Advertisement

SY3000-TFS01EN

ORIGINAL INSTRUCTIONS

Instruction Manual

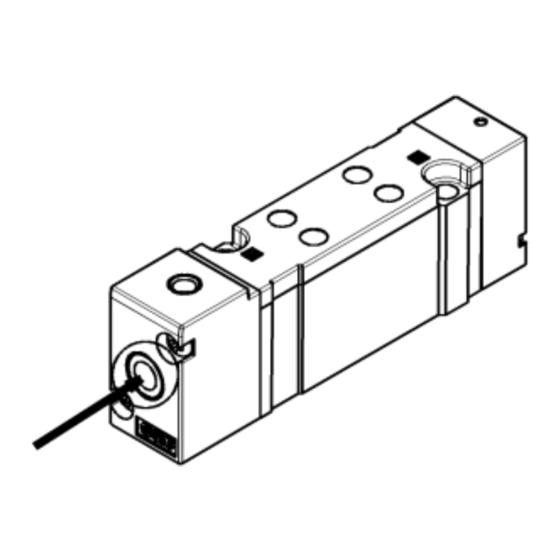

5 Port Air Operated Valve

Series SYA3000/5000/7000

The intended use of this product is to control the movement of an

actuator.

Note 1)

Validated according to ISO 13849

, see section 2.

Note 1)

Not all variants of this product series are validated. Please

refer to "How to Order" section 5 for details.

Refer to product catalogues for additional information.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of "Caution", "Warning" or "Danger".

They are all important notes for safety and must be followed in addition

*1)

to International Standards (ISO/IEC)

, and other safety regulations.

*1)

ISO 4414: Pneumatic fluid power - - General rules relating to

systems.

ISO 4413: Hydraulic fluid power - - General rules relating to

systems.

IEC 60204-1: Safety of machinery - -Electrical equipment of

machines. (Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety.etc.

This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct

handling, and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• To ensure safety of personnel and equipment the safety instructions

in this manual must be observed, along with other relevant safety

practices.

Caution indicates a hazard with a low level of risk

Caution

which, if not avoided, could result in minor or

moderate injury.

Warning indicates a hazard with a medium level

Warning

of risk which, if not avoided, could result in death

or serious injury.

Danger indicates a hazard with a high level of risk

Danger

which, if not avoided, will result in death or serious

injury.

Warning

• The compatibility of the product is the responsibility of the

person who designs the equipment or decides its specifications.

Since the product specified here is used under various operating

conditions, its compatibility with specific equipment must be decided

by the person who designs the equipment or decides its

specifications based on necessary analysis and test results. The

expected performance and safety assurance of the equipment will be

the responsibility of the person who has determined its compatibility

with the product. This person should also continuously review all

specifications of the product referring to its latest catalogue

information, with a view to giving due consideration to any possibility

of equipment failure when configuring the equipment.

1 Safety Instructions - continued

• Only personnel with appropriate training should operate

machinery and equipment.

The product specified here may become unsafe if handled

incorrectly.

The assembly, operation and maintenance of machines or equipment

including our products must be performed by an operator who is

appropriately trained and experienced.

• Do

not

service

or

attempt

to

remove

product

machinery/equipment until safety is confirmed.

1) The inspection and maintenance of machinery/equipment should

only be performed after measures to prevent falling or runaway of the

driven objects have been confirmed.

2) When the product is to be removed, confirm that the safety

measures as mentioned above are implemented and the power from

any appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3) Before machinery/equipment is restarted, take measures to

prevent unexpected operation and malfunction.

• Contact SMC beforehand and take special consideration of

safety measures if the product is to be used in any of the

following conditions.

1) Conditions and environments outside of the given specifications, or

use outdoors or in a place exposed to direct sunlight.

2) Installation on equipment in conjunction with atomic energy,

railways, air navigation, space, shipping, vehicles, military, medical

treatment, combustions and recreation, or equipment in contact with

food and beverages, emergency stop circuits, clutch and brake

circuits in press applications, safety equipment or other applications

unsuitable for the standard specification described in the product

catalogue.

3) An application which could have negative effects on people,

property, or animals requiring special safety analysis outside the

scope of ISO 13849 described in this document.

4) Use in an interlock circuit, which requires the provision of double

interlock for possible failure by using a mechanical protective

function, and periodical checks to confirm proper operation.

• Always ensure compliance with relevant safety laws and

standards.

All electrical work must be carried out in a safe manner by a qualified

person in compliance with applicable national regulations.

Caution

• The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in

manufacturing industries.

