Summary of Contents for Inficon BPG400-SD

- Page 1 (217) 352-9330 | Click HERE Find the Inficon BPG400 DN 40 CF-R at our website:...

- Page 2 Operating Manual Bayard-Alpert Pirani Gauge BPG400 BPG400-SD BPG400-SP BPG400-SR RS485 tina03e1-b (2004-02) Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

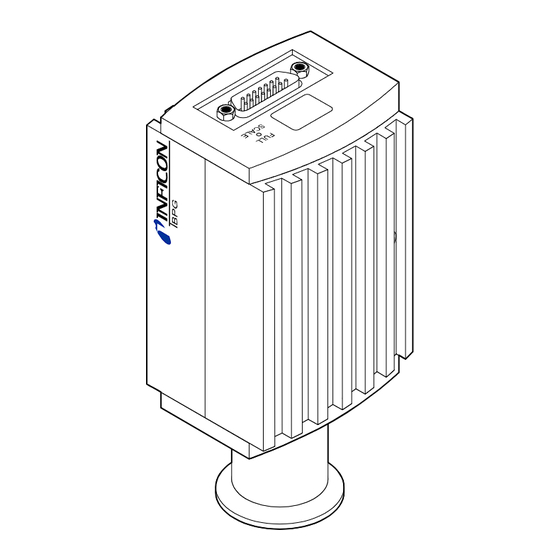

Page 3: Product Identification

Product Identification In all communications with INFICON, please specify the information on the product nameplate. For convenient reference copy that information into the space provided below. INFICON AG, LI-9496 Balzers Model: Validity This document applies to products with the following part numbers:... -

Page 4: Functional Principle

Functional Principle Over the whole measuring range, the gauge has a continuous characteristic curve and its measuring signal is output as logarithm of the pressure. The gauge functions with a Bayard-Alpert hot cathode ionization measurement system (for p < 2.0×10 mbar) and a Pirani measurement system (for p >... -

Page 5: Table Of Contents

3.1.2 Installing the Optional Extension 3.1.3 Using the Optional Baffle 3.2 Electrical Connection 3.2.1 Use With INFICON VGC103 or VGC40x Vacuum Gauge Controller 3.2.2 Use With Other Controllers 3.2.2.1 Making an Individual Sensor Cable 3.2.2.2 Making a DeviceNet Interface Cable (BPG400-SD) 3.2.2.3 Making a Profibus Interface Cable (BPG400-SP) - Page 6 5 Deinstallation 6 Maintenance, Repair 6.1 Maintenance 6.1.1 Cleaning the Gauge 6.2 Adjusting the Gauge 6.2.1 Adjustment at Atmospheric Pressure 6.2.2 Zero Point Adjustment 6.3 What to Do in Case of Problems 6.4 Replacing the Sensor 7 Options 8 Spare Parts 9 Storage 10 Returning the Product 11 Disposal...

-

Page 7: Safety

1 Safety 1.1 Symbols Used DANGER Information on preventing any kind of physical injury. WARNING Information on preventing extensive equipment and environmental damage. Caution Information on correct handling or use. Disregard can lead to malfunctions or mi- nor equipment damage. Notice Hint, recommendation The result is O.K. -

Page 8: General Safety Instructions

Communicate the safety instructions to all other users. 1.4 Liability and Warranty INFICON assumes no liability and the warranty becomes null and void if the end- user or third parties • disregard the information in this document •... -

Page 9: Technical Data

The gauge must only be connected to power supplies, instruments or control devices that conform to the requirements of a grounded extra- low voltage (SELV-E according to EN 61010). The connection to the gauge has to be fused (INFICON-controllers fulfill these requirements). tina03e1-b (2004-02) BPG400 v1.om... - Page 10 BPG400 BPG400-SD, -SP, -SR ≤18 W Fuse necessary 1.25 AT BPG400-SD requires an additional, separate power supply for the DeviceNet interface (→ 22). Supply voltage at the DeviceNet con- nector, (Pin 2 and Pin 3) +24 VDC (+11 … 25 VDC) Power consumption <2 W...

- Page 11 Pin 13 RxD (Receive Data) Pin 14 Pin 5 (Function and communication protocol of the RS232C interface → DeviceNet interface Fieldbus name DeviceNet (BPG400-SD) Standard applied → → Communication protocol, data format [1], [4] Interface, physical CAN bus Data rate (adjustable via "RATE"...

