Table of Contents

Advertisement

Quick Links

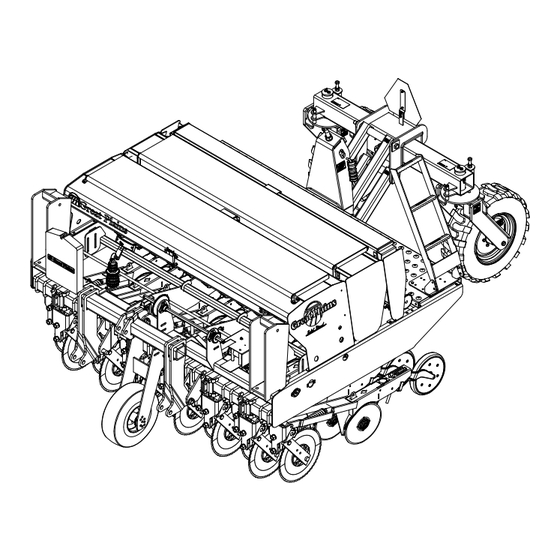

Great Plains

Semi-Mounted 8-Foot No-Till Drill

OPERATOR MANUAL

MODEL 3P806NT

Table of Contents

Original Instructions

!

Index

Read the operator manual entirely. When you see

this symbol, the subsequent instructions and

warnings are serious - follow without exception.

Your life and the lives of others depend on it!

Illustrations may show optional equipment not

supplied with standard unit.

151-143M

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for GREAT PLAINS 3P806NT

- Page 1 Table of Contents Index Great Plains Semi-Mounted 8-Foot No-Till Drill OPERATOR MANUAL MODEL 3P806NT 151-143M Original Instructions Read the operator manual entirely. When you see this symbol, the subsequent instructions and warnings are serious - follow without exception. Your life and the lives of others depend on it! Illustrations may show optional equipment not supplied with standard unit.

- Page 2 Machine Identification Record your machine details in the log below. If you replace this manual, be sure to transfer this information to the new manual. If you or the dealer have added options not originally ordered with the machine, or removed options that were originally ordered, the weights and measurements are no longer accurate for your machine.

- Page 3 Printed 03/04/2024 | English Great Plains reserves the right to revise and improve its products at any time. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future. The content of this publication may be...

- Page 4 Trademarks of Great Plains Manufacturing, Inc. include: AccuShot, DrillCommand, Max-Chisel, Row-Pro, Singulator Plus, Short Disk, Swath Command, Terra-Tine, Ultra-Chisel, and X-Press. Registered trademarks of Great Plains Manufacturing, Inc. include: Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand, Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo-Max, Turbo-Trill, Ultra-Till, Whirlfilter, and Yield-Pro.

-

Page 5: Table Of Contents

Warning: Hand Crush....9 Coulter Depth (Individual Rows)..32 Warning: Hand Crush (Option)... 10 Great Plains | 151-143M | 03/04/2024... - Page 6 Appendix C - Accessory Installation ..83 Second Ladder......53 Great Plains | 151-143M | 03/04/2024...

- Page 7 Hitch Extension Installation ....84 Weight Bracket Installation....84 Great Plains | 151-143M | 03/04/2024...

-

Page 9: Introduction

This manual applies to drill model: Right-hand and left-hand as used in Standard 3P806NT Models have a main seed box. A this manual are determined by second main seed box (Dual Seed), Fertilizer, Native... -

Page 10: Owner Assistance

If your dealer is unable to resolve the problem or the issue is parts related, please contact: If you need customer service or repair parts, contact a Great Plains dealer. They have trained personnel, 1525 E. North St. repair parts and equipment specially designed for P.O. -

Page 11: Safety Information

Non-Great Plains components on this machine may contain additional safety information not found in this The notice symbol indicates a potential for machine manual. -

Page 12: Machine Use

Avoid contacting overhead obstructions such as low bridges, overpasses, and power lines. Do not operate near ditches, holes, steep slopes, embankments, or other surfaces which may collapse under the machine’s weight or tip the machine over. Great Plains | 151-143M | 03/04/2024... -

Page 13: Machine Maintenance

Detach the tractor. Secure the implement using blocks. Stay clear of and never step over any rotating parts. Great Plains | 151-143M | 03/04/2024... -

