Subscribe to Our Youtube Channel

Summary of Contents for Leuze RSL 440

- Page 1 Original operating instructions RSL 440 RSL 445 Safety Laser Scanner We reserve the right to make technical changes EN • 2020-06-15 • 50128257...

- Page 2 © 2020 Leuze electronic GmbH + Co. KG In der Braike 1 73277 Owen / Germany Phone: +49 7021 573-0 Fax: +49 7021 573-199 www.leuze.com info@leuze.com Leuze electronic GmbH + Co. KG RSL 440...

-

Page 3: Table Of Contents

User management ...................... 24 4.4.4 Exiting Sensor Studio ...................... 24 Using configuration projects .................... 25 4.5.1 Selecting access level ....................... 27 4.5.2 IDENTIFICATION ...................... 28 4.5.3 PROCESS ......................... 28 4.5.4 CONFIGURATION ...................... 28 4.5.5 DIAGNOSIS ........................ 28 4.5.6 SETTINGS ........................ 29 Leuze electronic GmbH + Co. KG RSL 440... - Page 4 Stationary point of operation guarding .................. 47 Stationary access guarding .................... 48 Mobile danger zone guarding .................... 49 Danger zone safeguarding on side-tracking skates.............. 51 Vehicle navigation......................... 52 6.6.1 Signal strength and reflector detection................ 52 Leuze electronic GmbH + Co. KG RSL 440...

- Page 5 Defining permissible field pair changeovers ................. 90 Configuring signal outputs .................... 90 Saving configuration ...................... 91 Transferring configuration project to safety sensor............... 91 Selecting access level ...................... 93 9.10 Reset safety configuration .................... 93 Leuze electronic GmbH + Co. KG RSL 440...

- Page 6 15.1 General specifications ...................... 109 15.2 Dimensions ......................... 114 15.3 Dimensioned drawings: Accessories .................. 116 15.4 Representation of safety sensor status ................ 124 Standards and legal regulations .............. 128 Order guide and accessories................ 129 EC Declaration of Conformity................ 134 Leuze electronic GmbH + Co. KG RSL 440...

-

Page 7: About This Document

Machine identifies the product that the safety sensor is installed in. Downloading configuration software from the Internet Ä Call up the Leuze home page: www.leuze.com. Ä Enter the type designation or part number of the device as the search term. -

Page 8: Checklists

They replace neither testing of the complete machine or system prior to the initial start-up nor their periodic testing by a competent person. The checklists contain minimum testing requirements. Depending on the application, other tests may be necessary. Leuze electronic GmbH + Co. KG RSL 440... -

Page 9: Safety

• The construction of the safety sensor must not be altered. When manipulating the safety sensor, the protective function is no longer guaranteed. Manipulating the safety sensor also voids all warranty claims against the manufacturer of the safety sensor. Leuze electronic GmbH + Co. KG RSL 440... -

Page 10: Vapors, Smoke, Dust, Particles

Ä Only operate the device in accordance with its intended use. Ä Leuze electronic GmbH + Co. KG is not liable for damages caused by improper use. Ä Read these operating instructions before commissioning the device. Knowledge of the oper- ating instructions is an element of proper use. -

Page 11: Foreseeable Misuse

Ä Manipulating the safety sensor voids all warranty claims against the manufacturer of the safety sensor. Ä Repairs must only be performed by Leuze electronic GmbH + Co. KG. Competent persons Connecting, mounting, commissioning and adjustment of the safety sensor must only be carried out by competent persons. -

Page 12: Disclaimer

Ä The device must not be tampered with and must not be changed in any way. There are no user-serviceable parts inside the device. Repairs must only be performed by Leuze electronic GmbH + Co. KG. Responsibility for safety Manufacturer and operator must ensure that the machine and implemented safety sensor function properly and that all affected persons are adequately informed and trained. -

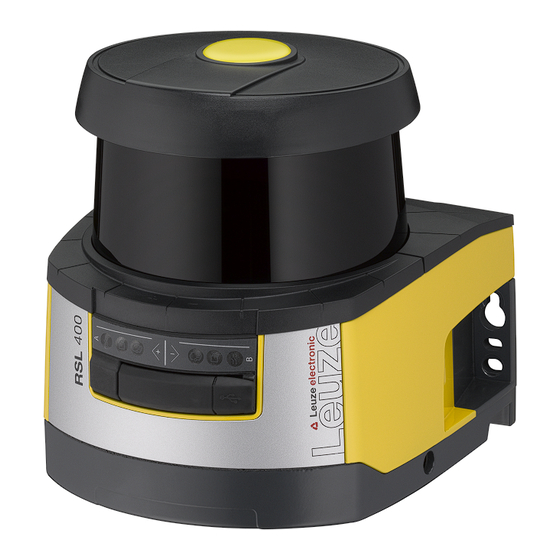

Page 13: Device Description

Performance Level (PL) in accordance with ISO 13849-1 Scanner unit Connection unit Optics cover Alphanumerical display (displayed) LED indicators Mini-B USB connection (behind protective cap) Fig. 3.1: Device overview of RSL 400 safety laser scanners Leuze electronic GmbH + Co. KG RSL 440... -

