Summary of Contents for Inficon Transpector CPM

- Page 1 Cover Page ® Transpector CPM Compact Process Monitor PN 074-641-P1B...

- Page 2 All other brand and product names are trademarks or registered trademarks of their respective companies. Disclaimer The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related to the use of this product.

- Page 3 Declaration Of Conformity Page 1...

- Page 4 Seller product was not designed nor against any defects due to plans or instructions supplied to Seller by or for Buyer. This manual is intended for private use by INFICON® Inc. and its customers. Contact INFICON before reproducing its contents.

-

Page 5: Table Of Contents

Purpose of Transpector CPM ........ - Page 6 Transpector CPM IP Address........3-2...

- Page 7 Show Settings..........3-5 Connecting Transpector CPM ........3-6 3.4.1...

- Page 8 Transpector CPM Operating Manual Chapter 5 Theory and Application Guide Theory of Operation ......... . . 5-1 Sensors .

- Page 9 Transpector CPM Operating Manual 6.3.2 Turbo Molecular Pump ......... 6-6 6.3.2.1...

- Page 10 Introduction..........10-1 10.3 Connecting to Transpector CPM ....... . 10-2 10.4 RGA Configuration—CPM tab .

- Page 11 Transpector CPM Operating Manual 10.6.2.2 Start Parameters ......... . . 10-21 10.6.2.2.1...

-

Page 12: Getting Started

Transpector CPM Operating Manual Chapter 1 Getting Started 1.1 General Safety Information WARNING Transpector CPM is not for use in a manner not specified by INFICON. WARNING - Risk Of Electric Shock There are no user serviceable components within the Transpector CPM case. -

Page 13: Purpose Of Transpector Cpm

Transpector CPM Operating Manual 1.2 Purpose of Transpector CPM Transpector CPM samples a representative fraction of a process environment and directs the gas sample to a Residual Gas Analyzer (RGA). The CPM can detect levels of impurities in process gases at sub-ppm levels. -

Page 14: Using This Operating Manual

Transpector CPM Operating Manual 1.3 Using this Operating Manual Before using this manual, please take a moment to understand the Cautions and Warnings used throughout. They provide pertinent information that is useful in achieving maximum instrument efficiency while ensuring personal safety. -

Page 15: How To Contact Inficon

Authorization (RMA) number must be obtained from the Customer Support Representative. If a package is delivered to INFICON without an RMA number, the package will be held and customer contact will be made. This will result in delays in servicing Transpector CPM. -

Page 16: Transpector Cpm Performance Specifications

Transpector CPM Operating Manual 1.5 Transpector CPM Performance Specifications 1.5.1 General Specifications Table 1-1 General specifications Mass Range (AMU) 1 – 100 1 – 200 1 – 300 Resolution <1 AMU wide @ 10% peak height over entire mass range... - Page 17 Transpector CPM Operating Manual Table 1-1 General specifications (continued) Mass Range (AMU) 1 – 100 1 – 200 1 – 300 Minimum Background 1x10 Torr Pressure (1.3x10 mbar) Maximum Sensor and 150°C Inlet Temperature Ion source pressure reading @ low emission using total pressure lens...

-

Page 18: Hex Block Orifice Sampling Inlets

Transpector CPM Operating Manual 1.5.2 Hex Block Orifice Sampling Inlets Table 1-2 HexBlock inlets and available orifices (maximum nominal pressure for orifice) Inlet Orifices V1 (LP) 3 mTorr (no orifice) 10 mTorr 15 mTorr 100 mTorr 360 mTorr 1 Torr... -

Page 19: Atmospheric Pressure (Capillary) Sampling

Transpector CPM Operating Manual 1.5.3 Atmospheric Pressure (Capillary) Sampling Table 1-3 Capillary sampling option Process Pressure Range 300 to 900 Torr (400 to 1199 mbar) C ambient, no purge) Capillary Size and Lengths 1/16 in. OD x 1.5 m SS capillary 1/16 in. -

Page 20: Physical Requirements

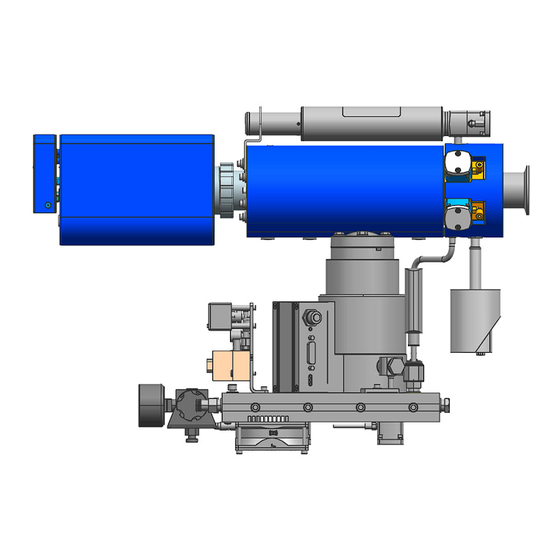

Transpector CPM Operating Manual 1.6 Physical Requirements 1.6.1 Physical Dimensions Figure 1-1 Pumping system dimensions 545 mm (21.5 in.) 152 mm (6.0 in.) 378 mm (14.9 in.) 183 mm 362 mm (7.2 in.) (14.3 in.) Pumping System dimensions 545 x 152 x 378 mm (21.5 x 6.0 x 14.9 in.) CPM Controller dimensions 195 x 207 x 89 mm (7.7 x 8.1 x 3.5 in.) -

Page 21: Weight

Transpector electronics module, the CPM heaters and the pumping system. If enclosing Transpector CPM, the enclosure must be large enough or ventilated to provide adequate cooling airflow to the fan on the Transpector CPM pumping system and the fan in the Transpector CPM controller. -

Page 22: Fuse Rating

Transpector CPM Operating Manual 1.7.1.4 Fuse Rating 3.15 A @ 250 V Interrupt Current 35 A @ 250 V Type T (5 x 20 mm) 1.7.1.5 Overvoltage Category Overvoltage Category II (per EN61010-1:2010) Short Term: 1440 V < 2 seconds ... -

Page 23: Exhaust Gas

Transpector CPM Operating Manual Figure 1-2 Compressed air supply connection Dry Compressed Air 58–100 psi (gauge) Recommended Setting is 75-80 psi (gauge) Dry nitrogen 58–100 psi (gauge) Bearing Purge Corrosive System Only The pressure range is 58–100 psi (gauge) (4–6.9 bar) [400–690 kPa]. -

Page 24: Air Pressure Requirements

Transpector CPM Operating Manual 1.10 Air Pressure Requirements 1.10.1 Required Air Pressure Dry compressed air (or dry nitrogen) is used to operate the electro-pneumatic inlet valves. The minimum air pressure required to operate the inlet valves is 58 psi (gauge) (4 bar) [400 kPa]. Recommended setting is 75-80 psi (gauge) (5.17 to 5.52 bar) [517 kPa to 552 kPa]. -

Page 25: Vacuum Requirements

1.12.1 Use Indoor use only. 1.12.2 Altitude Range Up to an altitude of 2000 m (6561 ft.) Contact INFICON for operation at higher altitudes. 1.12.3 Maximum Humidity 80% relative humidity (no condensation) 1.12.4 Pollution Degree Pollution Degree 2 (per EN61010-1:2001) 1.12.5 Maximum Operating Temperature... -

