Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hitachi air Core 700

- Page 1 – OPERATION INSTALLATION & MAINTENANCE MANUAL – SINGLE SPLIT INVERTER SERIES INDOOR UNITS MODELS CEILING SUSPENDED TYPE PPFC-2.0UFA1NQ PPFC-2.5UFA1NQ PPFC-3.0UFA1NQ PPFC-4.0UFA1NQ PPFC-5.0UFA1NQ PPFC-6.0UFA1NQ Scan the code to get the electronic manual. EN INSTRUCTION MANUAL P02132Q...

- Page 2 IMPORTANT NOTICE • Hitachi pursues a policy of continuous improvement in design and performance of products. The right is therefore reserved to vary specifications without notice. • Hitachi cannot anticipate every possible circumstance that might involve a potential hazard. •...

- Page 3 DANGER • Do not install pipe work with diameters that are not specified for that model. • Do not ground units to water pipes, gas pipes, telephone wires, or lightning rods as incomplete grounding can cause a severe shock hazard resulting in severe injury or death. Additionally, grounding to gas pipes could cause a gas leak and potential explosion causing severe injury or death.

- Page 4 supervision or instruction concerning use of the appliance in a safe way and understand the hazards involved. Cleaning and user maintenance shall not be made by children without supervision. • Wear adequate personal protective equipment (protective gloves, safety glasses,…) when installing, maintaining or servicing the system.

- Page 5 Precuations for R32 This air conditioner uses R32 flammable refrigerant. Air conditioner with R32 refrigerant, if not be treated carefully, may cause serious harm to the human body or surrounding things. Please read the following instructions carefully before installing, using and maintaining. WARNING •...

- Page 6 ○ Computers and other high electrostatic appliances. ○ Sockets that plug frequently. • Installation, maintenance, service, repairing, removing and disposal operations, shall only be performed by the qualified personnel or recommended by the manufacturer. • Every working procedure that affects safety means shall only be carried out by competent persons. Examples for such working procedures are: ○...

- Page 7 ○ Marking to the equipment continues to be visible and legible. Markings and signs that are illegible shall be corrected. ○ Refrigerating pipe or components are installed in a position where they are unlikely to be exposed to any substance which can corrode refrigerant containing components, unless the components are constructed of materials which are inherently resistant to being corroded or are suitably protected against being so corroded.

- Page 8 Hoses or lines shall be as short as possible to minimise the amount of refrigerant contained in them. ○ Cylinders shall be kept in an appropriate position according to the instructions. ○ Ensure that the refrigerating system is earthed prior to charging the system with refrigerant. ○...

- Page 9 Please contact your local agent, as the occasion arises. Hitachi’s liability shall not cover defects arising from the alteration performed by a customer without Hitachi’s consent in a written form.

-

Page 10: Table Of Contents

Table of Contents Operation Manual 1. Safety Summary ............................1 2. System Description ............................2 3. Before Operation ............................2 4. Operation Method ............................2 5. Setting of Automatic Swing Louver .......................2 5.1 Common ..............................2 6. Filter Cleaning ..............................3 6.1 Taking Out the Filter ..........................3 6.2 Clean the Filter ............................3 6.3 Reset of Filter Indication ..........................3 7. -

Page 11: Operation Manual

1. Safety Summary Operation Manual 1. Safety Summary DANGER • Do not pour water into the indoor or outdoor unit. This product contains electrical components and if wet, can cause serious electrical shock. • Do not tamper with or adjust safety devices inside the indoor unit or outdoor unit. If these devices are tampered with or readjusted, it may cause a serious accident. -