Page 14: Device Overview

Configurable signal outputs Number of changeover-capable pro- 10 + 10 tective/warning field pairs E-stop linkage Four field mode (quads) Internal safe time delay Measurement data output optimized Only RSL 425 Only RSL 445 for vehicle navigation USB interface Leuze electronic GmbH + Co. KG RSL 440... -

Page 15: Protective Function Of Rsl 400 Safety Sensors

• Monitoring and release of field pair changeover • Configurable output of the indication signals for the following functions groups: • Protective function • Warning messages • Error messages • Diagnosis • Status messages Leuze electronic GmbH + Co. KG RSL 440... -

Page 16: Usb Connection

• Quick-release connection to the scanner unit (see Quick Start Guide) for easy device swap-out NOTICE To ensure the IP protection and leak tightness of the devices, the supplied protection caps must always be placed on unused connections. Leuze electronic GmbH + Co. KG RSL 440... -

Page 17: Display Elements

It also provides assistance during detailed error diagnostics (see chapter 12 "Diagnosis and troubleshooting"). Tab. 3.3: Alphanumerical displays Display Description Example Upon startup without configuration/upon initial commissioning Sensor type Sensor type 420M Leuze electronic GmbH + Co. KG RSL 440... - Page 18 Message via a signal output or diag- ProtF A: E123 nosis ID Device: P007 - wrong Config Error diagnostics F… Failure, internal device error E… Error, external error U… Usage info, application error I… Information Leuze electronic GmbH + Co. KG RSL 440...

-

Page 19: Field-Of-View Display

The loop guard for the optics cover prevents damage to the safety sensor caused by light contact with for- eign objects. The loop guard is available as an accessory (see chapter 17 "Order guide and accessories"). Leuze electronic GmbH + Co. KG RSL 440... -

Page 20: Configuration And Diagnostic Software Sensor Studio

• Each device DTM has a communication DTM that sets up and monitors the communication connec- tions to the sensor. NOTICE Only use the software for safety sensors manufactured by Leuze. System requirements To use the software, you need a PC or laptop with the following specifications: Hard disk space At least 250 MB free memory... - Page 21 RSL 400 device DTM. The password for the safety sensor only needs to be entered (i.e. the access level only needs to be changed) when the changes are downloaded to the safety sensor (see chapter 4.5.1 "Selecting access level"). Leuze electronic GmbH + Co. KG RSL 440...

-

Page 22: User Interface

The device managers (DTM) of the safety sensors are created and managed in the FDT frame menu. Device manager DTM Configuration projects for setting up the selected safety sensor are created and managed in the device managers (DTM) of the safety sensors. Leuze electronic GmbH + Co. KG RSL 440... -

Page 23: Fdt Frame Menu

Ä Start the Project Wizard in the FDT frame menu by clicking the button. NOTICE Information on the Project Wizard can be found in the online help for the FDT frame menu under Sensor Studio Options. Leuze electronic GmbH + Co. KG RSL 440... -

Page 24: Dtm Change

Ä Save the configuration settings as a configuration project on the PC. You can open the configuration project again at later time via File > Open or with the Sensor Studio Project Wizard ( Leuze electronic GmbH + Co. KG RSL 440... -

Page 25: Using Configuration Projects

ð The project wizard displays the SEARCH DEVICES dialog box. Ä Select the interface and click the [Start] button. Ä Find the safety sensor for your configuration project using the search function of the communication DTM. Leuze electronic GmbH + Co. KG RSL 440... - Page 26 Search function Fig. 4.4: Communication DTM with search function ð The project wizard displays the device list of configurable safety sensors in the SEARCH DEVICES di- alog box. Fig. 4.5: Device selection in project wizard Leuze electronic GmbH + Co. KG RSL 440...

-

Page 27: Selecting Access Level

• Expert can change communication and diagnostics settings (default password = comdiag) • Engineer can additionally change the safety configuration (default password = safety) The password is case-sensitive (i.e. a distinction is made between upper-case and lower-case letters). Ä Confirm with [OK]. Leuze electronic GmbH + Co. KG RSL 440... -

Page 28: Identification

ð In the display of the safety sensor connected to the device manager (DTM), the message "PING re- ceived" flashes for ten seconds. Reset sensor Acknowledge messages and faults Set safety sensor to safety mode Leuze electronic GmbH + Co. KG RSL 440... -

Page 29: Settings

Create and save service file The service file contains all available information on the safety sensor as well as configuration and settings. When requesting support, send the service file to the Leuze customer service (see chapter 14 "Service and support"). - Page 30 Ä Generate a one-time password. Note down the generated reset password. Ä Send the reset password to the Leuze customer service for confirmation (see chapter 14 "Service and support"). The device can now be switched off and the connection can be terminated.

