Advertisement

Quick Links

ASSEMBLY TEMPLATE

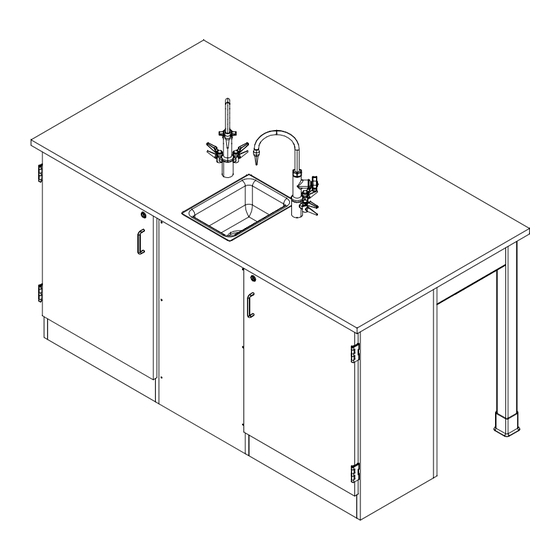

FORWARD VISION III

NOTE:

1.

MODEL VIEWS MAY NOT REPRESENT EXACT MODEL PURCHASED

2924 & 2924F, 2926 & 2926F, 2964 & 2964F, 2966 & 2966F SERIES

ASSEMBLY INSTRUCTIONS

C

UPDATED SILICONE PROCEDURE

8/21/23

A

CREATED DRAWING

11/8/16

REV.

DESCRIPTION

DATE

REVISION LEVEL

ALL DIMENSIONS ARE IN INCHES UNLESS

DWN

EMR

NOTED OTHERWISE

BY:

DECIMALS: .X = ± .030

APR

.XX = ± .020

BY:

.XXX = ± .010

ANGLES: = ± 1°0'

APR

CABINET SQUARENESS = ± .0625

BY:

CONFIDENTIAL:

ALL DESIGN RIGHTS RESERVED

THE INFORMATION, DATA, DESIGN, AND DRAWINGS EMBODIED

IN THIS DOCUMENT AND ALL REPRODUCTIONS THEREOF ARE

THE EXCLUSIVE PROPERTY OF DIVERSIFIED WOODCRAFTS, INC.

RJM

-

THESE DOCUMENTS ARE SUPPLIED WITH THE UNDERSTANDING

THAT THEY WILL NOT BE DISCLOSED TO THIRD PARTIES WITHOUT

EMR

-

WRITTEN CONSENT OF DIVERSIFIED WOODCRAFTS, INC. ANY

NAME

ECN NO.

REPRODUCTION IN PART OR WHOLE WITHOUT WRITTEN

CONSENT IS SUBJECT TO LEGAL ACTION.

DATE

11/8/16

DWN:

DATE

APR:

DATE

APR:

TITLE:

FORWARD VISION III

ASSEMBLY INSTRUCTIONS

DRAWING NUMBER:

FORWARD VISION III

300 South Krueger Street

Suring, WI 54174

diversifiedwoodcrafts.com

SCALE:

SHEET:

REVISION:

REV C

NTS

1 OF 14

Advertisement

Summary of Contents for DIVERSIFIED SPACES FORWARD VISION III 2924 Series

- Page 1 ASSEMBLY TEMPLATE FORWARD VISION III 2924 & 2924F, 2926 & 2926F, 2964 & 2964F, 2966 & 2966F SERIES ASSEMBLY INSTRUCTIONS DATE ALL DIMENSIONS ARE IN INCHES UNLESS 11/8/16 NOTED OTHERWISE DWN: 300 South Krueger Street DECIMALS: .X = ± .030 NOTE: DATE .XX = ±...

- Page 2 ASSEMBLY TEMPLATE ASSEMBLY COMPONENTS TOOLS REQUIRED ITEMS INCLUDED PART # PART DESCRIPTION " WRENCH TOP, (STYLE VARIES), 1.00X36X68,BLK, VARIES " SOCKET AND TORQUE WRENCH - OPTIONAL (EITHER FIXTURE OR FLAT) DRILL CABINET 24"W X 35"H X 15.25"D " DRILL BIT REMOVABLE PANEL 18"W X 35"H X 0.75"D CONTACT CEMENT...

- Page 3 ASSEMBLY TEMPLATE ASSEMBLY COMPONENTS ITEMS INCLUDED PART # PART DESCRIPTION ELECTRICAL BOX 100033 ELECTRICAL BOX 3.00X2X2.5 DEEP ELECTRICAL OUTLET 100034 ELEC,OUTLET,GFI,20A 125V,BLK FIXTURE,L65-WSA-DIV(MULTI-SERVICE) **FIXTURE - FAUCET** 100074-BKR SINK,EPOXY L3,BLK **FIXTURE - SINK** 100691 SINK TRAP,PLASTIC ADJUSTABLE **FIXTURE - SINK TRAP** 100056 **FIXTURE - SINK SINK OUTLET TAIL PIECE/INTEGRAL...

- Page 4 ASSEMBLY TEMPLATE HARDWARE REQUIRED FOR STEP LEFT CABINET DESCRIPTION PART NUMBER CABINET STEP 1: POSITION THE TWO CABINETS IN DESIRED LOCATION. MAKE SURE DOOR HINGES ARE ON THE OUTSIDE. IF YOU HAVE A UNIT WITH A SINK/FIXTURES, PLACE CABINETS OVER UTILITY HOOKUPS. LEAVE ENOUGH ROOM IN BETWEEN CABINETS FOR RIGHT CABINET REMOVABLE PANEL.

