Advertisement

Quick Links

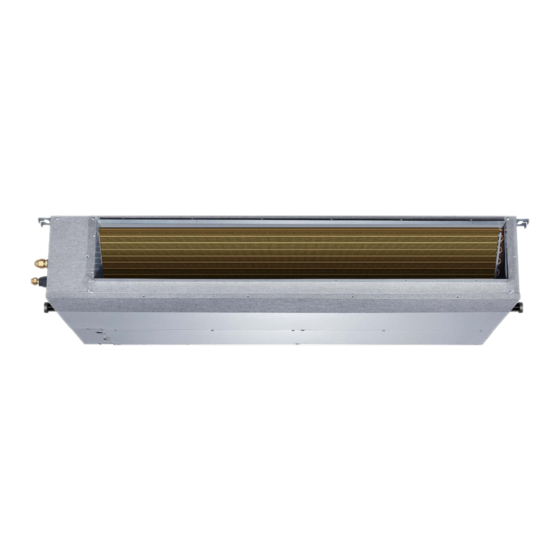

GIA-MDI-12IX43R32 | GIA-MDI-18IX43R32

GIA-D-12IX43R32 | GIA-D-18IX43R32

GIA-D-24IX43R32 | GIA-D-30IX43R32

GIA-D-36IX43R32 | GIA-D-42IX43R32

GIA-DT3-48IX43R32 | GIA-DT3-60IX43R32

Por favor lea atentamente este manual antes de usar este producto.

Please, read carefully this manual before using the product.

Avant d'utiliser l'équipement, lisez attentivement les instructions.

Por favor leia atentamente este manual antes de usar o equipamento.

Per favore leggere attentamente questo manuale prima di utilizzare questo prodotto.

G r a c i a s | T h a n k y o u | M e r c i | O b r i g a d o | G r a z i e

ES

EN

INSTALLATION MANUAL

FR

PT

IT

DUCT

IX43 R32

Advertisement

Summary of Contents for Giatsu GIA-D-12IX43R32

- Page 1 INSTALLATION MANUAL DUCT IX43 R32 GIA-MDI-12IX43R32 | GIA-MDI-18IX43R32 GIA-D-12IX43R32 | GIA-D-18IX43R32 GIA-D-24IX43R32 | GIA-D-30IX43R32 GIA-D-36IX43R32 | GIA-D-42IX43R32 GIA-DT3-48IX43R32 | GIA-DT3-60IX43R32 Por favor lea atentamente este manual antes de usar este producto. Please, read carefully this manual before using the product.

- Page 2 ENGLISH INSTALLATION MANUAL DUCT IX43 R32 GIA-MDI-12IX43R32 | GIA-MDI-18IX43R32 GIA-D-12IX43R32 | GIA-D-18IX43R32 GIA-D-24IX43R32 | GIA-D-30IX43R32 GIA-D-36IX43R32 | GIA-D-42IX43R32 GIA-DT3-48IX43R32 | GIA-DT3-60IX43R32...

- Page 3 Table of Contents Installation Manual Safety Precautions ........Accessories ............ Indoor Unit Installation Indoor Unit Installation ............Indoor Unit Parts ........Indoor Unit Installation Instructions ..10 Outdoor Unit Installation ......Outdoor Unit Installation Instructions ..15 Outdoor Unit Types and Specifications ..

- Page 4 Refrigerant Piping Connection ....... Notes on Pipe Length and Elevation ....20 Refrigerant Piping Connection Instructions ...22 Wiring ..........Outdoor Unit Wiring ....Indoor Unit Wiring ..... Power Specifications ....Air Evacuation ..........Evacuation Instructions ........ Note on Adding Refrigerant .......

- Page 5 Safety Precautions Read Safety Precautions Before Installation Incorrect installation due to ignoring instructions can cause serious damage or injury. The seriousness of potential damage or injuries is classified as either a WARNING or CAUTION. Failure to observe a warning may result in death. The appliance must be installed in accordance with national regulations.

- Page 6 WARNING 11. If the supply cord is damaged, it must be replaced by the manufacturer,its service agent or similarly quali ed persons in order to avoid a hazard. 12. The appliance shall be installed in accordance with national wiring regulations. 13.

- Page 7 Cautions for using R32/R290 refrigerant Installation (Space) - That the installation of pipe-work shall be kept to a minimum. - That pipe-work shall be protected from physical damage. - That compliance with national gas regulations shall be observed. - That mechanical connections shall be accessible for maintenance purposes. - In cases that require mechanical ventilation, ventilation openings shall be kept clear of obstruction.

- Page 8 Max Refrigerant Charge (kg) Table.1-1 Installation Refrigerant LFL(kg/m ) Floor Area (m ) Height H0(m) Type 0.68 0.90 1.08 1.32 1.53 1.87 2.41 0.306 1.14 1.51 1.80 2.20 2.54 3.12 4.02 2.05 2.71 3.24 3.97 4.58 5.61 7.24 2.50 3.31 3.96 4.85 5.60...