- Page 12 RS485 interface Fieldbus name RS485 (BPG400-SR) Data rate 300 … 28'800 Baud Device address (Adjustable via hexadecimal "ADDRESS", "MSD", "LSD" switches) 00 … 7F (0 … 127 ), (→ RS485 connection D-Sub, 9 pins, male Cable shielded RS485 cable (→ Cable length ≤100m Vacuum...

- Page 13 Dimensions Part number Part number 353-500 353-502 353-501 353-503 353-505 353-506 353-509 353-513 (353-507) (353-508) 4-40UNC 2B 4-40UNC 2B DN 25 ISO-KF DN 40 CF-R Gauges with DeviceNet connector are 14 mm longer. The other dimensions of housing and vacuum connection are identical. Part number 353-507 353-508...

-

Page 14: Installation

3 Installation 3.1 Vacuum Connection DANGER Caution: overpressure in the vacuum system >1 bar Injury caused by released parts and harm caused by escaping process gases can result if clamps are opened while the vacuum system is pressurized. Do not open any clamps while the vacuum system is pressurized. Use the type of clamps which are suited to overpressure. -

Page 15: Removing And Installing The Electronics Unit

Make the flange connection to the vacuum system, preferably without applying vacuum grease. When installing the gauge, make sure that the area around the con- nector is accessible for the tools required for adjustment while the gauge is mounted (→ 44, 47). - Page 16 Remove the electronics unit without twisting it. Removal of the electronics unit is completed. Installing the electronics unit Place the electronics unit on the sensor (3) (be careful to correctly align the pins and notch (4)). Slide the electronics unit in to the mechanical stop and lock it with the hexa- gon socket set screw (1).

-

Page 17: Installing The Optional Extension

3.1.2 Installing the Optional With the optional extension (→ 52) the sensor can also be baked during opera- Extension tion at temperatures up to 150 °C (only at p<10 mbar because at high tempera- tures, the accuracy of the Pirani sensor decreases). Caution Caution: rising heat The electronics unit of gauges that are installed vertically, above the... -

Page 18: Using The Optional Baffle

Slide the electronics unit (2) in to the mechanical stop (be careful to cor- rectly align the pins and notch (4a)). Secure the electronics unit (2) with the hex socket set screw (1) using an Allen key, size 2.5 mm. The extension is now installed. - Page 19 Carefully place the baffle onto the sensor opening. Using a pin, press the baffle down in the center until it catches. The baffle is now installed (Installation of the gauge → 13). Deinstallation Using a pin, press the baffle down in the center until it catches. The new baffle is now installed (Installation of the gauge →...

-

Page 20: Electrical Connection

3.2 Electrical Connection 3.2.1 Use With INFICON If the gauge is used with an INFICON VGC103 or VGC40x controller, a corre- VGC103 or VGC40x sponding sensor cable is required (→ [10]). The sensor cable permits supplying the gauge with power, transmitting measurement values and gauge statuses, and Vacuum Gauge making parameter settings. -

Page 21: Making An Individual Sensor Cable

BPG400-SR) is normally transmitted via DeviceNet, Profibus or RS485. The sensor cable is required for supplying all BPG400 types with power. In connection with the gauges with fieldbus interface (BPG400-SD, BPG400-SP and BPG400-SR), it also permits access to the relay con- tacts of the switching functions (→... - Page 22 Sensor cable connection BPG400-SD, BPG400-SP, BPG400-SR BPG400-SD, -SP, -SR Threshold value, SP A Threshold value, SP B SP A SP B RS232 Degas Degas 1.25 AT Measuring signal 42 kΩ Identification Electrical connection Pin 1 Relay Switching function A, COM contact Pin 2 Signal output (measuring signal) 0 …...

