Table of Contents

Advertisement

Instructions - Parts List

Parts

PresidentR Air Motors

For use with Graco fluid handling pumps.

See your pump instruction manual for Maximum Working Pressure.

Model 205647, Series L

For in-line mounting, medium-pressure oil pump

Model 206078, Series L

For in-line mounting, high-pressure grease pump

Model 205038, Series M

For stanchion tube mounting

Model 207352, Series F

For divorced mounting

Model 222772, Series F

For divorced mounting

Read warnings and instructions.

Table of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawings and Parts LIsts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Copyright 1997, Graco Inc. is registered to I.S. EN ISO 9001

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

2

5

7

8

14

16

18

20

22

24

24

25

26

26

306982AF

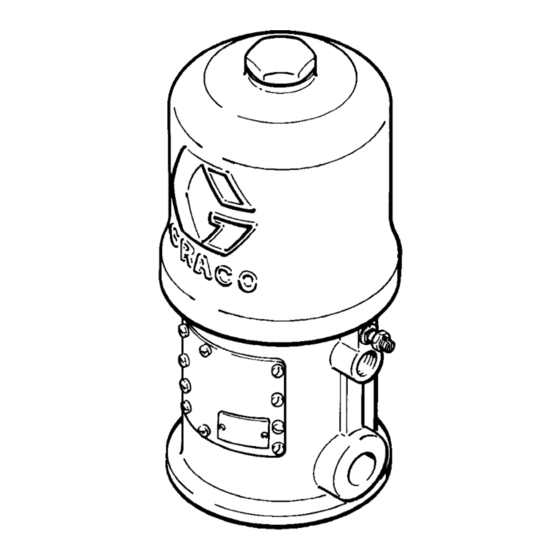

Model 207352 Shown

Advertisement

Table of Contents

Summary of Contents for Graco President L Series

-

Page 1: Table Of Contents

......GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 Copyright 1997, Graco Inc. is registered to I.S. EN ISO 9001... -

Page 2: Warnings

D This equipment is for professional use only. D Read all instruction manuals, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. D Do not alter or modify this equipment. - Page 3 WARNING INJECTION HAZARD Spray from the gun, leaks or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also cause serious injury. D Fluid injected into the skin is a serious injury.

- Page 4 WARNING FIRE AND EXPLOSION HAZARD Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and re- sult in a fire or explosion and serious injury. D Ground the equipment and the object being sprayed. Refer to Grounding on page 5. D If there is any static sparking or you feel an electric shock while using this equipment, stop spray- ing immediately.

-

Page 5: Installation

D Object being sprayed: Follow your local code. NOTE: Always use Genuine Graco Parts and Accessories, available from your Graco distributor. D Solvent pails used when flushing: Follow your local Grounding code. - Page 6 Installation Pressure Relief Procedure WARNING WARNING A bleed-type master air valve is required in your system to reduce the risk of serious bodily injury INJECTION HAZARD from moving parts if you are adjusting or repairing Fluid under high pressure can be in- the air motor.

-

Page 7: Operation

Operation NOTE: See your separate pump manual for detailed To reseat the air transfer valves and restart a stalled operation instructions. air motor, relieve the air supply pressure to the motor by closing the bleed-type master air valve. If the air Restarting a Stalled Air Motor transfer valves fail to reseat, screw the cap nut (F) out of the cylinder (G), pull up on the trip rod (H) and... -

Page 8: Service

Service Servicing the Air Motor Before you Start 4. Remove the eight screws (Z) holding the cylinder (G) to the base (J). Carefully pull the cylinder D Be sure you have all necessary parts on hand. Air straight up off the piston. See Fig. 2. Motor Repair Kit 207385 includes repair parts for the motor. - Page 9 Service 6. Grip the toggle rockers (S) with a pliers. Compress NOTE: To remove the exhaust valve poppets (X), the springs (T) and swing the toggle assembly (E) stretch them out and cut with a sharp knife. up and away from the piston lugs (U), and remove 8.

- Page 10 Service Reassembly 1. Clean all the parts carefully in a compatible solvent 7. Before installing the lockwires (L**) in the adjusting and inspect for wear or damage. Use all the repair nuts (M** and Q**), use the special gauge 171818 kit parts during reassembly and replace other parts to adjust the transfer valve (N) so there is 0.125 in.