-

Page 31: Functions

• Load the signed safety configuration from a file and transfer/download to the safety sensor • Transfer changed communication and diagnostics settings from the PC to the safety sensor • Print configuration data incl. protective/warning fields • Calibrate optics cover Leuze electronic GmbH + Co. KG RSL 440... -

Page 32: Function Modes Of Safety Sensor

1 FP / 1 PF + 1 WF Fixed selection of one field pair 5 FP / 5 PF + 5 WF Selection by signal input: • Overlapped monitoring 10 FP / 10 PF + 10 WF Selection by signal input: • Fixed changeover moment Leuze electronic GmbH + Co. KG RSL 440... -

Page 33: One Protective Function

For the field pair changeover, see chapter 5.7 "Field pair changeover". Safe, time-delayed switch-off of safety-related switching outputs OSSD-B. Example of use: • AGV with varying operating conditions and different speed levels Leuze electronic GmbH + Co. KG RSL 440... - Page 34 B-CLEAR Switching output MELD – not safe Protective function B: protective field violation A-WF-VIO Switching output A1 Protective function A: Violation of warning field B-WF-VIO Switching output EA1 Protective function B: Violation of warning field Leuze electronic GmbH + Co. KG RSL 440...

- Page 35 For the field pair changeover, see chapter 5.7.6 "Changeover of 10x ten field pairs". • Manual restart when the configuration bank is changed over • Safe, time-delayed switch-off of safety-related switching outputs OSSD-B. Leuze electronic GmbH + Co. KG RSL 440...

-

Page 36: Selectable Resolution For Hand, Leg And Body Detection

The response time is the maximum time from a protective field violation to switch-off of the safety-related switching outputs. The response time is selected in the configuration project together for all protective/warning field pairs of a configuration bank. Leuze electronic GmbH + Co. KG RSL 440... -

Page 37: Configurable Start-Up Behavior

The machine only starts when you press the reset button. Automatic restart The automatic restart function starts the machine automatically as soon as the protective field is free again. Leuze electronic GmbH + Co. KG RSL 440... -

Page 38: Start/Restart Interlock (Res)

(AGVs), to control the field pair changeover for straight and curved stretches. If the rules for field pair changeover are not complied with, the safety sensor signals a fault and the safety- related switching outputs are switched off. Leuze electronic GmbH + Co. KG RSL 440... -

Page 39: Fixed Selection Of One Field Pair

• The changeover time starts when the second field pair is connected. When the changeover time has expired, only one field pair should still be active. • The changeover time is specified with the configuration and diagnostics software (see chapter 9.4.4 "Creating and configuring protective/warning field pairs"). Leuze electronic GmbH + Co. KG RSL 440... -

Page 40: Changeover Of Ten Field Pairs In Changeover Mode Fixed Changeover Moment

• Monitoring of the newly activated field pair starts when the changeover time has expired. • The changeover time is specified with the configuration and diagnostics software (see chapter 9.4.4 "Creating and configuring protective/warning field pairs"). Leuze electronic GmbH + Co. KG RSL 440... - Page 41 Fixed end – field pair changeover complete … Only one field pair change Field pair or quad X X Field pair changeover Fig. 5.4: Signal/time diagram: Overlapped monitoring Leuze electronic GmbH + Co. KG RSL 440...

-

Page 42: Changeover Of 100 Field Pairs

Multi configuration: one protective function, ten configuration banks each with ten field pairs Examples of use: • Machine with multiple operating modes (y) • AGV with different speed levels (x; control inputs F1 to F5) and multiple load states (y; control inputs F6 to F10) Leuze electronic GmbH + Co. KG RSL 440... -

Page 43: Monitoring Of Field Pair Changeover

(OSSDs). This is advisable when parking vehicles, for example. Activation of the function Ä Activate field pair monitoring in the configuration and diagnostics software (see chapter 9.4.5 "Configur- ing field pair monitoring"). Leuze electronic GmbH + Co. KG RSL 440... -

Page 44: Internal Safe Time Delay

"Internal safe time delay"), the response time of the delayed switch-off increases by up to 40 ms. Ä Take the extended response time of the delayed switch-off into account when configuring the system. Leuze electronic GmbH + Co. KG RSL 440... -

Page 45: 5.13.1 Contact-Based Safety Circuit

(see chapter 9.6 "Configuring signal outputs"). For an overview of all logic and electrical signals of the safety sensor, see chapter 15.4 "Representation of safety sensor status". Leuze electronic GmbH + Co. KG RSL 440... -

Page 46: Applications

If the danger zone changes during operation, the respective danger zone is guarded by means of a field pair changeover while the working area is accessible. Safety sensor Danger zone, protective function activated Fig. 6.1: Stationary danger zone guarding Leuze electronic GmbH + Co. KG RSL 440... -

Page 47: Stationary Point Of Operation Guarding

In accordance with EN ISO 13855, resolutions from 14 to 40 mm make sense here. This yields the necessary safety distance for finger protection, among others (see chapter 7.3 "Stationary point of operation guarding"). Leuze electronic GmbH + Co. KG RSL 440... -

Page 48: Stationary Access Guarding

This is why the start/restart interlock function is vital for access guarding. Safety sensor Reference contour Danger zone 1, protective function activated Danger zone 2, protective function deactivated Fig. 6.3: Stationary access guarding Leuze electronic GmbH + Co. KG RSL 440... -

Page 49: Mobile Danger Zone Guarding

Protective field 1 for forward travel, deactivated Protective field 2 for forward travel, activated Protective field 1 for reverse travel, activated Protective field 2 for reverse travel, deactivated Warning field for reverse travel Fig. 6.4: Mobile danger zone guarding Leuze electronic GmbH + Co. KG RSL 440... - Page 50 Protective field 1 for forward travel, deactivated Protective field 2 for forward travel, activated Protective field 1 for reverse travel, activated Protective field 2 for reverse travel, deactivated Warning field for reverse travel Fig. 6.5: Mobile danger zone guarding Leuze electronic GmbH + Co. KG RSL 440...