- Page 9 Explanation of symbols displayed on the indoor unit or outdoor unia (applicable to the unit adopts R32/R290 Refrigerant only): This symbol shows that this appliance uses a ammable refrigerant. If the WARNING refrigerant is leaked and exposed to an external ignition source, there is a risk of re.

- Page 10 Accessories The air conditioning system comes with the following accessories. Use all of the installation parts and accessories to install the air conditioner. Improper installation may result in water leakage, electrical shock and re, or equipment failure. NAME SHAPE QUANTITY Soundproof / insulation sheath Tubing &...

-

Page 11: Indoor Unit Installation Indoor Unit Installation

Indoor Unit Installation Indoor Unit Parts Air inlet Electric control cabinet Air filter(on some models) Drain hose Air outlet Refrigerant connecting pipe Fig. 3.1 Safety Precautions CAUTION WARNING • Securely install the indoor unit on a structure • Install the indoor and outdoor units, cables that can sustain its weight. - Page 12 Step 2: Hang indoor unit. 1. Please refer to the following diagrams to locate the four positioning screw bolt holes on the ceiling. Be sure to mark the paces where you will drill ceiling hook holes. Air outlet dimensions Air inlet dimensions Air lter Descending ventilation opening and mounted hook Air lter...

- Page 13 3. Install hanging screw bolts. Wood Cut o the roof beam. Place the wood mounting across the roof beam, then install the hanging screw bolts.(See Fig.3.4) Strengthen the point at which the cut was made. Consolidate the roof beam. Wood mounting 4.

- Page 14 Step 4: Adjust the air inlet direction Step 3: Duct and accessories installation (From rear side to under-side.) 1. Install the lter (optional) according to the size 1. Take o the ventilation panel and ange. of the air inlet. 2. Install the canvas tie-in between the body and Air return ange duct.

- Page 15 Step 5: Fresh air duct installation Dimension : Duct joint for fresh air MODLE 18-60 Ø125mm(4.92”) Ø160mm(6.3”) Fig. 3.14 Step 6: Motor and drain pump maintenance (the rear ventilated panel is used as an example) Motor maintenance: Take o the ventilated panel. Take o the blower housing.

- Page 16 Outdoor Unit Installation The area must be free of combustible gases √ Outdoor Unit Installation Instructions and chemicals. The pipe length between the outdoor and √ Step 1: Select installation location. indoor unit may not exceed the maximum The outdoor unit should be installed in the allowable pipe length.

- Page 17 Outdoor Unit Types and Specifications Vertical Discharge Type Outdoor Unit Split Type Outdoor Unit (Refer to Fig 4.7, 4.8, 4.9 and Table 4.2) (Refer to Fig 4.4, 4.5, 4.6, 4.10 and Table 4.1) (Wall or obstacle) Air Outlet >152.4cm / 60” Fig.

- Page 18 2. Insert the drain joint into the hole in the base NOTE: The minimum distance between the pan of the unit. outdoor unit and walls described in the installation guide does not apply to airtight 3. Rotate the drain joint 90° until it clicks in place rooms.

-

Page 19: Drainpipe Installation

Drainpipe Installation The drainpipe is used to drain water away from NOTE ON DRAINPIPE INSTALLATION the unit. Improper installation may cause unit When using an extended drainpipe, • and property damage. tightenthe indoor connection with an additionalprotection tube. This prevents CAUTION it from pulling loose. - Page 20 Units with a pump. 3. Using a 65-mm (2.5”) core drill, drill a hole in the wall. Make sure that the hole is drilled at 1. Remove the test cover. a slight downward angle, so that the outdoor Fill the water pan with 2 liters of water. end of the hole is lower than the indoor end by about 12mm (0.5”).

- Page 21 Refrigerant Piping Connection Safety Precautions Notes On Pipe Length and Elevation Ensure that the length of the refrigerant pipe, the WARNING number of bends, and the drop height between • All eld piping must be completed by a the indoor and outdoor units meets the licensed technician and must comply with requirements shown in Table 6.1: the local and national regulations.

- Page 22 CAUTION CAUTION Oil traps If the outdoor unit is installed higher than • the indoor unit: If the indoor unit is installed higher than the outdoor unit: -It is recommended that vertical suction risers not be upsized. Proper oil return to -If oil flows back into the outdoor unit’s the compressor should be maintained with compressor, this might cause liquid...

- Page 23 Step1: Cut pipes Table 6.2 When preparing refrigerant pipes, take extra Permitted length care to cut and flare them properly. This will Total piping length 18K+18K 30/98’ L+Max ensure efficient operation and minimize the (L1, L2) 24K+24K 50/164’ need for future maintenance. For R32/R290 30K+30K refrigerantmodels, the pipe connection...

- Page 24 8. Remove the flaring tool and flare form, Step 3: Flare pipe ends then inspect the end of the pipe for cracks Proper flaring is essential to achieve an airtight seal. and even flaring. 1. After removing burrs from cut pipe, seal the ends with PVC tape to prevent foreign Step 4: Connect pipes materials from entering the pipe.

