Table of Contents

Advertisement

Quick Links

Warnings for the safe use of this tool are included in this manual.

Los avisos para el uso seguro de esta herramienta están incluidos en este manual.

Les consignes pour l'utilisation en toute sécurité de cet outil se trouvent dans ce manuel.

KYOCERA-SENCO Industrial Tools, Inc.

8450 Broadwell Road

Cincinnati, OH 45244

1-800-543-4596

www.senco.com

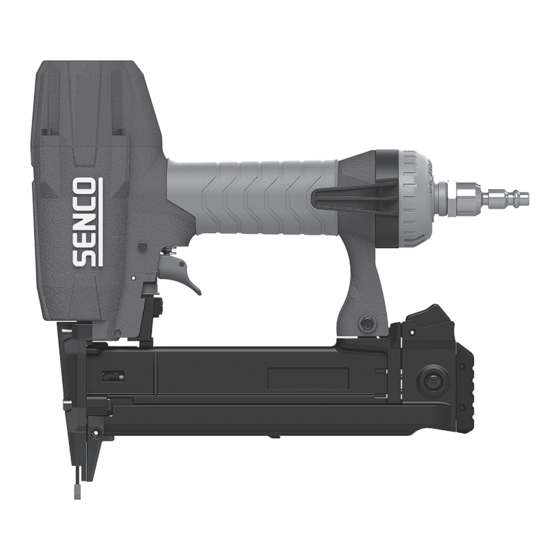

18 GauGe FiniSH StaPLer

LS61H1P

Operating instructions

IMPORTANT:

Read before use.

NFD8LS6 • Issued July 7, 2023

© 2023 by KYOCERA-SENCO Industrial Tools, Inc.

Advertisement

Table of Contents

Summary of Contents for Senco LS61H1P

- Page 1 Les consignes pour l’utilisation en toute sécurité de cet outil se trouvent dans ce manuel. IMPORTANT: Read before use. KYOCERA-SENCO Industrial Tools, Inc. NFD8LS6 • Issued July 7, 2023 8450 Broadwell Road Cincinnati, OH 45244 1-800-543-4596 www.senco.com © 2023 by KYOCERA-SENCO Industrial Tools, Inc.

-

Page 2: Table Of Contents

table of Contents Employer’s Responsibilities ........................2 Safety Warnings ............................3 Maintenance ............................... 6 Functional Operation ..........................8 Tool Use ..............................9 Clearing Jam ............................10 Features ..............................10 Maintenance ............................. 10 Troubleshooting ............................11 Accessories .............................. 11 Technical Specifications ........................... 11 Fastener Specifications .......................... -

Page 3: Safety Warnings

SaFety WarninGS Read and understand tool labels and manual. Failure to follow WARNING warnings will result in DEATH or SERIOUS INJURY. Save These Instructions. Personal Protective equipment Use safety equipment. Always wear ANSI Z87+ safety glasses with permanently attached side shields. Dust mask, non-skid safety shoes, hard hat, or hearing protection must be used for appropriate conditions. - Page 4 It is recommended that operators that are less experienced using pneumatic fastener driving tools choose a sequential mechanism until they become familiar with the tool and its operation. Please call Senco Customer Service to obtain an alternate trigger type in those tools that can be user modified to fit the application and/or level of operator experience.

- Page 5 Operating Controls Do not use tool without danger label on tool. If label is missing, damaged or unreadable, contact your SENCO represen- tative to obtain a new label. Never use tool if safety element, trigger or springs have become inoperable, missing or damaged. Do not tamper with or remove safety element, trigger or springs.

-

Page 6: Maintenance

Wipe tool clean daily and inspect for wear. Use non-flammable cleaning solutions only if necessary. DO nOt SOaK. no routine oiling necessary. WarninG Repairs other than those described here should be performed only by trained, qualified personnel. Contact SENCO for information at 1-800-543-4596. - Page 7 SaFety WarninGS the employer, tool owner and tool operator: • are responsible for ensuring that the tools are kept in safe working order. • are responsible for ensuring that only qualified personnel shall repair the tool. • are responsible for ensuring that manufacturers tool maintenance instructions are available to personnel performing maintenance.

-

Page 9: Tool Use

➁ Lay strip of fasteners into magazine. ③ Push rail forward until it latches. Do not load with workpiece contact (safety element) or trigger depressed. Use only genuine SENCO fasteners (see Fastener Specifications). actuation System: With a Contact-actuation (“Dual-action”) trigger, fasteners can be driven two ways: the First Way: ➀... -

Page 10: Clearing Jam

Wipe tool clean daily and inspect for wear. Use non-flammable cleaning solutions only if necessary–DO nOt SOaK Caution: Such solutions may damage O-rings and other tool parts. no routine oiling necessary. repairs other than those described here should be performed only by trained, qualified personnel. Contact SenCO for information at 1-800-543-4596. -

Page 11: Troubleshooting

Clean tool / Tighten screws Other problems Contact SENCO accessories SENCO offers a full line of accessories for your SENCO tools, including: • Air Compressors • Couplers • Safety Glasses • Regulators • Hose •... -

Page 12: Limited Warranty

KYOCERA-SENCO Industrial Tools, Inc. (“SENCO”) designs and constructs its products using the highest standards of material and workmanship. SENCO warrants to the original retail purchaser that the following products will be free from defects in material or workmanship for the warranty period...

Need help?

Do you have a question about the LS61H1P and is the answer not in the manual?

Questions and answers