Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Aerotech BM Series

-

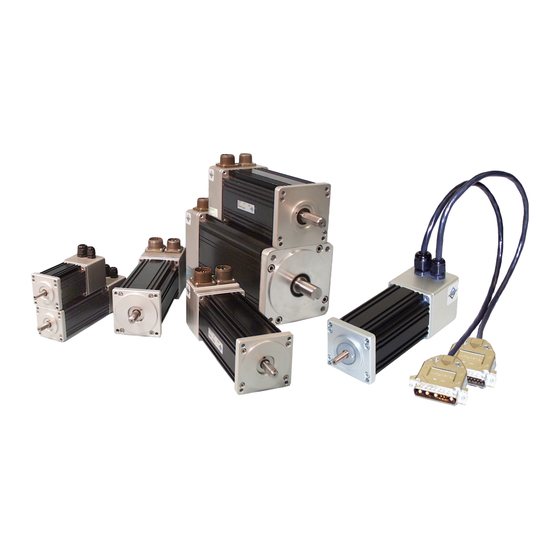

Page 1: Bm/Bms Series Brushless Rotary Motor

BM/BMS Series Brushless Rotary Motor HARDWARE MANUAL Revision 3.00... - Page 2 Global Technical Support Portal for information and support about your Aerotech, Inc. products. The website supplies software, product manuals, Help files, training schedules, and PC-to-PC remote technical support. If necessary, you can complete Product Return (RMA) forms and get information about repairs and spare or replacement parts.

-

Page 3: Table Of Contents

2.2.3. Over-Current Protection 2.2.4. Hall-Effect Device and Thermistor Wiring 2.2.5. Wiring Guidelines 2.2.6. Thermal Protective Device [BMS Motors Only] 2.3. Hall-Effect Operation and Motor Phasing 2.4. Motor Heating Chapter 3: Maintenance Appendix A: Warranty and Field Service Appendix B: Revision History Index www.aerotech.com... -

Page 4: List Of Figures

Thermal Sensor Resistance as a Function of Temperature Figure 2-2: Typical Thermistor Interface Circuit Figure 2-3: Hall Effect and Motor Phasing Figure 2-4: Test Setup Configuration Figure 2-5: Motor Lead Phasing with Oscilloscope Figure 2-6: Hall Phasing with Oscilloscope Figure 2-7: Operating Regions Example www.aerotech.com... -

Page 5: List Of Tables

Feedback Connector Pinout (with Limits, -D25-9D, -9D-CMS, -5D, -FLB, -4TS) Table 2-17: Mating Connector Part Numbers for the -D25-XX Feedback Connector Table 2-18: Limit Connector Pinout (-D25-9D,-9D-CMS, -5D, -FLB, -4TS) Table 2-19: Mating Connector Part Numbers for the Limit Connector www.aerotech.com... - Page 6 BM/BMS Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 7: Eu Declaration Of Conformity

Hardware Manual BM/BMS EU Declaration of Conformity Manufacturer Aerotech, Inc. Address 101 Zeta Drive Pittsburgh, PA 15238-2811 Declares that the product: Product Standard BM and BMS motors (excluding VAC6 versions) BM75, BM130, BM200, BM250, BM500, BM800, BM1400, BMS35, BMS60, Model/Types... -

Page 8: Ukca Declaration Of Conformity

BM/BMS Hardware Manual UKCA Declaration of Conformity Manufacturer Aerotech, Inc. Address 101 Zeta Drive Pittsburgh, PA 15238-2811 Declares that the product: Product Standard BM and BMS motors (excluding VAC6 versions) Model/Types BM75, BM130, BM200, BM250, BM500, BM800, BM1400, BMS35, BMS60,... -

Page 9: Safety Procedures And Warnings

To find the newest information about this product, refer to www.aerotech.com. If you do not understand the information in this manual, contact Aerotech Global Technical Support. IMPORTANT: This product has been designed for light industrial manufacturing or laboratory environments. -

Page 10: Installation And Operation

To decrease the risk of damage to the equipment, you must obey the precautions that follow. IMPORTANT: Aerotech motors are meant to be part of a drive package that consists of an amplifier and a controller. The motor relies on the drive package for fault protection. - Page 11 WARNING: Trip Hazard! Route, house, and secure all cables, duct work, air, or water lines. Failure to do so could introduce trip hazards around the system that could result in physical injury or could damage the equipment. www.aerotech.com...