-

Page 51: Danger Zone Safeguarding On Side-Tracking Skates

Protective and warning field pair for side guarding, left, activated Protective and warning field pair for side guarding, right, activated Protective and warning field pair for reverse travel, deactivated Fig. 6.6: Mobile side guarding on side-tracking skates Leuze electronic GmbH + Co. KG RSL 440... -

Page 52: Vehicle Navigation

• Angle of incidence of the laser beam on the object surface 0°: vertically incident light • Share of area of the light spot on the object 100%: the light spot lies completely on the measured object Leuze electronic GmbH + Co. KG RSL 440... - Page 53 3M™ Diamond Grade 983-10™. The lower curve (4) shows the typical, distance-dependent change of the signal strength for a white, natu- rally scattering surface with 90% diffuse reflection, e.g., a white wall. Leuze electronic GmbH + Co. KG RSL 440...

-

Page 54: Mounting

= Stopping time of the machine [mm] = Additional distance to the safety distance NOTICE If longer stopping times are determined during regular inspections, an appropriate additional time must be added to t Leuze electronic GmbH + Co. KG RSL 440... -

Page 55: Suitable Mounting Locations

• Make sure that the scanning range of the safety sensor is not limited. To mount the safety sensor tak- ing the scanning range into consideration, a template must be attached to the top cover of the safety sensor. Leuze electronic GmbH + Co. KG RSL 440... - Page 56 Ä Align the mounted safety sensor horizontally and vertically using the integrated electronic spirit level. • For the electronic spirit level to work, the supply voltage of 24 V must be present at the safety sensor. Leuze electronic GmbH + Co. KG RSL 440...

- Page 57 You can easily test the safety sensor along this marking. After mounting, you can electrically connect (see chapter 8 "Electrical connection"), start up, align (see chapter 10 "Starting up the device"), and test (see chapter 11 "Testing") the safety sensor. Leuze electronic GmbH + Co. KG RSL 440...

-

Page 58: Mounting Examples

Safety sensor Column BT856M mounting bracket Fig. 7.3: Example: mounting on a post all dimensions in mm Safety sensor BT840M mounting bracket Fig. 7.4: Example: mounting on a chamfered corner Leuze electronic GmbH + Co. KG RSL 440... -

Page 59: Information On Protective Field Dimensioning

There is an area behind the safety sensor that the safety sensor does not monitor. Unmonitored areas can also materialize, e.g. if you install a safety sensor on a rounded off vehicle front. It must not be possible to walk behind unmonitored areas. Leuze electronic GmbH + Co. KG RSL 440... - Page 60 Stepping behind protection by countersinking into the machine contour Ä Use a physical cover set at an angle over the safety sensor if you expect that the safety sensor will be used as a climbing aid or standing surface. Leuze electronic GmbH + Co. KG RSL 440...

- Page 61 Shielding prevents reciprocal influencing of safety sensors set up beside one another Ä Install the safety sensors off-set on the height. Minimum distance, min. 100 mm Scan level Fig. 7.9: Height offset mounting, parallel alignment Leuze electronic GmbH + Co. KG RSL 440...

-

Page 62: Stationary Danger Zone Guarding

120 ms or higher. Ä Determine the machine/system's stopping time t If data is not available, you can commission Leuze to perform measurements; see chapter 14 "Service and support". Ä If an increase in the stopping time within the regular test periods is to be expected, take an additional time into account for the machine's stopping time t... - Page 63 Largest protective field radius without additional distances, measured from the rotation axis of the rotary mirror Fig. 7.12: Defining the protective field contour for a stationary, horizontal protective field Ä Define the limits of the protective field using the safety distance S without an additional distance. Leuze electronic GmbH + Co. KG RSL 440...

- Page 64 Ä Prevent obstructions within the calculated protective field boundaries. If this is not possible, implement protective measures so that the point of operation cannot be reached from out of the shadow of the ob- struction. Leuze electronic GmbH + Co. KG RSL 440...