Page 14: Safety Decals

On rear face of lift assist cross tube, inside red reflectors; 2 total See “Transporting” starting on page 20. On top of lift assist pivot weldment; 1 total See “Transporting” starting on page 20. Great Plains | 151-143M | 03/04/2024... -

Page 15: Reflectors: Amber

2 total To prevent serious injury from moving chain: DO NOT operate with enclosure missing See “Transporting” starting on page 20. 818-518C Native Grass: On outside of box end wall, under both covers; 2 total Great Plains | 151-143M | 03/04/2024... -

Page 16: Danger: Moving Chain (Option)

818-337C Rev. B On front face of upper front cross tube, left of gauge See “Hitching Tractor to Drill” starting on page 13. wheel; 1 total See “Transporting” starting on page 20. Great Plains | 151-143M | 03/04/2024... -

Page 17: Warning: Transport Locks

On front face of upper front cross-tube, left of hitch; moving parts. 1 total 838-611C axle tube; axle tube See “Hitching Tractor to Drill” starting on page 13. 2, 3, 4, or 5 total Great Plains | 151-143M | 03/04/2024... -

Page 18: Warning: Hand Crush (Option)

On outside face of caster arms above tires; 2 total. moving parts. 838-611C Native Grass: Under lid; under 2, 3, 4, or 5 total See “Hitching Tractor to Drill” starting on page 13. Great Plains | 151-143M | 03/04/2024... -

Page 19: Caution: General

FOR LOADING/UNLOADING ON TRAILERS. USING THEM IN OTHER SITUATIONS COULD LEAD TO LIMITED MANUVERABILITY IN TRANSPORTATION. 848-339C On top face of caster cross tube; 2 total On rim of each lift assist wheel; 2 total Great Plains | 151-143M | 03/04/2024... -

Page 20: Notice: Petroleum Products

Semi-Mounted 8-Foot No-Till DrillTable of Contents Index Safety Decals NOTICE: Petroleum Products 28214 858-679C left-hand ends seed boxes; 1 per seed box Great Plains | 151-143M | 03/04/2024... -

Page 21: Preparation And Setup

Native Grass Seed Rate Reduction installation, found in manual 202-583M in the Reduction kit. The 3P806NT is a 3-Point Category II hitch Pre-Planting Setup implement, employed in 2-point Semi-Mounted The balance of this section covers items that need to mode. -

Page 22: Hydraulic Hose Hookup

11. Remove transport lock channels from lift assist drill. cylinders. See “Drill Lift/Lower” on page 17. The hydraulic system of the 3P806NT drill has one single-acting lift-assist cylinder. The cylinder raises the rear of the drill during lift (tractor 3-point lift arms raise the front). - Page 23 6 inches (165 mm). 15. Remove the desired combination of stroke control spacers from the lift-assist weldment storage rod and install on the cylinder rod . Great Plains | 151-143M | 03/04/2024...

- Page 24 19. Check level of frame front-to-rear. If not level, adjust the rear height with the stroke control spacers. If changed, re-check front tool bar height, and re-adjust tractor 3-point lift arms. Repeat until level. Great Plains | 151-143M | 03/04/2024...

-

Page 25: Operation

3-point lift arms in front, and hydraulic lift-assist cylinder at rear. When setup for field use, the hitch and lift circuits may be operated in any order, or simultaneously. Both, however, must be lowered for Great Plains | 151-143M | 03/04/2024... -

Page 26: Lowering

Float (and not Draft or Depth Control mode). 32057 Stroke Control Spacers 4. Install stroke control spacers . Remove needed set from rod on lift-assist weldment and clamp around cylinder rod . Use a locally developed spacer combination (see page 15). Great Plains | 151-143M | 03/04/2024... -

Page 27: Caster Pivot Locks

To prevent side movement of the drill when transported by trailer, the lift-assist casters may be locked in their full-reversing orientation. Use this feature only for trailer transport. Do not use these locks for semi-mounted towing or field operations. Great Plains | 151-143M | 03/04/2024... -