-

Page 12: Electrical Warnings

It is the responsibility of the End User/System Integrator to make sure that motors are properly connected and grounded per Engineering Standards and applicable safety requirements. It is the responsibility of the End User/System Integrator to configure the system drive or controller within the Aerotech motor electrical and mechanical specifications. www.aerotech.com... -

Page 13: Motor-Related Warnings

Hardware Manual BM/BMS Motor-Related Warnings Aerotech motors are capable of producing high forces and velocities. Obey all warnings and all applicable codes and standards when you use or operate a stage or system that incorporates Aerotech motors. DANGER: Mechanical Hazard! Personnel must be made aware of the mechanical hazards during set up or when you do service to the motor. -

Page 14: Pinch Points

(during normal operation, for example). when the system is moved manually (during the installation process or when you do maintenance, for example). Motors are capable of very high speeds and acceleration rates. Figure 1: Typical Pinch Point Locations www.aerotech.com... -

Page 15: Handling And Storage

Use a cart, dolly, or similar device to move the motor to a new location. Gently set the motor on a smooth, flat, and clean surface. Use compressed nitrogen or clean, dry, oil- free air to remove any dust or debris that has collected during shipping. www.aerotech.com... - Page 16 Before you operate the motor, let it stabilize at room temperature for at least 12 hours. This will ensure that all of the alignments, preloads, and tolerances are the same as they were when they were tested at Aerotech. Storage Store the motor in the original shipping container.

-

Page 17: Chapter 1: Overview

BM75, BM130, BM200, BM250, BM500, BM900, BM1400 -E2500H 2500 lines/rev TTL incremental encoder with Hall tracks 5000 lines/rev TTL incremental encoder with Hall tracks; compatible -E5000H with: BM75, BM130, BM200, BM250, BM500, BM900, BM1400 -E1000ASH 1000 lines/rev 1 Vpp incremental encoder with Hall tracks www.aerotech.com... - Page 18 Torr -VAC6 Accessories MC-HPD25-M High-power D-style motor mating connector MC-DB25-F D-style 25-pin motor and feedback mating connector Military style motor power mating connector; compatible with: BM75, BM130, MCM-3 BM200, BM250, BM500, BM800, BM1400 MCF-3 Military style feedback mating connector www.aerotech.com...

-

Page 19: Table 1-2: Bms Motor Options

BMS465 NEMA 34 brushless servomotor Winding Options Standard winding NOTE: Alternate winding options are available. Contact Aerotech for more information. Connectors Integral cables with military-style feedback and motor connectors; compatible with: BMS60, BMS100, BMS280, BMS465 Integral cables with D-style 25-pin feedback and D-style 4-pin motor -D25 connectors;... - Page 20 50 dm maximum; compatible with: BMS35, BMS60, BMS100 Vacuum Preparation (Optional) Vacuum preparation to 10 Torr -VAC6 Accessories MC-HPD25-M High-power D-style motor mating connector MC-DB25-F D-style 25-pin mating connector MCM-3 Military style motor power mating connector MCF-3 Military style feedback mating connector www.aerotech.com...

-

Page 21: Motor Specifications

Hardware Manual BM/BMS 1.1. Motor Specifications The specifications for the BM series brushless motors are listed in Table 1-3, Table 1-4, and Table 1-5. The specifications for the BMS series brushless motors are listed in Table 1-6 Table 1-7. Table 1-3:... -

Page 22: Figure 1-1: Torque Speed Curves (Bm24, Bm75, And Bm130)

BM/BMS Hardware Manual Figure 1-1: Torque Speed Curves (BM24, BM75, and BM130) www.aerotech.com... -

Page 23: Table 1-4: Bm200, Bm250, And Bm500 Motor Specifications

(2) All performance and electrical specifications have a tolerance of ±10%. (3) Values shown at maximum coil temperature, with housed motor mounted to a 305×305×12.7 mm aluminum heat sink. (4) Peak torque assumes correct rms current; consult Aerotech. (5) Torque constant and motor constant specified at stall. www.aerotech.com... -

Page 24: Figure 1-2: Torque Speed Curves (Bm200, Bm250, And Bm500)

BM/BMS Hardware Manual Figure 1-2: Torque Speed Curves (BM200, BM250, and BM500) www.aerotech.com... -