-

Page 65: Stationary Point Of Operation Guarding

80 ms or higher. Ä Determine the machine/system's stopping time t If data is not available, you can commission Leuze to perform measurements (see chapter 14 "Service and support"). Ä If an increase in the stopping time within the regular test periods is to be expected, take an additional time into account for the machine's stopping time t... -

Page 66: Stationary Access Guarding

40 ms. With K = 2000 mm/s approach speed this corre- sponds with an increase in the safety distance of 80 mm per additional scan. With K = 1600 mm/s it is 64 mm. Leuze electronic GmbH + Co. KG RSL 440... -

Page 67: Mobile Danger Zone Guarding On Agvs

1600 mm/s. Ä Determine the machine/system's stopping time t If data is not available, you can commission Leuze to perform measurements (see chapter 14 "Service and support"). Ä If an increase in the stopping time within the regular test periods is to be expected, take an additional time into account for the machine's stopping time t... -

Page 68: Minimum Distance D

Its size depends on the biggest radius R from the safety sensor mirror's rotary axis to the protective field boundary without Z . The position of the rotary mirror axis depends on the installation situation. Leuze electronic GmbH + Co. KG RSL 440... -

Page 69: Protective Field Dimensions

A full brake with a subsequent interruption of the protective field is then executed moderately and is less demanding on the vehicle's drives. Dimension the minimum distance D for the maximum speed as if the speed reduction initiated by the warning field had not happened. Leuze electronic GmbH + Co. KG RSL 440... -

Page 70: Mobile Side Guarding On Agvs

Ä Mount the mounting system on the wall mount or on the mounting bracket for floor mounting. Ä Attach the safety sensor to the mounting system. Tightening the screws fixes the safety sensor in position. Ä Align the safety sensor using the integrated electronic spirit level. Leuze electronic GmbH + Co. KG RSL 440... -

Page 71: Loop Guard

BTU800M mounting system Loop guard Safety sensor Fig. 7.18: Loop guard Ä Attach the safety sensor to the mounting system. Ä Engage the loop guard for the optics cover from above into the mounting system. Leuze electronic GmbH + Co. KG RSL 440... -

Page 72: Electrical Connection

(see chapter 8.3 "Connection unit CU429"). • Functional grounding via the shield of the connection cable. For grounding, the shield of the connection cable in the switch cabinet must be connected to earth or machine/vehicle ground. Leuze electronic GmbH + Co. KG RSL 440... -

Page 73: Interfaces

Ä For permanent connection, connect the safety sensor to the Ethernet connection of the con- nection unit. The control cable is permanently attached to the connection unit. A protection cap on the connection unit protects the communication interface when no PC is connected. Leuze electronic GmbH + Co. KG RSL 440... -

Page 74: Connection Cable, Control

Field pair changeover with 100 field pairs (Ay.1) – 1st position White/Red Bank changeover with multi configuration (Ay.1) Brown/Red White/Black Brown/Black Gray/Green RES2 Start/restart input, protective function B Acknowledgment Yellow/Gray OSSDB1 Safety-related switching output, protective function B Pink/Green OSSDB2 Safety-related switching output, protective function B Leuze electronic GmbH + Co. KG RSL 440... -

Page 75: Connection Cable With M30 Connector

Linkage input (E-Stop, OSSD – external device) White/Yellow Linkage input (E-Stop, OSSD – external device) Yellow/Brown Output signal state signaling, configurable White/Gray Output signal state signaling, configurable Gray/Brown Output signal state signaling, configurable Leuze electronic GmbH + Co. KG RSL 440... -

Page 76: Pin Assignment Of M12 Ethernet Interface (Communication) ( D-Coded)

Functional earth, communication cable shield. The shield of the inter- connection cable is on the thread of the M12 connector. The thread is part of the metallic housing. The housing is at the same potential as functional earth. Leuze electronic GmbH + Co. KG RSL 440... -

Page 77: Connection Unit Cu429

16.8 V. NOTICE The recommended operating voltage is at least 19 V! Leuze recommends an operating voltage U of at least 19 V at the input terminals of the con- nection unit. Ä The operating voltage should not be allowed to drop below the recommended value if possi- ble. - Page 78 When using the OSSD linkage function, observe the specifications of the upstream device for the cable length and for the maximum permissible cable resistance (see chapter 5.13.2 "Linkage of electronic safety-related switching outputs"). Leuze electronic GmbH + Co. KG RSL 440...

-

Page 79: Cable Lengths According To The Operating Voltage

16.8 V. NOTICE The recommended operating voltage is at least 19 V! Leuze recommends an operating voltage U of at least 19 V at the input terminals of the con- nection unit. Ä The operating voltage should not be allowed to drop below the recommended value if possi- ble. -

Page 80: Circuit Diagram Example

Electrical connection Circuit diagram example Spark extinction circuit, suitable spark extinction provided Fig. 8.6: RSL 440 with MSI-SR4B safety relay Leuze electronic GmbH + Co. KG RSL 440... -

Page 81: Configuring The Safety Sensor

Ä For example, make sure that the distance range in which manipulation is possible cannot be accessed by personnel under normal operating conditions. Leuze electronic GmbH + Co. KG RSL 440... - Page 82 To document the configuration, you can create a PDF file of the safety configuration or save the config- uration and settings in an *.xml file. Leuze electronic GmbH + Co. KG RSL 440...