- Page 25 CAUTION Ensure to wrap insulation around the • piping. Direct contact with the bare piping may result in burns or frostbite. Make sure the pipe is properly connected. • Over tightening may damage the bell mouth and under tightening may lead to leakage.

- Page 26 Wiring To prevent distortion when the compressor starts Safety Precautions (you can nd the unit’s power information on WARNING the rating sticker): • The unit must be connected to the main Disconnect the power supply before • outlet. Normally, the power supply must working on the unit.

- Page 27 Table 7.2: Other World Regions Indoor Unit Wiring Rated Current of Nominal Cross-Sectional 1. Prepare the cable for connection. Appliance (A) Area (mm²) a. Using wire strippers, strip the rubber jacket 0.75 from both ends of the signal cable to reveal ≤...

- Page 28 CAUTION While connecting the wires, please strictly • - Press “CONFIRM”. The air conditioning follow the wiring diagram. unit will then start the fan for air ow The refrigerant circuit can become very • automatic adjustment. hot. Keep the interconnection cable away from the copper tube.

- Page 29 Power Specifications NOTE: Electric auxiliary heating type circuit breaker/fuse need to add more than 10 A. Indoor Power Supply Specifications ≤18K MODEL(Btu/h) 19K~24K 25K~36K 37K~48K 49K~60K PHASE 1 Phase 1 Phase 1 Phase 1 Phase 1 Phase POWER 208-240V 208-240V 208-240V 208-240V 208-240V VOLT CIRCUIT BREAKER/ 25/20...

- Page 30 ≤36K ≤36K MODEL(Btu/h) 37K~60K 37K~60K PHASE 1 Phase 1 Phase 1 Phase 1 Phase POWER (indoor) 208-240V 208-240V 208-240V 208-240V VOLT CIRCUIT BREAKER/FUSE(A) 15/10 15/10 15/10 15/10 PHASE 3 Phase 3 Phase 3 Phase 3 Phase POWER (outdoor) 380-420V 380-420V 208-240V 208-240V VOLT...

- Page 31 Air Evacuation 4. Turn on the vacuum pump to evacuate the Safety Precautions system. 5. Run the vacuum for at least 15 minutes, or CAUTION until the Compound Meter reads -76cmHG (-1x105Pa). Use a vacuum pump with a gauge reading •...

- Page 32 Note On Adding Refrigerant CAUTION • Refrigerant charging must be performed after wiring, vacuuming, and the leak testing. • DO NOT exceed the maximum allowable quantity of refrigerant or overcharge the system. Doing so can damage the unit or impact it’s functioning. •...

- Page 33 Test Run f. Check to see that the drainage system is Before Test Run unimpeded and draining smoothly. A test run must be performed after the entire g. Ensure there is no vibration or abnormal system has been completely installed. Confirm noise during operation.

- Page 34 European Disposal Guidelines Users in European Countries may be required to properly dispose of this unit. This appliance contains refrigerant and other potentially hazardous materials. When disposing of this appliance, the law requires special collection and treatment. DO NOT dispose of this product as household waste or unsorted municipal waste.

- Page 35 Information Servicing (Required for the units adopt R32/R290 Refrigerant only) 1. Checks to the area Prior to beginning work on systems containing flammable refrigerants, safety checks are necessary to ensure that the risk of ignition is minimised. For repair to the refrigerating system, the following precautions shall be complied with prior to conducting work on the system.

- Page 36 the charge size is in accordance with the room size within which the refrigerant containing parts are installed; the ventilation machinery and outlets are operating adequately and are not obstructed; if an indirect refrigerating circuit is being used, the secondary circuits shall be checked for the presence of refrigerant;...

- Page 37 11. Repair to intrinsically safe components Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that this will not exceed the permissible voltage and current permitted for the equipment in use. Intrinscially safe components are the only types that can be worked on while live in the presence of a flammable atmosphere.

- Page 38 When the final OFN charge is used, the system shall be vented down to atmospheric pressure to enable work to take place. This operation is absolutely vital if brazing operations on the pipe-work are to take place. Ensure that the outlet for the vacuum pump is not closed to any ignition sources and there is ventilation available.

- Page 39 18. Labelling Equipment shall be labelled stating that it has been de-commissioned and emptied of refrigerant. The label shall be dated and signed. Ensure that there are labels on the equipment stating the equipment contains flammable refrigerant. 19. Recovery When removing refrigerant from a system, either for service or decommissioning, it is recommended good practice that all refrigerants are removed safely.

- Page 40 C/ Industria, 13, Polígono Industrial El Pedregar. 08160 Montmeló. Barcelona (España) Tel (0034) 93 390 42 20 - Fax (0034) 93 390 42 05 info@giatsu.com - www.giatsu.com FRANCE PORTUGAL ITALIA info.fr@giatsu.com info.pt@giatsu.com info.it@giatsu.com L L L I I I T T T H H H U U U A A A N N N I I I A A A info@giatsu.lt...

Need help?

Do you have a question about the GIA-D-12IX43R32 and is the answer not in the manual?

Questions and answers