Table of Contents

Troubleshooting

Summary of Contents for Miller ArcReach Australia Dimension 650

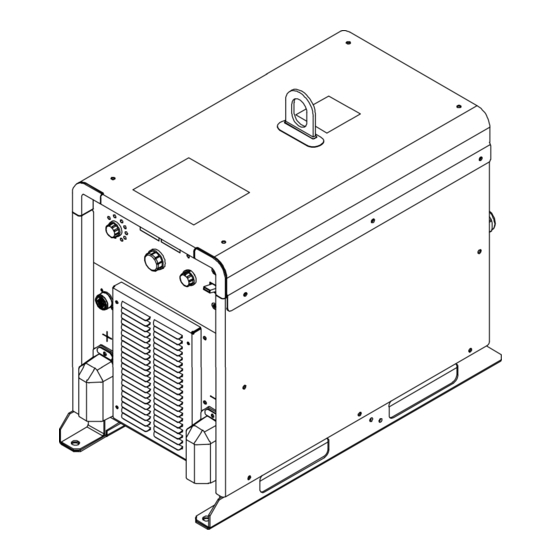

- Page 1 OM-287308C 2020-08 Processes Multiprocess Welding Description Arc Welding Power Source Dimension 650 ArcReach Australia For product information, File: MULTIPROCESS Owner’s Manual translations, and more, visit www.MillerWelds.com...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING ....... . . 1-1. - Page 4 TABLE OF CONTENTS SECTION 8 − GMAW/FCAW OPERATION ............8-1.

-

Page 5: Section 1 − Safety Precautions - Read Before Using

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING som 2020−02 Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! − Indicates a hazardous situation which, if Indicates special instructions. - Page 6 D Do not cut or weld on tire rims or wheels. Tires can explode if heat- FUMES AND GASES can be hazardous. ed. Repaired rims and wheels can fail. See OSHA 29 CFR 1910.177 listed in Safety Standards. D Do not weld on containers that have held combustibles, or on Welding produces fumes and gases.

-

Page 7: Additional Hazards For Installation, Operation, And Maintenance

D Never weld on a pressurized cylinder − explosion will result. CYLINDERS can explode if damaged. D Use only correct compressed gas cylinders, regulators, hoses, and fittings designed for the specific application; maintain them Compressed gas cylinders contain gas under high and associated parts in good condition. -

Page 8: California Proposition 65 Warnings

H.F. RADIATION can cause interference. ARC WELDING can cause interference. D High-frequency (H.F.) can interfere with radio D Electromagnetic energy can interfere with navigation, safety services, computers, and sensitive electronic equipment such as communications equipment. computers and computer-driven equipment such as robots. D Have only qualified persons familiar with electronic equipment D Be sure all equipment in the welding area is electromagnetically perform this installation. -

Page 9: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION som_2020−02_fre Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire. 2-1. - Page 10 D Déplacer toutes les substances inflammables à une distance de LES PIÈCES CHAUDES peuvent 10,7 m de l’arc de soudage. En cas d’impossibilité les recouvrir provoquer des brûlures. soigneusement avec des protections homologués. D Ne pas toucher à mains nues les parties chaudes. D Ne pas souder dans un endroit là...

-

Page 11: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

D Protéger les bouteilles de gaz comprimé d’une chaleur excessive, Les CHAMPS ÉLECTROMAGNÉTIQUES (CEM) des chocs mécaniques, des dommages physiques, du laitier, des peuvent affecter les implants médicaux. flammes ouvertes, des étincelles et des arcs. D Placer les bouteilles debout en les fixant dans un support station- D Les porteurs de stimulateurs cardiaques et naire ou dans un porte-bouteilles pour les empêcher de tomber ou autres implants médicaux doivent rester à... -

Page 12: Proposition Californienne 65 Avertissements

D Effectuer régulièrement le contrôle et l’entretien de l’installation. LIRE LES INSTRUCTIONS. D Maintenir soigneusement fermés les portes et les panneaux des sources de haute fréquence, maintenir les éclateurs à une distan- D Lire et appliquer les instructions sur les ce correcte et utiliser une terre et un blindage pour réduire les étiquettes et le Mode d’emploi avant l’instal- interférences éventuelles. -

Page 13: Section 3 − Definitions

SECTION 3 − DEFINITIONS 3-1. Additional Safety Symbols And Definitions Some symbols are found only on CE products. Warning! Watch Out! There are possible hazards as shown by the symbols. Safe1 2012−05 Do not discard product (where applicable) with general waste. Reuse or recycle Waste Electrical and Electronic Equipment (WEEE) by disposing at a designated collection facility. - Page 14 Welding sparks can cause fires. Have a fire extinguisher nearby, and have a watchperson ready to use it. Safe14 2012−05 Do not weld on drums or any closed containers. Safe16 2017−04 Do not remove or paint over (cover) the label. Safe20 2017−04 Flying pieces of parts can cause injury.