Page 28: Transporting

Grass box. Heavier mix components settle to the bottom, which can prevent drive Comply with all national, regional and local safety system from operating, and results in laws when traveling on public roads. irregular seed rate and population distribution. Great Plains | 151-143M | 03/04/2024... -

Page 29: Trailer Transport

7. Secure the load with cargo straps or chains. Equipment Damage Risk - The drill must be hitched to a Great Plains recommends locking casters prior to loading for 3-point tractor for any movement. Coulter or opener damage trailer transport, and leaving them locked for transport and is likely if unhitched movement is attempted. -

Page 30: Loading Materials

3. The main seed box lid handle is also a latch. It needs to pivot up to release the lid. 4. Load seed evenly into compartments. To reduce wear on unused boxes that may also be present: Great Plains | 151-143M | 03/04/2024... -

Page 31: Material Rates Overview

Main Box Native Grass Small Seeds Fertilizer Dual Seed Rate Range Seed Rate Reduction Coarse Rate Drive Type Drive Type Rate Handle Rate Knob Fine Rate Rate Handle Driver/Driven Cup Adjustment Door Handle Great Plains | 151-143M | 03/04/2024... -

Page 32: Seeding Depth Overview

Seeding depth will also change (or become irregular), unless adjustments are made to blade spacing and the T-handle setting. Generally, the blades need to be replaced completely before coulter height adjustments would be needed. Great Plains | 151-143M | 03/04/2024... -

Page 33: Acremeter Operation

Down Arrow - Decrements current value. If the current screen only displays a reading, then arrow buttons can be used to reset current reading or for navigation. Great Plains | 151-143M | 03/04/2024... -

Page 34: Acremeter Screens

Use the arrow buttons to increase or decrease the swath width. Pressing Select will save the configuration and navigate to the CAL1 screen. Great Plains | 151-143M | 03/04/2024... - Page 35 USA - Imperial - or METRIC. If displaying the status and status is NO, pressing Pressing Select saves the unit selection, converts Select navigates to the A1 screen. the swath width value, and navigates to the SENSOR screen. Great Plains | 151-143M | 03/04/2024...

-

Page 36: Field Operation

4. Remove pins from lower 3-point links on drill (not 19. Cover with a tarp if stored outside. from the front of any hitch extension in use). 5. Disconnect lighting harness and any other electrical connections. Great Plains | 151-143M | 03/04/2024... -

Page 37: Adjustments

Feed Cup Door (one each seed tube) many provide adjustments for optimal field results. Dual Box Seed rate is controlled by adjustments for: The 3P806NT has double-disc 06 Series openers Right Drive Type gearbox lever with depth-controlling press wheels mounted on ... -

Page 38: Coulter Adjustments

(Individual Rows)” on page 32. The amount of coulter down force needed to cut a soil groove varies with soil conditions. Adding weight or shortening the coulter spring increases coulter down pressure and cutting force. Great Plains | 151-143M | 03/04/2024... -

Page 39: Coulter Down Pressure

(which declines to zero during planting). Spring Length Force at Blade 3P806NT configurations typically are too light to in. (26.7 cm) 175 lbs. (79 kg) reach the factory down-force of 400 lbs at all rows. in. (26.0 cm) 300 lbs. -

Page 40: Coulter Depth (Individual Rows)

6. Tighten the four U-bolts . 32337C 7. Lower the drill and pull forward 30 feet (10m). 8. Check coulter blade to opener blade (furrow centerline) alignment. Great Plains | 151-143M | 03/04/2024... -

Page 41: Row Unit Adjustments

[except “Seed Flap Replacement” on page 42 for ® Fertilizer and Seed-Lok ] supported for use with the maintenance. 3P806NT drill; coulter is not part of opener assembly and is not shown) ® Seed-Lok firming wheel... -

Page 42: Disc Blade Adjustments

. 3. To reduce the spacing between the discs (the normal case), move one spacer washer from the inside to the outside of the disc. 4. Re-assemble and check disc contact. Great Plains | 151-143M | 03/04/2024... -

Page 43: Opener Adjustments

12103 Maximum Pressure “W” 18647 Disc Scraper Adjustment standard scraper shown. Optional 12102 Minimum Pressure spring-loaded carbide scrapers are available (see Opener Down Pressure page 48). They require no adjustment. Adjustment Great Plains | 151-143M | 03/04/2024... -