-

Page 23: Making A Devicenet Interface Cable (Bpg400-Sd)

The gauge can now be operated via analog and RS232C interface. 3.2.2.2 Making a DeviceNet For operating BPG400-SD via DeviceNet, an interface cable conforming to the Interface Cable DeviceNet standard is required. (BPG400-SD) If no such cable is available, make one according to the following indications. -

Page 24: Making A Profibus Interface Cable (Bpg400-Sp)

Plug the DeviceNet (and sensor) cable connector into the gauge. DeviceNet cable Sensor cable Lock the DeviceNet (and sensor) cable connector. The gauge can now be operated via DeviceNet interface ( → 34). 3.2.2.3 Making a Profibus For operating BPG400-SP via Profibus, an interface cable conforming to the Interface Cable Profibus standard is required. -

Page 25: Making A Rs485 Interface Cable (Bpg400-Sr)

Plug the Profibus (and sensor) cable connector into the gauge. Sensor cable Profibus cable Lock the Profibus (and sensor) cable connector. The gauge can now be operated via Profibus interface ( → 36). 3.2.2.4 Making a RS485 For operating BPG400-SR via RS485 bus, a suitable interface cable is required. Interface Cable If no such cable is available, make one according to the following indications. -

Page 26: Using The Optional Power Supply (With Rs232C Line)

Plug the RS485 (and sensor) cable connector into the gauge. Sensor cable RS485 cable Lock the RS485 (and sensor) cable connector. The gauge can now be operated via RS485 interface ( → 37). 3.2.3 Using the Optional Power The optional 24 V power supply ( → 52) allows RS232C operation of the BPG400 Supply (With RS232C gauge with any suitable instrument or control device (e.g. - Page 27 Connecting the power supply Connect the gauge to the power supply and lock the connector with the screws. Connect the RS232C line to the instrument or control device and lock the connector with the screws. RS232C Power supply Mains BPG400 Connect the power supply to the mains.

-

Page 28: Operation

4 Operation 4.1 Measuring Principle, The BPG400 vacuum gauges consist of two separate measuring systems (hot cathode Bayard-Alpert (BA) and Pirani). Measuring Behavior Bayard-Alpert The BA measuring system uses an electrode system according to Bayard-Alpert which is designed for a low x-ray limit. The measuring principle of this measuring system is based on gas ionization. -

Page 29: Operational Principle Of The Gauge

Schematic Pirani sensor The bridge voltage U is a measure for the gas pressure and is further processed electronically (linearization, conversion). Measuring range The BPG400 gauges continuously cover the measuring range 5×10 mbar … 1000 mbar. • The Pirani constantly monitors the pressure. •... -

Page 30: Putting The Gauge Into Operation

4.3 Putting the Gauge Into When the operating voltage is supplied ( → Technical Data), the output signal is available between Pin 2 (+) and Pin 12 (–) of the sensor cable connector Operation (Relationship Output Signal – Pressure → Appendix A). Allow for a stabilizing time of approx. -

Page 31: Display (Bpg400)

4.5 Display (BPG400) The gauges with part number 353-501 and 353-503 have a built-in two-line display with an LCD matrix of 32×16 pixels. The first line shows the pressure, the second line the pressure unit, the function and possible errors. The background illumination is usually green, in the event of an error, it changes to red. -

Page 32: Rs232C Interface

4.6 RS232C Interface The built-in RS232C interface allows transmission of digital measurement data and instrument conditions as well as the setting of instrument parameters. Caution Caution: data transmission errors If the gauge is operated with the RS232C interface and a fieldbus in- terface at the same time, data transmission errors may occur. - Page 33 Status byte Bit 1 Bit 0 Definition Emission off Emission 25 µ A Emission 5 mA Degas Bit 2 Definition 1000 mbar adjustment off 1000 mbar adjustment on Bit 3 Definition 0 ⇔ 1 Toggle bit, changes with every string received correctly Bit 5 Bit 4 Definition...

-

Page 34: Input String (Receive)

Example The example is based on the following output string: Byte No Value The instrument or controller (receiver) interprets this string as follows: Byte No Function Value Comment Length of data (Set value) string Page number BPG400 Emission = off Status Pressure unit = mbar No error... -

Page 35: Devicenet Interface (Bpg400-Sd)

353-507 and 353-508 in connection with other devices that are suited for DeviceNet operation. The physical interface and communication firmware of BPG400-SD comply with the DeviceNet standard ( → [4], [6]). Two adjustable switching functions are integrated in BPG400-SD. The corre- sponding relay contacts are available at the sensor cable connector ( →... -

