Table of Contents

Advertisement

Quick Links

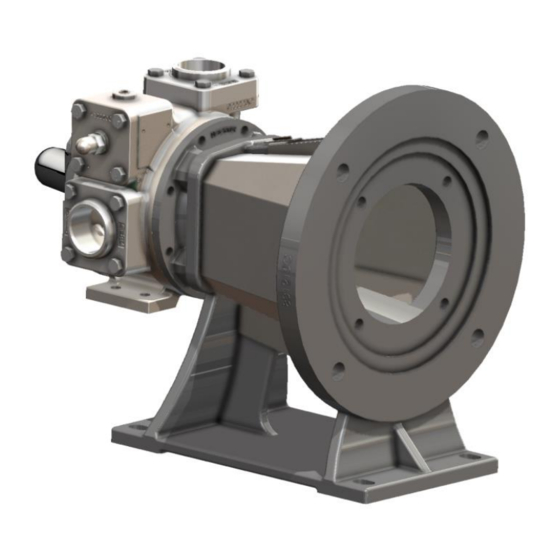

BLACKMER TRUCK PUMPS

INSTALLATION OPERATION AND MAINTENANCE INSTRUCTIONS

Numbers in parentheses following individual parts

indicate reference numbers on Blackmer Parts Lists

101-D01 and 101-D02.

Blackmer pump manuals and parts lists may be

obtained from Blackmer's website (www.blackmer.com)

or by contacting Blackmer Customer Service.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the product, or in the

manual, look for one of the following signal words and be

alert to the potential for personal injury, death or major

property damage

Warns of hazards that WILL cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury

or property damage.

NOTICE:

Indicates special instructions which are very

important and must be followed.

MODELS: X1220A & X1225A

TABLE OF CONTENTS

Technical Data ....................................................... 2

Initial Pump Start Up Information ........................... 2

Pre-Installation Cleaning ........................................ 3

Location and Piping ............................................... 3

Pump Drive ............................................................ 3

Pump Rotation ....................................................... 4

To Change Pump Rotation .................................... 4

Pre-Start Up Check List ......................................... 5

Start Up Procedures .............................................. 5

Pump Speed .......................................................... 5

Reverse Rotation ................................................... 5

Flushing the Pump ................................................. 6

Pump Relief Valve ................................................. 6

Relief Valve Setting and Adjustment ..................... 7

Strainers ................................................................ 7

Lubrication ............................................................. 7

Vane Replacement ................................................ 8

Pump Disassembly ................................................ 8

Pump Assembly ..................................................... 9

TROUBLE SHOOTING .....................................

SAFETY DATA

Blackmer Truck Pumps MUST only be installed in systems,

which have been designed by qualified engineering

personnel.

local and national regulations and safety standards.

This manual is intended to assist in the installation and

operation of the Blackmer truck pumps, and MUST be kept

with the pump.

Pump service shall be performed by qualified technicians

ONLY. Service shall conform to all applicable local and

national regulations and safety standards.

Thoroughly review this manual, all instructions and hazard

warnings, BEFORE performing any work on the pump.

Maintain ALL system and pump operation and hazard

warning decals.

961928

INSTRUCTIONS NO. 101-D00

Section

Effective

Replaces

NOTICE:

The system MUST conform to all applicable

101

Aug 2023

New

Page

11

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for BLACKMER X1220A

-

Page 1: Table Of Contents

This manual is intended to assist in the installation and operation of the Blackmer truck pumps, and MUST be kept with the pump. Warns of hazards that WILL cause serious personal injury, Pump service shall be performed by qualified technicians death or major property damage. -

Page 2: Pump Data

A pump Identification tag, containing the pump serial number, I.D. number, and model designation, is attached to each pump. It is recommended that the data from this tag be recorded and filed for future reference. If replacement parts are needed, or if information pertaining to the pump is required, this data must be furnished to a Blackmer representative. TECHNICAL DATA... -

Page 3: Installation

INSTALLATION NOTICE: Install pressure gauges in the NPT ports provided in the Blackmer pumps must only be installed in systems pump casing to check pump performance at start up. designed by qualified engineering personnel. System ALL piping and fittings MUST be properly supported to design must conform with all applicable regulations and prevent any piping loads from being placed on the pump. -

Page 4: Pump Rotation

INSTALLATION CHECK VALVES The use of check valves or foot valves in the supply tank is not recommended with self-priming, positive displacement pumps. If the possibility of liquid backflow exists when the pump is off, a check valve in the pump discharge piping is recommended because the pump can motor in the reverse rotation and create undue stress on all attached components. -

Page 5: Operation

INSTALLATION Operation without guards in place can cause serious personal injury, major property damage, or death. Do not operate without guard in place PUMP ROTATION NOTICE: Confirm correct pump rotation by checking the pump rotation arrows respective to piping flow direction. Do not operate the pump in reverse rotation to reverse the direction of flow. -

Page 6: Start Up Procedures

OPERATION START UP PROCEDURES NOTICE: Consult the "General Pump Troubleshooting" section of this manual if difficulties during start up are experienced. Start the pump. Priming should occur within one minute. Check the vacuum and pressure gauges to ensure the pump is operating within the expected conditions. Inspect piping, fittings, and associated system equipment for leaks, noise, vibration and overheating. -

Page 7: Relief Valve Setting And Adjustment

Retighten the locknut DO NOT adjust the relief valve pressure setting while the Refer to Blackmer Pump Parts List 101-A01 for relief valve pump is in operation. spring pressure ranges. Unless specified otherwise, pumps are supplied from the factory with the relief valve adjusted to the mid-point of the spring range. -

Page 8: Vane Replacement

MAINTENANCE Bend up the engaged lockwasher tang and rotate VANE REPLACEMENT the locknut counterclockwise to remove it from the NOTICE: shaft. Maintenance shall be performed by qualified technicians Slide the lockwasher off the shaft. Inspect the only. Following the appropriate procedures and lockwasher for damage and replace as required. -

Page 9: Pump Assembly

MAINTENANCE PUMP ASSEMBLY 16. Install locknut (24A) onto threads of shaft with the Before reassembling the pump, inspect all component parts tapered end inward. for wear or damage, and replace as required. Wash out the 17. Tighten the locknut (24A) with a spanner wrench to pull bearing/seal recess of the head and cylinder and remove any the rotor flat against the back wall of the cylinder. - Page 10 MAINTENANCE the locknut. The pump should continue to turn freely 31. Install and finger tighten the head capscrews (21). The when rotated by hand. head capscrews will be fully tightened after the second locknut is installed. 44. To check adjustment, grasp the nut and washer with fingers and rotate back and forth.

- Page 11 PUMP TROUBLESHOOTING NOTICE: MAINTENANCE SHALL BE PERFORMED BY QUALIFIED TECHNICIANS ONLY, FOLLOWING THE APPROPRIATE PROCEDURES AND WARNINGS AS PRESENTED IN THIS MANUAL. SYMPTOM PROBABLE CAUSE 1. Pump not wetted. Pump Not Priming 2. Worn vanes. 3. Internal control valve closed. 4.

- Page 12 NOTES 101-A00 Page 12/14...

- Page 13 1809 Century Avenue, Grand Rapids, Michigan 49503-1530 U.S.A. Telephone: (616) 241-1611 • Fax: (616) 241-3752 E-mail: blackmer @blackmer.com • Internet Address: www .blackmer.com 101-A00 Page 13/14...

- Page 14 101-A00 Page 14/14...

Need help?

Do you have a question about the X1220A and is the answer not in the manual?

Questions and answers