sk Screw 30mm Pin Nail (Steps 1, 4, 6, 9 &...

- Page 7 Assembly Steps Items required: Pre-drill before fixing with screws or bolts 6x P-35x70x2320 (Bearer) 14x 90mm c/sk screw STEP 1 1a) Prepare a minimum overall base dimension of 2520mm x 1200mm. 1b) Join the double bearers using 90mm c/sk screws. Place the bearers on the base as shown in the diagram below. 2520 minimum overall base 2320 Flush with house wall...

- Page 8 Assembly Steps Items required: Pre-drill before fixing with screws or bolts 1x L Profile 50x50x2x1100mm.A (0200PW) L.H. 1x L Profile 50x50x2x1100mm.A (0200PW) R.H. 1x L Profile 50x50x2x2324mm (0200PW) 13x 30mm Pin Nail STEP 3 3a) Place the L.H. & R.H. side L Profiles with the 50x50mm cut outs at the front of the porch. Place the front L Profile between the two side L Profiles as shown in the diagram, ensuring the side L Profiles are flush with the edges of the floor panel &...

- Page 9 Assembly Steps Pre-drill before fixing with screws or bolts Items required: 1x P-ESWP-2400x1100x105 L.H. (External Side Wall Panel L.H.) 1x P-ESWP-2400x1100x105 R.H. (External Side Wall Panel R.H.) 8x 90mm c/sck screw Suitable wall fixings (not supplied) STEP 4 4a) Fix the base of the external side wall panels through to the bearers, as shown in the diagrams, using 90mm c/sk screws. It is imperative that the dimensions are checked frequently, including the diagonal dimensions, to ensure the porch is being built square, as this will determine the placement of the roof assembly.

-

Page 10: Right Side

Assembly Steps Items required: Pre-drill before fixing with screws or bolts P-ISWP-2400x1100x35 L.H. (Internal Side Wall Panel L.H.) P-ISWP-2400x1100x35 R.H. (Internal Side Wall Panel R.H.) 30x 60mm Drywall Screw STEP 5 5a) Attach the left & right internal side wall panels to the external side wall panels, as shown in the diagrams. Use 60mm Drywall screws, ensuring each screw is screwed to the timber frame, using the given dimensions. - Page 11 Assembly Steps 35mm c/sk screw Items required: Pre-drill before fixing with screws or bolts P-70x70x2040 (Support Beam) 90mm c/sk screw Support Beam L Metal Bracket 75x75x1.8mm Thick (ISL2644) 35mm C/sk Screw ISL2644 L BRACKET 90mm C/sk Screw STEP 6 6a) Attach the underside of the Support Beam to the side walls by RIGHT using the 75x75 L Brackets as shown in the diagrams, ensuring the SIDE...

- Page 12 Assembly Steps Pre-drill before fixing with screws or bolts Items required: 50x Self Adhesive Red Cap RIGHT SIDE STEP 8 8a) Cover the c/sk screws on the left & right side of the WPC brick effect walls with self-adhesive red caps (approx. 25 on each side). Items required: 1x Window &...

- Page 13 Glazing Windows and Doors Sealed units are approximately 10mm smaller in length and width than the aperture. This difference in size will be packed using bridge packers (4mm), black shims (2mm), and green shims (1mm). Bridge packers must be used only against the frame, while shims are to be used only next to sealed units.

- Page 14 Glazing Windows and Doors 5. After packing the sealed units correctly, refit the beads in the same position as you removed them; start with the smallest lengths first before inserting the longer lengths. Carefully use a nylon or non-marking rubber mallet to help tap the beads into position, starting at the ends.

- Page 15 Variants Please note: This manual describes the assembly steps for the first variant. To assemble the second variant, please apply the same assembly principles. Page 15...

- Page 16 Assembly Steps Items required: Pre-drill before fixing with screws or bolts 1x Door Frame 2x 70mm c/sk screw & 7x 120mm c/sk screw STEP 10 10a) Please remove the glazing beads as per the glazing windows & doors instructions on pages 13 & 14. 10b) Position the door frame as shown in the diagrams, allowing a 4mm gap approx.