Page 36: Data Rate Setting

4.7.2.3 Data Rate Setting The admissible data rate depends on a number of factors such as system pa- rameters and cable length → [4], [6]). It can be set on the gauge or pro- grammed via DeviceNet. By means of the "RATE" switch, the data rate can be set to 125 ("1"), 250 ("2") or 500 kBaud ("5"). -

Page 37: Profibus Interface (Bpg400-Sp)

4.8 Profibus Interface This interface allows operation of BPG400-SP with part number (BPG400-SP) 353-505 and 353-506 in connection with other devices that are suited for Profibus operation. The physical interface and communication firmware of BPG400-SP comply with the Profibus standard ( → [7], [5]. -

Page 38: Rs485 Interface (Bpg400-Sr)

4.9 RS485 Interface This interface allows operation of BPG400-SR with part number (BPG400-SR) 353-509 and 353-513 in connection with other devices that are suited for RS485 bus operation. Two adjustable switching functions are integrated in BPG400-SR. The corre- sponding relay contacts are available on the sensor cable connector ( → 21). -

Page 39: Device Address

4.9.2.2 Device Address For unambiguous identification of the gauge in a RS485 bus environment, a device address is required. The device address (base address) setting is primarily made on the gauge. Via RS485 communication, an address offset can be added from the host: Operating device address base address + offset... -

Page 40: Syntax Description

4.9.3 Syntax Description 4.9.3.1 Definitions, Legend In the table "Commands and Responses" ( → 40) the following variables are used: Variable Description Values, range, Operating device 00 … 3F address = 25 µ A Emission current _25UA 5.0MA = 5 mA _20MA = 20 mA modeR... -

Page 41: Commands And Responses

4.9.3.2 Commands and The following table lists all permissible commands of the RS485 host and the cor- Responses responding responses of a BPG400 SR during data transfer. Depending on the operation mode selected (BPG or RIG mode) the BPG400-SR responses may differ. Syntax errors will produce an error message. For each command listed, a programming example is given in the last column where: Command data transmitted by the host... - Page 42 "Commands and Responses" continued: Host Command Host BPG mode RIG mode Programming example and remarks Command syntax Response syntax Response syntax Set + threshold #aaSL+x.xxEsyy CR *aa_PROGM_OK CR → BPG mode T: #02SL+1.00E–04 CR (Setpoint A) (*aa_zMIN_HYS CR) R: *02_PROGM_OK CR Set –...

-

Page 43: Switching Functions

Hysteresis = 10% of threshold • Relays energize when pressure falls below threshold (Same as BPG400-SD/SP, → Threshold voltages can be read by the host using the appropriate commands ( → 41) or measured on the corresponding pins of the gauges 25 pin D-Sub connector ( →... -

Page 44: Programming The Switching Functions

4.9.4.1 Programming the The programming procedure of the switching functions via the RS485 interface im- Switching Functions plemented in the BPG400-SR differs from the one used on BPG400-SD/SP. The table below describes the programming possibilities. Programming Threshold values, Function example relay operation ( →... -

Page 45: Switching Functions (Bpg400-Sd, -Sp, -Sr)

4.10 Switching Functions The gauges BPG400-SD, BPG400-SP and BPG400-SR have two independent, manually settable switching functions. Each switching function has a floating nor- (BPG400-SD, -SP, -SR) mally open relay contact. The relay contacts are accessible at the sensor cable connector ( →... - Page 46 There is no local visual indication of the statuses of the switching func- tions. However, a functional check of the switching functions (On/Off) can be made with one of the following methods: • Reading the status via fieldbus interface → [1] for BPG400-SD, → [2] for BPG400-SP, → 41 for BPG400-SR. •...

-

Page 47: Deinstallation

5 Deinstallation DANGER Caution: contaminated parts Contaminated parts can be detrimental to health and environment. Before beginning to work, find out whether any parts are contaminated. Adhere to the relevant regulations and take the necessary precautions when handling contaminated parts. Caution Caution: vacuum component Dirt and damages impair the function of the vacuum component. -

Page 48: Maintenance, Repair

6 Maintenance, Repair 6.1 Maintenance DANGER Caution: contaminated parts Contaminated parts can be detrimental to health and environment. Before beginning to work, find out whether any parts are contaminated. Adhere to the relevant regulations and take the necessary precautions when handling contaminated parts. 6.1.1 Cleaning the Gauge Small deposits on the electrode system can be removed by baking the anode (Degas →... -

