Table of Contents

Advertisement

Quick Links

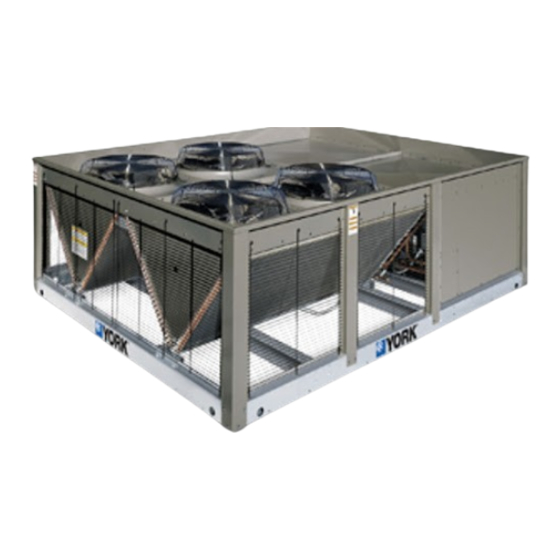

R-410A

MODELS:

YD360 Thru 600

30 - 50 Ton

60 Hertz

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Phasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 YD360 thru 600 Physical Data . . . . . . . . . . . . . . . . . . . . . 4

2 Unit Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Corner Weight & Center Of Gravity (Inches) . . . . . . . . . . 6

4 Minimum Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Electrical Data - Outdoor Unit. . . . . . . . . . . . . . . . . . . . . . 9

1 Corner Weights & Center Of Gravity . . . . . . . . . . . . . . . . . 6

2 Typical Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Matched with YD360/480/600 Condenser . . . . . . . . . . . 12

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Typical Liquid Line Solenoid Wiring . . . . . . . . . . . . . . . . . 13

6 YD Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 30 Ton Power And Control Wiring Connections . . . . . . . . 15

9 30 Ton Piping Connections . . . . . . . . . . . . . . . . . . . . . . . 16

TABLE OF CONTENTS

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Refrigerant Mains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Piping And Electrical Connection Sizes . . . . . . . . . . . . . . 16

Piping And Electrical Connections . . . . . . . . . . . . . . . . . . 17

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Crankcase Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Unit Control Board Option Setup. . . . . . . . . . . . . . . . . . . . 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Start-Up Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

LIST OF TABLES

6 Unit Dimensions (Inches) . . . . . . . . . . . . . . . . . . . . . . . . 14

(Inches) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Electrical Power Knockout Sizes (Inches) . . . . . . . . . . . 16

9 YD360 thru 600 Unit Control Board Flash Codes . . . . . 20

LIST OF FIGURES

10 40 & 50 Ton Piping Connections . . . . . . . . . . . . . . . . . . . 17

11 Fan Orientation Control Box End . . . . . . . . . . . . . . . . . . 19

12 Compressor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

13 Unit Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

14 YD360 Charging Curves . . . . . . . . . . . . . . . . . . . . . . . . . 22

15 YD480 Charging Curves . . . . . . . . . . . . . . . . . . . . . . . . . 22

16 YD600 Charging Curves . . . . . . . . . . . . . . . . . . . . . . . . . 23

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1062444-YIM-A-0913

Advertisement

Table of Contents

Summary of Contents for Johnson Controls YD360

-

Page 1: Table Of Contents

Matched with YD360/480/600 Condenser ... 12 14 YD360 Charging Curves ......22 4 Typical ND360/480 &... -

Page 2: Nomenclature

(power and control) can be made through the front of the unit. Please refer to the equipment Technical Guide, Installation Manual and the piping applications bulletin 247077 or call the applications department for Unitary Products @ 1-877-UPG-SERV for guidance. Johnson Controls Unitary Products... -

Page 3: Renewal Parts

R-410A. If you are unsure, consult the equipment manufacturer. Failure to use R-410A compatible servicing equipment may result in property damage or injury. Johnson Controls Unitary Products... -

Page 4: Physical Data

1062444-YIM-A-0913 Physical Data Table 1: YD360 thru 600 Physical Data Models Component YD360 YD480 YD600 Nominal Tonnage REFRIGERANT Refrigerant type R-410A R-410A R-410A Holding charge (lb) System #1 47.0 51.0 Operating Charge (lb) System #2 47.0 51.0 DIMENSIONS (inches) Length 128.5... -