Page 44: Small Seeds Tube Adjustment (Option)

If a Keeton or Seed-Lok is present, seed falls on the firmer and may be scattered rather than placed deeper. 27122 ® Seed-Lok Lock-Up 2. Pull firming-wheel arm up and release wire to catch arm. Great Plains | 151-143M | 03/04/2024... -

Page 45: Opener Depth (Press Wheel Height)

To adjust, first raise drill slightly, then lift and slide T-handles on top of openers. 15659 Press Wheel Adjustment For shallower seeding, slide T-handles toward drill. For deeper seeding, slide T-handles away from drill. Great Plains | 151-143M | 03/04/2024... -

Page 46: Caster Brake Adjustment

5. Inspect hydraulic hoses for cuts, cracks and aging. Check fittings for evidence of leaks. 6. Replace any worn, damaged or illegible safety decals. Order new decals from your dealer. See “Safety Decals” on page 6. Great Plains | 151-143M | 03/04/2024... -

Page 47: Materials Clean-Out

Set the Seed Rate Handle to 100 and disengage the lock-out hub. With openers lowered to engage the clutch, the seed meter jackshaft can be slowly turned with the calibration crank, while another person inspects the flutes from the open seed boxes. Great Plains | 151-143M | 03/04/2024... -

Page 48: Native Grass Box Clean-Out

Fertilizer Tray Small Seeds Box Clean-Out 1. Open box lid and scoop out as much seed as possible. 2. To recover remaining seed, place a collection tarp under the small seeds tubes at the openers. Great Plains | 151-143M | 03/04/2024... -

Page 49: Disc Maintenance

Thereafter, check the chains every 100 chain routing diagrams). hours. Lubricate chains any time there is a chance of moisture, and when being stored at the end of the planting season. 26482 Chain Clip Orientation Great Plains | 151-143M | 03/04/2024... -

Page 50: Seed Flap Replacement

Moving the eyebolt lower increases height. Moving the eyebolt higher decreases height. 5. Tighten the jam nut. 6. Lower the drill and check the setting. factory setting eyebolt reveal in. (88.9 mm) Great Plains | 151-143M | 03/04/2024... -

Page 51: Bleeding Hydraulics

2. Hitch drill to tractor (page 13). 3. If lift-assist lock channel or stroke control spacers are installed, raise drill and remove them. 4. Fully lower drill (page 17). 5. Set tractor lift circuit to Float and shut off tractor. Great Plains | 151-143M | 03/04/2024... -

Page 52: Lubrication And Scheduled Maintenance

One zerk each pivot; 4 total Type Lubrication: Grease Quantity: Until Type of Lubrication: Grease resistance is felt Quantity = Until grease emerges If Small Seeds is also installed, access these zerks from below. Great Plains | 151-143M | 03/04/2024... -

Page 53: Small Seeds Shaft Bearings (Option)

Quantity = Coat thoroughly. 1 seal at each shaft end, 2 total Type of Lubrication: Oil Quantity: Soak seal If Small Seeds is also installed, access these seals from below or through the end wall gaps. Great Plains | 151-143M | 03/04/2024... -

Page 54: Coulter Hub Bearings

Type of Lubrication: Grease Type of Lubrication: Grease Quantity = Until resistance is felt Quantity = repack Ground Drive Wheel Bearings 28299 Seasonal 2 races per wheel; 4 total Type of Lubrication: Grease Quantity = repack Great Plains | 151-143M | 03/04/2024... -

Page 55: Gearbox

(replace if needed) the rubber seals on gearbox drive and shifter shafts. Spread a small skim coat of anaerobic sealant ® (Loctite 525 or equivalent) to gear case mating surfaces before bolting them back together. Great Plains | 151-143M | 03/04/2024... -

Page 56: Agitator, Main Seed Box

Semi-Mounted 8-Foot No-Till DrillTable of Contents Index Options Agitator, Main Seed Box The standard coulter blades on the 3P806NT drill are 17 in. (43.2 cm) 820-156C Turbo or 820-018C Fluted. Available replacement and alternate blades include: Description Part Number... -