Page 26: Clean Room Requirements

® Operating Windows 7 or Windows 8 System INFICON can supply a controller to run the software that operates Transpector CPM System. (Refer to section 1.4 on page 1-4.) 1.13.1 Operating System FabGuard Explorer software requires either Windows 7 or Windows 8 for proper operation. -

Page 27: Installation

Chapter 2 Installation 2.1 Installation Overview The Transpector CPM system is partially disassembled for shipping and must be re-assembled prior to operation. The Transpector sensor is shipped inside the CPM manifold tee, but the remaining components such as the Transpector... -

Page 28: Transpector Electronics Module, Heat Guard, And Cable Box Installation

Transpector CPM Operating Manual 2.2 Transpector Electronics Module, Heat Guard, and Cable Box Installation The Transpector electronics module and cable box must be mounted in an area where the ambient temperature does not exceed 50°C (122°F) and there is ample air flow. -

Page 29: Attach Heat Guard

Transpector CPM Operating Manual 2.2.2 Attach Heat Guard To decrease the risk of burns when the heating jacket is on, a heat guard is provided for the metal surfaces between the Transpector electronics box and the CPM manifold tee. Loosen the single screw that attaches the calibration reference shipping bracket to remove the bracket. -

Page 30: Attach Cable Box

Transpector CPM Operating Manual 2.2.3 Attach Cable Box The cable box and Transpector electronics module are connected via an Ethernet connection, a 15-pin Aux I/O connection, and a 62-pin extended I/O connection. Three screws are used to stabilize the cable box on the electronics module. -

Page 31: Sniffer Installation

(6.35 mm) nut and vespel ferrule supplied with the sniffer. 2.4 Mounting the Pumping System The Transpector CPM system typically mounts directly to a process chamber via the CF or KF process connection at the end of the Hexblock inlet. Normally there is no need to use an additional isolation valve between the Hexblock and the process chamber. -

Page 32: Installing The Support Kit

Tighten all hardware. Install the safety cap. Figure 2-4 Adjusting leg position Unscrew the adjustable foot until it supports Transpector CPM and relieve pressure from the flange. Tighten the lock nut on the adjustable foot against the support leg. 2 – 6... -

Page 33: Atmospheric Support Frame

Transpector CPM Operating Manual 2.4.2 Atmospheric Support Frame Atmospheric Transpector CPMsystems do not need the standard support legs. An atmospheric system is mounted to a support frame, which also houses the CPM controller. (See Figure 2-5.) Figure 2-5 CPM configured with support frame for atmospheric sampling 2.5 CPM Controller Installation... - Page 34 Transpector CPM Operating Manual The back panel of the CPM controller is shown in Figure 2-6. Connections are shown in Figure 2-8. Figure 2-6 CPM controller rear panel Main Power Fuse Electrical Ground On/Off Input Foreline Heater CPM Interface Power...

-

Page 35: Transpector Cable Box Connections

Transpector CPM Operating Manual 2.6 Transpector Cable Box Connections The cable box mounted on the back of the Transpector electronics module makes cable connections to most of the subcomponents of the CPM System. (See Figure 2-7. Cable connections for the entire CPM system are shown in Figure 2-8.) - Page 36 Transpector CPM Operating Manual Figure 2-8 CPM cable connections Cable Box (Bottom View) CPM Sensor Transpector CPM Heater Jacket Block Inlet 600-1474-P1 600-1475-P1 Turbo Pressure Switch Ethernet Molecular Valve Pump Block 600-1476-P1 Foreline Block 600-1473-P1 1, 3, 5 Or 10 m...

-

Page 37: Cpm Foreline Pump Installation

Transpector CPM Operating Manual 2.7 CPM Foreline Pump Installation The 24 V (dc) dry Foreline Pump has the following connections: Electrical connection to the CPM controller Foreline hose connection from the UHV Turbo Molecular Pump foreline block ... -

Page 38: Connecting Transpector Cpm

IP address, which will result in a loss of communication and loss of data. Transpector CPM follows the IPv4 IP address convention. An example IP address 192.168.1.100 . Each of the four parts is referred to as an “octet”. The IP address consists of a Network Prefix and a Host Protocol. -

Page 39: Subnetworking

NOTE: When connecting to an existing local network, there must be a static IP address for each Transpector RGA. Contact the network administrator for IP address assignments. Two methods of changing the Transpector CPM IP address are available. INFICON Mass Spectrometer Search Utility. (See section 3.3.1.) -

Page 40: Using The Inficon Mass Spectrometer Search Utility To Change The Transpector Cpm Ip Address

3.3.1 Using the INFICON Mass Spectrometer Search Utility to Change the Transpector CPM IP Address The INFICON Mass Spectrometer Search Utility (IMSSU) is located on the software installation disk and the RGA Manuals CD. The IMSSU does not need to be installed. -

Page 41: Change Ip Address

Transpector CPM MAC Address Transpector CPM IP address Change To text box, to enter a new Transpector CPM IP address DHCP On or DHCP Off selection CAUTION Set DHCP Off so the IP address cannot be automatically assigned. -

Page 42: Launch Web Ui

Transpector CPM Operating Manual 3.3.1.2 Launch Web UI Transpector Web UI can be launched from inside of the IMSSU. (Refer to the 074-581-P1 Transpector Web UI Operating Manual.) 3.3.1.3 Find Device Find Device On will flash the power indicator on the device. The indicator will flash for up to 60 seconds and then illuminate. -

Page 43: Connecting Transpector Cpm

When installing a single Transpector CPM on a private network or directly connected to a computer, changing the IP address of Transpector CPM is necessary only if the computer being used to connect to Transpector CPM has a different network prefix than Transpector CPM. -

Page 44: Installing Multiple Transpector Cpm Sensors

Each Transpector CPM is shipped with an identical default IP address. When installing multiple Transpector CPM, the IP address of each Transpector CPM must be changed one at a time so that each Transpector CPM has a unique IP address. (Refer to section 3.3.1, Using the INFICON Mass Spectrometer Search... -

Page 45: Changing The Computer Ip Address

Transpector CPM Operating Manual 3.5 Changing the Computer IP Address An alternative to changing the Transpector CPM IP address is to change the host computer’s IP address to allow for communication between the host computer and Transpector CPM. 3.5.1 Windows 7 NOTE: Changing the IP address of the host computer requires administrator rights. - Page 46 On the network status and tasks window, click Change adapter settings. (See Figure 3-6.) Figure 3-6 Change adapter settings If the host computer is connected directly to Transpector CPM through the Ethernet port of the computer, right-click Local Area Connection and select Properties. (See Figure 3-7.) Figure 3-7 Changing adapter settings 3 –...

- Page 47 Transpector CPM Operating Manual Click Internet Protocol Version 4 (TCP/IPv4). Click Properties. (See Figure 3-8.) Figure 3-8 TCP/IPv4 On the TCP/IPv4 properties window, click Use the following IP address. (See Figure 3-9.) Figure 3-9 Use the following IP address 3 – 10...

- Page 48 Transpector CPM Operating Manual In IP address, type 192.168.1.XXX . The last octet can be any number as long as it is unique to the network and is not the same as the Transpector CPM IP address. (See Figure 3-10.) In Subnet mask, type 2 55.255.0.0...