Page 12: System Description

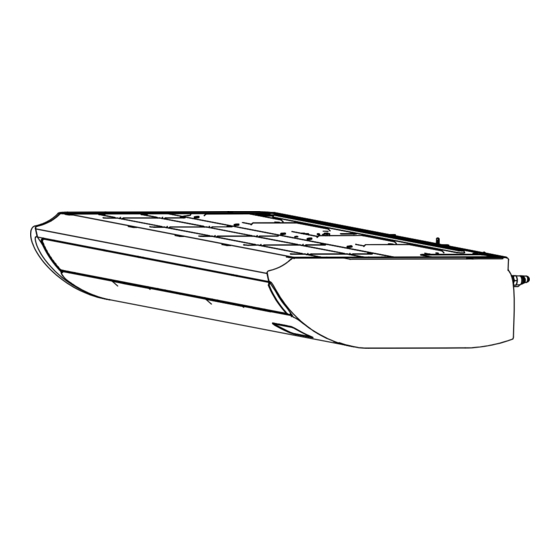

2. System Description 2. System Description The heat pump air conditioner is designed to offer cooling, heating, dehumidification and fan operations. These operation modes are controlled by the remote control switch. Table 2.1 Indoor Unit Type List Standard Capacity (HP) Indoor Unit Type Ceiling Suspended Type ○... -

Page 13: Filter Cleaning

6. Filter Cleaning 6. Filter Cleaning CAUTION • Do not operate the system without the air filter to protect the indoor unit heat exchanger against being clogged. Turn Off the main power switch before taking out the filter. (The previous operation mode may appear.) 6.1 Taking Out the Filter The indication, “FILTER”... -

Page 14: Not Cooling Or Heating Well

7. Troubleshooting 7.3 Not Cooling or Heating Well • Check for obstruction of air flow of the outside or inside units. • Check if too much heat source exists in the room. • Check if the air filter is clogged with dust. •... -

Page 15: Installation & Maintenance Manual

1. Safety Summary Installation & Maintenance Manual 1. Safety Summary WARNING • Do not perform installation work, refrigerant piping work, drain piping and electrical wiring connection without referring to the installation manual. • Check that the ground wire is securely connected. •... -

Page 16: Transportation And Handling

3. Transportation and Handling 3. Transportation and Handling 3.1 Transportation Transport the product as close to the installation location as practical before unpacking. CAUTION • Do not put any material on the product. 3.2 Handling of Indoor Unit WARNING • Do not insert any objects into the indoor unit and check to ensure that none exists in the indoor unit before the installation and test run. -

Page 17: Indoor Unit Installation

4. Indoor Unit Installation Fixing screw of side cover Hooking Push Fixing screw Plate forward of side cover Hooking Fixing screws Part Push forward of air inlet grille Inside of resin side cover The three hooking parts and one hooking plate Removing the air inlet grille and resin side cover should be mounted when recovering resin side cover. -

Page 18: Factory-Supplied Accessories

4. Indoor Unit Installation 4.1 Factory-supplied Accessories Check to ensure that the following accessories are packed with the indoor unit. NOTE: • If any of these accessories are not packed with the unit, please contact your contractor. Table 4.1 Factory-supplied Accessories Accessory Q'ty Purpose... -

Page 19: Initial Check

4. Indoor Unit Installation 4.2 Initial Check • Install the indoor unit with a proper clearance around it for operation and maintenance working space, as shown in Fig.4.1. (mm) ceiling Min.300 Min.200 Min.100 Min.400 Fig.4.1 Operation and Maintenance Space • Check to ensure that the ceiling or wall has a sufficient strength to hang the indoor unit. -

Page 20: Installation

4. Indoor Unit Installation 4.3 Installation 4.3.1 Mounting of Suspension Bolts Step1 Select final location and installation direction of the indoor unit paying careful attention to the space for the piping, wiring and maintenance. Step2 Mount suspension bolts, as shown in Fig.4.2. *For Concrete Slab *For Steel Beam ceiling or wall... -

Page 21: Refrigerant Piping Work

5. Refrigerant Piping Work 4.3.4 Mounting the Indoor Unit (1) Mount the nuts and washers to the suspension bolts. Suspension Bolt (field-supplied) (mm) Nut (field-supplied) (The nut is unnecessary if the unit is installed against the ceiling) *Washer with Insulation (accessory) Suspension Blacket (attached indoor unit) Washer (accessory) Nut (field-supplied) -

