Table of Contents

Advertisement

Woodbine, Iowa

Before installing or using this liftgate, please observe the Vehicle Loading

!

Limitations. These loading limitations are outlined in the Vehicle Owner's Manual

and the Safety Compliance Certification Label located on the driver's door pillar.

CAUTION

DPN: 009120

OWNER'S / OPERATOR'S

Safety Information

·

Warranty Information

·

Operator's Instructions

·

Maintenance Instructions

·

Parts List

·

G2 SERIES

700-2000 LB CAPACITY

PLEASE KEEP IN VEHICLE

Page 1 of 28

MANUAL

!

CAUTION

Rev 29

11-2-23

Advertisement

Table of Contents

Summary of Contents for Tommy Gate G2 Series

- Page 1 Maintenance Instructions · Parts List · G2 SERIES 700-2000 LB CAPACITY Before installing or using this liftgate, please observe the Vehicle Loading Limitations. These loading limitations are outlined in the Vehicle Owner's Manual and the Safety Compliance Certification Label located on the driver's door pillar.

-

Page 2: Table Of Contents

Safety Decals Location and Descriptions----------------------------------------------------------------- 4 - 6 Decal Replacement------------------------------------------------------------------------- 6 Operator's Instructions G2 Series Terms and Method of Operation----------------------------------------------7 Operator's Instructions--------------------------------------------------------------------- 8 Latch Adjustment--------------------------------------------------------------------------- 9 - 10 Lift-N-Dump as a Dump Body----------------------------------------------------------- 11 Platform Drop Away Feature (Excludes 2000# TP Platform)------------------------ 12 - 13... -

Page 3: To The Owner\Operator

Be sure you read and understand all operating, safety, maintenance and service information. Should you need repair or service information, contact Tommy Gate or an authorized distributor for assistance. This is the safety alert symbol. It is used to alert you to potential personal injury hazards. -

Page 4: Safety Decals Location And Descriptions

UNATTENDED. NEVER LEAVE PLATFORM DOWN TO BE USED AS A STEP. ALL REPAIRS OR REINSTALLATIONS OF TOMMY GATE LIFTS SHOULD BE PERFORMED BY AN AUTHORIZED DISTRIBUTOR THAT IS FAMILIAR WITH ITS OPERATION AND SAFETY FEATURES. ALL REPLACEMENT PARTS MUST BE OF ORIGINAL QUALITY, AND ALL... - Page 5 DECAL LOCATIONS AND DESCRIPTIONS WARNING The original TOMMY GATE ® hydraulic lift Do not ride the platform. Part Number: This lift is not Serial Number: designed as a wheelchair or personnel lift. Center Load Center load on platform side to side and front to Decal No.

-

Page 6: Decal Replacement

DECAL LOCATIONS AND DESCRIPTIONS CAUTION CAUTION Never use Lift-N-Dump as a liftgate when the dump body hoist is raised. Pinned Never unfold the platform, unless both insert latch Latched pins are fully engaged in the platform frame, and the The liftgate must be fully raised with the latch lever is latched and platform folded and secured with both pinned. -

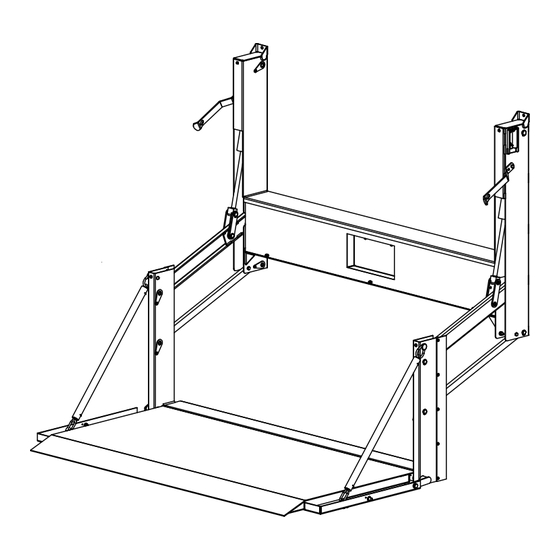

Page 7: G2 Series Terms And Method Of Operation

SERIES TERMS AND METHOD OF OPERATION Your Tommy Gate is connected to your vehicle battery. The vehicle battery powers a motor, coupled to a hydraulic pump. This motor and pump combination is called a power unit. Flow from the pump retracts the two cylinders attached to the upper arm assembly that lift the gate platform. -