-

Page 49: How The Cpm System Works

Transpector CPM Operating Manual Chapter 4 How the CPM System Works 4.1 CPM Components A fully configured CPM corrosive pumping system is illustrated in Figure 4-1. (The CPM controller and foreline diaphragm pump are not shown.) Figure 4-1 CPM pumping system components 1 . -

Page 50: Theory Of Operation

Chemical Vapor Deposition (CVD), etch, vacuum furnace analysis, and laser gas analysis. Transpector CPM pressure is the pressure inside the closed ion source (CIS). The nominal operating pressure inside the closed ion source is approximately 2E-4 Torr. Since the conductance between the closed source and the sensor manifold is 0.7 L/s and given the effective pumping achieved using the turbo... -

Page 51: Cpm Aux I/O Connector

Controlling emission through digital inputs bypasses all software and hardware interlocks. When using digital inputs for controlling Transpector CPM emission, develop an interlock that will not allow the emission to turn on if the pressure is too high for operation of Transpector CPM. -

Page 52: One Analog Input

Transpector CPM Operating Manual 4.3.1.4 One Analog Input One analog input is differential and can handle inputs between 0 to +10 volts and common mode voltages of 100 volts. See Table 4-3. Table 4-3 2 analog inputs ANALOG INPUT 1... -

Page 53: Foreline Subsystem

Transpector CPM Operating Manual 4.3.2.1 Foreline Subsystem The foreline subsystem components include a flexible foreline hose of various lengths ( 10 m), a foreline Pirani gauge, and a diaphragm foreline pump. The Foreline Pump produces base pressures (no gas flow) of 2 Torr, significantly less than the 10 Torr needed for the Turbo Molecular Pump operation. -

Page 54: Solenoid Valves

Transpector CPM Operating Manual 4.3.5 Solenoid Valves The solenoid-controlled valves are a group of valves joined together as one manifold assembly which is mounted to a bracket on the Turbo Molecular Pump foreline block. The valves are controlled either by the CPM controller rocker switches or the Valves Aux I/O connector. -

Page 55: Sensor And Transpector Electronics Module Subsystem

Transpector CPM Operating Manual 4.3.6 Sensor and Transpector Electronics Module Subsystem The sensor is a quadrupole partial pressure analyzer that analyzes gases by: Ionizing some of the gas molecules. Separating the ions by mass. Measuring the quantity of ions at each mass. -

Page 56: Application

Transpector CPM Operating Manual 4.4 Application The pumping system reduces the pressure of process gas to a pressure at the ion source which optimizes partial pressure measurements. The pressure reduction orifices produce 2x10 Torr pressure in the closed ion source (CIS). The flow rate... -

Page 57: Sample Inlet Systems And Examples Of Use

Transpector CPM Operating Manual 4.5 Sample Inlet Systems and Examples of Use 4.5.1 Inlet System Figure 4-4 shows the HexBlock inlet. Figure 4-4 HexBlock inlet Table 4-4 Inlet system Hex Block Inlets Part Number Hex Block Inlet with one orifice (V1) and high vacuum (V3) - Page 58 Transpector CPM Operating Manual When both volume and high vacuum pump speed are constant, the orifice hole size determines the pressure at the sensor. Orifices are available in various sizes to cover several pressure ranges. Table 4-5 Table 4-6 show different orifices for low and high pressure range application.

- Page 59 Transpector CPM Operating Manual Table 4-6 Hex Block orifices, sniffers and capillaries (V2 for high pressure, typically process pressure) Size of Orifices, Sniffers and Capillaries Part Number 30 Torr sniffer 923-707-G4 (requires high pressure by-pass, 10 cm length) 300 Torr sniffer...

-

Page 60: High Pressure Sampling: Orifice Bypass (V4)

Transpector CPM Operating Manual 4.5.2 High Pressure Sampling: Orifice Bypass (V4) When process pressures exceed 10 Torr, the process gas is dense enough that the gas molecules collide with each other more often than with the walls of the sampling system. In this transition or viscous flow regime, the time constant for... -

Page 61: Dual-Capillary Sampling Option

Transpector CPM Operating Manual 4.5.3 Dual-Capillary Sampling Option The Dual-Capillary Sampling option reduces the pressure of a process atmosphere ranging 300–1400 Torr to an intermediate pressure that is <10 Torr at the closed ion source. (See Figure 4-6.) The exit orifice to the pumping line limits the flow to the Turbo Molecular Pump and establishes the interstage pressure. -

Page 62: Advice And Tips

Transpector CPM Operating Manual 4.6 Advice and Tips 4.6.1 Achieving Good Base Pressure in the CPM The CPM vacuum manifold must be baked out after initial installation or whenever the RGA sensor is exposed to air. After an eight hour bakeout and cool down, the ... -

Page 63: Theory And Application Guide

Turbo Molecular Pump through fixed geometry pump-in channels. Transpector CPM detects levels of impurities in process gases that are significantly lower—at sub-ppm levels for many components—than those detected by open-ion source RGA analyzers. -

Page 64: The Ion Source

Inside the closed ion source, a heated filament emits electrons which bombard the incoming gas molecules giving them an electrical charge. While this charge may be either positive or negative, Transpector CPM detects only positive ions. Once a molecule is charged (ionized), electric fields can be used to manipulate the molecule. - Page 65 Transpector CPM Operating Manual The term emission current refers to the stream of electrons emitted by the filament. Emission current is controlled by the temperature of the filament. The filament is centered over a hole in the anode cylinder. The potential (voltage) on the anode is positive with respect to the filament.

-

Page 66: The Quadrupole Mass Filter

Transpector CPM Operating Manual 5.2.2 The Quadrupole Mass Filter The ions produced in the ion source are injected into the mass filter, which rejects all ions except those with a specific mass-to-charge ratio. Most ions contain only one unit of charge. The mass filter is a quadrupole, to which is applied a combination of RF and DC potentials. - Page 67 Transpector CPM Operating Manual The following equations summarize the potentials applied to the rods: 2ft 2ft – = RF amplitude = RF frequency = time = DC potential = pole zero. The RF component removes the low-mass ions from the beam. Ions of sufficiently low mass have their motions remain in phase with the applied RF.

-

Page 68: Scanning Characteristics

Transpector CPM Operating Manual The mass of ions transmitted (M) is directly proportional to the RF amplitude (provided f is constant). As the RF amplitude is increased, progressively higher mass ions will be made to oscillate in phase with the RF field and thus gain sufficient energy to strike the poles. -

Page 69: The Zero Blast

Transpector CPM Operating Manual 5.2.2.2 The Zero Blast When the RGA scans over the very low end of the mass spectrum, the RF and DC voltages applied to the rods approach zero. The quadrupole then ceases to act as a filter and a large current of unseparated ions is detected, called the zero blast. -

Page 70: The Ion Detector

Transpector CPM Operating Manual 5.2.3 The Ion Detector The ion detector region of the sensor consists of the quadrupole exit lens, the electron multiplier and the detector itself. The quadrupole exit aperture is biased negatively with respect to the anode, focusing ions that have been transmitted through the quadrupole into the electron multiplier and detector. -

Page 71: The Continuous Dynode Electron Multiplier/Faraday Cup Detector

Transpector CPM Operating Manual 5.2.3.2 The Continuous Dynode Electron Multiplier/Faraday Cup Detector The Continuous Dynode Electron Multiplier/Faraday Cup (CDEM/FC) detector amplifies the electron pulse, significantly increasing the analyzer’s sensitivity. Figure 5-5 CDEM/FC detector Electron Collector CDEM Cone Deflector Shield Signal Output The CDEM/FC detector continuous dynode element is a special type of glass, rather than a discrete dynode EM which is a copper-beryllium alloy. - Page 72 Transpector CPM Operating Manual CAUTION Do not operate the CDEM/FC detector at temperatures above 150°C. Permanent damage may result. CAUTION Avoid output currents in excess of 1 x 10 amps. Either decrease the high voltage or decrease the pressure. Use the minimum CDEM/FC detector voltage required to obtain the necessary peak amplitudes and/or signal-to-noise ratio.