Page 25: Table 1-5: Bm800 And Bm1400 Motor Specifications

(2) All performance and electrical specifications have a tolerance of ±10%. (3) Values shown at maximum coil temperature, with housed motor mounted to a 305×305×12.7 mm aluminum heat sink. (4) Peak torque assumes correct rms current; consult Aerotech. (5) Torque constant and motor constant specified at stall. www.aerotech.com... -

Page 26: Figure 1-3: Torque Speed Curves (Bm800 And Bm1400)

BM/BMS Hardware Manual Figure 1-3: Torque Speed Curves (BM800 and BM1400) www.aerotech.com... -

Page 27: Table 1-6: Bms35, Bms60, And Bms100 Motor Specifications

(2) Values shown at 75 °C temperature rise above a 25 °C ambient temperature, with housed motor mounted to a 250×250×6 mm aluminum heat sink. (3) Peak torque assumes correct rms current; consult Aerotech. (4) Torque constant and motor constant specified at stall. (5) All Aerotech amplifiers are rated A ;... -

Page 28: Figure 1-4: Torque Speed Curves (Bms35, Bms60, And Bms100)

BM/BMS Hardware Manual Figure 1-4: Torque Speed Curves (BMS35, BMS60, and BMS100) www.aerotech.com... -

Page 29: Table 1-7: Bms280 And Bms465 Motor Specifications

(2) Values shown at 75 °C temperature rise above a 25 °C ambient temperature, with housed motor mounted to a 250×250×6 mm aluminum heat sink. (3) Peak torque assumes correct rms current; consult Aerotech. (4) Torque constant and motor constant specified at stall. (5) All Aerotech amplifiers are rated A ;... -

Page 30: Figure 1-5: Torque Speed Curves (Bms280 And Bms465)

BM/BMS Hardware Manual Figure 1-5: Torque Speed Curves (BMS280 and BMS465) www.aerotech.com... -

Page 31: Dimensions

Hardware Manual BM/BMS 1.2. Dimensions Figure 1-6: BM24 Model Dimensions (NEMA 17) www.aerotech.com... -

Page 32: Figure 1-7: Bm75, Bm130, Bm200 Model Dimensions (Nema 23)

BM/BMS Hardware Manual Figure 1-7: BM75, BM130, BM200 Model Dimensions (NEMA 23) www.aerotech.com... -

Page 33: Figure 1-8: Bm250, Bm500 Model Dimensions (Nema 34)

Hardware Manual BM/BMS Figure 1-8: BM250, BM500 Model Dimensions (NEMA 34) www.aerotech.com... -

Page 34: Figure 1-9: Bm800, Bm1400 Model Dimensions (Nema 42)

BM/BMS Hardware Manual Figure 1-9: BM800, BM1400 Model Dimensions (NEMA 42) www.aerotech.com... -

Page 35: Figure 1-10: Bms35 Model Dimensions (Nema 17)

Hardware Manual BM/BMS Figure 1-10: BMS35 Model Dimensions (NEMA 17) www.aerotech.com... -

Page 36: Figure 1-11: Bms60 And Bms100 Model Dimensions (Nema 23)

BM/BMS Hardware Manual Figure 1-11: BMS60 and BMS100 Model Dimensions (NEMA 23) www.aerotech.com... -

Page 37: Figure 1-12: Bms280 And Bms465 Model Dimensions (Nema 34)

Hardware Manual BM/BMS Figure 1-12: BMS280 and BMS465 Model Dimensions (NEMA 34) www.aerotech.com... -

Page 38: Environmental Specifications

WARNING: Use this product only in environments and operating conditions that are approved in this manual. Table 1-8: Environmental Specifications Operating: 0 °C to 25 °C, consult Aerotech for operation outside of this Temperature: range. Storage: -20 °C to 85 °C... -

Page 39: Vacuum Operation

6. To reduce outgassing during the initial pump-down to vacuum pressure, Aerotech recommends that you bake out vacuum systems when you first install them into the vacuum chamber. Bake the vacuum components at 60 °C for 24 to 48 hours to desorb water vapor from surfaces and... - Page 40 BM/BMS Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 41: Chapter 2: Assembly And Installation