Page 57: Dual Seed Box

It is used for planting the box, stainless steel meters, and delivery tubes. same or additional crops as the main seed box. Dual Consult your Great Plains dealer for ordering Seed can plant at the same or different rate than the information. -

Page 58: Hitch Extension Kit

The kit includes pins for the forward holes. II agitator, and seed tubes. This extension hitch is compatible with most standard Consult your Great Plains dealer for ordering quick hitches. information. See “Hitch Extension Installation” on page 84. ... -

Page 59: Removable Partition

This plug stops seed flow from the main or dual seed 12677 box above the meter. Order one per row to be set inactive. The standard 3P806NT drill includes seed flaps. Only one type of optional seed firmer may be Description Part Number installed at the same time. -

Page 60: Seed Tube Plug (Small Seeds)

1.9 Description Part Number bushel box (67 liter), meters and seed tubes. SML SDS CUP PLUG 133-315H Consult your Great Plains dealer for ordering information. The Small Seeds attachment is compatible with an existing, concurrently... -

Page 61: Weight Brackets

The weight brackets are available as an Option with the original drill order, or as a separate kit. The kit does not include weights. See also: “Weight Bracket Installation” on page 84, and “Drill Weight Adjustment” on page 32. Great Plains | 151-143M | 03/04/2024... - Page 62 Press wheels not compacting soil as desired Press wheel depth does not match coulter Readjust press wheel depth, page 37. depth. Not enough down pressure on disc Increase down pressure on openers, page 35. openers. Great Plains | 151-143M | 03/04/2024...

- Page 63 Activate display. Lower left corner must be “656.2 Check that acremeter is for your drill. revs/ac” or “1621.5 revs/ha”. Contact dealer if otherwise. Replace acremeter. See page 25. (unit is sealed Acremeter battery exhausted and battery is not replaceable). Great Plains | 151-143M | 03/04/2024...

-

Page 64: Warranty

Great Plains reserves the right to make changes in materials or design of the product at any time without notice. This warranty is not valid unless the unit is registered with Great Plains within 10 days from the date of the original purchase. -

Page 65: Appendix A - Reference Information

Tire warranty information is found online at the manufacturer’s websites listed below. For assistance or 50 psi information, contact your nearest Authorized Farm Tire 5.70-8 8-Ply 621 kPa Retailer. Manufacturer Website Firestone www.firestoneag.com Goodyear www.goodyearag.com www.bkt-tires.com Gleason www.gleasonwheel.com Titan www.titan-intl.com Great Plains | 151-143M | 03/04/2024... -

Page 66: Torque Values Chart

2640 1950 4290 3160 ⁄ d. ft-lb = foot pounds 1330 2970 2190 4820 3560 ⁄ 25199m 25199 Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above. Great Plains | 151-143M | 03/04/2024... -

Page 67: Connector Identification

(or 37 degrees flare on “F”) ORB - O-Ring Boss (SAE J514) Note straight threads and, elastomer O-Ring . Fittings needing orientation, such as the ell above, also have a washer and jam nut (“adjustable thread port stud”) Great Plains | 151-143M | 03/04/2024... -

Page 68: Hydraulic Diagram

Semi-Mounted 8-Foot No-Till DrillTable of Contents Index Appendix A - Reference Hydraulic Diagram Lift-Assist 32056 Great Plains | 151-143M | 03/04/2024... -

Page 69: Chain Routing

“T” callouts show sprocket and idler tooth counts. See “Gearbox to Main Seed Box Meters” on “P” callout show chain pitch count. page 62 for gearbox output chain routing. 28339 Great Plains | 151-143M | 03/04/2024... -

Page 70: Gearbox To Main Seed Box Meters

Appendix A - Reference Gearbox to Main Seed Box Meters See “Ground Drive to Gearbox” on page 61 for gearbox input. Main box meters are the only meters coupled to the left gearbox output. 28412 Great Plains | 151-143M | 03/04/2024... -

Page 71: Gearbox To Dual Seed Box Meters (Option)

Semi-Mounted 8-Foot No-Till DrillTable of Contents Index Appendix A - Reference Gearbox to Dual Seed Box Meters (Option) See “Ground Drive to Gearbox” on page 61 for gearbox input. 31626 Great Plains | 151-143M | 03/04/2024... -