-

Page 73: How To Interpret The Result

Transpector CPM Operating Manual 5.3 How to Interpret The Result Qualitative Interpretation Of Mass Spectra explains how to determine which substances are present in the gas sample being analyzed. (See section 5.3.1.) Quantitative Interpretation of Mass Spectra (Calculating Partial Pressures) ... - Page 74 Transpector CPM Operating Manual Figure 5-6 Air mass spectrum 5 – 12...

-

Page 75: Ionization Process

Transpector CPM Operating Manual 5.3.1.1 Ionization Process When a sufficiently energetic electron strikes a gas molecule, there are many processes that can occur, some of which are summarized in Table 5-1. Table 5-1 Electron Impact Ionization Processes XYZ + e... - Page 76 Transpector CPM Operating Manual Figure 5-7 A nitrogen fragmentation pattern This nitrogen fragmentation pattern shows (14 AMU), (28 AMU), and (29 AMU). In general, peaks from multiple charged species will be less intense than those for the corresponding singly charged ion. For example, the doubly charged peak for argon is typically less than one fifth as intense as the singly charged peak (this intensity ratio is sensitive to the incident electron energy).

-

Page 77: Isotope Ratios

Transpector CPM Operating Manual 5.3.1.2 Isotope Ratios An additional cause of multiple peaks in the mass spectrum of a pure substance is that most elements are comprised of more than one isotope. For example, 99.63% of all nitrogen atoms in nature have a mass of 14 AMU; only 0.37% have a mass of 15 AMU. - Page 78 Transpector CPM Operating Manual Table 5-2 Isotope ratios (continued) Isotope Ratios Element Mass No. Relative Abundance 99.759 0.0374 0.2039 100.0 90.92 0.257 8.82 100.0 100.0 92.27 4.68 3.05 100.0 95.06 0.74 4.18 0.016 75.4 24.6 0.337 0.063 99.600 5 – 16...

-

Page 79: Electron Energy Effects

Transpector CPM Operating Manual 5.3.1.3 Electron Energy Effects The exact fragmentation pattern will depend on the energy of the bombarding electrons. Figure 5-8 graphs the number of argon ions (of different charge states) produced per incident electron per Torr of gas pressure as a function of electron energy. - Page 80 Transpector CPM Operating Manual Sometimes there is a problem with mass spectral overlap—ions with differing chemical composition form chemically distinct source molecules, but with the same mass. For example, there is a problem with detecting small amounts of water vapor in argon, as is often desired when monitoring a PVD process.

-

Page 81: A Qualitative Interpretation Guide

13.5 eV, it is possible to produce the water vapor ion without producing doubly charged argon ions, permitting the detection of water vapor at 18 AMU. The Transpector CPM sensor and electronics can operate at electron energies below 70 eV, with reduced electron emission (200 μA, max.). When monitoring PVD processes, the CPM should be operated at 40 eV with an electron emission current of 200 μA to reduce power to the filament. - Page 82 Transpector CPM Operating Manual Table 5-4 Spectrum interpretation guide AMU # Chemical Symbol Sources water F or hydrogen F hydrogen, deuterium ( hydrogen-deuterium, tritium ( helium No known elements Doubly Ionized C (Rare) N (Rare) O (Rare) No known elements...

- Page 83 Transpector CPM Operating Manual Table 5-4 Spectrum interpretation guide (continued) AMU # Chemical Symbol Sources ethane F or ethanol F or isopropyl alcohol , NO ethane P, nitric oxide P, CH phosphorus, methanol F, oxygen, sulfur, methanol P hydrogen sulfide F...

-

Page 84: Dry Etching Chemistries

Transpector CPM Operating Manual 5.3.1.5 Dry Etching Chemistries Table 5-5 lists materials to be etched, the typical chemistries used, the chemical species that are important, and a list of masses used to monitor each specie. Many different chemistries exist for etching any given film. Only a few of the more... - Page 85 Transpector CPM Operating Manual Table 5-5 Dry etching chemistries (continued) Etched Typical Important Monitored Material Reagents Species Masses W (and alloys) 127, 89, 108 279, 281 18, 17 32, 16 28, 14 257, 259 (TiN liner) 86, 67, 105, 48...

-

Page 86: Tungsten Cvd

Transpector CPM Operating Manual Table 5-5 Dry etching chemistries (continued) Etched Typical Important Monitored Material Reagents Species Masses Si3N4 69, 50, 31 32, 16 85, 66, 47 52, 33, 71 18, 17 47, 66 28, 14 28, 12 Poly-Si 81, 83, 116, 118, 46, 48... -

Page 87: Copper Mocvd

Transpector CPM Operating Manual may be the only indication that water vapor or oxygen are also present, but not detected by the mass spectrometer because of rapid reaction with the tungsten hexafluoride. Table 5-6 Tungsten CVD materials of interest Chemical... -

Page 88: Quantitative Interpretation Of Mass Spectra

Transpector CPM Operating Manual 5.3.2 Quantitative Interpretation of Mass Spectra (Calculating Partial Pressures) Partial pressure is defined as the pressure of a designated component in a gas mixture. By Dalton’s Law, the sum of all the partial pressures is the total pressure. - Page 89 Transpector CPM Operating Manual Fragmentation factors can be calculated from fragmentation patterns given in the general references cited in Chapter 12, Bibliography. Other valuable references include the Index of Mass Spectral Data from ASTM, and EPA/NIH Mass Spectral Data Base by Heller and Milne and an extensive library of spectra is available from the National Institute of Standards and Technology.

- Page 90 Transpector CPM Operating Manual Table 5-8 Typical fragmentation factors for the major peaks of some common substances (at 70eV electron energy) Mass Mass Mass acetone: (CH helium: He oxygen: O 1.00 hydrogen: H 1.00 toulene: C argon: Ar krypton: Kr...

- Page 91 Transpector CPM Operating Manual Ionization probability factors can be approximated by substituting the relative ion gauge sensitivities for various gases. Table 5-9 lists relative ion gauge sensitivities for some common gases. NOTE: Table 5-9 lists relative ionization gauge sensitivities for selected molecules.

- Page 92 Transpector CPM Operating Manual Table 5-9 Ionization Probabilities For Some Common Substances (continued) Substance Formula Relative Substance Formula Relative Ionization Ionization Gauge Gauge Sensitivity Sensitivity cyclohexane propane deuterium 0.35 silver perchlorate AgClO dichlorodifluormethane stannic iodide dichloromethane sulfur dioxide dintrobenzene sulfur hexafluoride...

- Page 93 Transpector CPM Operating Manual The overall relation between partial pressure and ion current, given in equation [8], is quite general. The constants for this equation can be obtained from various tables, but for the best accuracy, they should be measured for each instrument.