-

Page 15: Miscellaneous Symbols And Definitions

Kasjf;laksf;lkasdf'l;aksdf;lkasd;flksadflkasd;lk Kasjf;laksf;lkasdf'l;aksdf;lkasd;flksadflkasd;lk Kasjf;laksf;lkasdf'l;aksdf;lkasd;flksadflkasd;lk Become trained and read the instructions before working on the machine or welding. Safe40 2012−05 Hazardous voltage remains on input capacitors after power is turned off. Do not touch fully charged capacitors. Always wait 60 seconds after power is turned off before working on unit, AND check input ca- pacitor voltage, and be sure it is near 0 before touching any parts. -

Page 16: Section 4 − Specifications

4-5. Information About Default Weld Parameters And Settings NOTICE − Each welding application is unique. Although certain Miller Electric products are designed to determine and default to certain typical welding parameters and settings based upon specific and relatively limited application variables input by the end user, such default settings are for reference purposes only;... -

Page 17: Dimensions And Weight

A complete Parts List is available at www.MillerWelds.com B. Output Range Process Output Range Rated No-Load Voltage (U 380 VAC 460 VAC GTAW (Lift-Arc TIG) Output On 10A−815A GTAW (TIG) Remote 10A−815A SMAW (Stick) Remote 30A−815A Output On 30A−815A 65V* 79V* CAC-A (Gouge) Output On... -

Page 18: Duty Cycle And Overheating

A complete Parts List is available at www.MillerWelds.com C. Information On Electromagnetic Compatibility (EMC) This Class A equipment is not intended for use in residential locations where the electrical power is provided by the public low− voltage supply system. There can be potential difficulties in ensuring electromagnetic compatibility in those locations, due to con- ducted as well as radiated disturbances. -

Page 19: Section 5 − Installation

A complete Parts List is available at www.MillerWelds.com SECTION 5 − INSTALLATION 5-1. Selecting A Location Movement Do not move or operate unit where it could tip. Location And Airflow Special installation may be required where gasoline or volatile liquids are present − see NEC Article 511 or CEC Section 20. -

Page 20: Selecting Cable Sizes

A complete Parts List is available at www.MillerWelds.com 5-2. Selecting Cable Sizes* NOTICE − The Total Cable Length in Weld Circuit (see table below) is the combined length of both weld cables. For example, if the power source is 100 ft (30 m) from the workpiece, the total cable length in the weld circuit is 200 ft (2 cables x 100 ft). Use the 200 ft (60 m) column to determine cable size. -

Page 21: Connecting Weld Output Cables

A complete Parts List is available at www.MillerWelds.com 5-4. Connecting Weld Output Cables Tools Needed: 269322-A 3/4 in. (19 mm) Weld Output Terminal nals to weld output terminal with nut and Turn off power before connecting to bolt as shown, so that weld cable terminal weld output terminals. -

Page 22: Supplementary Protector

A complete Parts List is available at www.MillerWelds.com 5-6. Supplementary Protector 115 V 20 Amp AC Receptacle Supplementary Protector CB1 Supplementary Protector CB2 CB1 protects duplex receptacle. CB2 protects 24 volts AC portion of Remote receptacle from overload. Press button to reset supplement- ary protector. -

Page 23: Electrical Service Guide

A complete Parts List is available at www.MillerWelds.com 5-7. Electrical Service Guide Elec Serv 2020−02 NOTICE − INCORRECT INPUT POWER can damage this welding power source. This welding power source requires a CONTINUOUS supply of input power at rated frequency(+10%) and voltage (+10%). Phase to ground voltage shall not exceed +10% of rated input voltage. Do not use a genera- tor with automatic idle device (that idles engine when no load is sensed) to supply input power to this welding power source. -

Page 24: Connecting Input Power

A complete Parts List is available at www.MillerWelds.com 5-8. Connecting Input Power = GND/PE Earth Ground U (L1) V (L2) W (L3) U (L1) V (L2) W (L3) Tools Needed: 3/8 in. 3/16 in. Input12 2016−06 / Ref. 803766-C / 272784-A OM-287308 Page 20... - Page 25 A complete Parts List is available at www.MillerWelds.com 5-8. Connecting Input Power (Continued) national, state, and local electrical codes. If Connect input conductors to welding power Turn Off welding power source. applicable, use lugs of proper amperage source line terminals. Installation must meet all National capacity and correct hole size.