- Page 5 ASSEMBLY TEMPLATE HARDWARE REQUIRED FOR STEP TOP MOUNTING CLEAT - TYPICAL ATTACH BACK TO TOP AND BOTTOM MOUNTING DESCRIPTION PART NUMBER CLEATS FROM INSIDE OF BOTH CABINETS (BOTTOM MOUNTING CLEAT NOT SHOWN) REMOVABLE PANEL BACK PANEL SCREWS - REMOVABLE PANEL 100495 BACK SCREWS - BACK PANEL...

- Page 6 ASSEMBLY TEMPLATE HARDWARE REQUIRED FOR STEP DESCRIPTION PART NUMBER LONG APRON SHORT APRON CORNER BRACKET BRACKET - CORNER LEG 100077 (FLUSH WITH SQUARE SCREWS - CORNER LEG 100037 EDGES OF APRON) STEP 3: LAYOUT WORKSTATION FRAME WITH SQUARE EDGES OF APRONS ON FLOOR, ROUNDED EDGES FACING UP.

- Page 7 ASSEMBLY TEMPLATE HARDWARE REQUIRED FOR STEP DESCRIPTION PART NUMBER 500101 LEG HARDWARE KIT 520001 STEP 4: INSERT HANGER BOLT ON ONE LEG THROUGH CORNER INSERT HANGER BOLT BRACKET AND INSERT LOCK WASHER AND HEX NUT. THROUGH HERE WITH LOCK TIGHTEN NUT USING "...

- Page 8 ASSEMBLY TEMPLATE HARDWARE REQUIRED FOR STEP LEG LEVELER DESCRIPTION PART NUMBER LEG BOOT 100076 LEG HARDWARE KIT 520001 LEG BOOT STEP 5: SLIDE LEG BOOT ONTO LEG WITH FLARED END TOWARDS BOTTOM OF LEG. SCREW LEG LEVELER INTO T-NUT ON BOTTOM OF THE LEG. REPEAT FOR ALL LEGS.

- Page 9 ASSEMBLY TEMPLATE HARDWARE REQUIRED FOR STEP L BRACKET - TYPICAL DESCRIPTION PART NUMBER L BRACKET 100355 SCREWS - L BRACKET 100649 STEP 6: WITH HELP FROM ANOTHER PERSON, STAND WORKSTATION FRAME UP. POSITION FRAME UP TO CABINET. ATTACH L BRACKET ONTO APRON USING PROVIDED HARDWARE LISTED ABOVE.

- Page 10 ASSEMBLY TEMPLATE STEP 7: HARDWARE REQUIRED FOR STEP ADJUST LEG LEVELERS TO LEVEL WORKSTATION FRAME WITH CABINETS. DESCRIPTION PART NUMBER APPLY SILICONE ADHESIVE TO TOP EDGES OF CABINET AND WINGS. VARIES APPLY SILICONE ADHESIVE IN DOT PATTERN LIKE SHOWN BELOW FOR BEST RESULTS. PLACE TOP ON UNIT WITH PROPER OVERHANG (CENTERED ON WORKSTATION).

- Page 11 ASSEMBLY TEMPLATE HARDWARE REQUIRED FOR STEP STEP 8: DESCRIPTION PART NUMBER IF YOU DON'T HAVE A UNIT WITH A SINK OR FIXTURES, SKIP FIXTURE - SINK 100691 TO STEP 10. APPLY SILICONE ADHESIVE TO THE SINK OPENING ON TOP. SILICONE 100711 LOWER SINK INTO OPENING.

- Page 12 ASSEMBLY TEMPLATE HARDWARE REQUIRED FOR STEP DESCRIPTION PART NUMBER FIXTURE - FAUCET 100074-BKR MULTI-SERVICE FIXTURE - SINK TRAP 100056 FIXTURE - TYPICAL FIXTURE - SINK OUTLET/STRAINER 254047 STEP 9: INSTALL MULTI-SERVICE FIXTURES IN THE HOLES PROVIDED ON TOP. DATE ALL DIMENSIONS ARE IN INCHES UNLESS 11/8/16 NOTED OTHERWISE DWN:...

- Page 13 ASSEMBLY TEMPLATE HARDWARE REQUIRED FOR STEP DESCRIPTION PART NUMBER RUBBER BASE MOLDING 100283 STAINLESS STEEL CORNERS 100057 SCREWS - BASE 100064 STEP 10: ATTACH RUBBER MOLDING TO BASE OF WORKSTATION USING CONTACT CEMENT. SCREW STAINLESS STEEL CORNER BRACKETS ON EACH CORNER OVER BASE MOLDING USING HARDWARE LISTED ABOVE.

- Page 14 TROUBLESHOOTING YOUR GFCI ELECTRICAL RECEPTACLE: PLEASE NOTE: THROUGHOUT ANY OF THE FOLLOWING STEPS (PROCEDURES); IF YOU ARE NOT SURE YOU CAN DO THIS JOB SAFELY, AND COMPETENTLY, REFER THIS WORK TO QUALIFIED PROFESSIONAL! If your unit comes equipped with a GFCI (Ground Fault Circuit Interrupter) electrical receptacle, and there is no power in the receptacle please consider/check the following: •...

Need help?

Do you have a question about the FORWARD VISION III 2924 Series and is the answer not in the manual?

Questions and answers