-

Page 94: Additional Information For Interpreting Mass Spectra

Transpector CPM Operating Manual 5.3.3 Additional Information For Interpreting Mass Spectra 5.3.3.1 Ion Source Characteristics A closed ion source, and the particular inlet system selected, can have an effect on the mass spectrum obtained. The analyzer itself is a source of gas molecules because of outgassing from its surfaces. -

Page 95: Scanning Characteristics

Transpector CPM Operating Manual for extended periods of time, it is not uncommon for a strong F peak at 19 AMU to remain even after the fluorine containing substance has been removed. When operating in the UHV region, ESD/EID of H... -

Page 96: Fragmentation Factors

Transpector CPM Operating Manual 5.3.3.3 Fragmentation Factors The fragmentation factor is the fraction of the total ion current contributed by ions of the chosen mass. Only peaks contributing at least one percent to the total ion current are included in the list. The sum of the factors for all the peaks in a mass spectrum cannot exceed 1.00. -

Page 97: Operation

Transpector CPM Operating Manual Chapter 6 Operation 6.1 HexBlock The HexBlock provides several inlets, a process pressure gauge (CDG) and a calibration reference. It allows for up to three pressure ranges, including a high conductance inlet that covers various applications such as High Density Plasma Etch (HDP), TiN Deposition such as TDMAT, W CVD, or any other semiconductor process. -

Page 98: Hexblock Inlet

Transpector CPM Operating Manual 6.1.1 HexBlock Inlet V1—Low pressure sampling (LP). Indicates background pressures for some etch or CVD process. (No bypass available.) V2—High pressure sampling (HP). Indicates process pressures for etch, CVD and 300 mm degas sampling. Bypass is optional. -

Page 99: Hex Block Process Connections

Transpector CPM Operating Manual 6.1.1.1 Hex Block Process Connections Table 6-1 Hex block process connections Types of connections Part Number KF25 In-line connection 923-700-G1 KF40 In-line connection 923-701-G1 CF40 In-line connection 923-702-G1 KF25 90 degree elbow connection 923-703-G1 KF40 90 degree elbow connection... -

Page 100: High Mass Fc5311 Tuning Reference

Transpector CPM Operating Manual 6.1.2.1 High Mass FC5311 Tuning Reference The FC5311 Tuning Reference Gas option is available for adjusting peak position for 300 AMU CPMs. It is controlled via a manual valve. FC5311 Tuning Reference Gas is a volatile liquid. It is located at the inlet of the high vacuum pump. -

Page 101: Process Gauge (Cdg)

1000 Torr range 964-208-G14 6.2 Heaters A Transpector CPM software interlock will turn on the heater only when the Turbo Molecular Pump is at normal speed (72,000 RPM). There are two temperature settings: low (90°C); high (150°C). 6.3 Pumping System The pumping system is preconfigured at the factory. -

Page 102: Foreline Pump

6.3.1 Foreline Pump The system controlled Foreline Pump configuration is selected when there is a INFICON supplied Foreline Pump. If a customer supplied foreline pump is used to back other vacuum equipment, a check valve can be used to temporarily isolate the CPM from any short (<10 seconds) pressure bursts that would damage the... -

Page 103: Turbo Molecular Pump Status

72,000 RPM. 6.5.2 Total Pressure Calibration To protect the filament, Transpector CPM has a factory-calibrated total pressure lens that measures the total pressure in the closed ion source. The filament will turn off (within 50 ms) after the pressure in the ion source rises above the total pressure setpoint, typically 1E-3 Torr @ 40 eV 200 A for a CVD closed ion source. -

Page 104: Filament Lifetime

Transpector CPM Operating Manual When operating at high emission (2 mA at 70 eV), the pressure will read approximately 20 times high. Therefore, the over-pressure will trip at a pressure about 20 times lower. Typically, this is not an issue since high emission should only be used when high sensitivity is needed, such as when leak checking a system. - Page 105 Transpector CPM Operating Manual The highest oxide, WO is yellow in color and has a melting point of 1473°C. No boiling point or sublimation temperature is reported, but presumably it is far more volatile than the pure metal itself. At normal filament operating temperature, tungsten will readily react with oxygen or water vapor to form oxides.

- Page 106 Transpector CPM Operating Manual filament would stay on and react with the oxygen, producing relatively volatile tungsten oxides, until the filament diameter had been reduced to the point where the tension on the wire was sufficient to cause the wire to pull apart.

-

Page 107: Pneumatic Digital Pressure Switch And Pressure Gauge

Transpector CPM Operating Manual 6.6 Pneumatic Digital Pressure Switch and Pressure Gauge The Pneumatic Digital Pressure Switch and Pressure Gauge: provide a visual display of the air (or nitrogen) pressure provided to the pneumatic block ensure proper pressure for the CPM to function. If the pressure has decreased below 58 psi (3.999 bar) [399.9 kPa] or exceeds 100 psi (6.895 bar) - Page 108 Transpector CPM Operating Manual Figure 6-4 Location of display and controls Pressure Unit Setup Press and hold for 5 seconds. The display will show LoC (locked condition). Press to display UnL (unlock). Press . The CPM will return to Measure Mode.

- Page 109 Transpector CPM Operating Manual Response Time Mode Press . The display will show the current Response Time. The default is 20, at which the display color will change to red. Change the setting by pressing Press to return to Measure Mode.

-

Page 110: How To Test For Proper Settings

Transpector CPM Operating Manual 6.6.2 How to Test for Proper Settings With zero pressure applied, the display will show 0 pressure (small negative numbers are acceptable) and the display will be colored red. NOTE: The following test assumes the pressure unit is psi. -

Page 111: Maintenance

1.4, How to Contact INFICON, on page 1-4.) 7.2 Safety Considerations WARNING If Transpector CPM is used in a manner not specified by the manufacturer, the protection provided by Transpector CPM may be impaired. WARNING Transpector CPM maintenance should only be performed by qualified personnel. -

Page 112: Toxic Material

7.2.2 Radiation Transpector CPM does not produce harmful radiation. 7.2.3 Electrical Voltages The Transpector CPM does not present electrical hazards when enclosed and grounded according to the specifications given in the installation instructions. WARNING - Risk Of Electric Shock The Transpector electronics and CPM controller modules should never be operated with their covers removed. -

Page 113: Maintenance Procedures

7.3.2 Spare Heating Jacket INFICON offers several heating jackets to help in baking a sensor. These heating jackets operate at a maximum temperature of 150 C. (Refer to section 1.4 on page... -

Page 114: General Instructions For All Repair Procedures

Transpector CPM Operating Manual 7.4 General Instructions For All Repair Procedures CAUTION Do servicing in a clean, well illuminated area. WARNING Obey all cautions and warnings. CAUTION Wear clean nylon, lint free lab gloves or finger cots. Do not touch the vacuum side of any component with unprotected fingers. -

Page 115: Required Tools, Materials, Or Parts

Transpector CPM Operating Manual 7.5 Required Tools, Materials, or Parts 7.5.1 Tools for Replacing the Filament Kit 3 mm nut driver 1/16 in. flat blade screwdriver 7.5.2 Tools for Replacing the Ion Source 1/16 in. flat blade screwdriver ... -

Page 116: Changing Diaphragms In The Foreline Pump

Transpector CPM Operating Manual 7.6 Changing Diaphragms in the Foreline Pump 7.6.1 Replacement Interval The foreline pump diaphragm disks, valve seals, valve disks, and O-rings must be replaced every 8000 hours of operation. 7.6.2 Diaphragm kit PN 923-418-G1 Figure 7-1 Diaphragm kit contents... -

Page 117: Procedure

Transpector CPM Operating Manual 7.6.3 Procedure CAUTION Wear safety glasses and latex gloves during this procedure. Using two 9/16 in. open-end wrenches, remove the interstage tubing between the two pump heads. (See Figure 7-2.) Figure 7-2 Removing the interstage tubing... - Page 118 Transpector CPM Operating Manual Inspect the inside of the pump for cleanliness. A buildup of a black, powdery substance indicates bearing wear requiring pump replacement. The diaphragm disks are screwed into the cams. (See Figure 7-4.) Figure 7-4 Foreline pump cams...

