Advertisement

Quick Links

Advertisement

Summary of Contents for SANY SAP60C-8

- Page 1 Quality Changes the World Sany Paver SAP60C-8 Safety, Operation & Maintenance Manual...

- Page 2 Find manuals at https://best-manuals.com...

- Page 3 Font-Arial Size:12pt SAP Series Paver 线粗:1pt SAP Series Paver Safety, Operation & Maintenance Manual WARNING Read and follow the safety precautions and instructions in this manual and on the machine decals. Failure to do so can cause serious injury, death or property damage. Keep this manual with the machine for reading and future reference.

- Page 4 Tel: 0086- 4006098318 © 2016 by Sany Group. All rights reserved. No part of this publication may be reproduced, used, distributed or disclosed except during normal operation of the machine as described herein. All information included within this publication was accurate at the time of publication.

- Page 5 RCC base material, stabilized soil material and road material (like graded broken stone). Any other use or any operation beyond the specified working range is not authorized use. SANY expressly bears no liability for any consequence due to any unauthorized use.

- Page 6 Duty of managers • Ensure the operators are trained and fully understand the Operation and Maintenance Manual supplied by Sany. Ensure they are in physical fitness and have the certification of operation. Otherwise, it is forbidden to operate the paver. •...

- Page 7 1.2.3.2 Safety 1.2.3.3 System Functions 1.2.3.4 Operation 1.2.3.5 Maintenance 1.2.3.6 Troubleshooting 1.2.3.7 Specifications 1.3 Your SANY Machine 1.3.1 Machine Directions 1.3.2 Breaking in a New Machine 1.3.3 Machine Information 1.3.4 Serial Number and Distributor Information 1.3 Contact Information 2 Safety 2.1 General...

- Page 8 Table of contents SAP Sereis Paver 2.2.2.2 Noise Prevention 2-16 2.2.3 Precautions for Asphalt Paving 2-16 2.2.4 Precautions against Emergency 2-17 2.2.4.1 Precautions against Fire 2-17 2.2.4.2 Fire-prevention during Operation 2-17 2.2.4.3 Shockproof Precautions 2-20 2.3 Precautions for Driving and Working 2-21 2.3.1 Preoperational Check 2-22...

- Page 9 SAP Series Paver Table of contents 2.6.2 Loading Machine 2-41 2.6.3 Towing Machine 2-41 2.6.4 Hoisting Machine 2-42 3 System Functions 3.1 General 3.2 Power System 3.3 Electrical System 3.3.1 General 3.3.2 Console 3.3.3 Control Panel 3.3.3.1 Function of Switches 3.3.4 Use of Display 3-18 3.3.4.1 Home Page Information...

- Page 10 Table of contents SAP Sereis Paver 3.3.5 Layout of Electric Control Cabinet 3-39 3.3.6 Fuses in Electric Control Cabinet 3-40 3.3.7 Screed Panel 3-41 3.4 Hydraulic System 3-42 3.4.1 Travel System 3-43 3.4.1.1 Components 3-43 3.4.1.2 Introduction of Valve Body 3-44 3.4.2 Vibration System (Option) 3-45...

- Page 11 SAP Series Paver Table of contents 3.5.3.5 Tension of Drive Chains 3-64 3.5.4 Centralized Lubrication System 3-65 3.5.5 Cleaning System 3-67 3.5.5.1 Automatic Cleaning System 3-67 3.5.5.2 Manual Cleaning System 3-67 3.5.6 Towed Arm 3-68 3.5.7 Hopper 3-70 3.5.8 Frame 3-71 3.5.9 Control System 3-72...

- Page 12 Table of contents SAP Sereis Paver 4.4 Machine Assembly 4.4.1 Screed Assembly and Adjustment 4.4.1.1 Assembling the Screed 400(750)mm 4.4.1.2 Vibrator Assembly 4.4.1.3 400(750)mm Tamper Assembly 4.4.1.4 Striker Plate Assembly 4.4.1.5 Stroke and Bottom Dead Center Adjustment for Tamper 4.4.2 Auger Units Assembly 4.4.2.1 Height Adjustment 4.4.2.2 Height Adjustment Procedures 4-10...

- Page 13 SAP Series Paver Table of contents 4.7.7 Adjusting the Towed Arm 4-37 4.7.8 Adjusting the Centralized Lubrication System 4-37 4.8 Construction 4-38 4.8.1 Line of Direction 4-38 4.8.2 Adjusting the Indicator Pole 4-38 4.8.3 Spraying Diesel Oil 4-39 4.8.4 Screed Warm-up 4-39 4.8.5 Placing the Screed 4-39...

-

Page 14: Maintenance

Table of contents SAP Sereis Paver 5 Maintenance 5.1 General 5.1.1 Notes on Maintenance 5.1.2 Notes on Fuel System 5.1.3 Notes on Engine Performance 5.1.4 Notes on Hydraulic System 5.1.5 Notes on Cooling System 5.2 Oil & Fluids Selection 5.2.1 General requirements 5.2.2 Requirements of oil and fluids 5.3 Maintenance 5.3.1 Routine Maintenance... - Page 15 SAP Series Paver Table of contents 5.3.6.3 Replacing the Fuse 5-34 5.3.7 Replacing the Gear Oil in Transfer Case 5-35 5.3.8 Routine Maintenance of Engine and Reducer 5-35 5.3.8.1 Before Starting the Engine 5-35 5.3.9 Lubricating Points 5-37 5.3.10 Routine Inspection of Tamper Blade, Base Plate, Auger Blade and Conveyor 5-39 5.3.11 Hydraulic System...