25 pin D-style connector (no limits) Table 2-14 -D25-9D -D25-9D-CMS -D25-5D 25 pin D-style connector (with limits) Table 2-16 -D25-FLB -D25-4TS Table 2-3: Limit Connector Options Option Connector Description Pinout Table -D25-9D -D25-9D-CMS -D25-5D 9 pin D-style connector Table 2-18 -D25-FLB -D25-4TS www.aerotech.com... -

Page 42: Motor Connectors

Motor Phase C Frame Ground (motor protective ground) Backshell Motor Cable Shield P/N: MS3101A18-10P Table 2-5: Mating Connector Part Numbers for the Motor Power Connector (-MS Option) Mating Connector Aerotech P/N Third Party P/N Plug MCM00475 Amphenol MS3106A18 Insert MCM00495 Amphenol 9718-10S... -

Page 43: Table 2-8: Motor Power Flying Leads Pinout (-D25-Flb Option)

Motor Phase C Reserved Frame Ground (motor protective ground) Table 2-11: Mating Connector Part Numbers for the -D25-5D Option Motor Power Connector Mating Connector Aerotech P/N Third Party P/N Backshell ECK00656 Amphenol #17E-1726-2 Sockets [QTY. 5] ECK00659 ITT Cannon #DM53744-6... -

Page 44: Feedback Connectors

Brake + (with Brake Option) Reserved Brake - (with Brake Option) (1) 24 VDC @ 1 A max Table 2-13: Mating Connector Part Numbers for the -MS Option Feedback Connector Mating Connector Aerotech P/N Third Party P/N Plug MCM00454 Amphenol MS3106A-20 Insert MCM00464... -

Page 45: Table 2-14: Feedback Connector Pinout (Without Limits, -D25 Option)

Common ground (PIN 21 is internally connected to PIN 20) Reserved Reserved Reserved Reserved Brake + (with Brake Option) Table 2-15: Mating Connector Part Numbers for the -D25 Option Feedback Connector Mating Connector Aerotech P/N Third Party P/N 25-Socket D-Connector ECK00300 FCI DB25S064TLF Backshell ECK00656 Amphenol 17E-1726-2 www.aerotech.com... -

Page 46: Table 2-16: Feedback Connector Pinout (With Limits, -D25-9D, -9D-Cms, -5D, -Flb, -4Ts)

Common ground (PIN 21 is internally connected to PIN 20) Home Limit Reserved -Limit/CCW (Negative/Counterclockwise Limit) Reserved Brake + (with Brake Option) Table 2-17: Mating Connector Part Numbers for the -D25-XX Feedback Connector Mating Connector Aerotech P/N Third Party P/N 25-Socket D-Connector ECK00300 FCI DB25S064TLF Backshell ECK00656 Amphenol 17E-1726-2 www.aerotech.com... -

Page 47: Table 2-18: Limit Connector Pinout (-D25-9D,-9D-Cms, -5D, -Flb, -4Ts)

+Limit/CW (Positive/Clockwise Travel Limit) Home Limit -Limit/CCW (Negative/Counterclockwise Limit) Reserved Common ground Reserved Reserved Table 2-19: Mating Connector Part Numbers for the Limit Connector Mating Connector Aerotech P/N Third Party P/N 9-Pin D-Connector ECK00340 FCI DE09S064TLF Backshell ECK01021 Amphenol 17E-1724-2 www.aerotech.com... -

Page 48: External Motor Wiring

RMS current rating of the motor. For most applications, you should use slow-blow type fuses. When the motor is part of an Aerotech system that uses an Aerotech controller and drive, use the “A ”... -

Page 49: Hall-Effect Device And Thermistor Wiring

Do not bundle signal, motor power cables, or AC power lines within the same protective shield or conduit. Use separate protective shields or conduits. Do not introduce multiple paths to ground from a grounding point. Multiple paths to ground can create ground loops within the system. If necessary, use an EMI suppression device. www.aerotech.com... -

Page 50: Thermal Protective Device [Bms Motors Only]

1,000 ohms as the motor temperature increases to the 100 °C transition temperature of the thermistor. WARNING: The thermal protective device used in the motor must be connected to an external shutdown circuit to provide protection to the motor. Figure 2-1: Thermal Sensor Resistance as a Function of Temperature www.aerotech.com... -

Page 51: Figure 2-2: Typical Thermistor Interface Circuit

WARNING: If you connect the thermistor to the interface circuit incorrectly, you could cause the thermistor to self-heat. If too much current passes through the thermistor, the temperature will increase and cause the thermistor to activate and increase resistance. Figure 2-2: Typical Thermistor Interface Circuit www.aerotech.com... -

