Advertisement

Quick Links

A P A S S I O N

F O R P E R F E C T I O N

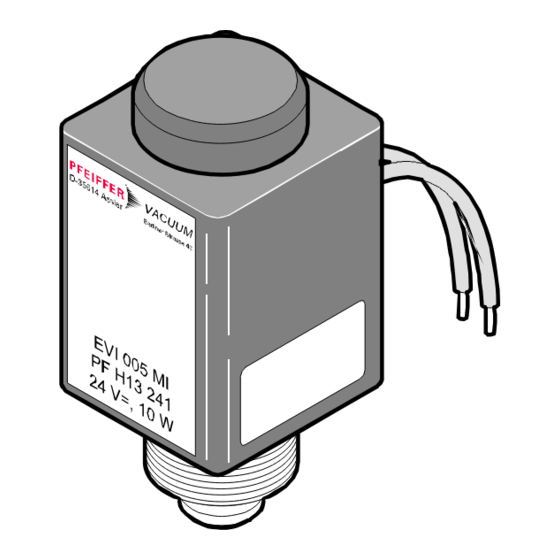

EVI 005 MI

Insert Valve, electromagnetically actuated

Operating Instructions

Product Identification

In all communications with Pfeiffer Vacuum, please specify

the information on the product nameplate. For convenient

reference copy that information into the space provided

below.

D-35614 Asslar

Berliner Strasse 43

V=,

W

Validity

This document applies to products with part number

PF H13 241.

The part number (No.) can be taken from the product name-

plate.

We reserve the right to make technical changes without prior

notice.

Intended Use

The insert valve is predominantly used in fast-cycling vacuum

systems, for example, for gas analysis and coating proc-

esses.

Functional Principle

The EVI 005 MI is opened by the solenoid coil and closed by

the prestressed pressure spring. It will close, or remain

closed, on power loss.

Safety

Symbols Used

DANGER

Information on preventing any kind of physical injury.

Information on preventing extensive equipment and en-

vironmental damage.

Information on correct handling or use. Disregard can lead

to malfunctions or minor equipment damage.

Personnel Qualifications

Skilled personnel

All work described in this document may only be carried

out by persons who have suitable technical training and

the necessary experience or who have been instructed by

the end-user of the product.

General Safety Instructions

• Adhere to the applicable regulations and take the neces-

sary precautions for the process media used.

Consider possible reactions between the materials

(→ "Technical Data") and the process media.

Consider possible reactions of the process media due to

the heat generated by the product.

• Adhere to the applicable regulations and take the neces-

sary precautions for all work you are going to do and con-

sider the safety instructions in this document.

• Before beginning to work, find out whether any vacuum

components are contaminated. Adhere to the relevant re-

Pfeiffer Vacuum, D-35614 Asslar

gulations and take the necessary precautions when hand-

F-No:

ling contaminated parts.

Communicate the safety instructions to all other users.

Liability and Warranty

Pfeiffer Vacuum assumes no liability and the warranty be-

comes null and void if the end-user or third parties

• disregard the information in this document

• use the product in a non-conforming manner

• make any kind of interventions (modifications, alterations

etc.) on the product

• use the product with accessories not listed in the corres-

ponding product documentation.

The end-user assumes the responsibility in conjunction with

the process media used.

Failures due to contamination or wear and tear, as well as

expendable parts (e.g. seals), are not covered by the

warranty.

WARNING

Caution

Technical Data

Version

normally closed

Nominal diameter

5 mm

Threaded connection

M20 × 1

Power specifications

Nominal voltage

24 VDC ±10%

Nominal power

10 W

Duty cycle

100%

(i.e. continuous duty possible)

Degree of protection

IP 65

Mounting orientation

any

1)

Switching frequency max.

300 / min

Cycles to first main-

tenance

2'000'000

>

-9

Tightness

1×10

mbar l/s

-8

Resistance to pressure

1×10

mbar ... 10 bar (absolute)

-8

Operating pressure

1×10

mbar ... 1 bar

Pressure difference

Δ

p

In closing direction

5 bar

In opening direction

1.5 bar

Opens against a pressure

difference Δp

1 bar (with 24 VDC)

1)

Closing time

7 ms

1)

Opening time

30 ms

Temperature

3)

Ambiance

5 °C

... 40 °C

Heat generation

60 °C (after 1¼ hours on con-

tinuous duty and at an ambient

temperature of 25 °C)

Bakeout

120 °C

with idle solenoid coil

(

150 °C

without solenoid coil

(

Materials

Bellows, connection

nut

stainless steel 1.4301

Actuator

stainless steel 1.4105

Seals

FPM

Weight

0.2 kg

1)

With pressure difference Δp = 0 bar.

2)

Under clean operating conditions.

If the valve is operated under harsh or dirty conditions, it

should be cleaned / maintained before the specified service

time to maintenance has been reached.

3)

–15 °C, if the ambiance is free of condensable gases.

Dimensions [mm]

300

32

0.38 mm

2

(AWG 22)

M20×1

Recommended flow direction

Electrical connection

Protective lid (vacuum connection)

2)

)

)

Advertisement

Summary of Contents for Pfeiffer Vacuum EVI 005 MI

- Page 1 (e.g. seals), are not covered by the esses. warranty. Functional Principle The EVI 005 MI is opened by the solenoid coil and closed by the prestressed pressure spring. It will close, or remain closed, on power loss.

- Page 2 The armature needs to be in an specific po- sition to be introduced into the guiding tube or Power Connection Installation removed there from. The power connection is established via the two cable strands. Adhere to the local regulations with regard to the Vacuum Connection installation.

- Page 3 Unscrew the guiding tube. Deinstallation Maintenance, Repair The armature and pressure spring can drop Under clean operating conditions the product requires no out. Be careful when removing the guiding maintenance during the rated cycle life. DANGER tube. Failures due to contamination or wear and tear, as DANGER: contaminated parts well as expendable parts (e.g.

- Page 4 Products returned to Pfeiffer Vacuum should preferably be free of harmful substances. Ad- here to the forwarding regulations of all involved countries and forwarding companies and en-...

Need help?

Do you have a question about the EVI 005 MI and is the answer not in the manual?

Questions and answers