- Page 11 Service Throat Packing Service for In-Line Pump Model 205647 3. Remove one louvered air exhaust plate (BB) and WARNING unscrew the throat packing nut (HH), using a spanner wrench or a 0.22 in. (5.6 mm) diameter The piston in the air motor, located behind the air rod.

- Page 12 Service In-Line Pump Models 205647 and 206078 DETAIL B, for In-Line Pump Model 205647 DETAIL A 190249 112843 1 in. 190495 (25 mm) SEE DETAIL A NOTE: To avoid seal damage during installa- tion, insert the seal at an angle as shown above, so that side A is below hole C.

- Page 13 Service Throat Packing Service for In-Line Pump Model 206078 5. Clean the throat packing area in the base and the WARNING packing nut. Clean and inspect all parts, and replace as necessary. The piston in the air motor, located behind the air motor plates, moves when air is supplied to the 6.

-

Page 14: Model 205647

Parts Model 205647, Series L for in-line mounting, medium-pressure oil pump 28** 27** 38** 18** 27** 21** **20 37** 30** 306982... - Page 15 Do 158379** SEAL, o-ring; nitrile rubber not cover the air exhaust holes. Order the labels 190495 SPACER, throat free of charge directly from Graco. Contact your 190249 NUT, packing 160261** NUT, adjusting distributor to order.

-

Page 16: Model 206078

Parts Model 206078, Series L for in-line mounting, high-pressure grease pump 28** 27** 38** 18** 27** 21** **20 37** 30** Torque to 45 to 55 ft-lb (61 to 75 N-m). 06733B 306982... - Page 17 Do not cover the air exhaust holes. 28** 160618 LOCKWIRE, transfer valve Order the labels free of charge directly from 160623 ARM, toggle Graco. Contact your distributor to order. 30** 160896 STEM, valve 161435 NUT, cylinder cap German 290467...

-

Page 18: Model 205038

Parts Model 205038, Series M for stanchion tube mountings 23** 22** 33** 18** 22** 21** **20 32** 25** 306982... - Page 19 Do 158377 SEAL, flat ring; nitrile rubber not cover the air exhaust holes. Order the labels 158378** SEAL, o-ring; nitrile rubber free of charge directly from Graco. Contact your 158379** SEAL, o-ring; nitrile rubber 160261** NUT, adjusting distributor to order.

-

Page 20: Model 207352

Parts Model 207352, Series F for divorced mountings 23** 22** 34** 18** includes 22** items 2 to 4 21** **20 33** 25** 306982... - Page 21 Do 158367** GROMMET; rubber not cover the air exhaust holes. Order the labels 158377 SEAL, flat ring; nitrile rubber free of charge directly from Graco. Contact your 158378** SEAL, o-ring; nitrile rubber 158379** SEAL, o-ring; nitrile rubber distributor to order.

-

Page 22: Model 222772

Parts Model 222772, Series F for divorced mountings 23** 22** 34** 18** includes 22** items 2 to 4 21** **20 33** 25** 306982... - Page 23 Do 158367** GROMMET; rubber not cover the air exhaust holes. Order the labels 158377 SEAL, flat ring; nitrile rubber free of charge directly from Graco. Contact your 158378** SEAL, o-ring; nitrile rubber 158379** SEAL, o-ring; nitrile rubber distributor to order.

-

Page 24: Mounting Hole Layouts

Mounting Hole Dimensional Layouts Drawing 3-Tie-Rod Pumps 4.38 in. (111.3 mm) dia. 2.5 in. (64 mm) 5 in. (127 mm) 0.28 in. (7.2 mm) dia. 14.75 in. (375 mm) 7.25 in. Models (184.2 mm) 205647 2-Stanchion-Tube Pumps diameter 206078 207352 16.45 in. -

Page 25: Technical Data

Technical Data Maximum inbound air pressure ........... 180 psi (1.2 MPa, 12 bar) Effective piston area . -

Page 26: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the President L Series and is the answer not in the manual?

Questions and answers