Summary of Contents for Nu-Way MOL350 T1L 370 2H

- Page 1 Installation and Maintenance Manual MOL350 T1L 370 2H LMO24.2V55C2E A2L 75 CK Translation of the original instructions. Keep for future use. Read carefully before use. 178 123 54-5 CR00730 2024-02-28...

- Page 2 BENTONE exempel example Beispiel 352011030141 Serial no. 1234567 Man.Year 2019 Designation BF 1 KS 76-24 BF 1 Type BF 1 KS 76-24 Model Cap. Min-Max LIGHT OIL 35-90kW 1,25-6,0 cSt 7-14bar Main supply 1~230V 1,0A 50Hz IP 20 Motor supply MADE IN SWEDEN BY 1.

-

Page 3: Table Of Contents

BENTONE Table of contents General Information ............5 Pump A2L 65 CK/A2L 75 CK ..........23 6.1 Technical data ................23 Delivery inspection................ 5 Safety ....................5 Components ................. 23 Pump operating principle ............24 Technical data ...............7 6.4 Suction line tables ............... 25 Dimensioner B 40 A2.2H ............. 7 Check oil line seals .............. -

Page 5: General Information

BENTONE General Information The burner may only be used for its intended purpose in accordance with the product’s technical data. We reserve the right to make design changes and cannot be held liable for any misprints or typographical errors. Modifying the design or using accessories or components that have not been approved by CTC in writing is strictly prohibited. - Page 6 BENTONE • Care must be taken by the installer to ensure that no electrical cables or fuel lines are pinched or otherwise damaged during installation or service. • Flame tubes, fan wheels and air dampers, for example, may contain sharp edges. - before first start: •...

-

Page 7: Technical Data

BENTONE Technical data The burner is intended for: • Operation in installations according to EN 303 and EN 267. When operating with a hot air boiler, the LMO24.255 or LMO44.255 control unit must be used. Fuels: • HVO/XTL according to EN 15940. •... -

Page 8: Working Field

BENTONE Working field 9.3-27.0 kg/h 110-320 kW mbar Do not exceed working field. Basic settings - Fuel oil Basic settings should only be seen as setting values to get burner to start. Once the burner has started and established flame, it is necessary to adjust the settings so that they are adapted to the installation and the fuel used. -

Page 9: Basic Settings - Hvo/Xtl

BENTONE Basic settings - HVO/XTL Air settings Nozzle assembly Scale <˚ Burner output Scale nozzle assembly and air damper without damper motor. Settings air damper with damper motor. Flame signal When operating at high power or low air excess and HVO/XTL is used as fuel, the flame signal may deteriorate (blue flame), the signal lamp in the reset button flashes green. -

Page 10: Setting Of Ignition Electrodes And Brake Plate

BENTONE Setting of ignition electrodes and brake plate *NB It is important that the spark does not strike against the brake 3.5-4.0 5,0-6,0 2.0-3.0 5.0-6.0 plate or nozzle. Nozzle and pump pressure Due to different furnace geometries and capacities, it is not possible to recommend a nozzle model. -

Page 11: Nozzle Table

BENTONE Nozzle table Pump pressure bar kg/h Mcal/h kg/h Mcal/h kg/h Mcal/h kg/h Mcal/h 1,00 3,72 3,90 4,08 4,24 1,10 4,09 4,29 4,48 4,67 1,20 4,47 4,68 4,89 5,09 1,25 4,65 4,88 5,10 5,30 1,35 5,02 5,27 5,50 5,73 1,50 5,58 5,85 6,11... - Page 12 BENTONE Pump pressure bar kg/h Mcal/h kg/h Mcal/h kg/h Mcal/h kg/h Mcal/h 1,00 4,40 4,56 4,71 4,85 1,10 4,84 5,01 5,18 5,34 1,20 5,29 5,47 5,65 5,82 1,25 5,51 5,70 5,89 6,07 1,35 5,95 6,15 6,36 6,55 1,50 6,60 6,83 7,06 7,27 1,65...

-

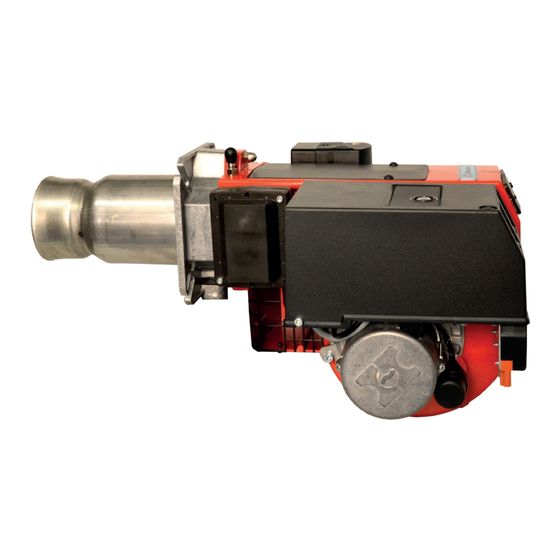

Page 13: 2.10 Components

BENTONE 2.10 Components Brake plate Cover, inspection glass Air intake Nozzle Indicating lamp Scale, air damper Ignition electrodes Change-over switch Air damper Nozzle assembly Fan wheel Solenoid valve Ignition cable Motor Solenoid valve Ignition transformer Flame tube Pump Photo cell Nozzle assembly adjustment Adjustment device Reset button... -