Page 8: Operator's Instructions

OPERATOR'S INSTRUCTIONS Step 1. To open the platform, go to the driver's side of the Tommy Gate, push the latch to the side, off the platform pin, and rotate the latch down. Proceed to the passenger's side of the Tommy Gate and remove the latch padlock. -

Page 9: Latch Adjustment

LATCH ADJUSTMENT 700-2000 SERIES Make sure the liftgate is in the fully raised position. Disconnect the #4 power cable from the positive side of the battery or manually trip the circuit breaker. Remove the latch padlock from the passenger's side of the platform. Unlatch the driver's side latch and then the passenger's side latch. - Page 10 LATCH ADJUSTMENT 700-2000 SERIES Latch Spring Lock Nut Bolt Latch Latch Spring Latch Lock Nut Bolt Figure 8. Latch spring Flat Washer 1" Driver's Side " Passenger's Side Upright Figure 9. Latch spring Platform Platform Latch Latch Latch Hole Latch Hole Platform Latch Pin 8 "...

-

Page 11: Lift-N-Dump As A Dump Body

SERIES LIFT-N-DUMP AS A DUMP BODY TAILGATE ! Caution: Never show children or unauthorized personnel how to operate the gate. To prevent children or unauthorized personnel from operating the gate before leaving the truck unattended be sure: -the gate is in the stored position -both the driver's side and passenger's side lynch pins are installed -the insert latch handle is latched and pinned -the control is deactivated. -

Page 12: Platform Drop Away Feature (Excludes 2000# Tp Platform)

PLATFORM DROP AWAY FEATURE Not available for 2000# Treadplate Platforms Installing platform drop away pin (Figure 15). 1. Insert the platform drop away pin through the Upright Back existing 3/8" hole in the upright back. 2. Fasten the pin to the upright using the 3/8"... - Page 13 PLATFORM DROP AWAY FEATURE Not available for 2000# Treadplate Platforms Using platform drop away feature (Figure 18). 1. Unhook both platform chains from the sub-assembly pins. 2. Pull chain link through slit cut in driver side chain cover. Unhook both chains from the !Caution - The platform may spring back with sub assembly pins.

-

Page 14: Spare Tire Access (Pickup Liftgate Only)

SPARE TIRE ACCESS (pickup liftgate only) Accessing the Spare Tire There are holes in the back of the liftgate which provide access to the factory spare tire crank on some pickup liftgates. The following will help you locate the spare tire access hole for your application. -

Page 15: Electrical Wiring Diagrams

ELECTRICAL WIRING DIAGRAM Standard Fixed Control WELDING NOTE !!! DISCONNECT ALL BATTERY CABLES. ALWAYS DISCONNECT THE GROUND CABLE FIRST. ATTACH THE WELDING GROUND TO THE TRUCK RATHER THAN THE LIFTGATE. IMPORTANT NOTE !!! IF GATES ARE NOT WIRED PLEASE READ AND FOLLOW ALL IN ACCORDANCE WITH THIS DIAGRAM DIRECTIONS BEFORE PROCEEDING YOUR WARRANTY WILL BE VOID. -

Page 16: Optional Pendant Control

ELECTRICAL WIRING DIAGRAM Optional Pendant Control WELDING NOTE !!! DISCONNECT ALL BATTERY CABLES. ALWAYS DISCONNECT THE GROUND CABLE FIRST. ATTACH THE WELDING GROUND TO THE TRUCK RATHER THAN THE LIFTGATE. IMPORTANT NOTE !!! IF GATES ARE NOT WIRED PLEASE READ AND FOLLOW ALL IN ACCORDANCE WITH THIS DIAGRAM DIRECTIONS BEFORE PROCEEDING YOUR WARRANTY WILL BE VOID. -

