Table of Contents

Advertisement

Quick Links

Instructions - Parts List

Fast

Fast - - - Flo®

Fast

Flo® Air

Flo®

Air Motor

Air

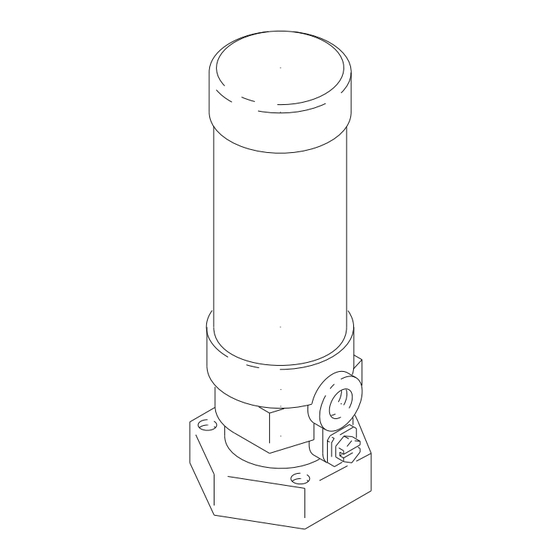

Model 215963,

215963, Series

Series A, A, A, 101.6

Model

Model

215963,

Series

Important

Important

Important Safety

Safety Instructions

Safety

Read all warnings and instructions in this manual. Save

instructions.

instructions.

instructions.

12.5 bar (1.25 MPa, 180 psi) Maximum

Air Working Pressure

NOTE: To replace Air Motor 215963,

order Motor Replacement Kit 223099.

See manual 307977 for parts.

Motor

Motor

101.6 mm

mm (4 (4 (4 in.)

in.) stroke

stroke

101.6

mm

in.)

stroke

Instructions

Instructions

PROVEN QUALITY. LEADING TECHNOLOGY.

Save these

Save

these

these

307456W

EN

Advertisement

Table of Contents

Summary of Contents for Graco Fast-Flo A Series

- Page 1 Instructions - Parts List 307456W Fast Fast - - - Flo® Fast Flo® Air Flo® Air Motor Motor Motor Model 215963, 215963, Series Series A, A, A, 101.6 101.6 mm mm (4 (4 (4 in.) in.) stroke stroke Model Model 215963, Series 101.6...

-

Page 2: Table Of Contents

Upper Spring Replacement......8 Grounding ........... 5 Cleaning the Muffler ........8 To ground the pump........5 Parts..............10 Operation ............6 Pressure Relief Procedure......6 Dimensions ............12 Troubleshooting..........7 Technical Data ........... 13 Service .............. 8 Graco Standard Warranty........14 307456W... -

Page 3: Warnings

• This equipment is for professional use only. • Read all instruction manuals, tags, and labels before operating the equipment. • Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. • Do not alter or modify this equipment. Use only genuine Graco parts and accessories. - Page 4 Warnings WARNING WARNING WARNING SKIN SKIN SKIN INJECTION INJECTION INJECTION HAZARD HAZARD HAZARD Spray from the gun, leaks, or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also cause serious injury.

-

Page 5: Installation

Installation Installation Installation Installation Grounding To ground ground the the pump pump Grounding Grounding ground pump Proper grounding is an essential part of maintaining 1. UL–Listed Pumps: Use a ground wire, connector, a safe system. and clamp. See Fig. 1. Loosen screw (X). Insert one exposed end of a 12 ga (1.5 mm ) minimum To reduce the risk of static sparking, ground the... -

Page 6: Operation

Operation Operation Operation Operation Pressure Relief Relief Procedure Procedure Pressure Pressure Relief Procedure 1. Shut off the air to the pump. 2. Close the bleed-type master air valve (required in your system). INJECTION HAZARD HAZARD INJECTION INJECTION HAZARD 3. Hold a metal part of the gun to the side of a grounded metal pail and trigger the gun to relieve The system pressure must be manually relieved pressure. -

Page 7: Troubleshooting

Troubleshooting Troubleshooting Troubleshooting Troubleshooting Follow Pressure Relief Procedure, page 6 before you check or service any system equipment. NOTE: Check all other possible problems and NOTE NOTE solutions before disassembling the pump. Problem Solution Problem Problem Solution Solution Air motor stalls Turn off and relieve air pressure to the motor. -

Page 8: Service

Service Service Service Service NOTE NOTE NOTE: Repair Kit 214584 is available. For best 6. Reassemble the air piston (11), using new parts results, use all the new parts in the kit, even if the as needed. Apply a good grade of thread sealant old parts look good. - Page 9 Service 220168 Air Valve and Piston Assembly (11) Motor Cap and Cylinder Piston Rod and Base Piston Detail Figure 2. 307456W...

-

Page 10: Parts

Parts Parts Parts Parts Apply Sealant Torque to 1.3–1.6 N•m (10-14 in-lb) 307456W... - Page 11 Parts Part Part Part Part Part Part Description Description Description Description Description Description 116343 SCREW, grounding, for 181485 SPACER, valve plate non-listed pumps 189210 PISTON, air, aluminum 104029 LUG, grounding, for 181487 PLATE, air intake valve UL-listed pumps 16*† 162729 PLATE, air exhaust valve 104582 WASHER, tab, for UL-listed pumps 178780 SPRING, compression...

-

Page 12: Dimensions

Dimensions Dimensions Dimensions Dimensions 307456W... -

Page 13: Technical Data

Technical Data Technical Technical Technical Data Data Data Fast- - - Flo Flo Air Air Motor Motor Fast Fast Motor Metric U.S. U.S. U.S. Metric Metric Maximum inbound Air Pressure 180 psi 12.5 bar, 1.25 MPa Air Inlet 1/4 npt (f) Effective piston area 1.6 in 10 cm... -

Page 14: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Fast-Flo A Series and is the answer not in the manual?

Questions and answers