Page 72: Gearbox To Native Grass Meters (Option)

14T through 23T from storage tower (ships with 17T, shown on this page) Gearbox Output Sprocket: Standard drill: 19T w/ Rate Reduction kit: 12T N. G. Jackshaft Input Sprocket: Standard drill: 17T w/ Rate Reduction kit: 22T 29340 Great Plains | 151-143M | 03/04/2024... -

Page 73: Main Seed Box Agitator (Option)

Index Appendix A - Reference Main Seed Box Agitator (Option) No Fertilizer or Small Seeds installed. 28336 Agitator and Fertilizer Drive (Options) No Small Seeds installed. See page 67 for Fertilizer Box drive. 28335 Great Plains | 151-143M | 03/04/2024... -

Page 74: Agitator And Small Seeds Drive (Options)

See page 69 for Small Seeds Box drive 28351 Agitator and Small Seeds Drive w/Native Grass (Options) No Fertilizer installed. See above if Native Grass not installed. See page 69 for Small Seeds Box drive 28337 Great Plains | 151-143M | 03/04/2024... -

Page 75: Fertilizer Drive (Option)

DrillTable of Contents Index Appendix A - Reference Fertilizer Drive (Option) Main Seed Agitator installed. See below for Fertilizer Box drive 28338 Fertilizer Box Drive (Option) See page 68 if Small Seeds also installed. 28345 Great Plains | 151-143M | 03/04/2024... -

Page 76: Fertilizer Box Drive W/ Small Seeds (Options)

28354 Small Seeds Drive (Option) above Fertilizer also installed. See page 66 if Main Box Agitator is also installed, with without Native Grass installed. See next diagram for Small Seeds Box drive details. 28356 Great Plains | 151-143M | 03/04/2024... -

Page 77: Small Seeds Drive W/Native Grass (Options)

See page 66, page 68 or page 69 for Accessory Jackshaft to Small Seeds chain detail. Accessory to Small Seeds chain: 122P If Small Seeds only Option 214P if Native Grass installed (see page 70 if Fertilizer installed) 28344 Great Plains | 151-143M | 03/04/2024... -

Page 78: Small Seeds Box Drive W/ Fertilizer (Option)

Appendix A - Reference Small Seeds Box Drive w/ Fertilizer (Option) When Fertilizer is also installed, Small Seeds Jackshaft is driven from Fertilizer jackshaft. If Fertilizer is not also installed, see page 69. 13742 Great Plains | 151-143M | 03/04/2024... -

Page 79: Appendix B - Pre-Delivery

8. Check for proper tension and alignment on all drive chains. 9. Check that all safety labels and reflectors are correctly located legible. Replace improperly located or damaged. Refer to Safety Great Plains | 151-143M | 03/04/2024... -

Page 80: Unloading

5. Slowly pull the trailer straight out from under the drill. 6. Making sure to keep the drill level front-to-back and side-to-side, slowly lower the drill to the ground 12 inches off the ground. Great Plains | 151-143M | 03/04/2024... -

Page 81: Install Lift-Assist

Refer to (which depicts the caster frame to the front of the caster arm) 4. Align the wheel/spindle assemblies in the caster frames. Orient the wheels with the valve stems to the outside (which is toward the inside if the Great Plains | 151-143M | 03/04/2024... -

Page 82: Install Pivot

Tighten nut to Grade 2 torque. Caster Shaft Installation Begin Install Shaft 11. Select each: 161-116D LIFT ASSIST CASTER SHAFT 802-060C HHCS 5/8-11X4 GR5 803-024C NUT LOCK 5/8-11 PLT 32803 Rear Pivot Installation Great Plains | 151-143M | 03/04/2024... - Page 83 Semi-Mounted 8-Foot No-Till DrillTable of Contents Index Appendix B - Pre-Delivery Insert caster shaft through caster frame plate and secure with bolt and nut 32119 Caster Assembled 32115 Caster Shaft Installation Great Plains | 151-143M | 03/04/2024...

