Table of Contents

Advertisement

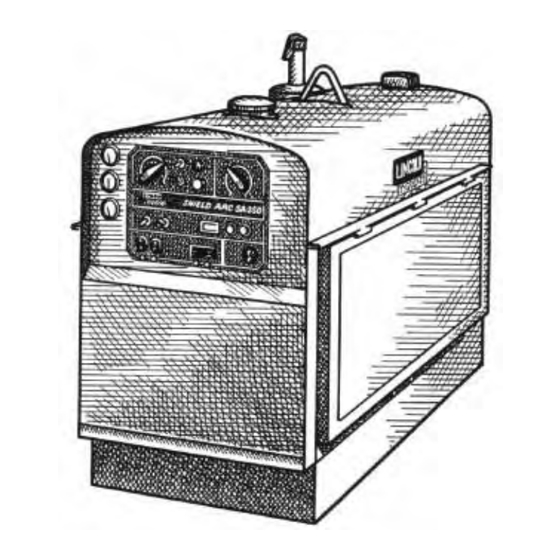

Diesel Engine Driven DC Arc Welding Power Source

For use with machines having Code Number 10073 or 10073CV: 10074

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

Date of Purchase:

Serial Number:

Code Number:

Model:

Where Purchased:

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

SA-250 PERKINS

RETURN TO MAIN MENU

THIS

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

Copyright © 2000 Lincoln Global Inc.

IM518-A

October, 2000

R

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Lincoln Electric SA-250 PERKINS

- Page 1 IM518-A SA-250 PERKINS October, 2000 Diesel Engine Driven DC Arc Welding Power Source For use with machines having Code Number 10073 or 10073CV: 10074 RETURN TO MAIN MENU Safety Depends on You Lincoln arc welding and cutting equipment is designed and built with safety in mind.

- Page 2 351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

- Page 3 SAFETY ARC RAYS can burn. ELECTRIC SHOCK can 4.a. Use a shield with the proper filter and cover kill. plates to protect your eyes from sparks and 3.a. The electrode and work (or ground) circuits the rays of the arc when welding or observing are electrically “hot”...

- Page 4 SAFETY WELDING SPARKS can CYLINDER may explode cause fire or explosion. if damaged. 6.a. Remove fire hazards from the welding area. 7.a. Use only compressed gas cylinders If this is not possible, cover them to prevent containing the correct shielding gas for the the welding sparks from starting a fire.

- Page 5 SAFETY 5. Toujours porter des lunettes de sécurité dans la zone de PRÉCAUTIONS DE SÛRETÉ soudage. Utiliser des lunettes avec écrans lateraux dans les zones où l’on pique le laitier. Pour votre propre protection lire et observer toutes les instruc- tions et les précautions de sûreté...

- Page 6 QUALITY product by Lincoln Electric. We want you Thank You to take pride in operating this Lincoln Electric Company product ••• as much pride as we have in bringing this product to you! Please Examine Carton and Equipment For Damage Immediately When this equipment is shipped, title passes to the purchaser upon receipt by the carrier.

-

Page 7: Table Of Contents

TABLE OF CONTENTS Page GENERAL DESCRIPTION ....................7 DESIGN SUMMARY......................7 OPTIONAL FEATURES.......................8 SPECIFICATIONS .......................9 PRE-OPERATION INSTALLATION .................10-11 Safety Precautions .......................10 Exhaust Spark Arrester ....................10 Location/Ventilation ......................10 Machine Grounding ......................10 Lift Bail..........................10 Trailers ........................10-11 Polarity Control and Cable Sizes..................11 PRE-OPERATION SERVICE .....................12 Oil ..........................12 Fuel..........................12 Cooling System ......................12... -

Page 8: General Description

GENERAL DESCRIPTION Auxiliary Power 3.0 kVA of nominal 115/230V, 60 Hz, AC (See The SA-250 is a heavy duty engine-driven DC arc Optional Features for Power Plug Kits). welding power source capable of providing constant current output for stick welding or DC TIG welding. Output voltage is within ±... -

Page 9: Optional Features

Do not use a welder to thaw pipe before reviewing Lincoln Bulletin E695.1 (dated October 1987 or later.) ------------------------------------------------------------------------ Mufflers Mufflers are standard on the SA-250 Perkins. – –... -

Page 10: Specifications

SPECIFICATIONS Machine Auxiliary Product Current Range Rated DC Output Dimensions & Weight Ordering Description (Fine Adjustments Amps / Volts / Duty Cycle Power H x W x L Name Information in each Range) 250 Amp DC 40 - 325 Amps 3 kVA 43.1 x 28 x 67 in K1283-4... -

Page 11: Pre-Operation Installation

PRE-OPERATION INSTALLATION Machine Grounding Safety Precautions According to the United States National Electrical Code, the frame of this portable generator is not WARNING required to be grounded and is permitted to serve as Do not attempt to use this equipment until you the grounding means for cord connected equipment have thoroughly read the engine manufacturer’s plugged into its receptacle. -