- Page 16 Table of contents SAP Sereis Paver 5.4.7.2 Adjusting Procedures 5-54 5.4.7.3 Required Tools 5-55 5.4.7.4 Notes 5-55 5.4.8 Replacing the Travel Reducer 5-55 5.4.8.1 Replacing Requirements 5-56 5.4.8.2 Replacing Procedures 5-56 5.4.8.3 Required Tools 5-56 5.4.9 Installing and Removing the Hopper 5-57 5.4.9.1 Installing the Hopper 5-57...

- Page 17 SAP Series Paver Table of contents 5.4.21.9 Adjusting Pressure of Manual Brake Relief Valve 5-70 5.4.21.10 Adjusting Pressure of Relief Valve for Generation System 5-70 6 Troubleshooting 6.1 Tractor 6.1.1 Troubleshooting for Power System 6.1.2 Troubleshooting for Travel System 6.1.3 Troubleshooting for Conveyor 6-10 6.1.4 Troubleshooting for Centralized Lubrication System 6-11...

- Page 18 Table of contents SAP Sereis Paver WARNING R e a d a n d u n d e r s t a n d a l l s a f e t y precautions and instructions in this manual before reading any other manuals provided with this roller and before operating or servicing the roller.

- Page 19 1.2.3.2 Safety 1.2.3.3 System Functions 1.2.3.4 Operation 1.2.3.5 Maintenance 1.2.3.6 Troubleshooting 1.2.3.7 Specifications 1.3 Your SANY Machine 1.3.1 Machine Directions 1.3.2 Breaking in a New Machine 1.3.3 Machine Information 1.3.4 Serial Number and Distributor Information 1.3 Contact Information Safety, Operation & Maintenance - December 2016...

- Page 20 Introduction SAP Series Paver WARNING R e a d a n d u n d e r s t a n d a l l s a f e t y precautions and instructions in this manual before reading any other manuals provided with this roller and before operating or servicing the roller.

- Page 21 S A N Y- b u i l t e q u i p m e n t i s w i d e l y u s e d throughout the engineering construction technology for various types of applications. SANY is a leading manufacturer of heavy construction equipment worldwide with star- grade after-sales service support.

- Page 22 Spare Parts Drawing Volume The later includes the Parts List and the drawings needed when ordering parts. If the Spare Parts Drawing Volume is not attached with the equipment, contact SANY manual distribution department. 1.2.1 Recommendations on using the documentation •...

- Page 23 Introduction 1.2.3.1 Introduction This section provides an overview of what is covered in the rest of this manual, including equipment label information and SANY contact information. 1.2.3.2 Safety This section covers basic safety information relating to this equipment. Make sure you fully...

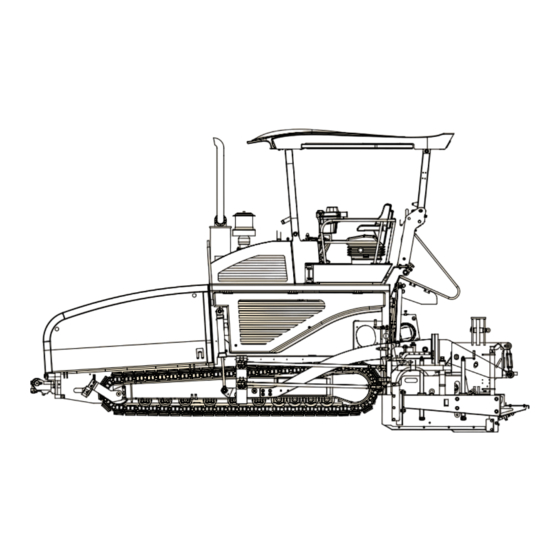

- Page 24 1.2.3.7 Specifications This section provides the general information about this equipment. Some information may change as design modification 1.3 Your SANY Machine 1.3.1 Machine directions (A) Front (B) Back (C) Left (D) Right Fig.

- Page 25 Thus SANY recommends you to perform 50-hour test run before putting the equipment into production use.

- Page 26 1.3.3 Machine information The serial numbers and model numbers on the components are the only numbers that your SANY distributor will need when ordering replacement parts or requiring assistance for your equipment. You can find the related information on the data plate. It is a good idea to record this information in this manual for future use.

- Page 27 SAP Series Paver Introduction 1.3.4 Serial number and distributor information This location is for you to record information relating to your equipment. It is advised that you keep this manual with your equipment at all times for reference. Model No. Serial No.

- Page 28 Introduction SAP Series Paver 1.4 Contact Information Thank you for purchasing a SANY product. In the event that you should need to contact us for any reason, you can reach us as follows. Address: SANY Industry Town, Economic and Technological Development Zone, Changsha,...

- Page 29 SAP Series Paver Introduction Safety, Operation & Maintenance - December 2016...

- Page 30 Introduction SAP Series Paver 1 - 10 Safety, Operation & Maintenance - December 2016...

- Page 31 This as a preview PDF file from best-manuals.com Download full PDF manual at best-manuals.com...

Need help?

Do you have a question about the SAP60C-8 and is the answer not in the manual?

Questions and answers