Page 17: Ladder Logic/Wiring Diagram

LADDER LOGIC/WIRING DIAGRAM Legend Circuit Breaker Contactor - Normally Open Contacts Motor Solenoid/Contactor - Coil Battery Cable Wire Grounded through pump body. Eyelet Terminal Splice Quick Disconnect Fuse Battery +12V Battery or +24V "Raise" Contactor Green Violet Fixed Control "Raise" Contactor Green Fuse... -

Page 18: Maintenance And Service

All replacement parts must be of original quality, and all safety and operational decals must be attached. No modifications are allowed to a Tommy Gate product unless authorized in writing by the Engineering Department at Tommy Gate. -

Page 19: Troubleshooting

TROUBLESHOOTING 700-2000 LB SERIES Page 19 of 28 DPN: 009120 Rev 29 11-2-23... -

Page 20: Standard Warranty

Tommy Gate Company's Warranty Department to discuss the problem and its correction. 2. If it is determined that the condition is potentially covered by Tommy Gate Company's warranty, the authorized distributor will receive instructions on how to proceed. A decision will be made to either repair or replace the product or part in question. - Page 21 Action taken, cost involved, complete with work orders and parts expense invoices. 6. If defective parts are to be returned to Tommy Gate Company, the parts: a. Must be packaged for each individual warranty return. No multiple warranty claims in the same box.

-

Page 22: Repair Parts Drawing

700-2000 SERIES REPAIR PARTS DRAWING FOR ALL MODEL WIDTHS 38 20 Page 22 of 28 DPN: 009120 Rev 29 11-2-23... - Page 23 SERIES REPAIR PARTS DRAWING FOR MODELS 73LD, 81LD, 87LD, 92LD Page 23 of 28 DPN: 009120 Rev 29 11-2-23...

-

Page 24: Repair Parts List

700-2000 SERIES REPAIR PARTS LIST ITEM# DESCRIPTION ITEM# DESCRIPTION Platform Tank Platform Chain Timed Control Sub Assembly Vent Plug-Cylinder License Plate Mount Kit License Plate Light Lower Arm Assembly Motor Only Cylinder Clevis Assembly 3/4" Upright Front Arm Pin Upper Arm Assembly "Lower"... -

Page 25: Hydraulic Fluid Notice

NOTICE TOMMY GATE ISO GRADE 32 HYDRAULIC FLUID OR ISO GRADE 32 EQUIVALENT RECOMMENDED. WITH THE USE OF AUTOMATIC TRANSMISSION FLUID (ATF) OR TOMMY GATE WINTER GRADE HYDRAULIC FLUID THE CYLINDERS MAY BEGIN TO MAKE NOISE. WHILE THERE WILL BE NO DAMAGE TO THE HYDRAULIC SYSTEM, IT MAY BECOME A NUISANCE. - Page 26 THIS PAGE INTENTIONALLY LEFT BLANK Page 26 of 28 DPN: 009120 Rev 29 11-2-23...

-

Page 27: Service Records

SERVICE RECORD LIFTGATE INFORMATION Date of Purchase: Serial Number: Installed By: Model Number: Reminders: Service liftgate according to page 18. Date of Service Services Performed Page 27 of 28 DPN: 009120 Rev 29 11-2-23... -

Page 28: Contact Information

Manufacturing Plant: Corporate Offices: 33717 N. Scottsdale Rd. Ste 120 83 Bus Brown Drive Woodbine, Iowa 51579 Scottsdale, AZ 85266 FAX (712) 647-2417 FAX (602) 955-3902 (712) 847-8000 www.tommygate.com Page 28 of 28 DPN: 009120 Rev 29 11-2-23...

Need help?

Do you have a question about the G2 Series and is the answer not in the manual?

Questions and answers