- Page 17 Assembly Steps Items required: Pre-drill before fixing with screws or bolts 1x Window Frame 8x 70mm c/sk screw 8x 120mm c/sk screw STEP 12 12a) Position the window frame as shown in the diagrams, allowing a 4mm gap approx. between the window frame & the wall panel.

- Page 18 Assembly Steps Items required: Pre-drill before fixing with screws or bolts P-White WPC-2005x150x10.B (Front Vertical Sides) 20x 70mm c/sk screw 20x Self-adhesive white cap STEP 13 13a) Position the components P-White WPC-2005x150x10.B on the left & right side of the porch, covering the face of the wall panels.

- Page 19 Assembly Steps Pre-drill before fixing with screws or bolts Items required: 2x P-White WPC-2320x85x10.A (Front Fascia) 5x 70mm c/sk screw 5x Self-adhesive white cap STEP 14 14a) Position the Front Fascia P-White WPC-2320x85x10.A on top of the two front WPC vertical sides P-White WPC-2005x150x10.B, ensuring the faces of the two components are flush with each other as well as the edges, &...

- Page 20 Assembly Steps Pre-drill before fixing with screws or bolts Items required: P-IRP-2400x1200x41 (Insulated Roof Panel) RTR Bar 36x36x1160.A (1777) 11x 70mm c/sk screw RTR Bar 36x36x2400 (1777) STEP 15 15a) Turn your insulated roof panel face down (slate effect facing the ground) with the smaller of the slate effect grooves at the rear of the porch roof, and the larger grooves at the front of the porch roof.

- Page 21 Assembly Steps Pre-drill before fixing with screws or bolts Items required: 1x Insulated Roof Panel with assembled 35x35 timber support Bars & H Trims from step 16. 6x 90mm c/sk screw 6x 120mm c/sk screw STEP 17 17a) Slide the Insulated Roof Panel on top of the Insulated Side Walls, with the 2400 RTR Bar at the front of the porch, ensuring an equal gap of 4mm approx.

- Page 22 Assembly Steps Pre-drill before fixing with screws or bolts Items required: 1x P-White WPC-2420x100x10.A (Front Roof Fascia) STEP 18 1x P-White WPC-1210x100x10.A LH (Side Roof Fascia) 18a) Ensure all roof fascia are flush with the top face of the 1x P-White WPC-1210x100x10.A RH (Side Roof Fascia) roof panel.

- Page 23 Assembly Steps Pre-drill before fixing with screws or bolts Items required: STEP 19 1x P-White WPC-2040x100x10 (Front Support Beam Covering) 19a) Connect the front support beam covering to the front 6x 35mm c/sk screw support beam, with 35mm c/sk screws, then cover with the 6x Self-adhesive white cap self-adhesive white caps, by following the diagrams below.

- Page 24 Assembly Steps Items required: Pre-drill before fixing with screws or bolts 1x P-White WPC-2040x80x10 STEP 21 (Side Rear Support Beam Covering) 21a) Connect the side rear support beam covering to the rear 6x 35mm c/sk screw side support beam, with 35mm c/sk screws, then cover with the 6x Self-adhesive white cap self-adhesive white caps, by following the diagrams below.

- Page 25 Assembly Steps Pre-drill before fixing with screws or bolts Items required: 1x P-70x70x990.A (Mid Support Beam) 2x L Metal Bracket 75x75x1.8mm Thick (ISL2644) 8x 35mm c/sk screw STEP 23 23a) Attach each of the brackets through each of the support beam coverings, then into the front and rear support beams, approximately in the middle of the porch.

- Page 26 Assembly Steps Items required: Pre-drill before fixing with screws or bolts Lead Flashing Strip - (not supplied) Clear exterior sealant + caulking gun - (not supplied) STEP 24 24a) Use a suitable lead flashing strip (not supplied) for making a watertight ridge connection between your Addroom Porch &...

- Page 27 Assembly Steps STEP 25 25a) Finally, go back to the door & window section to install the uPVC internal glazing beads & glass. Once installed, apply a bead of sealant on both the internal and external sides of the uPVC frames. Congratulations - Your Addroom Porch is now complete Page 27...

Need help?

Do you have a question about the ADDROOM G3-2412GPCH-G and is the answer not in the manual?

Questions and answers