Table of Contents

Advertisement

1

INTRODUCTION

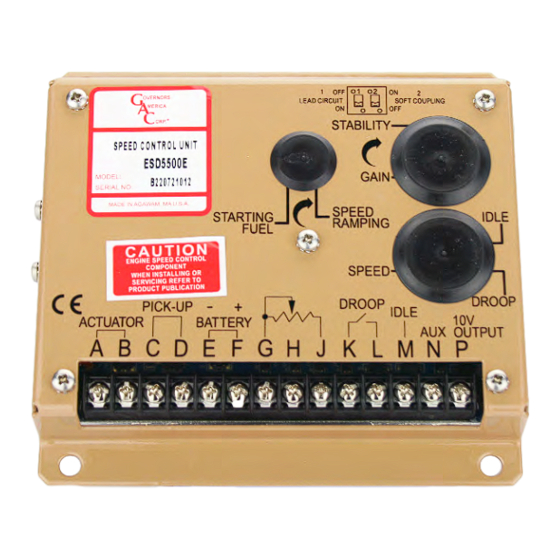

The ESD5500E Series Speed Control Unit is an all-electronic device designed to control

engine speed quickly and precisely in response to transient load changes.

The ESD5500E controls a wide variety of engines in isochronous or droop mode when

connected to a proportional electric actuator and magnetic speed sensor. The ruggedly

built ESD5500E series is designed to withstand the engine environment. Light-Force

variations are available.

moDeL

ESD5500E

Multi-VDC / Standard Unit

ESD5520E

Multi-VDC / Light-Force (Low-Current Optimized PID) / Enhanced Droop

Multi-VDC / Light-Force (Low-Current Optimized PID) / Enhanced Droop

ESD5522E

for Cummins EFC Forward Acting (Normally Closed)

Multi-VDC / Light-Force (Low-Current Optimized PID) / Anti-Windup

ESD5526E

Circuit (Gaseous) / Recommended for T1/T2 ATBs

Multi-VDC / Anti-Windup Circuit (Gaseous) / Recommended for T3/T4

ESD5528E

ATBs

2

SPECIFICATIONS

Performance

Isochronous Operation

Speed Range / Governor

Speed Drift with Temperature

Idle Adjust Clockwise

Idle Adjust Counterclockwise

Droop Range

Droop Adjust Maximum

(K-L jumpered)

Droop Adjust Minimum

(K-L jumpered)

Speed Trim Range

Remote Variable Speed

Range

Terminal Sensitivity

J

L

N

P

InPut / outPut

DC Supply

Polarity

Power Consumption

Speed Signal Range

Speed Sensor Signal

Actuator Current Range**

(77°F (25°C))

* Protected against short circuit to actuator (shuts off current to actuator), unit automatically turns on when short is removed.

** Protected against reverse voltage by a series diode. A 15 A fuse must be installed in the positive battery lead.

ESD5500E Series

Speed Control Unit

DeScrIPtIon

± 0.25 % or better

1 - 7.5 kHz Continuous

±1 % MAX

60 % of Set Speed

Less than 1200 Hz

1 - 5 % regulation

400 Hz ±75 Hz per 1.0 A change

15 Hz ±75 Hz per 1.0 A change

500 - 7.5 kHz

100 Hz ±15 Hz/Volt @ 5.0 kΩ Impedance

735 Hz ±60 Hz/Volt @ 65.0 kΩ Impedance

148 Hz ±10 Hz/Volt @ 1 MΩ Impedance

10 V DC Supply @ 20 mA MAX

12 V DC and 24 V DC Battery Systems

Transient and Reverse Voltage Protected*

Negative Ground (Case Isolated)

50 mA continuous plus actuator current

1.0 - 50 V AC

1.0 - 120 V RMS

Minimum 1.0 A

Nominal 7.0 A

Peak 10.0 A

Vibration

Testing

Ambient Temperature

Relative Humidity

All Surface Finishes

Agency

± 200 Hz

Dimension

Weight

Mounting

1

Governors America Corp. © 2021 Copyright All Rights Reserved

reLIaBILItY

100 % Functionally Tested

envIronmentaL

-40° to 85 °C [-40° to 180 °F]