Page 12: Polarity Control And Cable Sizes

3. Proper placement of the equipment on the under- carriage to ensure stability side to side and front to back when being moved and when standing by itself while being operated or serviced. 4. Typical conditions of use, i.e. travel speed, rough- ness of surface on which the trailer will be operat- ed, environmental conditions &... -

Page 13: Pre-Operation Service

Battery Charging PRE-OPERATION SERVICE WARNING CAUTION GASES FROM BATTERY can explode. READ the engine operating and maintenance instruc- • Keep sparks, flame and cigarettes tions supplied with this machine. away. ------------------------------------------------------------ WARNING BATTERY ACID can burn eyes and skin. Fuel can cause fire or explosion. -

Page 14: Engine Operation

ENGINE OPERATION Cold Weather Starting -- When overnight tempera- tures are between 10°F (-12°C) and freezing, use the standard “Thermostart” starting system installed on all WARNING engines. Follow the instructions on the nameplate Do not attempt to use this equipment until you and in the engine manual shipped with the welder. -

Page 15: Welder Operation

WELDER OPERATION When a forceful “digging” arc is required, usually for vertical and overhead welding, use a higher “Current WARNING Range Selector” setting and lower open circuit volt- age. For example: to obtain 175 amps and a forceful arc, set the “Current Range Selector” to the 240-160 ELECTRIC SHOCK can kill. -

Page 16: Auxiliary Power

MAINTENANCE Auxiliary Power WARNING The AC auxiliary power, supplied as a standard, has a rating of 3.0 kVA of 115/230V AC (60 Hz). Have qualified personnel do the maintenance work. Turn the engine off before working inside With the 3.0 kVA, 115/230V AC auxiliary power, one the machine. -

Page 17: Cooling System

3. Change the crankcase oil at regular intervals using clean equipment. More bearing failures are caused the proper grade of oil as recommended in the by dirt introduced during greasing than from insuffi- engine operating manual. cient grease. 4. Change the oil filter in accordance with the instruc- Commutator &... -

Page 18: Idler Maintenance

Idler Maintenance TROUBLESHOOTING WARNING CAUTION Before doing electrical work on the idler printed Have qualified personnel do the troubleshooting circuit board, disconnect the battery. work. Turn the engine off before working inside ------------------------------------------------------------------------ the machine. In some cases, it may be neces- sary to remove safety guards to perform 1. -

Page 19: Troubleshooting

TROUBLESHOOTING TROUBLE CAUSE WHAT TO DO A. Machine fails to hold the “heat” 1. Rough or dirty commutator. 1. Commutator should be turned or cleaned. consistently. 2. Replace brushes. 2. Brushes may be worn down to limit. 3. Field circuit may have variable 3. -

Page 20: Flashing The Fields

TROUBLESHOOTING (Continued) TROUBLE CAUSE WHAT TO DO 1. Check exciter field circuit. D. Welding current too great or 1. Exciter output low causing low too small compared to indica- output compared to dial indica- tion on the dial. tion. 2. Operating speed too low or high. 2. -

Page 21: Electronic Idler Troubleshooting

ELECTRONIC IDLER TROUBLESHOOTING GUIDE Engine Will Not Return to Idle in Approximately 15 Seconds Set Idler Control Switch to the Auto Position Check to see Whether Oil Pressure Light is On and Alternator is Charging Light OFF Light ON If Oil Light is O.K., Replace Check Continuity of Idler Oil Pressure Switch Control Switch... -

Page 22: Wiring Diagram - Sa-250

– –... -

Page 23: Dimension Print

DIMENSION PRINT 52.94 28.00 31.75 20.91 45.07 43.13 32.82 35.10 16.53 6.00 48.50 22.00 22.14 53.75 8.12 CENTER OF GRAVITY 61.00 3.00 24.50 WITH OIL AND WATER IN ENGINE, 65.25 27.12 BUT NO FUEL. 67.00 = .81 DIA HOLES = .69 DIA HOLES M8869-24 7-28-95E –... - Page 24 NOTES...

- Page 25 Year AMERICAN EXPRESS USE THIS FORM TO ORDER: Order from: BOOK DIVISION, The Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199 for fastest service, FAX this completed form to: 216-361-5901 BOOKS OR FREE INFORMATIVE CATALOGS Telephone: 216-383-2211 or,...

- Page 26 ● ● ● Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. WARNING electrode with skin or wet clothing. ● Insulate yourself from work and ground. Spanish ● ● ● No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el AVISO DE...

- Page 27 ● ● ● Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or ● WARNING Use ventilation or exhaust to guards off. remove fumes from breathing zone. ● Spanish Los humos fuera de la zona de res- ●...

- Page 28 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the SA-250 PERKINS and is the answer not in the manual?

Questions and answers