-

Page 83: Connecting Safety Sensor To Pc

The distance between safety sensor and PC is limited to 5 m if a standard USB cable is used. Use active USB cables if longer cable lengths are required. NOTICE Ä If possible, use the ready-made cables from Leuze (see chapter 17 "Order guide and acces- sories"). Leuze electronic GmbH + Co. KG... -

Page 84: Communication Between Safety Sensor And Pc

Bluetooth device scan. To allow com- munication via the Bluetooth interface, you must enter the device identification of the safety sensor manually. Leuze electronic GmbH + Co. KG RSL 440... -

Page 85: Determine The Configuration Project

Alternatively, you can select the safety sensor by entering the part number or by specifying the sensor range and the sensor type. ð The device manager (DTM) of the safety sensor shows the initial screen for the configuration project. Configuration Wizard Fig. 9.1: Safety configuration using Configuration Wizard Leuze electronic GmbH + Co. KG RSL 440... -

Page 86: Configuring Protective Function

ð The Protective function B option is shown in the CONFIGURATION menu if Two protective functions was selected in the FUNCTION MODE list. NOTICE The changeover-capable protective/warning field pairs for the selected protective function are defined in configuration banks. Leuze electronic GmbH + Co. KG RSL 440... -

Page 87: Creating And Configuring Protective/Warning Field Pairs

ð The RESOLUTION, RESPONSE TIME, START-UP BEHAVIOR and EXTENDED OUTPUT SIGNALS dialog boxes are displayed. Ä In the RESOLUTION dialog box, enter the resolution and, if applicable, the maximum speed of an auto- mated guided vehicle (AGV) in the input fields. Leuze electronic GmbH + Co. KG RSL 440... - Page 88 Ä Add the field pairs for the other banks of Protective function A if one protective function with multiple configuration banks has been selected. ð The added field pairs are shown in the CONFIGURATION menu under Bank [x] under Protective func- tion A. Leuze electronic GmbH + Co. KG RSL 440...

- Page 89 It is also possible to read in an RS4 configuration file as well as to convert the protective fields on the RSL400. Note here, that the converted field pairs are only contour suggestions. Therefore, check that the fields are appropriate for the requirements of your safety application. Leuze electronic GmbH + Co. KG RSL 440...

-

Page 90: Configuring Field Pair Monitoring

Ä For each usable connection, select the function group and the function of the indication signal. Ä Click the [Confirm] button. NOTICE All signal outputs are high active, i.e. logical 1 or +24 V DC with an active signal. Leuze electronic GmbH + Co. KG RSL 440... -

Page 91: Saving Configuration

ð The software asks for the access level and the password. Ä Select the access level Engineer and enter the preset default password (safety) or the defined individ- ual password. Confirm with [OK]. Leuze electronic GmbH + Co. KG RSL 440... - Page 92 Ä Confirm successful transfer of the safety configuration to the safety sensor with [OK]. The safety configuration has only been successfully transferred to the safety sensor when the confirma- tion dialog is displayed during the download. Leuze electronic GmbH + Co. KG RSL 440...

-

Page 93: Selecting Access Level

Ä In the DTM menu bar, click the [Reset safety configuration] button. ð Users with the access level Engineer can additionally transfer the changed safety configuration to the safety sensor (see chapter 9.8 "Transferring configuration project to safety sensor"). Leuze electronic GmbH + Co. KG RSL 440... -

Page 94: Starting Up The Device

Ä Unlock the start/restart interlock using the reset button. The safety-related switching outputs are only enabled if you hold down the reset button for between 0.12 s and 4 s. Leuze electronic GmbH + Co. KG RSL 440... -

Page 95: Shutting Down

Ä Change the configuration parameters of the safety sensor using the configuration and diag- nostic software according to the operating range of the replacement scanner unit. Leuze electronic GmbH + Co. KG RSL 440... - Page 96 Ä If you transferred a new configuration to the safety sensor, check the safety sensor according to the routine for initial start-up (see chapter 11.1.1 "Checklist for integrator – to be performed prior to the ini- tial start-up and following modifications"). Leuze electronic GmbH + Co. KG RSL 440...

-

Page 97: Testing

Is the safety sensor correctly aligned and are all fastening screws and connec- tors secure? Are safety sensor, connection cables, connectors, protection caps and com- mand devices undamaged and without any sign of manipulation? Leuze electronic GmbH + Co. KG RSL 440... -

Page 98: To Be Performed Periodically By Competent Persons

Ä Have all tests performed by competent persons. Ä Observe the nationally applicable regulations and the time periods specified therein. Ä As preparation, observe the checklist (see chapter 11.1 "Before the initial start-up and following modifi- cations"). Leuze electronic GmbH + Co. KG RSL 440... -

Page 99: Periodically By The Operator

Use a sample item with the set resolution as the test rod. The sample item should have a matt surface structure. Do the LED 1 and LED 6 on the safety sensor illuminate constantly red while the protec- tive field is interrupted? Leuze electronic GmbH + Co. KG RSL 440... - Page 100 – are the obviously dangerous machine parts stopped with- out noticeable delay? Protective device with presence detection: the protective field is interrupted with the test object – does this prevent operation of the obviously dangerous machine parts? Leuze electronic GmbH + Co. KG RSL 440...

