Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Simpson 42141

- Page 1 Operating Instructions Friability Tester Model 42141 www.simpsongroup.com...

- Page 2 Simpson Technologies Corporation or its subsidiaries which shall not be disclosed outside or duplicated, used or disclosed in whole or in part for any purpose other than to evaluate Simpson Technologies for a proposed transaction. Any use or disclosure in whole or in part of this information without the express written permission of Simpson Technologies Corporation is prohibited.

-

Page 3: Table Of Contents

Rotating Drum Assembly ............. 10 Electrical Power Connection ............12 Connecting the Power and Set-Up ..........12 Airborne Noise Emission ............. 13 5 Operating Instructions ............14 Preparing the Sand Specimens ........... 14 Test Procedure ................14 man-stc-42141-V16-3 Friability Tester... - Page 4 6 Maintenance ............... 21 7 Apparatus Layout .............. 22 8 Spare Parts / Ordering Parts / Returns ......25 Spare Parts ..................25 Ordering Replacement / Spare Parts .......... 25 Returned Goods Policy ..............25 9 Decommissioning .............. 27 Friability Tester man-stc-42141-V16-3...

-

Page 5: Introduction 1

Section 2 and operating instructions in Section 5. Application and Designated Use The Friability Tester, Model 42141 is intended exclusively for determining the friability (surface integrity) of clay bonded foundry molding sand. Any other application outside the intended usage will... -

Page 6: Safety

Safety Signs and Labels Simpson Technologies has incorporated the ANSI Z535.6 / ISO 3864- 1-2 safety symbol only label format on all of its laboratory equipment. The harmonized ANSI Z535.6 format became an established safety... -

Page 7: Safety Alert Symbols

. This symbol indicates information containing important instructions concerning the use of the machine or directions for further procedures. Ignoring this information can lead to malfunction of the machine. man-stc-42141-V16-3 Friability Tester... -

Page 8: Safety Symbol Labels

Operating Instructions manual. All protective guards and covers shall be installed and all doors closed before operating the equipment. If any questions exist, you must contact your Supervisor or Simpson Technologies Corporation before taking further action. Follow Lockout and Tagout procedures before servicing. -

Page 9: Lockout And Tagout System Procedure

The tagout device does so by identifying the energy-isolating device as a source of potential danger; it indicates that the energy-isolating device and the equipment being controlled may not be operated until the tagout device is removed. man-stc-42141-V16-3 Friability Tester... -

Page 10: Glossary

Zero Mechanical State - The mechanical potential energy of all portions of the equipment or machine is set so that the opening of pipes, tubes or hoses, and the actuation of any valve, lever or button, will not produce a movement which could cause injury. Friability Tester man-stc-42141-V16-3... -

Page 11: Short Description & Specifications

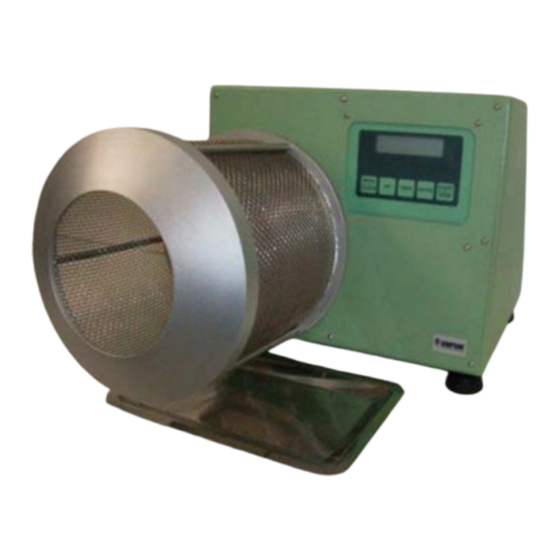

Short Description & Specifications 3 Short Description & Specifications Application The Friability Tester, Model 42141, is used to determine the friability (surface integrity) of a clay bonded foundry molding sand. The instrument consists of a rotating wire mesh cage which causes two standard 2"... -

Page 12: Unpacking And Installation

The Friability Tester, Model 42141, is shipped in two pieces with the rotating drum assembly removed for shipping. The instrument will require some basic assembly before use. No lifting equipment for handling is required;... -

Page 13: Components

• 2.5 mm Allen Wrench If any of the above components are missing, contact your local Simpson Technologies office. Do not store the device in the open and unprotected from atmospheric conditons. If this instruction is not followed, claims under warranty will no longer be considered. -

Page 14: Rotating Drum Assembly

Figure 6) with set screws over flat area on Shaft. (Figure 2). This step may require loosening the two (2) set screws located on the drum assembly to increase the hole clearance. The set screws should not be removed from drum assembly. Friability Tester man-stc-42141-V16-3... - Page 15 3. Gently tighten the set screws onto flat area on shaft using a 2.5mm Allen wrench. (Figure 3) Figure 3: Allen Wrench Tightening Set Screws 4. The assembly of the Friability Tester is now complete. (Figure 4). man-stc-42141-V16-3 Friability Tester...