Page 14: Electric Equipment

BENTONE Electric equipment Safety system The safety system (safety switch for hatches, doors, water level, pressure, temperature and other safety devices) must be installed in the safety circuit in accordance with current regulations for the system. The cables of the safety system must be separated so that the outgoing signal is not placed in the same cable as the incoming signal. -

Page 15: Function

BENTONE 3.2.1 Components Burner control Control thermostat Plug-in contact ”Euro”, boiler Temperature limiter Plug-in contact ”Euro”, Flame detector high/low burner Fuse Safety switch for hinged door Plug-in contact ”Euro”, Lamp, low capacity Control thermostat, high/low boiler high/low capacity Lamp, high capacity Solenoid valve 1 Main switch Alarm lamp... -

Page 16: Colour Codes

BENTONE Colour codes When the burner starts, the light in the reset switch indicates the normal sequence, and also indicates whether something abnormal is happening as per the following table: Preheater in operation Solid yellow Ignition switched on Flashing yellow Normal operation Solid green Operation, poor flame signal... -

Page 17: Installation

BENTONE Installation General instructions Oil burners must be installed in accordance with local regulations. The installer must therefore be knowledgeable of the regulations pertaining to oil and combustion. Only oil suitable for the burner must be used and then in combination with a suitable oil filter installed before the burner’s oil pump. -

Page 18: Electrical Connection

BENTONE Electrical connection • Before work on the electrical connection, the current must be disconnected so that the installation is isolated. • Electrical connection must be done in accordance with the applicable regulations. • Burners must be connected to an all-pole switch. •... -

Page 19: Handling And Lifting Instruction

BENTONE Handling and lifting instruction The lifting aid are available as accessories. -

Page 20: Mounting

BENTONE Mounting Remove fan housing from fixing flange. Remove the brake plate from the oil line. Install the selected nozzles, (see Technical data). Install the brake plate on the oil line. Remove the flame tube from the flange. Install the flange with gasket on the boiler. Install flame tube, be sure to install the drainage hole downwards (not available on all flame tubes) so that any oil spills can drain out. -

Page 21: Example Of Basic Settings

BENTONE Example of Basic settings Basic settings should only be seen as setting values to get burner to start. Once the burner has started and established flame, it is necessary to adjust the settings so that they are adapted to the installation and the fuel used. B 40 A2.2H Burner output: 274 kW... -

Page 22: Air Setting

BENTONE Air setting Set the control switch (S2) to Low Load (I). Loosen the screw (A), turn the damper to the desired position, and retighten the screw (A). Set the control switch (S2) to High Load (II). Use a hex key to screw the socket (B) in to decrease or out to increase. The damper position can be read on the damper scale (C). -

Page 23: Pump A2L 65 Ck/A2L 75 Ck

BENTONE Pump A2L 65 CK/A2L 75 CK Technical data One or two-pipe system Viscosity range:: 2-12 mm Pressure range:: 8-15 bar Rated voltage of coil: 220/240V 50/60 Hz Oil temperature:: max 60°C Components Suction line G 1/4” ... -

Page 24: Pump Operating Principle

BENTONE Pump operating principle The SUNTEC A2L oil pump has two nozzle outlets. It Bleed incorporates two blocking solenoid Bleeding in two-pipe operation is automatic : it is assured by a bleed flat on the piston. valves with in-line cut-off function, one for each nozzle outlet. -

Page 25: Suction Line Tables

BENTONE Suction line tables 6.4.1 Overlying tank 1-pipe system Nozzle*/Düse* One pipe siphon feed system Gicleur*/Ugello* 0,50 0,60 0,80 1,00 1,50 2,00 4,00 6,00 9,50 Einstranginstallation - Tank höher als Pumpe (US GPH) Installation monotube en charge Impianti monotubo a sifone d (mm) H (m) 131 109... - Page 26 BENTONE 6.4.2 Underlying tank 1-pipe system With an underlying tank a 1-pipe-system is not recommended. Two-pipe system Two pipe lift system Pump/Pumpe Zweistranginstallation - Tank tiefer als Pumpe 35/45 Pompe/Pompa Installation bitube en aspiration Q** (l/h) Impianti bitubo in aspirazione d (mm) H (m) 124 150...

