Table of Contents

Advertisement

Quick Links

Operator's Manual

PORTABLE BUTT WELDER

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10201

| Issue D ate Oct- 14

© Lincoln Global, Inc. All Rights Reserved.

For use with machines having K Numbers:

K3924-1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric K3924-1

- Page 1 Operator’s Manual PORTABLE BUTT WELDER For use with machines having K Numbers: K3924-1 Register your machine: www.lincolnelectric.com/register Authorized Service and Distributor Locator: www.lincolnelectric.com/locator Save for future reference Date Purchased Code: (ex: 10859) Serial: (ex: U1060512345) IM10201 | Issue D ate Oct- 14...

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

-

Page 3: Section A: Warnings

W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. - Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

- Page 6 PORTABLE BUTT WELDER TABLE OF CONTENTS...

- Page 7 PORTABLE BUTT WELDER TABLE OF CONTENTS...

-

Page 8: General Description

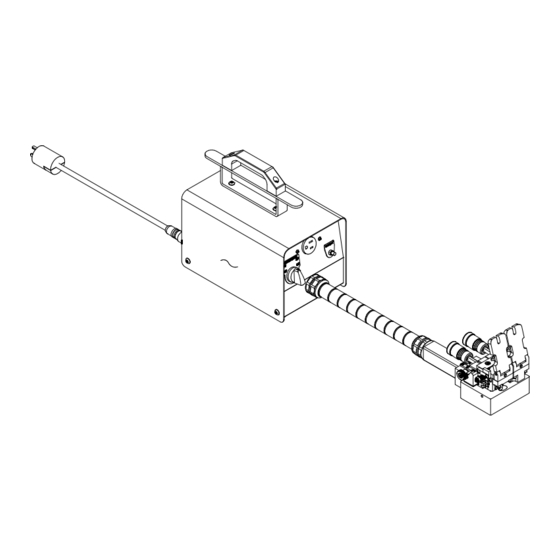

PORTABLE BUTT WELDER GENERAL DESCRIPTION GENERAL DESCRIPTION The Lincoln Electric Portable Butt Welder is designed to quickly and efficiently join ferrous metal wires up to .078 (2mm) in diameter. ARC RAYS CAN BURN. This unit will weld both solid and cored ferrous wires. Not compatible with non-ferrous wires, such as aluminum. -

Page 9: Installation

PORTABLE BUTT WELDER INSTALLATION INSTALLATION TECHNICAL SPECIFICATIONS Weight: 34 lbs / 15.4 kg Wire Compatibility: .030 to .078 (0.8 to 2 mm) ferrous wire Dimensions: Power Requirements: Base Unit: 8” W x 9” H x 16” L / 203 x 229 x 406 mm 120V, 5 Amps Handle &... -

Page 10: Operation

PORTABLE BUTT WELDER OPERATION OPERATION BUTT WELDING INSTRUCTIONS: 1. Ensure the Wire Size Select switch is in the OFF position (center). Connect Butt Welder to power supply. 2. Pull down both locking knobs to open wire clamps. 3. Pull and turn the Weld/Open switch to the “Open” position. 4. -

Page 11: Maintenance

PORTABLE BUTT WELDER MAINTENANCE MAINTENANCE SAFETY PRECAUTIONS: • Do not touch the wire or butt welder components during the butt welding cycle • Protective gloves and safety glasses are required when operating this unit • Do not operate near explosive or flammable materials •... -

Page 12: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. - Page 13 PORTABLE BUTT WELDER TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual Wire Blocks Note: Adjustment of the Set Screw wire blocks / set screw Location is only necessary when troubleshooting. CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

- Page 14 PORTABLE BUTT WELDER DIAGRAMS DIAGRAMS...

- Page 15 We respond to our customers based on the best information OPERATION BUTT WELDING INSTRUC- TIONS: in our possession at that time. Lincoln Electric is not in a position to MAINTENANCE SAFETY PRECAUTIONS: warrant or guarantee such advice, and assumes no liability, with...

Need help?

Do you have a question about the K3924-1 and is the answer not in the manual?

Questions and answers