-

Page 16: Electrical Power Connection

These special electrical plugs will need to be purchased separately by the customer. 2. Verify the proper voltage of the electrical outlet before plugging the power cord into the outlet. Connect power cord to an AC Friability Tester man-stc-42141-V16-3... -

Page 17: Airborne Noise Emission

TO GO to RPM to SET then back to TO GO. 6. The equipment is ready to start operation. Airborne Noise Emission The equivalent continuous A-weighted sound pressure level at the workstation does not exceed 70db(A). man-stc-42141-V16-3 Friability Tester... -

Page 18: Operating Instructions

(50mm x 50mm metric sand specimens). Manufacture a standard (AFS or metric) sand specimen using a standard sand rammer or pneumatic sand squeezer. (Simpson Technologies Model numbers; 42100, 42100-M, 42117, 42117-M, 42160 and 42160-M). Detailed sand specimen preparation instructions can be found in the operation manual for the sand rammer or sand squeezer being used. - Page 19 (see Figure 5). The sides of the sand specimens will be touching and the ends of the specimens should be in contact with the back support plate of the rotating drum. man-stc-42141-V16-3 Friability Tester...

- Page 20 7. To abort a test, press START/STOP. This will stop machine and the display will go back to the screen as shown in Graphic 2. Friability Tester man-stc-42141-V16-3...

- Page 21 Operating Instructions 5 Graphic 2: Aborting Test 8. After 1 minute (or programed test time), the rotating drum will stop and the display will indicate the test is done as shown in Graphic Graphic 3: Friability Test man-stc-42141-V16-3 Friability Tester...

- Page 22 Graphic 4: Starting on a New Test The effect of line down time, or the effect of time lapse after mold preparation on the erosion characteristics of sand may be simulated by testing for friability at various time intervals after specimen preparation. Friability Tester man-stc-42141-V16-3...

-

Page 23: Changing The Rpm Or To Go Time

ENTER to save the selected time. 6. The display will show “READY TO START” as shown in Graphic The parameters you set will remain until you change them. Turning off the power will not lose the settings. man-stc-42141-V16-3 Friability Tester... - Page 24 5 Operating Instructions Graphic 5: Changing the RPM/Testing Time Friability Tester man-stc-42141-V16-3...

-

Page 25: Maintenance

Maintenance 6 Maintenance For more information on how to use and care for your Simpson Analytics equipment and accessories visit our Simpson Technologies channel on YouTube and search our library of videos. Subscribe to our channel to keep updated on new releases. -

Page 26: Apparatus Layout

7 Apparatus Layout Apparatus Layout Figure 6: Front View of Tester without Rotating Drum Assembly Programming Icon Button MENU/CLEAR DOWN ENTER Figure 7: Item 2 Control Panel Close-Up START/STOP Friability Tester man-stc-42141-V16-3... - Page 27 Item Description Shaft Control Panel Leveling Feet Figure 7 Menu/Clear Button Up Button Down Button Enter Button Start/Stop Button Figure 8: Front View with Rotating Drum & Catch Tray Item Description Control Panel Rotating Drum Catch Tray man-stc-42141-V16-3 Friability Tester...

- Page 28 7 Apparatus Layout Figure 9: Back View of Tester Item Description Leveling Feet Power Switch Power Cord Receptacle Specifications Nameplate Friability Tester man-stc-42141-V16-3...

-

Page 29: Spare Parts / Ordering Parts / Returns

Spare Parts / Ordering Parts/ Returns 8 Spare Parts / Ordering Parts / Returns Spare Parts Simpson maintains a large inventory of common spare parts for all current Simpson Analytics products. The following table provides part numbers for common spare parts for this device. Contact Simpson Technologies with the part number and description when ordering. - Page 30 (subject to a restocking charge). • A Safety Data Sheet (SDS) must accompany material that is sent to Simpson Technologies Corporation for testing purposes. Simpson Technologies Corporation will NOT authorize the return of hazardous materials. RETURN PROCEDURE: • The customer must obtain a Return Material Authorization Number (RMA#) from Simpson Technologies prior to returning the goods.

-

Page 31: Decommissioning

WASTE DISPOSAL The Machinery and Controls Consists of: • Iron • Aluminum • Copper • Plastic • Electronic Components and Circuit Boards Dispose of the parts in accordance with the applicable regulations. man-stc-42141-V16-3 Friability Tester... - Page 32 Fax: +91 (33) 2290 8050 simpsongroup.com Copyright 2019. All rights reserved. SIMPSON, the illustrative logo and all other trademarks indicated as such herein are registered trademarks of Simpson Technologies Corporation. For illustrative purposes the Simpson equipment may be shown without any warning labels and with some of the protective devices removed. The warning labels and guards must always be in place when the equipment is in use.

Need help?

Do you have a question about the 42141 and is the answer not in the manual?

Questions and answers