Page 5: Installation

The slab should not be tied to the building foundation, as noise will telegraph The condenser fans are the propeller type and are not through the slab. suitable for use with ductwork in the condenser air stream. Johnson Controls Unitary Products... -

Page 6: Corner Weight & Center Of Gravity (Inches)

Further safety precautions such as a fenced enclosure or locking devices on the panels may be advisable. Check local On either rooftop or ground level installations, rubber padding authorities for safety regulations. can be applied under the unit to lessen any transmission of vibration. Johnson Controls Unitary Products... -

Page 7: Clearances

(see Figure 2). width of the skid and can cause damage to the unit’s base rails or condenser coils. Spreaders, longer than the largest dimension across the unit must be used across the top of the unit. Johnson Controls Unitary Products... -

Page 8: Phasing

Do not leave the system open to the atmosphere. Unit damage could occur due to moisture being absorbed by the POE oil in the system. This type of oil is highly susceptible to moisture absorption. Johnson Controls Unitary Products... -

Page 9: Electrical Data - Outdoor Unit

18.6 460-3-60 1 1/2 90.7 575-3-60 14.7 575-3-60 1 1/2 71.3 1. Maximum fuse or maximum circuit breaker (HACR type per NEC). 2. Based on three, 75°C insulated copper conductors in conduit and ambient of 30°C. Johnson Controls Unitary Products... -

Page 10: Refrigerant Mains

Erodes the seat of the refrigerant control device. atmosphere is provided. Causes erratic control of the refrigerant entering the evaporator. NOTE: Dry nitrogen should flow through the system at all times when heat is being applied and until the joint has Johnson Controls Unitary Products... - Page 11 Punch a small hole "Application Data - General Piping Recommendations in the sealing disks, the flow of nitrogen will prevent any debris for Split System Air Conditioning and Heat Pumps". from entering the system. Unbraze both liquid and suction Johnson Controls Unitary Products...

-

Page 12: Typical Field Wiring Diagram Nd360/480 Evaporator Units, Nd600 Air Handler And M1Cz600A Evaporator Coil When Matched With Yd360/480/600 Condenser

1062444-YIM-A-0913 Figure 3: Typical Field Wiring Diagram ND360/480 Evaporator Units, ND600 Air Handler and M1CZ600A Evaporator Coil when Matched with YD360/480/600 Condenser NOTE: On non ND evaporator models, isolation relays must be NOTE: For applications on airhandlers/evaporator DX coils installed to avoid overloading on 75VA transformers on other than ND360-600 certified matchups liquid line the condensing unit. -

Page 13: Typical Liquid Line Solenoid Wiring

Non ND units may not include any or all of the components required to wire the unit. Use the diagram as general reference only. Figure 5: Typical Liquid Line Solenoid Wiring Johnson Controls Unitary Products... -

Page 14: Yd Unit Dimensions

YD Unit Dimensions Table 6: Unit Dimensions (Inches MODEL YD360 128.5 88.5 37.5 41.8 40.0 46.1 37.1 23.6 YD480 128.5 88.5 57.7 41.8 40.0 46.1 37.1 23.6 YD600 128.5 88.5 57.7 41.8 40.0 46.1 37.1 23.6 Johnson Controls Unitary Products... -

Page 15: 30 Ton Power And Control Wiring Connections

DETAIL RIGGING HOLES SCALE 0.250 88.140 Figure 7: Ton Power And Control Wiring Connections Control Wiring Power Wiring 57.689 33.049 29.799 19.358 20.858 22.358 88.140 Figure 8: 40 & 50 Ton Power And Control Wiring Connections Johnson Controls Unitary Products... -

Page 16: 30 Ton Piping Connections

Table 8: Electrical Power Knockout Sizes (Inches) CONNECTION ENTRY 30-40-50T/230V 30-40-50T/460-575V POWER WIRING 2-1/2” 1-1/2” 37.518 10.984 11.385 Liquid (Sys 2) 37.826 Suction (Sys 2) 41.859 Suction (Sys 1) 46.190 Liquid (Sys 1) 50.313 88.140 Figure 9: 30 Ton Piping Connections Johnson Controls Unitary Products... -

Page 17: Piping And Electrical Connections

12. Is any electrical wire laying against a hot refrigerant line? hours of crankcase heat or compressor damage can occur. Initial Start-Up Supply power to the unit through the disconnect switch at least 8 hours prior to starting the compressor. Johnson Controls Unitary Products... -