Fungus Proof, Corrosion Resistant

comPLIance / StanDarDS

CE (EN55011, EN50081-2, EN50082-2),

RoHS, Lloyds Register,

DNV/GL, Bureau Veritas

PHYSIcaL

See Wiring Diagram and Outline

Any position, vertical preferred

ESD5500E Series Speed Control Unit 2-2021-F2 PIB1002

1 g @ 20-100 Hz

up to 95 %

1.20 lbf [0.54 kgf]

Advertisement

Table of Contents

Summary of Contents for GAC ESD5522E

- Page 1 Multi-VDC / Standard Unit ESD5520E Multi-VDC / Light-Force (Low-Current Optimized PID) / Enhanced Droop Multi-VDC / Light-Force (Low-Current Optimized PID) / Enhanced Droop ESD5522E for Cummins EFC Forward Acting (Normally Closed) Multi-VDC / Light-Force (Low-Current Optimized PID) / Anti-Windup ESD5526E...

- Page 2 INSTAllATION & OUTlINE DIAgRAm reaD tHIS entIre GuIDe Before Per- formInG an InStaLLatIon. Vertical orientation allows fluids to drain in moist environ- ments. Avoid Extreme Heat Mount in a cabinet, engine enclosure, or sealed metal box. Dimensions [mm] WIRINg ESD5500E Series Speed Control Unit 2-2021-F2 PIB1002 Governors America Corp.

-

Page 3: Terminal Definition

Load Sharing/Synchronizing, 0-10 V DC (5V Nominal, Reversed, 148 Hz/V). Shielded cabling recommended. Accessory Power Supply 10 V DC Output To Power GAC Load Sharing and Synchronizing Modules aDDInG a PotentIometer Use a single remote speed adjustment potentiometer to adjust engine speed. - Page 4 ADJUSTmENTS BEFORE ENgINE STARTUP Make sure the following adjustments are set before starting the engine. GAIN Middle Position STABILITY Middle Position SPEED TRIM CONTROL Middle Position STARTING FUEL Full CW (MAX fuel) SPEED RAMPING Full CCW (fastest) START ThE ENgINE The speed control unit governed speed setting is factory set at approximately engine idle speed.

- Page 5 STARTINg FUEl ADJUSTmENT The engine’s exhaust smoke at start-up can be minimized by complet- ing the following adjustments: Place the engine in idle by connecting Terminals M and G. Adjust the IDLE speed for as low a speed setting as the appli- cation allows.

- Page 6 SuPPLY The +10 volt regulated supply, Terminal P, can be utilized to provide power to GAC governor system accessories. Up to 20 mA of current can be drawn from this supply. Ground reference is Terminal G.

-

Page 7: Conversion Formulas

An additional fixed resistor may be placed across the potentiometer to obtain the exact desired range. Connect the speed note range potentiometer as shown to the right using Terminals G and J. Contact GAC for assistance if you experience difficulty obtaining the desired variable speed governing performance. -

Page 8: Troubleshooting

TROUBlEShOOTINg If the engine governing system does not function, the fault may be determined by performing the voltage tests described in Steps 1 through 4. Positive (+) and negative (-) refer to meter polarity. Should normal values be indicated during troubleshooting steps, and then the fault may be with the actuator or the wiring to the actuator. - Page 9 TROUBlEShOOTINg (CONTINUED) unSatISfactorY Performance SYmPtom cHecK ProBaBLe cauSe After the actuator goes to full fuel, disconnect the speed sensor at Terminal C and D. If the actuator Do Not Crank. Apply DC is still at full fuel-speed then the speed control unit is defective. power to the governor system.

Need help?

Do you have a question about the ESD5522E and is the answer not in the manual?

Questions and answers