- Page 119 Transpector CPM Operating Manual Remove the foreline pump head cover and diaphragm plate. (See Figure 7-6.) Figure 7-6 Diaphragm and diaphragm plate Diaphragm Thin O-ring Diaphragm Plate Head Cover 7 – 9...

- Page 120 Transpector CPM Operating Manual Separate the diaphragm plate from the head cover. (See Figure 7-7.) NOTE: Take note of the orientation of the valves in the head cover and diaphragm plate. They must be reassembled in exactly the same orientation.

- Page 121 Transpector CPM Operating Manual Remove the old valve disks, valve seals and O-rings from both sides of the diaphragm plate. (See Figure 7-8.) Figure 7-8 Removed valve seals, valve disks, and O-rings Diaphragm Plate (Valve Side) Diaphragm Plate (Diaphragm Side)

- Page 122 Transpector CPM Operating Manual Clean both sides of the diaphragm plate and the foreline pump head cover with methanol and lint free wipes. Pay special attention to the sealing surfaces (grooves) inside of the head cover and on either side of the diaphragm plate.

- Page 123 Transpector CPM Operating Manual There are spacers between the diaphragm disks and the cam. Note the position of the spacers when removing the diaphragm disks. The spacers must be reassembled on the new diaphragm disks in exactly the same position. (See Figure 7-10.)

- Page 124 Transpector CPM Operating Manual Figure 7-11 Placing original spacers on new diaphragm Clean the channel that the diaphragm disk is seated in with methanol and lint free wipes. (See Figure 7-12.) Screw the diaphragm disk, with original spacers, into the cam screw hole. (See Figure 7-12.)

- Page 125 Transpector CPM Operating Manual Figure 7-12 Installing the new diaphragm disk Clean Channel Cam Screw Hole Diaphragm Disk with Spacers Place the thin O-ring into the groove on the diaphragm side of the diaphragm plate. (See Figure 7-13.) Figure 7-13 Thin O-ring...

-

Page 126: Transpector Sensor Maintenance

Sensors must be cleaned only by qualified factory personnel. Refer to section 1.4, How to Contact INFICON, on page 1-4 for assistance. Maintenance of the Transpector CPM sensor is limited to filament, ion source and electron multiplier replacement. 7 – 16... -

Page 127: How To Determine If A Filament Kit Replacement Is Required

Transpector CPM Operating Manual 7.7.1 How to Determine if a Filament Kit Replacement is Required Do these steps to determine if a filament replacement is required. Measure the resistance of the filament while the sensor is under vacuum by measuring the resistance between pins 3 and 10. (See Figure 7-16). -

Page 128: Transpector Sensor Filament Replacement

Transpector CPM Operating Manual Measure the resistance of each of the pins with respect to ground (pin 7 and 8). These measurements must be above 30 M. Measure the resistance of each of the pins with respect to each other. All of these measurements must be above 30 M, with the exception of the... - Page 129 Transpector CPM Operating Manual Remove three nuts (F) and the washers holding the filament assembly in place. Be careful; do not to lose the two ceramic sealing disk wire hold downs. (See Figure 7-18.) Figure 7-18 Removing sensor filament assembly Carefully remove the filament assembly.

-

Page 130: Transpector Sensor Ion Source Replacement

Transpector CPM Operating Manual Remove the three screws holding the filament assembly on the shipping fixture. Carefully remove the new filament from its fixture and place it on the ion source posts. Replace the three filament assembly nuts and washers. Be sure to install the wire hold downs. - Page 131 Transpector CPM Operating Manual Pull the electrical leads away from the sensor. Remove the three ion source retaining screws (C) around the bottom of the ion source assembly. (See Figure 7-21; one screw is not visible in the figure). They hold the ion source onto the quadrupole assembly.

- Page 132 Transpector CPM Operating Manual The ion source can now be removed by lifting it off the quadrupole assembly. Install a new ion source by reversing the above steps. (See Figure 7-22.) Figure 7-22 Ion Source and quadrupole assembly Using an ohm meter, check that the filament is not shorted to ground or to any of the ion source plates and that the two filament leads show a filament resistance of approximately 1 at the feed-through (approximately 0.5 ...

-

Page 133: Electron Multiplier Replacement

Transpector CPM Operating Manual 7.7.4 Electron Multiplier Replacement NOTE: Refer to section 7.5.3, Tools for Replacing the Electron Multiplier, on page before continuing. Remove filament lead screw (A1), loosen filament lead screw (A2), and loosen the three screws (B) in the ion source lead connectors. Using the 1.5 x 50 mm hex driver, unscrew the screws (C) that secure the two RF leads. - Page 134 Transpector CPM Operating Manual Using the 2.0 x 75 mm hex driver, unscrew three screws (D; one is hidden in the figure) holding the sensor assembly to the feedthrough. Gently remove the sensor assembly from the feedthrough. (See Figure 7-24.) Figure 7-24 Removing the sensor assembly 7 –...

- Page 135 Transpector CPM Operating Manual Using the Phillips head screwdriver, remove three gold screws (E; one is hidden in the figure) holding the EM assembly inside of the sensor assembly. (See Figure 7-25) Figure 7-25 Removing the screws holding the EM...

- Page 136 Transpector CPM Operating Manual Gripping the bottom of the EM assembly, gently remove the EM assembly from the sensor assembly. (See Figure 7-26.) Figure 7-26 EM assembly 7 – 26...

- Page 137 Transpector CPM Operating Manual Remove the ceramic shield on the bottom of the old detector assembly. (See Figure 7-27.) Figure 7-27 Removing the ceramic shield Ceramic Shield 7 – 27...

- Page 138 When installing the sensor back into the feedthrough, ensure that the two pins on the bottom of the detector align with the two pins on the feedthrough. (See Figure 7-28.) Figure 7-28 Pin location Detector Pins Reverse steps 1-4 to reassemble the Transpector CPM sensor. 7 – 28...

-

Page 139: Hexblock Inlet Maintenance

Transpector CPM Operating Manual 7.8 HexBlock Inlet Maintenance 7.8.1 Valve and Orifice Replacement Under clean operating conditions, the HexBlock valves can operate 1,500,000 cycles before requiring maintenance. Depending on the application and the gases processed, valve and/or orifice replacement may be necessary. - Page 140 Transpector CPM Operating Manual CAUTION Do not scratch the seal surface. The seal surface can be easily damaged by a metal tweezer. Use a nonmetallic tweezer. Figure 7-31 Removal/installation of C-ring Carefully remove (by turning counterclockwise) the old orifice using the 2 mm allen wrench.

- Page 141 Transpector CPM Operating Manual Carefully press in place a new orifice gasket onto the new orifice. Install the new orifice using a 2 mm allen wrench. Tighten the orifice to a torque of 3-4 in-lbs (0.34 to 0.45 Nm), or approximately 1/4 turn (clockwise) past finger tight.