-

Page 101: Diagnosis And Troubleshooting

Ä Analyze the cause of the fault using the diagnostics displays and rectify the fault. Ä If you are unable to rectify the fault, contact the Leuze branch responsible for you or call the Leuze customer service (see chapter 14 "Service and support"). - Page 102 Swap out the safety sensor or change the known parameter. configuration. The type of safety sensor must be the same as the type stored in the connec- tion unit or in the Sensor Studio software. Leuze electronic GmbH + Co. KG RSL 440...

- Page 103 Field pair changeover without request. Check the request signal for field pair changeover or change the safety configura- tion. U0849 Field pair changeover not permitted. Check the wiring of the field pair inputs. Leuze electronic GmbH + Co. KG RSL 440...

- Page 104 (Without switch-off of the OSSDs) F..The monitoring functions have detected an Create the service file (see chapter 4.5.5 "DI- internal error. AGNOSIS") and contact the Leuze customer service (see chapter 14 "Service and sup- port"). Leuze electronic GmbH + Co. KG RSL 440...

-

Page 105: Care, Maintenance And Disposal

Ä Check the safety sensor according to the routine for initial start-up (see chapter 11.1.1 "Checklist for in- tegrator – to be performed prior to the initial start-up and following modifications"). Leuze electronic GmbH + Co. KG RSL 440... -

Page 106: Cleaning The Optics Cover

After cleaning is complete, the safety sensor resets itself auto- matically. Ä Clean the optics cover over the entire 360° range. Ä Soak cloth with cleaning agent. Ä Wipe optics cover free in one swipe. Leuze electronic GmbH + Co. KG RSL 440... -

Page 107: Servicing

The device does not normally require any maintenance by the operator. Repairs to the device must only be performed by the manufacturer. Ä For repairs, contact your responsible Leuze subsidiary or Leuze customer service (see chapter 14 "Ser- vice and support"). -

Page 108: Service And Support

Service and support Service and support 24-hour on-call service at: +49 7021 573-0 Service hotline: +49 7021 573-123 E-mail: service.protect@leuze.de Return address for repairs: Servicecenter Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen/Germany Leuze electronic GmbH + Co. KG RSL 440... -

Page 109: Technical Data

Device range Resolution [mm] Protective field range [m] 3.00 4.50 6.25 8.25 3.00 4.50 6.25 8.25 3.00 4.50 6.25 8.25 3.00 4.50 6.25 6.25 3.00 4.50 4.50 4.50 3.00 3.50 3.50 3.50 Leuze electronic GmbH + Co. KG RSL 440... - Page 110 Measurement range: 0 m … 9 m • Diffuse reflection: 20% … retro-reflector Measurement range: 0 m … 25 m Laser spot height 10 m 60 mm 20 m 165 mm 30 m 265 mm 40 m 285 mm Laser spot width 10 m 13 mm 20 m 24 mm 30 m 40 mm 40 m 57 mm Leuze electronic GmbH + Co. KG RSL 440...

- Page 111 Reset +24 V, dynamically monitored (0.12 s to 4 s) Field pair changeover Selection of 10, 10 x 10 or 100 field pairs via 10 control cables +24 V, dynamically monitored Signal definition: High/logical 1 16 - 30 V Low/logical 0 < 3 V Leuze electronic GmbH + Co. KG RSL 440...

- Page 112 Control input Current-limited, short-circuit proof (-20 mA) (A3, A4) AX=output 100 mA Lamp (PNP only) Current-limited, short-circuit proof (-20 mA) Control input (PNP/ (A1, A2, MELD) NPN) Signal definition: High/logical 1 16 - 30 V Low/logical 0 < 3 V Leuze electronic GmbH + Co. KG RSL 440...

- Page 113 Weight of standard version incl. connection unit Approx. 3 kg Distance, beam level center to bottom housing edge 104 mm Tab. 15.16: Patents US patents US 7,656,917 B US 7,696,468 B US 8,520,221 B US 2016/0086469 A Leuze electronic GmbH + Co. KG RSL 440...

-

Page 114: Dimensions

Technical data 15.2 Dimensions M5 2x all dimensions in mm Scan level Fig. 15.2: Dimensions safety laser scanner with connection unit Leuze electronic GmbH + Co. KG RSL 440... - Page 115 Fig. 15.4: Minimum space requirements for installation and replacement of scanner unit all dimensions in mm Reference point for distance measurement and protective field radius Fig. 15.5: Dimensions of scanning range Leuze electronic GmbH + Co. KG RSL 440...

-

Page 116: Dimensioned Drawings: Accessories

Technical data 15.3 Dimensioned drawings: Accessories 157,5 166,3 all dimensions in mm Fig. 15.6: BTU800M mounting system Leuze electronic GmbH + Co. KG RSL 440... - Page 117 Technical data all dimensions in mm Fig. 15.7: BTF815M mounting bracket Leuze electronic GmbH + Co. KG RSL 440...

- Page 118 Technical data all dimensions in mm Fig. 15.8: BTF830M mounting bracket Leuze electronic GmbH + Co. KG RSL 440...

- Page 119 Technical data all dimensions in mm Fig. 15.9: Loop guard BTP800M 205,2 all dimensions in mm Fig. 15.10: BT840M mounting bracket Leuze electronic GmbH + Co. KG RSL 440...