Page 49: Zero Point Adjustment

Procedure Gauges BPG400-SD, -SP and -SR are mechanically slightly different from the BPG400. The adjustment opening of BPG400-SD, -SP and -SR is on one side of the gauge housing. However, the adjustment procedure is the same for all gauge versions. -

Page 50: What To Do In Case Of Problems

Required tools • Pin approx. ø1.3 × 50 mm (e.g. a bent open paper clip) Procedure The push button used for the adjustment at atmospheric pressure is also used for the zero point adjustment ( → 47). Operate gauge for approx. 10 minutes at a pressure of ≤ 1×10 mbar. - Page 51 Diagnosis of the fieldbus interface can (BPG400-SD, -SP, -SR) only be done via the superset bus controller ( → [1], [2] or 37). For diagnosis of the BPG400-SD (DeviceNet) gauges, the status lights might pro- duce some useful information ( → 35). tina03e1-b (2004-02) BPG400 v1.om...

-

Page 52: Replacing The Sensor

6.4 Replacing the Sensor Replacement is necessary, when • the sensor is severely contaminated • the sensor is mechanically deformed • the sensor is faulty, e.g. filament of hot cathode broken ( → • the sensor is faulty, e.g. Pirani element broken ( → Required tools / material •... -

Page 53: Options

7 Options Part number 24 VDC power supply / RS232C line ( → 353-511 Extension 100 mm ( → 353-510 Baffle DN 25 ISO-KF / DN 40 CF-R ( → 353-512 8 Spare Parts When ordering spare parts, always indicate: •... -

Page 54: Returning The Product

Contaminated products (e.g. radioactive, toxic, caustic or biological hazard) can be detrimental to health and environment. Products returned to INFICON should preferably be free of harmful substances. Adhere to the forwarding regulations of all involved coun- tries and forwarding companies and enclose a duly completed decla- ration of contamination ( →... -

Page 55: Appendix

Appendix Relationship Output Signal – Pressure (U - 7.75) / 0.75 + c Conversion formulae p = 10 U = 0.75 × (log p - c) + 7.75 where [mbar] [Pa] [Torr] -0.125 Conversion curve Pressure p [mbar] 1E+04 1E+03 1E+02 1E+01 1E+00... -

Page 56: B: Gas Type Dependence

Conversion table Output signal U Pressure p [mbar] [Torr] [Pa] 0.3 / 0.5 Sensor error ( → 0.51 … 0.774 Inadmissible range 0.774 5×10 3.75×10 5×10 1.00 1×10 7.5×10 1×10 1.75 1×10 7.5×10 1×10 1×10 7.5×10 1×10 3.25 1×10 7.5×10 1×10 4.00 1×10... - Page 57 Calibration in pressure range The gas type dependence in the pressure range 10 … 1 mbar can be compen- … 1 mbar sated by means of the following formula: = C × indicated pressure where Gas type Calibration factor C Air, O , CO Water vapor...

-

Page 58: C: Literature

Literature www.inficon.com Communication Protocol DeviceNet™ BPG400-SD tira03e1 INFICON AG, LI–9496 Balzers, Liechtenstein www.inficon.com Communication Protocol Profibus BPG400-SP tira36e1 INFICON AG, LI–9496 Balzers, Liechtenstein www.inficon.com Product descriptions and downloads INFICON AG, LI–9496 Balzers, Liechtenstein www.odva.org Open DeviceNet Vendor Association, Inc. DeviceNet™ Specifications www.profibus.com... -

Page 59: Declaration Of Contamination

Declaration of Contamination The service, repair, and/or disposal of vacuum equipment and components will only be carried out if a correctly completed declaration has been submitted. Non-completion will result in delay. This declaration may only be completed (in block letters) and signed by authorized and qualified staff. Description of product Reason for return Type... - Page 60 Notes tina03e1-b (2004-02) BPG400 v1.om Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 61 LI–9496 Balzers Liechtenstein Tel +423 / 388 3111 Fax +423 / 388 3700 reachus@inficon.com Original: German tina03d1-b (2004-02) www.inficon.com t i na03e1- b Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

Need help?

Do you have a question about the BPG400-SD and is the answer not in the manual?

Questions and answers