-

Page 142: Diagnosing Problems

Is Port 80 open on the host computer? Is there an IP address conflict between the Transpector sensor and another network device? NOTE: Refer to Chapter 3, Connecting Transpector CPM for more information on communications problems. 8 – 1... -

Page 143: Cpm Symptom-Cause-Remedy Chart

Transpector CPM Operating Manual 8.3 CPM Symptom—Cause—Remedy Chart Before proceeding, make sure that the insulation on all cables is intact. There must be no damage to the insulating material. If there is, replace the cable Table 8-1 Symptom—Cause—Remedy Chart SYMPTOM... - Page 144 Transpector CPM Operating Manual Table 8-1 Symptom—Cause—Remedy Chart (continued) SYMPTOM CAUSE REMEDY Process valve(s) don’t Low air pressure Check air pressure open Leaks in air lines Listen/check for leaks Water vapor high in Exposure to air or water in Bake out manifold and Inlet...

- Page 145 Transpector CPM Operating Manual Table 8-1 Symptom—Cause—Remedy Chart (continued) SYMPTOM CAUSE REMEDY EMISSION error (Cold Defective sensor filament Check sensor with OHM Start, Warm Start) open, or shorted meter Replace sensor or filament Electronics failure Return to INFICON for repair...

- Page 146 Transpector CPM Operating Manual Table 8-1 Symptom—Cause—Remedy Chart (continued) SYMPTOM CAUSE REMEDY Electron Multiplier error Defective sensor, EM Check sensor with Ohm shorted meter. See sensor pin-out diagram Fix or replace sensor EM just replaced Verify that EM is plugged...

- Page 147 Transpector CPM Operating Manual Table 8-1 Symptom—Cause—Remedy Chart (continued) SYMPTOM CAUSE REMEDY Mass filter error Bad tune file Retune RGA Contaminated quadrupole Return to INFICON for repair Ion source error Incorrect ion source Load original configuration settings file Ion source contaminated...

- Page 148 Transpector CPM Operating Manual Table 8-1 Symptom—Cause—Remedy Chart (continued) SYMPTOM CAUSE REMEDY Filament current error Insufficient vacuum Verify pressure is less than 5E-4 Torr at the ion source Filament broken Verify integrity of filament Filament shorted Verify that filament is not...

- Page 149 Transpector CPM Operating Manual Table 8-1 Symptom—Cause—Remedy Chart (continued) SYMPTOM CAUSE REMEDY Poor Sensor contaminated Degas sensor sensitivity Bake-out sensor Replace ion source Ion source pressure too low Increase process pressure, if possible Verify orifice is not blocked and replace orifice if...

-

Page 150: If You Cannot Resolve Your Problem

Transpector CPM Operating Manual Table 8-1 Symptom—Cause—Remedy Chart (continued) SYMPTOM CAUSE REMEDY High noise System grounding Verify that vacuum system level is grounded Electronics failure Return to INFICON for repair Transpector CPM Ensure the Transpector electronics module not CPM electronics module is... -

Page 151: Recommended Parts List

Transpector CPM Operating Manual Chapter 9 Recommended Parts List 9.1 Ordering Information To contact INFICON order services regarding Transpector CPM, please use the following contact information: INFICON, Inc. Two Technology Place East Syracuse, NY 13057 Tel: +315.434.1100 E-mail: reachus@inficon.com 9.2 CPM Consumable Parts The following consumable parts should be readily available. - Page 152 Transpector CPM Operating Manual Table 9-1 Consumables Part Number Description 922-204-G1 1.5 m capillary assembly kit 922-204-G3 3 m capillary assembly kit 923-706-G8 Bypass orifice kit 9 – 2...

-

Page 153: Preventative Maintenance Parts

Transpector CPM Operating Manual 9.3 Preventative Maintenance Parts The following preventative maintenance kits should be readily available. Table 9-2 Preventative maintenance kits INFICON Part Number Description 923-712-G1 Spare HexBlock Orifice Gaskets (pack of five) 923-711-G1 HexBlock Valve Replacement Kit 923-710-G1... -

Page 154: Fabguard Explorer Operation

Chapter 10 FabGuard Explorer Operation 10.1 Operation (FabGuard Explorer) Transpector CPM can be operated by any version of FabGuard gas analysis software. This chapter provides information on how to use FabGuard Explorer to operate the Transpector CPM Gas Analysis System. -

Page 155: Connecting To Transpector Cpm

Transpector CPM Operating Manual 10.3 Connecting to Transpector CPM Click Start and select FabGuard Explorer. When FabGuard Explorer is opened for the first time, the message shown in Figure 10-1 will display. Figure 10-1 Transpector connection prompt Click Yes. The Connection Type message is displayed. Select MP RGA HTTP as the connection type and Click OK. - Page 156 NOTE: Transpector MP sensors ship with a default IP address of 192.168.1.100 and a default Port of . If this IP address is not compatible with your network, the IP address can be changed using the INFICON Mass Spectrometer Search Utility. Click Add OK. 10 – 3...

-

Page 157: Rga Configuration-Cpm Tab

Transpector CPM Operating Manual 10.4 RGA Configuration—CPM tab The Transpector CPM system must be configured before use. This section explains the CPM tab in detail (See Figure 10-5.), but not the additional tabs in the RGA Configuration window. Additional information is located in the FabGuard Explorer Operating Manual (PN 074-528-P1). -

Page 158: Valves And Orifices Pane

Transpector CPM Operating Manual 10.4.1 Valves and Orifices pane Orifices in the HexBlock inlet system are replaceable. Transpector CPM is set up in the factory with the correct valve and orifice values. However, if a valve or orifice is changed, the new configuration must be entered in the RGA Configuration. -

Page 159: Inlet Calibration

If V5 is not installed, select No Valve. Figure 10-10 Inlet Calibration 10.4.2 Gauges pane 10.4.2.1 Process Gauge The Transpector CPM includes an optional CDG (capacitance diaphragm gauge). If the CDG is installed, enter its appropriate pressure range. Note that the scale is in millitorr. -

Page 160: Bypass Delay - Interlock Between V2 And V4

Transpector CPM Operating Manual 10.4.3 Bypass Delay - Interlock between V2 and V4 Bypass Delay defines the interlock between V2 (HP) and V4 (Bypass) valves. The time entered (in seconds) determines: How long the V4 (Bypass) valve will be open before the V2 (HP) valve will be... -

Page 161: Cpm Configuration Monitor

NOTE: The CPM Configuration Monitor window is different from the open ion source instruments’ Sensor window because of the pumping and inlet systems on the CPM. Figure 10-13 Transpector CPM configuration monitor Turbo Pump Speed Edit Data Bakeout Button... - Page 162 Transpector CPM Operating Manual Figure 10-14 Pumpout time for trapped volumes 10000 1000 V1 - 10T (20u); V2 - 10T (20u) V1 - 10T (20u); V2 - 10T (20u) + Bypass V1 - 1T (62u); V2 - 10T (20u) V1 - 1T (62u);...

- Page 163 Transpector CPM Operating Manual Click Multiplier to turn on the electron multiplier. The Multiplier button will be colored dark blue. It will progress to yellow and finally green to signify that the EM is on. (See Figure 10-16.) Figure 10-16 Multiplier status Click Edit to alter the sensor’s data acquisition parameters (see...

- Page 164 Transpector CPM Operating Manual Figure 10-18 Configuration monitor window illustration Determine which valve to open. V1 (LP) —low pressure valve V2 (HP) —high pressure valve (tied to V4, the bypass valve) V3 (HC) —high conductance valve (used if the sensor’s process connection is under high vacuum) ...