Page 52: Hall-Effect Operation And Motor Phasing

BM/BMS Hardware Manual 2.3. Hall-Effect Operation and Motor Phasing Aerotech brushless motors are shipped from the factory with the correct motor phase to Hall effect relationship. Figure 2-3 shows the correct Hall effect to motor phasing for both clockwise (CW) and counterclockwise (CCW) motor rotation. -

Page 53: Figure 2-4: Test Setup Configuration

1. Aerotech phasing expects ØC to be the lead signal in time, ØB to follow it, and ØA to follow ØB. This means that whichever signal has been determined to lead the others in time is designated as the ØC winding. -

Page 54: Figure 2-5: Motor Lead Phasing With Oscilloscope

Move channel 1 of the oscilloscope to the second motor lead and repeat the steps given above. Note which Hall signal corresponds to the currently selected motor lead. Repeat the process for the third motor lead until the desired relationships are attained and noted. www.aerotech.com... -

Page 55: Figure 2-6: Hall Phasing With Oscilloscope

Hardware Manual BM/BMS Figure 2-6: Hall Phasing with Oscilloscope www.aerotech.com... -

Page 56: Motor Heating

Continuous Operating Curve. Motor operation in the region bounded by the Peak Operating Curve has to be limited in time or the temperature of the motor will exceed the thermal limit. Figure 2-7: Operating Regions Example www.aerotech.com... -

Page 57: Chapter 3: Maintenance

Be careful when you clean the motor so that you do not remove the text on the motor labels. Lubrication Aerotech BM/BMS rotary motors do not require lubrication. It is the responsibility of the customer or OEM to lubricate customer-supplied components. Repairs In general, it is not possible for field service personnel to repair and/or replace damaged or components that have malfunctioned. - Page 58 BM/BMS Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 59: Appendix A: Warranty And Field Service

All Other Repairs - After Aerotech's evaluation, the buyer shall be notified of the repair cost. At such time the buyer must issue a valid purchase order to cover the cost of the repair and freight, or authorize the product(s) to be shipped back as is, at the buyer's expense. - Page 60 Aerotech's approval. On-site Warranty Repair If an Aerotech product cannot be made functional by telephone assistance or by sending and having the customer install replacement parts, and cannot be returned to the Aerotech service center for...

-

Page 61: Appendix B: Revision History

Revision Description 3.00 Declaration of Conformity updated. 2.10 2.09 2.08 2.07 2.06 2.05 2.04 2.03 Revision changes have been archived. If you need a copy of this revision, contact AerotechGlobal Technical Support. 2.02 2.01 2.00 1.04 1.03 1.02 1.01 1.00 www.aerotech.com... - Page 62 BM/BMS Hardware Manual This page intentionally left blank. www.aerotech.com...

-

Page 63: Index

BMS280 Motor Specifications Feedback Connector Pinout BMS35 Mating Connector Part Numbers (Motor Power Connector) 42,45 BMS35 Model Dimensions Motor Power Connector Pinout BMS35 Motor Specifications -MS Option BMS465 Model Dimensions (NEMA 34) Feedback Connector Pinout BMS465 Motor Specifications BMS60 www.aerotech.com... - Page 64 MS3101A18-10P Hall Phasing with Oscilloscope MS3102R20-29P Handling Humidity packing list part number label Part Numbers Limit Connector Pinout Feedback Mating Connector -D25-4TS Option -D25-5D Option -D25-5D Option -D25-9D-CMS Option -D25-9D-CMS Option -D25-9D Option -D25-9D Option -D25-FLB Option -D25-FLB Option www.aerotech.com...

- Page 65 Warranty and Field Service Limit Connector Wiring Guidelines -D25-4TS Option -D25-5D Option -D25-9D-CMS Option -D25-9D Option -D25-FLB Option Motor Power Connector -D25-4TS Option -D25-5D Option -D25-FLB Option -D25 Option -MS Option Protective Ground repair Revision History serial number Specifications www.aerotech.com...

- Page 66 Index BM/BMS Hardware Manual This page intentionally left blank. www.aerotech.com...

Need help?

Do you have a question about the BM Series and is the answer not in the manual?

Questions and answers