- Page 120 Technical data all dimensions in mm Fig. 15.11: Mounting bracket BT840M, view A 233,5 all dimensions in mm Fig. 15.12: BT856M mounting bracket Leuze electronic GmbH + Co. KG RSL 440...

- Page 121 Technical data all dimensions in mm Fig. 15.13: Mounting bracket BT856M, view A Leuze electronic GmbH + Co. KG RSL 440...

- Page 122 Technical data 120,4 all dimensions in mm Fig. 15.14: Drilling template for adapter plate, RS4/ROD4 BT800MA Leuze electronic GmbH + Co. KG RSL 440...

- Page 123 Technical data 157,5 166,3 all dimensions in mm The mounting plate BTU804MA supplements the old mounting system of the RS4/ROD4 for the mounting system BTU800M. Fig. 15.15: BTU804MA mounting plate Leuze electronic GmbH + Co. KG RSL 440...

-

Page 124: Representation Of Safety Sensor Status

OSSD state Protective function A B-OSSD OSSD state Protective function B Emergency stop and parking Status-Input-SE Status of the inputs SE1 and SE2 E-STOP Mode-PARK Park request fulfilled parked Reserved Reserved Reserved Reserved Reserved Reserved Leuze electronic GmbH + Co. KG RSL 440... - Page 125 EDM input Protective function B Linkage input Linkage input PNP-NPN PNP/NPN changeover Output Output Output Output MELD Output Reserved 8-11 31-0 SCAN Consecutive numbering of scans value uint32 Resetting to 0 by switching off Leuze electronic GmbH + Co. KG RSL 440...

- Page 126 A-PF-VIO-SEG-2 Status of active protective field violation free segment Protective function A A-FP-SEL-1 Defined field pair selected selected Protective function A A-FP-SEL-2 Defined field pair selected selected Protective function A Reserved Reserved Leuze electronic GmbH + Co. KG RSL 440...

- Page 127 B-PF-VIO-SEG-2 Status of active protective field violation free segment Protective function B B-FP-SEL-1 Defined field pair selected selected Protective function B B-FP-SEL-2 Defined field pair selected selected Protective function B Reserved Reserved Leuze electronic GmbH + Co. KG RSL 440...

-

Page 128: Standards And Legal Regulations

• Product Safety Law (ProdSG) • Standards for risk assessment, e.g. • ISO 12100 • ISO 13849-1, -2 • IEC 61508-1 to -7 • IEC 62061 • IEC 60204-1 • ISO 13849-1 • ISO 13855 • IEC 61496-3 • EN 1525 • IEC 62046 Leuze electronic GmbH + Co. KG RSL 440... -

Page 129: Order Guide And Accessories

2 OSSD pairs; 100 field pairs; 9 IOs; protective field range max. 3.0 m Connection: cable, 29-wire, length 5 m Ethernet: M12, 4-pin 53800242 RSL440-M/CU429-25 2 OSSD pairs; 100 field pairs; 9 IOs; protective field range max. 4.5 m Connection: cable, 29-wire, length 5 m Ethernet: M12, 4-pin Leuze electronic GmbH + Co. KG RSL 440... - Page 130 Connection: cable, 29-wire, length 5 m Ethernet: M12, 4-pin 53800287 RSL445-S/CU429-10 2 OSSD pairs; 100 field pairs; 9 IOs; data output for navigation, protective field range max. 3.0 m Connection: cable, 29-wire, length 10 m Ethernet: M12, 4-pin Leuze electronic GmbH + Co. KG RSL 440...

- Page 131 Connection: 0.3 m cable with 30-pin connector Ethernet: M12, 4-pin 53800298 RSL445-XL/CU429-300- 2 OSSD pairs; 100 field pairs; 9 IOs; data output for navigation, protective field range max. 8.25 m Connection: 0.3 m cable with 30-pin connector Ethernet: M12, 4-pin Leuze electronic GmbH + Co. KG RSL 440...

- Page 132 Connection cable, 30-pin, 5 m 50137270 KD S-M30-30A-V1-100 Connection cable, 30-pin, 10 m 50137271 KD S-M30-30A-V1-250 Connection cable, 30-pin, 25 m Connection technology – Connectors/sockets 50137267 S U-M30-30A-M Connection connector, 30-pin 50137268 D U-M30-30A-M Connection socket, 30-pin Leuze electronic GmbH + Co. KG RSL 440...

- Page 133 Drilling template for adapter plate, RS4/ROD4 Cleaning fluids 430400 Cleaning set 1 Cleaning fluid for plastic, 150 ml, cleaning cloths, 25x, soft, fuzz- free 430410 Cleaning set 2 Cleaning fluid for plastic, 1,000 ml, cleaning cloths, 100x, soft, fuzz-free Leuze electronic GmbH + Co. KG RSL 440...

-

Page 134: Ec Declaration Of Conformity

EC Declaration of Conformity EC Declaration of Conformity Leuze electronic GmbH + Co. KG RSL 440...

Need help?

Do you have a question about the RSL 440 and is the answer not in the manual?

Questions and answers