-

Page 26: Section 6 − General Operation

A complete Parts List is available at www.MillerWelds.com SECTION 6 − GENERAL OPERATION 6-1. Front Panel 273902-B / Ref. 269321-B Arc Control Weld process operation sections de- The meters display the actual weld output Output On Indicator scribe functionality of the identified items values after arc initiation and remains dis- (See Sections 7-1 thru 9-4). -

Page 27: Mode Switch Settings

A complete Parts List is available at www.MillerWelds.com 6-2. Mode Switch Settings Switch Position Process Output Control Panel Adjust Remote Adjust GMAW/FCAW Gas (1) Output On Volts Volts FCAW−S No-Gas (1) Output On Volts Volts No Remote Adjust - SMAW Stick (1) Output On Amps Panel Only*... -

Page 28: Alternate Configuration Functions

A complete Parts List is available at www.MillerWelds.com 6-5. Alternate Configuration Functions The function of the remote control and panel meters can be changed on this machine. To view or change the active configuration: S Place the process selection switch into SMAW (Stick) Output-On mode. S Quickly tap (press and release) the wire feeder gun trigger or remote output on-off switch 3 to 5 times within a few seconds to view the active configuration. -

Page 29: Section 7 − Gtaw Operation

A complete Parts List is available at www.MillerWelds.com SECTION 7 − GTAW OPERATION 7-1. Typical Connection For GTAW Process 269325-B Remote 14 Receptacle Gas Hose Turn off power before making con- nections. Negative (−) Weld Output Terminal Connect desired remote control to Remote 14 receptacle if required. -

Page 30: Gtaw - Tig Remote Welding Mode

A complete Parts List is available at www.MillerWelds.com 7-2. GTAW - TIG Remote Welding Mode 273902-B Setup Operation Weld terminals are energized through the remote control in For typical system connections refer to The Adjust Control is used to set desired GTAW - TIG Remote welding mode. -

Page 31: Gtaw - Lift-Arc Tig Output-On Welding Mode

A complete Parts List is available at www.MillerWelds.com 7-3. GTAW - Lift-Arc TIG Output-On Welding Mode 12.0 273902-B 1 − 2 “Touch” Seconds Do NOT Strike Like A Match! Left Display. Preset amperage is shown in Weld terminals are energized at all If an ArcReach device is used for am- the Right Display. -

Page 32: Section 8 − Gmaw/Fcaw Operation

A complete Parts List is available at www.MillerWelds.com SECTION 8 − GMAW/FCAW OPERATION 8-1. Typical Connection For Remote Control Feeder GMAW/FCAW Process 269323-B Workpiece Use of shielding gas is dependant on Wire Turn off power before making Type. connections. Remote 14-Receptacle The connection diagram illustrates Wire Feeder DCEP (reverse polarity) suitable for all... -

Page 33: Gmaw/Fcaw - Remote Welding Mode

A complete Parts List is available at www.MillerWelds.com 8-2. GMAW/FCAW - Remote Welding Mode 25.0 273902-B Rotate Mode Switch to GMAW/FCAW source. The Remote In Use indicator Weld terminals are energized Remote position as shown. will be lit. through the remote control in GMAW/FCAW Remote welding The preset voltage is shown in the Left Dis- An ArcReach remote control is not... -

Page 34: Typical Connection For Voltage-Sensing Feeder Gmaw/Fcaw Process

A complete Parts List is available at www.MillerWelds.com 8-3. Typical Connection For Voltage-Sensing Feeder GMAW/FCAW Process 269324-B Use of shielding gas is dependant on Wire Turn off power before making con- Type. nections. Gun Trigger Receptacle Positive (+) Weld Output Terminal The connection diagram illustrates Negative (−) Weld Output Terminal Wire Feeder... -

Page 35: Gmaw/Fcaw - (Gas) Output-On Welding Mode

A complete Parts List is available at www.MillerWelds.com 8-4. GMAW/FCAW - (Gas) Output-On Welding Mode 25.0 273902-B The Left Display toggles between open cir- may have the ability to override param- Weld terminals are energized at all cuit voltage and preset voltage. eter adjustments and mode switch set- times in GMAW/FCAW (Gas) Out- ting. -