If considering using the product in other industries, consult SMC

beforehand and exchange specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

2 Specifications

Fluid

Air

2 position single

0.15 to 0.7

Operating

pressure range

2 position double

-100 kPa to 0.7

[MPa]

3 position

-100 kPa to 0.7

(0.7 x P + 0.1) to 0.7 P:

2 position single

Pilot pressure

Operating pressure range

Note 1)

range

2 position double

0.1 to 0.7

[MPa]

3 position

0.2 to 0.7

Ambient and fluid temperature [° C]

-10 to +60 (no freezing)

Manual override (Manual operation)

Non-locking push type

Maximum

2 position single

5

operating

2 position double

5

frequency (Hz)

3 position

3

Minimum operating frequency

1 cycle/30days

Lubrication

Not required (refer to 3.4)

Mounting orientation

Unrestricted

Note 2)

2

Impact/Vibration resistance

[m/s

]

150 / 30

Air quality

5µm filtration or smaller

2 Specifications – continued

Flow

Complies with the basic and

Note 3)

Standards

well-tried safety principles of

ISO 13849-2:2012

2 Position single

Note 4)

B

10

3 Position

2 Position single

Note 4)

B

10D

and

3 Position

Table 1

Notes:

Note 1) In case of single type, be certain that pressure within operating

pressure range be supplied to supply port, because return

pressure is introduced from supply port {1(P)} for activation.

Note 2) Impact resistance: No malfunction resulted from the impact test

using a drop impact tester. The test was performed on the axis

and right angle directions of the main valve and armature, when

pilot signal is ON and OFF. (Value in the initial state)

Vibration resistance: No malfunction occurred in one sweep test

between 45 and 2000 Hz. Test was performed to axis and right

angle directions of the main valve and armature when pilot

signal is ON and OFF. (Value in the initial state)

Note 3) For validated variants refer to section 5 "How to Order".

Note 4) Under SMC test conditions. The B

figure is estimated from

10

SMC life tests. The B

figure is derived from B

10D

assumption in EN ISO 13849-1:2015 Annex C. Contact SMC for

details.

2.1 Flow characteristics

1 → 4/2 (P → A/B)

Model

3

C [dm

/(s·bar)]

b

SYA3000

1.0

0.30

SYA5000

2.4

0.41

SYA7000

4.9

0.29

Table 2

4/2 → 5/3 (A/B → EA/EB)

Model

3

C [dm

/(s·bar)]

b

SYA3000

1.1

0.30

SYA5000

2.8

0.29

SYA7000

4.5

0.27

Table 3

Note: The values given in Table 2 and Table 3 vary depending on the

different types of actuation and selected port size. Refer to the

catalogue for full details.

2.2 Pilot Pressure Range (Single pilot)

Pilot pressure

range

Operating pressure [MPa]

Figure 1

2 Specifications – continued

Refer to 2.1

2.3 Symbols

2 position single

47 million cycles

27 million cycles

94 million cycles

54 million cycles

3 position closed

3 position exhaust

center

Note) Refer to section "8 Limitations of Use" for valves with air return or

combined air/spring return spool.

2.4 Manual Override Operation

• Non-locking push type [Standard]

using the

10

Press in the direction of the arrow.

Cv

0.24

0.64

1.2

Cv

Special products might have specifications different from those shown

0.26

in this section. Contact SMC for specific drawings. These drawings will

0.66

give the appropriate specification details and compliance with the safety

1.1

principles of ISO 13849, if applicable.

3 Installation

3.1 Installation

• Do not install the product unless the safety instructions have been

read and understood.

• If air leakage increases or equipment does not operate properly,

stop operation.

Check mounting conditions when the air supply is connected. Initial

function and leakage tests should be performed after installation.

• Ensure sufficient space for maintenance activities.

When installing the products, allow access for maintenance.

• Operation in a vacuum condition

When a valve is used for switching a vacuum, take measures to

install a suction filter or similar to prevent external dust or other

foreign matter from entering inside the valve.

In addition, at the time of vacuum adsorption, be sure to vacuum at

all times. Failure to do so may result in foreign matter sticking to the

adsorption pad, or air leakage causing the workpiece to drop.

• Regarding a vacuum switch valve and a vacuum release valve

If a non-vacuum valve is installed in the middle of piping system

having a vacuum, the vacuum condition will not be maintained. Use a

valve designed for use under vacuum condition.

3.2 Environment

• Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

• Do not use in an explosive atmosphere.

2 position double

3 position pressure

center

center

Figure 2

Warning

Figure 3

Caution

Warning

Warning

Page 1 of 3

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for SMC Networks SYA5000 Series

- Page 1 SY3000-TFS01EN 1 Safety Instructions - continued 2 Specifications – continued 2 Specifications – continued ORIGINAL INSTRUCTIONS • Only personnel with appropriate training should operate Flow Refer to 2.1 2.3 Symbols machinery and equipment. Complies with the basic and 2 position single 2 position double Note 3) The product specified here may become unsafe if handled...

- Page 2 SY3000-TFS01EN 3 Installation – continued 3 Installation – continued 4 Settings – continued • About using the 2 position double type • Do not expose to direct sunlight. Use a suitable protective cover. Nylon tubing within ±0.1 mm When using the 2 position double type for the first time, actuators •...

- Page 3 SY3000-TFS01EN 6 Outline Dimensions (mm) 8 Limitations of Use – continued 9 Contacts Refer to the catalogue. Caution • SMC products are not intended for use as instruments for legal SMC Pneumatik GmbH,Girakstrasse 8, AT-2100 AUSTRIA 7 Maintenance Korneuburg, Austria metrology.

Need help?

Do you have a question about the SYA5000 Series and is the answer not in the manual?

Questions and answers