Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Kobold NBK-16

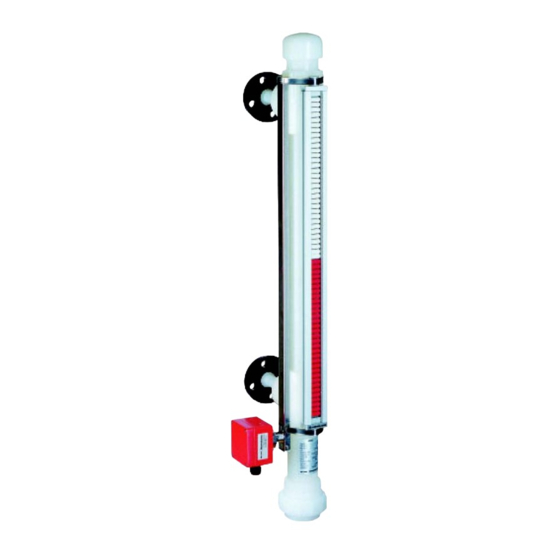

- Page 1 Operating Instructions Plastic Bypass Level Indicator Model: NBK -16...

-

Page 2: Table Of Contents

Maintenance ....................16 10.1 Bypass Level Indicator ............... 16 10.2 Reed sensors for NBK-16 ..............17 10.3 Messumformer für NBK-16 ..............17 Technical Information .................. 18 Order Codes ....................18 ... -

Page 3: Note

Please read these operating instructions before unpacking and putting the unit into operation. Follow the instructions precisely as described herein. The instruction manuals on our website www.kobold.com are always for currently manufactured version of our products. Due to technical changes, the instruction manuals available online may not always correspond to the product version you have purchased. -

Page 4: Regulation Use

NBK-16 4. Regulation Use Any use of the Bypass Level Indicator, model: NBK-16 or 17, which exceeds the manufacturer’s specification may invalidate its warranty. Therefore, any resulting damage is not the responsibility of the manufacturer. The user assumes all risk for such usage. -

Page 5: Commissioning/Operation Of Bypass Level Indicator

The suitability of the sealing must be specified with regard to the medium and its vapours. T = upper projection M = centre-to-centre distance U = lower projection NBK-16 K06/0623 page 5... -

Page 6: Commissioning

For the mounting of accessories (e.g. sensors or switches), the relevant maximum values for the instrument must be considered. The applicable laws and directives for the assembly and the planned purpose of application must be observed. page 6 NBK-16 K06/0623... -

Page 7: Commissioning Of The Reed Sensor "W

The electrical connection must only be made by qualified skilled personnel. Wire the reed sensor in accordance with the connection diagram of the electrical output (see product label). The connection terminals are appropriately marked. NBK-16 K06/0623 page 7... -

Page 8: Tightening Torques For Cable Glands

6.2 – 12 (depending on version) M20 / PG13 1 - 6 (depending on version) 8 – 12 (depending on version) NPT ½" 7 – 12 (depending on version) NPT ¾" 7 – 12 (depending on version) page 8 NBK-16 K06/0623... - Page 9 If the sealing insert is not flush but too deep in the cable gland clamp nut, the clamp nut was tightened with too low a torque. This can lead to the specified IP ingress of protection of the device not being achieved. NBK-16 K06/0623 page 9...

-

Page 10: Commissioning Of The Transmitter "M

Only use model “M” temperature transmitters in grounded thermometer Only use the temperature transmitter in grounded thermometers! page 10 NBK-16 K06/0623... -

Page 11: Mounting

Insert the measuring insert with the mounted transmitter into the protective fitting and secure into the connection head using screws in pressure springs. Mounting in the connection head cover When mounting it in the cover of a connection head, use suitable screws and matching washers. NBK-16 K06/0623 page 11... - Page 12 The load must not be too high, as otherwise, in the case of relatively high currents, the terminal voltage at the transmitter will be too low. Maximum permissible load depending on the supply voltage Load diagram page 12 NBK-16 K06/0623...

- Page 13 For the safety-relevant maximum values for the connection of the voltage supply and the sensors, see chapter “Specifications”. NBK-16 K06/0623 page 13...

-

Page 14: Faults

If faults cannot be eliminated by means of the listed measures, the instrument must be taken out of operation immediately. Ensure that there is no longer any pressure present and protect against being put into operation accidentally. Contact the manufacturer. page 14 NBK-16 K06/0623... -

Page 15: Reed Transducer

If faults cannot be eliminated by means of the listed measures, the instrument must be taken out of operation immediately. Ensure that there is no longer any pressure present and protect against being put into operation accidentally. Contact the manufacturer. NBK-16 K06/0623 page 15... -

Page 16: Maintenance

Electrical connections must not come into contact with moisture! CAUTION! Damage to property Improper cleaning may lead to damage to the instrument! Do not use any aggressive cleaning agents. Do not use any hard or pointed objects for cleaning. page 16 NBK-16 K06/0623... -

Page 17: Reed Sensors For Nbk-16

NBK-16 10.2 Reed transducer for NBK-16 10.2.1 Maintenance When used properly, the reed sensors work maintenance-free. They must be subjected to visual inspection within the context of regular maintenance, however, and included in the vessel pressure test. DANGER! Work on containers involves the danger of intoxication and suffocation. No work is allowed to be carried out unless by taking suitable personal protective measures (e.g. -

Page 18: Technical Information

NBK-16 11. Technical Information Operating instructions, data sheet, approvals and further information via the QR code on the device or via www.kobold.com 12. Order Codes Operating instructions, data sheet, approvals and further information via the QR code on the device or via www.kobold.com 13. -

Page 19: Disposal

(Cd, Hg, Li or Pb) of the heavy metal that is decisive for the classification as containing pollutants: 1. „Cd" stands for cadmium 2. „Hg" stands for mercury 3. „Pb" stands for lead 4. „Li" stands for lithium Electrical and electronic equipment NBK-16 K06/0623 page 19... -

Page 20: Eu Declaration Of Conformance

NBK-16 15. EU Declaration of Conformance We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole responsibility that the product: Bypass Level Indicator model: NBK -16 to which this declaration relates is in conformity with the standards noted below: EN 13445...

Need help?

Do you have a question about the NBK-16 and is the answer not in the manual?

Questions and answers