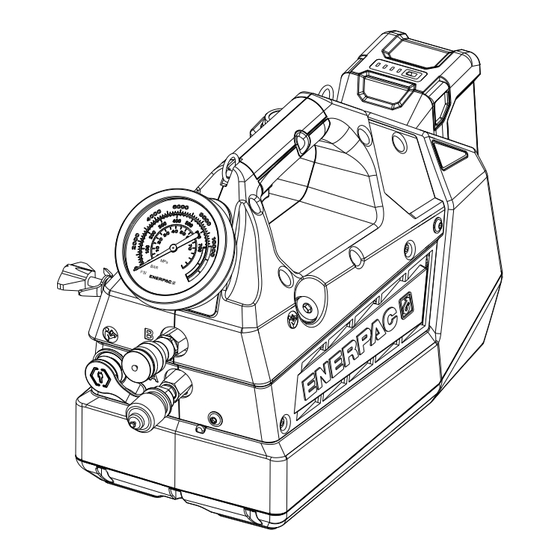

Enerpac XC2 Series Operation And Maintenance Manual

Cordless hydraulic bolting pumps

Hide thumbs

Also See for XC2 Series:

- Operation and maintenance manual (48 pages) ,

- Operation and maintenance manual (48 pages) ,

- Operation and maintenance manual (52 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Need help?

Do you have a question about the XC2 Series and is the answer not in the manual?

Questions and answers