Table of Contents

Advertisement

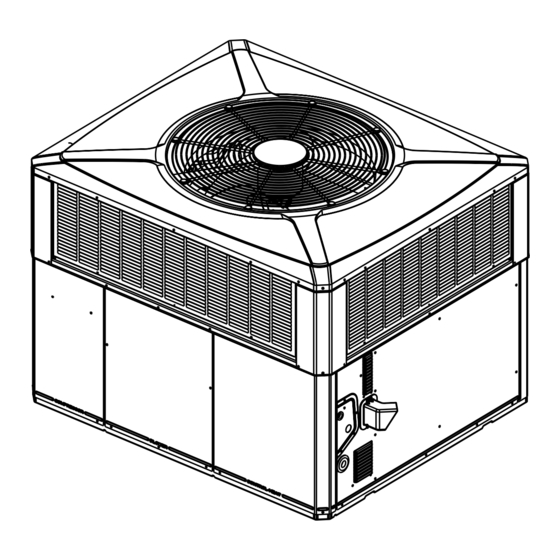

Installation and Operations Manual

Single Packaged Gas/Electric

13.4 SEER2 Convertible, 2 - 5 Ton

4YCC4024E1060A

4YCC4030E1070A

4YCC4036E1070A

4YCC4036E1090A

4YCC4042E1060A

4YCC4042E1090A

4YCC4048E1070A

4YCC4048E1090A

4YCC4060E1090A

4YCC4060E1115A

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning

equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person

could result in death or serious injury. When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that

are attached to the equipment.

January 2024

S S A A F F E E T T Y Y W W A A R R N N I I N N G G

1 1 8 8 - - E E B B 4 4 0 0 D D 1 1 - - 1 1 E E - - E E N N

N N o o t t e e : : "Graphics in this document are for representation

only. Actual model may differ in appearance."

Advertisement

Table of Contents

Need help?

Do you have a question about the 4YCC4024E1060A and is the answer not in the manual?

Questions and answers

I DO NOT KNOW WHERE IS THE FILTER?