Page 22: Piping Materials

5. Refrigerant Piping Work 5.1 Piping Materials (1) Prepare locally-supplied copper pipes suitable for use with R32 refrigerant and comply with local regulations. (2) Select the piping size from the following table. Table 5.1 Piping Size mm (in.) Model(HP) Gas Piping Liquid Piping 2.0-3.0 Φ... - Page 23 5. Refrigerant Piping Work (c) Piping from Right Side Cover Knock out hole Right resin side cover Knock out hole for drain piping (2) Piping work should be performed under the unit. Open the air inlet grille as is shown in Fig.7.1 of section 1 and remove the side cover as is shown in Fig.3.2 before the piping work.

-

Page 24: Drain Piping

6. Drain Piping CAUTION • Cap the end of the pipe when the pipe is to be inserted through a hole. • Do not put pipes on the ground directly without a cap or vinyl tape at the end of the pipe. Incorrect Correct (5) Evacuation and refrigerant charging procedures should be performed according to “Installation &... - Page 25 6. Drain Piping (2) For Left Side Connection Drain Boss Fan Runner Fan Motor Drain Plug Rear Side Fastener Band Insulation Plug Drain Plug Fig.6.2 Drain Plug Remove the drain plug of the left-side drain boss as indicated in the following procedure. (a) Cut the fastener.

-

Page 26: Electrical Wiring

7. Electrical Wiring (d) Wrap the insulation material around the connecting part. (e) Fasten the drain pipe to the connecting part with the factory-supplied clamp. Hose Clamp Hose Clamp Clamp (accessory) (accessory) (accessory) Thermal Insulation Drain Hose (field-supplied) Drain Boss (accessory) Ensure a downward slope Adhesive is... -

Page 27: General Check

7. Electrical Wiring material to protect the product from any condensate water or pests. • Tightly secure the wires with the cord clamp inside the indoor unit. • Secure the cable of the remote control switch using the cord clamp inside the electrical box. 7.1 General Check (1) Make sure that the field-supplied electrical components (main power switches, circuit breakers, wires, conduit connectors and wire terminals) have been properly selected in accordance with local... - Page 28 7. Electrical Wiring Outdoor Unit Indoor Unit Transmission R,S,C (Transmission) Power Supply Communication cable (220-240V ~50Hz) Power cord (220-240V~50Hz) Wired controller Transmission cable (Insert the transmission cable Earth terminal Earth terminal into the ring core and wrap it Ring core for around ring core) transmission cable (wrap the cable around the ring core)

-

Page 29: Test Run

8. Test Run 8. Test Run Test run should be performed according to “Installation & Maintenance Manual” of the outdoor unit or wired remote controller. WARNING • Do not operate the system until all need to add a table with the checks to be made. (a) Check to ensure that the electrical resistance is more than 1 megohm, by measuring the resistance between ground and the terminal of the electrical parts. -

Page 30: Setting Of Dip Switches

10. Common • Use a shielded cable for the transmitting circuit and connect it to ground. • In the case that power cables are connected in series, add each unit maximum current and select wires below. Current i (A) Wire Size (mm i≤6 6<i≤10 10<i≤16... - Page 31 10. Common (d) Capacity Code Setting (DSW3) This dip switch is utilized for setting the capacity code which corresponds to the Horse Power of the indoor unit. DSW3 Factory setting: (e) Refrigerant Cycle No. Setting (DSW5) Setting is required. DSW5 Factory setting: DSW5 can be set from 0 to 63.

- Page 32 Ring Core 1184168 Hitachi-Johnson Controls Air Conditioning, Inc. Add: 1-16-1, Kaigan Minato-ku, Tokyo, Japan Specifications in this catalogue are subject to change without notice, in order that Hitachi-Johnson Controls may bring the latest innovations to customers. 2023.10 Printed in China...

Need help?

Do you have a question about the air Core 700 and is the answer not in the manual?

Questions and answers