-

Page 27: Check Oil Line Seals

BENTONE Check oil line seals Once the burner has been installed and commissioned, the seals of the various coupling elements should be checked. When a leak is detected, it is usually sufficient to tighten the coupling element that is leaking. Use caution when operating the burner, surfaces may be hot. -

Page 28: Replacing The Solenoid Valve (Pump)

BENTONE Replacing the solenoid valve (pump) Disconnect the main power and shut off the fuel supply. Before obtaining access to electrical and fuel line components all supply circuits must be disconnected. Disconnect the solenoid valves’ electrical cables Loosen the nut holding the magnet terminal Loosen the screws securing the valve’s mounting plate Remove the valve Make sure it is the right valve, NC. -

Page 29: Service

BENTONE Service Service and maintenance work may only be performed by qualified personnel. Perform operational check of all safety systems and components at each service. Only CTC original parts should be used when replacing components. Use caution when operating the burner, surfaces may be hot. Burner Service Schedule, Oil Servicing must be carried out once a year or after 3,000 hours of operation. -

Page 30: Combustion Device

BENTONE Combustion device Disconnect the main power and shut off the fuel supply. Before obtaining access to electrical and fuel line components all supply circuits must be disconnected. Loosen nut (G) and lift fan housing off fixing flange. Remove brake plate and electrode holder from the oil tube and clean. Use caution when Replace nozzle. -

Page 31: Air Damper

BENTONE Air damper Disconnect the main power and shut off the fuel supply. Before obtaining access to electrical and fuel line components all supply circuits must be disconnected. Note the setting of the air damper and loosen the regulator locking screw (H). Loosen screws (G), set scale to 7 and lift up. Remove the intake grille at the air intake. -

Page 32: Fan

BENTONE Disconnect the main power and shut off the fuel supply. Before obtaining access to electrical and fuel line components all supply circuits must be disconnected. Detach the electrical panel (Y). Loosen the motor electrical connection and screws (X) enough to turn and lift out the motor. Check the fan wheel attachment and any skew, replace if damaged. -

Page 33: Replace Oil Pump

BENTONE Replace oil pump Disconnect the main power and shut off the fuel supply. Before obtaining access to electrical and fuel line components all supply circuits must be disconnected. Disconnect hoses, connection pipes and electrical connection from pump. Loosen screws (J) and pull out oil pump. Fit new pump coupling. -

Page 34: Replacement Of Electrical Components

BENTONE Replacement of electrical components Disconnect the main power and switch off the fuel supply. Before obtaining access to terminals, all supply circuits must be disconnected. Note the connection of the existing component and disassemble. Fit new component with same connection or with specified alternative connection. Switch on the main power and check the operation of the new component. -

Page 35: Vibrations

BENTONE Vibrations Maximum permitted vibration level is 5.0 mm/s. • Check tightness of fasteners. • Check fan wheel for damage and contamination (replace if necessary). • Check motor shaft and bearings. If they are worn, replace the motor. Use screw to attach the vibration sensor. -

Page 36: Fault Location

BENTONE Fault Location Burner will not start Symptom Causes Remedies Unstable flame Motor starts Burner pre-ventilates Excess air Adjust the damper Low oil pressure Check the oil pressure Flame formed Check the nozzle in relation to the combustion apparatus Burner trips Incorrect combustion apparatus dimensions and the ignition settings... -

Page 37: Burner Will Not Start After Normal Use

BENTONE Burner will not start after normal use Symptom Causes Remedies Burner does not start Fuse blown Check and replace fuse as necessary. Investigate cause of Boiler thermostat has not reset fault Adjust thermostat Preheater does not get up to Check preheater function temperature Reset the overheating protection. -

Page 38: Delayed Ignition

BENTONE Delayed ignition Symptom Causes Remedies Burner pulsates at start with hot Excessively strong draught Correct boiler draught flue gases Excessive pressure drop across Adjust the burner the brake plate Preheater temperature too low Check preheater function New oil type Adjust the preheater‘s set operating temperature Ensure that the new oil‘s physical... -

Page 39: Noise In Pump

BENTONE Noise in pump Symptom Causes Remedies The burner pump emits noise Check the oil system in order to during start reduce pressure drop Insufficient negative pressure on Rebuild the oil system to form a the suction side pump solution with a transport oil pump The burner pump emits noise during operation Check that the oil used has the... -

Page 40: Log Of Flue Gas Analysis

Log of flue gas analysis Owner Adresss Tel. no: Installation Tel. no: Boiler Type Make Power kW Burner Type Model Serial no. Fuel Step 1 Step 2 Step 3 Draught in fireplace Fan Press mbar Filter smoke number Flue gas temp. °C Setting brake disc Setting Air damper Pump pressure... - Page 41 EU Declaration of conformity Bentone Oil Burners Type: BF 1 ST 133 B 40 B 65 ST 108 ST 146 B 45 B 70 ST 120 B 30 B 55 B 80 This declaration of conformity is issued under the sole responsibility of the manufacturer. The object of the declaration described above is in conformity with: •...

- Page 42 UK Declaration of conformity Bentone Oil Burners Type: BF 1 ST 133 B 40 B 65 ST 108 ST 146 B 45 B 70 ST 120 B 30 B 55 B 80 This declaration of conformity is issued under the sole responsibility of the manufacturer. The object of the declaration described above is in conformity with: •...

- Page 44 CTC AB Box 309 SE-341 26 Ljungby info@bentone.se +46 372 88 000 www.bentone.se...

Need help?

Do you have a question about the MOL350 T1L 370 2H and is the answer not in the manual?

Questions and answers