Table of Contents

Advertisement

Quick Links

www.industrial-needs.com

PCE Instruments UK Ltd

Units 12/13 Southpoint Business

Park

Ensign Way, Southampton

Hampshire

United Kingdom, SO31 4RF

Phone +44 ( 0 ) 2380 98703 0

Fax

+44 ( 0 ) 2380 98703 9

e-mail: info@industrial-needs.com

Operating Instructions

Rotation Viscometer PCE-RVI 3

Version 1.0

27.08.2014

Advertisement

Table of Contents

Summary of Contents for PCE Instruments PCE-RVI 3

- Page 1 PCE Instruments UK Ltd Units 12/13 Southpoint Business Park Ensign Way, Southampton Hampshire United Kingdom, SO31 4RF Phone +44 ( 0 ) 2380 98703 0 +44 ( 0 ) 2380 98703 9 e-mail: info@industrial-needs.com Operating Instructions Rotation Viscometer PCE-RVI 3 Version 1.0 27.08.2014...

-

Page 2: Table Of Contents

OPERATING INSTRUCTIONS www.industrial-needs.com Table of contents General Information....................3 Introduction ............................3 Area of Application ..........................3 Hazard Symbols ..........................3 Safety Precautions ..........................4 Certification, Warranty and Documentation ................... 5 Technical Data ......................6 Putting Viscometer into Operation ................7 Unpacking the Viscometer ........................ -

Page 3: General Information

The PCE-RVI 3 is battery powered and operates at a constant speed (20, 30, 50 or 60 rpm). The low energy consumption of the device enables it to be used non-stop for more than 24 hours without the need to replace the batteries. -

Page 4: Safety Precautions

OPERATING INSTRUCTIONS www.industrial-needs.com Information This symbol warns of specific details relating to the viscometer which must be heeded all times. Users must pay close attention to the advice in this operating instruction, and be aware of and take into account all safety and hygiene standards concerning the local working conditions. -

Page 5: Certification, Warranty And Documentation

Warranty The Viscometer PCE-RVI 3 has a two year warranty against defects in materials or workmanship. During this period, any defective parts will be repaired or replaced free of charge. Warranty claims other than those previously mentioned are expressly excluded. Improper modifications, or repairs carried out by unauthorized third parties will result in the warranty being declared invalid. -

Page 6: Technical Data

OPERATING INSTRUCTIONS www.industrial-needs.com Technical Data Portable Viscometer PCE-RVI 3 Power requirement Alkaline batteries: 4 x AA/LR6 Rechargeable batteries: 4 x AA/R6 Battery capacity Alkaline batteries: 1900 mAh Rechargeable batteries: 2500 mAh 24 – 30 Std. continuous operation Battery life ... -

Page 7: Putting Viscometer Into Operation

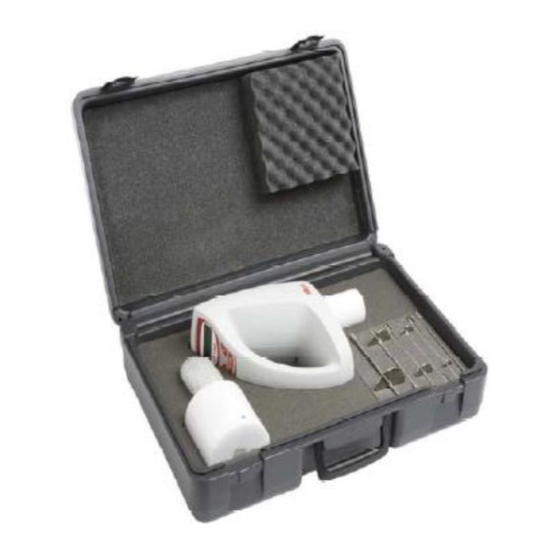

Remove all the packaging items and transport safety, recyclable material should be disposed in the intended containers, the main reason. Delivery Content Portable rotation viscometer PCE-RVI 3 Standard spindle set (R2-R7) Spindle guard ... -

Page 8: Battery Replacement

OPERATING INSTRUCTIONS www.industrial-needs.com Battery Replacement The portable Viscometer PCE RVI 3 is battery powered and is delivered with 4 pre-installed alkaline batteries (4x AA/LR6 (6V) plus 4 extra replacement batteries). The Viscometer can be operated with alkaline batteries (Type AA/LR6) or rechargeable batteries (Type AA/R6). In constant use, the battery life is 24-30 hours. -

