Nice Mindy A60 Instructions And Warnings

Hide thumbs

Also See for Mindy A60:

- Installation instructions manual (88 pages) ,

- Instructions for installation and use manual (116 pages) ,

- Instructions and warnings for installation and use (116 pages)

Table of Contents

Advertisement

Quick Links

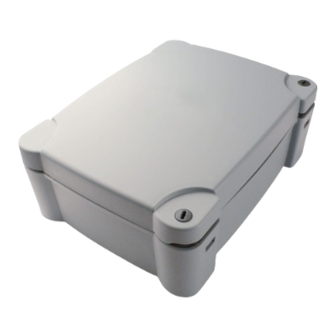

Mindy

Control unit

A60

Instructions and warnings for the fitter

Istruzioni ed avvertenze per l'installatore

Instructions et recommandations pour l'installateur

Anweisungen und Hinweise für den Installateur

Instrucciones y advertencias para el instalador

Instrukcje i uwagi dla instalatora

Aanwijzingen en aanbevelingen voor de installateur

Advertisement

Table of Contents

Summary of Contents for Nice Mindy A60

- Page 1 Mindy Control unit Instructions and warnings for the fitter Istruzioni ed avvertenze per l’installatore Instructions et recommandations pour l’installateur Anweisungen und Hinweise für den Installateur Instrucciones y advertencias para el instalador Instrukcje i uwagi dla instalatora Aanwijzingen en aanbevelingen voor de installateur...

-

Page 2: Table Of Contents

Mindy Index: page Warnings Programming Programmable functions Product description Description of functions Operating limits Typical system Testing List of cables Commissioning Installation Maintenance and Disposal Preliminary checks Maintenance Fixing the control unit Disposal Electrical connections Description of electrical connections Accessories Notes about connections Checking the connections Technical characteristics... -

Page 3: Warnings

Nice S.p.a. product catalogue. If the product is not used in the Visit “www.niceforyou.com” for further information and guidelines for specified configurations or is used with other products that have risk analysis and how to draw up the Technical Documentation. -

Page 4: Product Description

2) Product description This control unit for the automation of gates and doors enables control of two gearmotors with single-phase alternating current. The unit features a series of Dip-switches (mini switches) that enable the selection of the various functions, as well as trimmers used for mak- ing adjustments. -

Page 5: Operating Limits

2.1) Operating limits Chapter 9 “Technical Characteristics” provides the only data needed to determine whether the products are suitable for the intended appli- cation. 2.2) Typical system 1. Control Unit A60 5. Couple of photoelectric cells PHOTO 2. Flashing light with incorporated aerial 6. -

Page 6: Typical System 5

3) Installation The installation must be carried out by qualified personnel in compliance with current legislation, standards and reg- ulations, and the directions provided in this manual. 3.1) Preliminary checks Before proceeding with the installation: • The power supply line must be protected by suitable magne- •... -

Page 7: Electrical Connections

3.3) Electrical connections To safeguard the operator and avoid damaging the components, make sure that the control unit is switched off while you are wiring or plugging in the various cards. • Power the control unit using a 3 x 1.5 mm cable;... -

Page 8: Notes About Connections

3.5) Notes about connections For the most part, connections are easy; a lot of them are direct connections to a single user point or contact but some are a little more complex: All the single-phase asynchronous motors need a capacitor for them to work properly; some gearmotors have this capacitor already con- nected inside while others have to have the capacitor connected externally. -

Page 9: Checking The Connections

3.6) Checking the connections The following operations entail working on live circuits; The “OK” LED located in the centre of the board next to the micro- most of these run on extra-low safety voltage so they are processor has the task of signalling the status of the internal logic: not dangerous;... -

Page 10: Adjustments

4) Adjustments Adjustments can be made through trimmers that modify the follow- • FORCE (F): ing parameters: Take great care when adjusting the FORCE (F) trimmer, as this may affect the level of safety of the automatic system. Trial by error is required to adjust this parameter, measuring the force applied to the leaf and comparing it with regulatory values. -

Page 11: Operating Modes

4.1) Operating modes In the manual operating mode, the OPEN input enables an opening If an automatic operating mode has been chosen, the opening movement, while the CLOSE input enables a closing movement. The manoeuvre will be followed by a pause and then a closing manoeu- STEP-BY-STEP input enables an alternating opening and closing vre. -

Page 12: Description Of Functions

5.2) Description of functions cause shutdown of the motors. Here is a brief description of the functions that can be added by set- For this reason, this function is disabled on heavyweight gates and ting the corresponding Dip-Switch to “ON”. those subject to high friction. -

Page 13: Testing

6) Testing After the above checks and adjustments have been made, the sys- • connected to the “Photo” input causes the stop and subse- tem can be tested. quent reversal of the manoeuvre • connected to the “Photo1” input causes the stop and subse- The automation system must be tested by qualified and quent reversal of the manoeuvre. -

Page 14: Maintenance And Disposal

4 Close 9) Technical characteristics With the aim of improving products, Nice S.p.a reserves the right to modify technical characteristics at any time without notice, while main- taining the same functionalities and intended use. All technical characteristics stated refer to an ambient temperature of 20°C (±5°C). - Page 15 HIBITED! system in your home, call your old installation technician and use Nice products. You will get the services of a specialist and the Periodically check correct operation of the photocells and per- most advanced products available on the market, superior per- form the scheduled maintenance at least every six months.

- Page 16 Headquarter Nice worldwide Nice España Madrid Nice Romania Tel. +34.9.16.16.33.00 Cluj Napoca Nice SpA Nice France Fax +34.9.16.16.30.10 Tel/Fax +40.264.45.31.27 Oderzo TV Italia Buchelay info@es.niceforyou.com info@ro.niceforyou.com Tel. +39.0422.85.38.38 Tel. +33.(0)1.30.33.95.95 Fax +39.0422.85.35.85 Fax +33.(0)1.30.33.95.96 Nice España Barcelona Nice Deutschland info@niceforyou.com info@fr.niceforyou.com...

Need help?

Do you have a question about the Mindy A60 and is the answer not in the manual?

Questions and answers