-

Page 165: Cpm Sensor Acquisition Defaults

10.6 CPM Sensor Acquisition Defaults 10.6.1 What to Acquire (RGAs) The What to Acquire parameters decide the data that the Transpector CPM will collect. This menu is very similar for both CPMs and Open Ion Source RGAs. 10.6.1.1 Acquisition Modes There are two different acquisition modes: Spectrum (Scans) and Selected Masses (Bins). - Page 166 Transpector CPM Operating Manual Selected Masses (Bins) mode allows data collection of specific masses. Figure 10-21 What to Acquire—Selected Masses 10 – 13...

-

Page 167: Spectrum Mode Acquisition Parameters

Transpector CPM Operating Manual 10.6.1.1.1 Spectrum Mode Acquisition Parameters Figure 10-22 Spectrum mode acquisition parameters Start Mass (amu) ....The amu at which the RGA will begin scanning. -

Page 168: Selected Masses Mode

Transpector CPM Operating Manual 10.6.1.2 Selected Masses Mode It is possible to define specific masses of interest in Selected Masses Mode. Transpector CPM advanced sensor functions can be tracked as individual bins in this data acquisition mode. (See Figure 10-23.) Figure 10-23 Selected masses mode 10 –... -

Page 169: Existing Masses

Transpector CPM Operating Manual 10.6.1.2.1 Existing Masses Editing Masses If a mass has already been added but the mass has the wrong identity for the process, click Edit to open the Mass Properties window and change the identity. (See Figure 10-24.) -

Page 170: Adding Masses

Transpector CPM Operating Manual Figure 10-25 Editing special bins not allowed Removing Masses Click Remove to remove an individual mass. (See Figure 10-26.) Click Remove All to remove all of the masses. (See Figure 10-27.) Figure 10-26 Remove Figure 10-27 Remove All 10.6.1.2.2 Adding Masses... - Page 171 Transpector CPM Operating Manual Figure 10-29 Add mass 10 – 18...

- Page 172 Transpector CPM Operating Manual Add Masses from Chemistry Library Allows the selection of peaks based on chemicals that are present in a process. A compound is selected to monitor. The mass spectrum for the specific compound will be displayed in the graph. After clicking Add, the masses in the spectrum will be added to the active bin list.

-

Page 173: How To Acquire (Cpm)

Transpector CPM Operating Manual 10.6.2 How to Acquire (CPM) The How to Acquire menu for the CPM (see Figure 10-33) is similar to the Open Ion Source RGAs. However, there are a number of differences due to the additional valve assembly and pumping system of the CPM. -

Page 174: Ionizer Presets

Transpector CPM Operating Manual 10.6.2.1 Ionizer Presets Determines the ionization energy with which the sensor collects data. Figure 10-34 Ionizer presets Low selects the sensor’s low ionization energy for the run. High selects the sensor’s high ionization energy for the run. -

Page 175: Data Threshold

Transpector CPM Operating Manual 10.6.2.2.2 Data Threshold Defines the threshold that the Start Mode Type utilizes to determine when the run will start. The Data Threshold is set in units corresponding to the Start Mode Type selected. Maximum Signal is in units of current, Pressure Above/Below is in units of pressure, and Analog 1 Above/Below is in units of volts. -

Page 176: Stop Parameters

Transpector CPM Operating Manual 10.6.2.3 Stop Parameters Defines how and when the data acquisition stops. 10.6.2.3.1 Stop Mode Type Defines when the data acquisition stops. (See Figure 10-39.) Figure 10-39 Stop mode CPM Time (s) stops the acquisition after a set period of time. -

Page 177: Maximum Duration

Transpector CPM Operating Manual 10.6.2.3.3 Maximum Duration Defines the length of time in seconds that the RGA will collect data if using Time as a stop mode. If using a different stop mode, Maximum Duration defines the maximum amount of time that the RGA will collect data. (See Figure 10-41.) -

Page 178: Relay 1

Transpector CPM Operating Manual 10.6.2.3.6 Relay 1 Defines the state of Relay 1 when the run stops. As Is leaves the relay in its current state at the end of the run. Open opens the relay at the end of the run. -

Page 179: Dwell Mode

Transpector CPM Operating Manual 10.6.2.4.2 Dwell Time Defines the amount of time in milliseconds (ms) that FabGuard Explorer will collect data at every data point. In general, the longer the dwell time, the lower the noise of the signal. Longer dwell times at each point will result in longer overall scan times. -

Page 180: Time Between Scans

Transpector CPM Operating Manual 10.6.2.5.2 Time Between Scans Time Between Scans can be set to a value greater than the minimum scan time if additional wait time is desired. This field can only be set if Manual is chosen as the Delay Mode. -

Page 181: Peak Lock

Transpector CPM Operating Manual 10.6.2.6.2 Peak Lock Figure 10-49 Peak lock Peak Lock is a method of fine tuning the sensor while it is collecting data. Peak Lock is only available when running at 1 ppamu (either in spectrum mode or selected masses mode). -

Page 182: Close After

10.6.2.7.2 Duty Cycle When sampling aggressive gases, do not expose Transpector CPM to the aggressive gas for long periods of time. The CPM Inlet can be automatically opened and closed in a duty cycle. - Page 183 Transpector CPM Operating Manual Chapter 11 Glossary Anode The anode is the structure in the ion source in which ions are created by electron impact. It can be formed from a mesh, such as in the open ion source, or from a solid tube, such as in the closed ion source. Its electrical potential is positive with respect to the filament, focus lens, total pressure plate, pole zero, exit aperture and Faraday cup.

- Page 184 Transpector CPM Operating Manual Detection Factor The detection factor is the ratio of the detected signal for a given ion current from a certain substance to the detected signal for the same ion current of nitrogen ions as measured at mass 28. For Faraday cup detectors, the detection factor is usually 1.

- Page 185 Transpector CPM Operating Manual Focus Lens The focus lens is a conductive aperture located next to, and usually biased negatively with respect to, the anode. Its purpose is to draw the ions out of the anode, form them into a beam, and focus them into the next lens element.

- Page 186 Transpector CPM Operating Manual Ionization Probability The ionization probability for a chemical substance is the ratio of the total ion current (at all masses) produced from a given partial pressure of that substance, to the total ion current produced from nitrogen at the same partial pressure.

- Page 187 Transpector CPM Operating Manual Material Factor The material factor for a chemical substance is that part of the proportionality constant between the partial pressure of that substance and the resulting mass filtered ion current which depends on the chemical nature of that substance but not the particular instrument used for that measurement.

- Page 188 Transpector CPM Operating Manual Partial Pressure The partial pressure is the pressure of a specific chemical component of a gas mixture. The sum of all the partial pressures is the total pressure. Pole Zero See Center Voltage. Quadrupole A quadrupole is a mass filter consisting of four parallel electrodes or poles (hence quadrupole) arranged in a square array.

- Page 189 Transpector CPM Operating Manual Total Pressure Plate The total pressure plate, or collector, is an electrode in the ion source on which at least a part of the ion beam impinges. The current striking this plate is a function of the total pressure in the ion source.

- Page 190 Transpector CPM Operating Manual Chapter 12 Bibliography For further information on partial pressure analyzers, see Partial Pressure Analyzers and Analysis, M. J. Drinkwine and D. Lichtman, American Vacuum Society Monograph Series, or A User’s Guide to Vacuum Technology, J. F.

Need help?

Do you have a question about the Transpector CPM and is the answer not in the manual?

Questions and answers