Page 9: Installing The Spindle Guard

OPERATING INSTRUCTIONS www.industrial-needs.com Care must be taken at this point, in order to avoid bending the spindle or damaging the shaft. Both the thread on the spindle and on the shaft must be absolutely clean and dirt free. The R7 spindle must be dipped into the liquid up to the middle marker point. The spindle is made of stainless steel. -

Page 10: Stand Construction (Optional)

OPERATING INSTRUCTIONS www.industrial-needs.com After assembling the spindle guard, it must be attached to the Viscometer. Carefully push the Viscometer shaft into the upper disc of the spindle guard assembly as shown in the diagram. Using the Allen key provided, carefully tighten the spindle assembly to the Viscometer shaft. Take extra care when tightening the fixing screws on the spindle guard to the Viscometer, so as to avoid damage to the shaft or spindle. - Page 11 OPERATING INSTRUCTIONS www.industrial-needs.com Carefully push the viscometer into the opening. When the shaft is in the holder, carefully press the viscometer downwards to lock it into the holder. Attach the viscometer with the included Allen screw to the holder.

-

Page 12: Operation

Operation Switch on and Configuration The PCE-RVI 3 configuration is extremely simple, because the only parameter that can be adjusted is the one that determines the spindle. To adjust the display read out use the ENTER-button and “ ” and “... - Page 13 OPERATING INSTRUCTIONS www.industrial-needs.com The measuring range is dependent upon the maximum measurable viscosity value for the spindle/speed combination being used. By providing this value, it is much simpler to choose the correct spindle for the testing of a particular fluid. ...

-

Page 14: Measuring

OPERATING INSTRUCTIONS www.industrial-needs.com Measuring Start measurement Press the “ENTER” button to make the spindles rotate and to begin the measurements. The spindle starts to rotate; the display shows the following values: Speed (20, 30, 50 or 60 rpm), spindle selection as well as question marks which show that the viscometer is determining the viscosity values. - Page 15 OPERATING INSTRUCTIONS www.industrial-needs.com Finish Measurement To finish the measurement, press the “ENTER” button again. The current measuring value and the fraction of the full scale remain on the display. To start a new measurement, proceed as described above. Switch off Viscometer Press the “ENTER”...

-

Page 16: Calibration Of The Equipment

OPERATING INSTRUCTIONS www.industrial-needs.com Calibration of the Equipment Before the delivery the Viscometer is calibrated with Newtonian oils. We recommend a regular recalibration, depending on how often the equipment is used. Please contact your supplier for an appropriate calibration. Viscometer Function Check We recommend a functions check with our viscosity-standard fluids, which are available on request. -

Page 17: Optional Accessories

OPERATING INSTRUCTIONS www.industrial-needs.com Do not forget to remove the spindles during the automatic “zeroing” It is also recommended that the “zeroing” is carried out on the stand and not whilst holding in the hand. If this is not possible, then the viscometers vertical alignment should be ensured. ... -

Page 18: About The Viscosity

The PCE RVI 3 is a portable rotational viscometer, used to measure the viscosity of many types of liquid. The measurements are taken in accordance with the Brookfield method. The readings obtained from the PCE-RVI 3 are perfect for comparing results taken using other types of Brookfield Viscometers. - Page 19 OPERATING INSTRUCTIONS www.industrial-needs.com The following variables can influence viscosity measurements: Viscometer type Dimensions of sample container Fill level Sample temperature Spindle Rotation speed Whether or not the spindle protector is being used. Duration of the test Invariably any change in working methods will lead to a change in results.

-

Page 20: Viscosity Table

OPERATING INSTRUCTIONS www.industrial-needs.com Viscosity Table Spindle Model Viscosity in mPas VP20 2000 5000 10000 20000 50000 200000 VP60 1600 3300 6600 16600 66600 Viscosity measuring range (with standard spindles) (Between 10% - 100% of the maximum measuring value): Type VP20: 200 – 200000 mPas Type VP60: 66 –...

Need help?

Do you have a question about the PCE-RVI 3 and is the answer not in the manual?

Questions and answers