Page 36: Fcaw-S (No Gas) Output-On Welding Mode

A complete Parts List is available at www.MillerWelds.com 8-5. FCAW-S (No Gas) Output-On Welding Mode 25.0 273902-B The Left Display toggles between open cir- may have the ability to override param- Weld terminals are energized at all cuit voltage and preset voltage. eter adjustments and mode switch set- times in FCAW-S (No Gas) Out- ting. -

Page 37: Section 9 − Smaw/Cac-A Operation

A complete Parts List is available at www.MillerWelds.com SECTION 9 − SMAW/CAC-A OPERATION 9-1. Typical Connection For SMAW And CAC-A Process 269326-B cutting torch to positive weld output termi- Connect desired remote control to remote Turn off power before making con- nal. -

Page 38: Smaw - Stick Remote Welding Mode

A complete Parts List is available at www.MillerWelds.com 9-2. SMAW - Stick Remote Welding Mode 273902-B Operation Arc Control Weld terminals are energized through the remote control in The Adjust Control is used to set desired Arc control allows the arc characteristics, SMAW - Stick Remote welding preset amperage. -

Page 39: Smaw - Stick Output-On Welding Mode

A complete Parts List is available at www.MillerWelds.com 9-3. SMAW - Stick Output-On Welding Mode 65.0 273902-B The open circuit voltage is shown in the Left range of the preset amperage. Depen- Weld terminals are energized at all Display and the preset amperage is shown dent on the capabilities of the device, it times in SMAW - Stick Output-On in the Right Display. -

Page 40: Cac-A - Gouge Output-On Mode

A complete Parts List is available at www.MillerWelds.com 9-4. CAC-A - Gouge Output-On Mode 65.0 273902-B Setup Operation Weld terminals are energized at all times in CAC-A - Gouge Output-On For typical system connections refer to The Adjust Control is used to set desired welding mode. -

Page 41: Section 10 − Saw Operation

A complete Parts List is available at www.MillerWelds.com SECTION 10 − SAW OPERATION 10-1. Typical Connection For SAW Process Power Source Back View Power Source Front View 269792-A Ground Cable to Workpiece Saw Control Turn off power before making con- nections. -

Page 42: Saw - Subarc Remote Welding Mode

SAW Controller indicator will be lit. See SAW controller Setup Owner’s Manual for additional information. When using Miller Electric HDC DX con- An ArcReach remote control is not For typical system connections refer to troller, select Dimension 652 or SubArc DC Section 10-1. -

Page 43: Section 11 − Maintenance & Troubleshooting

A complete Parts List is available at www.MillerWelds.com SECTION 11 − MAINTENANCE & TROUBLESHOOTING 11-1. Routine Maintenance Disconnect power Maintain more often before maintaining. during severe conditions. 3 Months Repair Or Replace Replace Cracked Replace Damaged Or Torch Body Cracked Unreadable Cables Labels... -

Page 44: Help Displays

A complete Parts List is available at www.MillerWelds.com 11-3. Help Displays All directions are in reference to the front HELP of the unit. All circuitry referred to is lo- cated inside the unit. HELP Help 1, 6, 7 Display HELP Indicates a malfunction in the primary power circuit. -

Page 45: Troubleshooting

A complete Parts List is available at www.MillerWelds.com 11-4. Troubleshooting Trouble Remedy No weld output; unit completely inop- Place line disconnect switch in On position (see Section 5-8). erative. Check and replace line fuse(s), if necessary, or reset circuit breaker (see Section 5-8). Check for proper input power connections (see Section 5-8). -

Page 46: Section 12 − Electrical Diagrams

SECTION 12 − ELECTRICAL DIAGRAMS Figure 12-1. Circuit Diagram For Dimension 650 ArcReach CC/CV 380/400V OM-287308 Page 42... - Page 47 287300-B OM-287308 Page 43...

- Page 48 Notes...

- Page 49 Notes Start Your Professional Over 80,000 trained 400 Trade Square East, Troy, Ohio 45373 Welding Career Now! since 1930! 1-800-332-9448 www.welding.org...

- Page 50 Notes...

- Page 51 Effective January 1, 2020 (Equipment with a serial number preface of NA or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other guarantees or warranties expressed or implied. LIMITED WARRANTY − Subject to the terms and conditions Supplied Air Respirator (SAR) Boxes and Panels below, Miller Electric Mfg.

- Page 52 Contact the Delivering Carrier to: File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © ORIGINAL INSTRUCTIONS − PRINTED IN USA 2020 Miller Electric Mfg. LLC 2020−01...

Need help?

Do you have a question about the ArcReach Australia Dimension 650 and is the answer not in the manual?

Questions and answers