-

Page 84: Attach Lift-Assist Frame Mount

, spring and small Mount Clamp and Long Spacers round plate . Push up inside lock tube. 18. Select each: Complete with nut and bolt Select each: Select eight each: 802-057C HHCS 5/8-11X2 1/4 GR5 Great Plains | 151-143M | 03/04/2024... -

Page 85: Attach Lift-Assist Bolt On Mount

32123 Parallel Arms Installed into alignment with the rear tube of the lower arms Insert bolt . Add flat washer and lock washer . Secure with , tightened to Grade 2 torque. Great Plains | 151-143M | 03/04/2024... -

Page 86: Install Arm Zerks

(base end) port of the cylinder. Orient the elbow so that the hose route is down. Do not See “Bleeding Hydraulics” on page 43. tighten ORB fitting or its jam nut. 31. Select sets: 800-064C HOSE CLIP 13/16 Great Plains | 151-143M | 03/04/2024... -

Page 87: Lift-Assist Closeout

, using two the bolts and two nuts 3. Install the amber lamp to the lamp bracket with two 1/2-20x3/4 inch self tapping screws 4. Repeat the procedure for the other amber lamp. Great Plains | 151-143M | 03/04/2024... - Page 88 5. Route the rear of the wishbone harness over the center of the lift assist frame. 6. Use a wire tie to connect the wiring harness to the mounting post for the SMV 7. Connect the wiring harness to the two red lights. Great Plains | 151-143M | 03/04/2024...

-

Page 89: Attach Meter Hoses At Rows

, up against the ribs. Slide the outlet end of the hose fully onto the seed tube inlet at the forward row unit opening . Move the clamp to just below the raised lip of the seed tube inlet. Great Plains | 151-143M | 03/04/2024... -

Page 90: Install Smv Reflector

“Safety Decals” starting on page 6. Inflate tires to recommended pressure, see “Tire Inflation Chart” on page 57. Tighten wheel bolts as specified in “Torque Values Chart” on page 58. Great Plains | 151-143M | 03/04/2024... -

Page 91: Appendix C - Accessory Installation

Place the lock washer on the bolt (because the nut is not used). 4. Select one: 804-012C WASHER FLAT 3/8 SAE PLT Place this flat washer on the bolt. 5. Select one: 890-357C SCRAPER-SPRING LOAD-AIR DESIGN Great Plains | 151-143M | 03/04/2024... - Page 92 Once installed the extension may be left installed on case, a hitch extension kit (page 50) is available. the drill at unhitching, as it is secured at all three Great Plains CPH, PFH or SSH accessory points on the drill. hitches are not compatible with the Equipment Damage Risk: 3P806NT.

- Page 93 The orientation depicted is not optimal for all weights. 9. Select one: sets: 802-055C HHCS 5/8-11X2 GR5 804-021C WASHER FLAT 5/8 SAE PLT 804-022C WASHER LOCK SPRING 5/ 8 PLT 803-021C NUT HEX 5/8-11 PLT Great Plains | 151-143M | 03/04/2024...

- Page 94 Semi-Mounted 8-Foot No-Till Drill...

- Page 95 ...........44 coulter depth chart ......30 frame weight ........32 coulter depth, individual ......32 main box lid ........22 coulter springs ........31 gearbox ..........47 main seed box agitator .......48 CPH ..........13 graphite ..........51 Great Plains | 151-143M | 03/04/2024...

- Page 96 ........20 spacer, cylinder ........42 Rate Adjuster ........22 wheel ..........73 spacer, stroke control ....15 rate setting ..........23 Numerics spacing, opener disc ......34 red reflector ..........6 00P .............61 specifications ........57 reflectors 00T .............61 Great Plains | 151-143M | 03/04/2024...

- Page 97 803-027C, nut ........85 803-031C, nut ......74 803-048C, nut ........76 803-210C, nut ........73 804-009C, lock washer .......82 804-012C, washer ......83 804-013C, lock washer ....78 804-013C, washer ......83 804-015C, spring ........76 804-021C, washer ......85 Great Plains | 151-143M | 03/04/2024...

- Page 99 Table of Contents Index...

- Page 100 Great Plains, Mfg. 1525 E. North St. P.O. 5060 Salina, KS 67402...

Need help?

Do you have a question about the 3P806NT and is the answer not in the manual?

Questions and answers