Page 18: Operation

If the low-pressure switch opens during circuit from the “R” to “G” is completed and the supply air blower normal operation, the Simplicity™ control board will de- will operate continuously. energize the compressor, initiate the ASCD, and shut Johnson Controls Unitary Products... -

Page 19: Fan Orientation Control Box End

Fan 1 will start immediately upon a call for first stage cooling. Figure 12: Compressor Location However, Fan 2 is equipped with a fan cycling switch and will Johnson Controls Unitary Products... -

Page 20: Yd360 Thru 600 Unit Control Board Flash Codes

1062444-YIM-A-0913 Table 9: YD360 thru 600 Unit Control Board Flash Codes GREEN FLASH CODE DESCRIPTION On Steady This is a Control Failure 1 Flash Not Applicable 2 Flashes Flashing Control waiting ASCD 3 Flashes HPS1 Compressor Lockout 4 Flashes HPS2 Compressor Lockout... -

Page 21: Unit Control Board Option Setup

Check the wiring label inside the Normal Maintenance control box access panel for the correct wiring. Prior to any of the following maintenance procedures, shut off all power to the unit, to avoid personal injury. Johnson Controls Unitary Products... -

Page 22: Yd360 Charging Curves

2. This chart is applicable to unit with the TXV's left to the factory setting. If the TXV's have been adjusted in the field, the charging chart may no longer apply. Figure 14: YD360 Charging Curves Charging Curves 40 Ton 115º... -

Page 23: Yd600 Charging Curves

2. This chart is applicable to unit with the TXV's left to the factory setting. If the TXV's have been adjusted in the field, the charging chart may no longer apply. Figure 16: YD600 Charging Curves Johnson Controls Unitary Products... -

Page 24: Typical Wiring Diagrams

1062444-YIM-A-0913 Typical Wiring Diagrams Figure 17: Typical 208/230 Volt, YD360/480/600 Condensing Unit Wiring Diagram Johnson Controls Unitary Products... -

Page 25: Typical 460/575 Volt, Yd360/480/600 Condensing Unit Wiring Diagram

1062444-YIM-A-0913 Typical Wiring Diagrams Figure 18: Typical 460/575 Volt, YD360/480/600 Condensing Unit Wiring Diagram Johnson Controls Unitary Products... -

Page 26: Start-Up Sheet

30 days from installation. Refer to current standard EQUIPMENT STARTUP warranty policy and warranty manual found on UPGnet for details. In the event that communication with Johnson Controls/UPG is Simplicity PC is required to complete the start-up. Simplicity required regarding technical and/or warranty concerns, all parties PC software can be downloaded from www.york.com. - Page 27 1034350-UCL-A-0313 SAFETY WARNINGS The inspections and recording of data outlined in this procedure are required for start-up of Johnson Controls/UPG's packaged Lethal voltages are present during some start-up products. Industry recognized safety standards and practices checks. Extreme caution must be used at all times.

- Page 28 Air Moving Inspection Completed See Notes Alignment of drive components Belt tension adjusted properly Blower pulleys tight on shaft, bearing set screws tight, wheel tight to shaft Pressure switch or transducer tubing installed properly Unitary Products Group Johnson Controls Unitary Products...

- Page 29 1. VAV units with heat section - simulate heat call to drive VAV boxes and VFD/IGV to maximum design airflow position. 2. VAV units without heat section - VAV boxes must be set to maximum design airflow position. Notes above apply for 3rd party application only. Unitary Products Group Johnson Controls Unitary Products...

- Page 30 Measured List All Three Amperages Stage 1 _________AMPS _________AMPS _________AMPS _________AMPS Stage 2 _________AMPS _________AMPS _________AMPS _________AMPS Stage 3 _________AMPS _________AMPS _________AMPS _________AMPS Stage 4 _________AMPS _________AMPS _________AMPS _________AMPS Checked Heater Limit Air Moving Switch Installed? Unitary Products Group Johnson Controls Unitary Products...

- Page 31 ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ ________________________________________________________________________________________________________ Subject to change without notice. Printed in U.S.A. 1062444-YIM-A-0913 Copyright © 2014 by Johnson Controls, Inc. All rights reserved. Supersedes: 579883-YIM-B-0712 York International Corporation 5005 York Drive Norman, OK 73069...

Need help?

Do you have a question about the YD360 and is the answer not in the manual?

Questions and answers