Summary of Contents for Lochinvar AHP025

- Page 1 User’s Information Manual Series 100 Models: AHP025 - AHP060 - AHP090 - AHP125 - AHP185 - AHP250 Air Source Heat Pump Commercial Heat Pump Water Heating Systems Certified UL 1995:2015 CSA C22.2 NO. 236:2015...

-

Page 3: Table Of Contents

TABLE OF CONTENTS SAFE INSTALLATION, USE AND SERVICE....1 TEMPERATURE-PRESSURE RELIEF VALVE.....12 GENERAL SAFETY INFORMATION......2 TANK SELECTION...............12 PRECAUTIONS..............2 SOLAR TANKS..............12 GROUNDING INSTRUCTIONS..........2 CONTAMINATED AIR............13 INTRODUCTION............3 STORAGE & HANDLING...........13 QUALIFICATIONS..............3 STORAGE RECOMMENDATIONS......13 PREPARING FOR THE INSTALLATION........3 INSTALLATION............14 PRINCIPLE OF OPERATION..........4 REQUIRED ABILITY.............14 THE REFRIGERATION CYCLE..........4 GENERAL.................14 AIR TEMPERATURE RANGE..........4... - Page 4 TABLE OF CONTENTS SINGLE PHASE STARTUP PROCEDURES......21 HOME SCREEN..............29 INITIAL START-UP..............22 ALARM SCREEN..............29 MASTER CONTROL PANEL CONFIGURATION SCREEN..........29 PRE-STARTUP CHECKLIST ..........22 STOP SCREEN............30 ROTATION DIRECTION............22 IP CONFIGURATION..........30 STARTING SOUND..............22 MAINTENANCE AND SERVICE........30 START UP..............22 ROUTINE MAINTENANCE..........30 SETTING LOWER LIMIT CONTROL AIR FILTERS................30 VALVE LIMIT FOR SINGLE-PASS......23 DRAIN PAN................30...

-

Page 5: Safe Installation, Use And Service

SAFE INSTALLATION, USE AND SERVICE The proper installation, use and servicing of this commercial heat pump water heater is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your own heat pump water heater to warn you and others of a potential injury hazard. -

Page 6: General Safety Information

GENERAL SAFETY INFORMATION PRECAUTIONS GROUNDING INSTRUCTIONS This heat pump water heater must be grounded in accordance **DO NOT USE THIS UNIT IF ANY PART HAS BEEN UNDER WATER.** with the National Electrical Code and/or local codes. These Immediately call a qualifi ed service agency to inspect the unit must be followed in all cases. -

Page 7: Introduction

INTRODUCTION Thank you for purchasing this heat pump water heater. Properly This manual contains instructions for the installation, operation, installed and maintained, it should give you years of trouble and maintenance of the heat pump water heater (HPWH). It free service. also contains warnings throughout the manual that you must read and be aware of. -

Page 8: Principle Of Operation

4. In order to expedite your request, please have full model The Blower moves ambient air from the installed space or air and serial number available for the technician. ducted to the HPWH from another location across the fi ns of evaporator coil. -

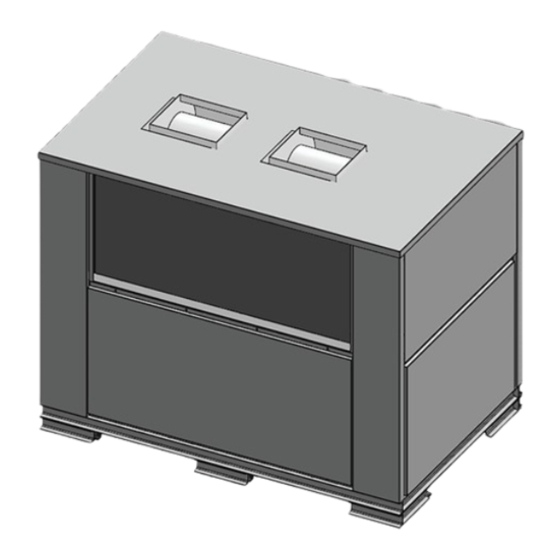

Page 9: Features & Components

FEATURES & COMPONENTS PRODUCT ILLUSTRATION ACCUMULATOR THERMOSTATIC RETURN AIR EXPANSION VAVLE INLET (TXV) (AIR FILTERS) RECIEVER BLOWER EVAPORATOR (HEAT EXCHANGER) (AIR TO REFRIGERANT) COMPRESSOR SUPPLY AIR OUTLET CONDENSER (HEAT EXCHANGER) (REFRIGERANT TO WATER) ELECTRICAL PANEL CONDENSATE BLOWER DRAIN MOTOR WATER OUTLET WATER INLET Figure 1 Component Refrigeration Circuit... -

Page 10: Air To Water Cycle

AIR TO WATER CYCLE... -

Page 11: Rough In Dimensions

*Water Heated from 50° F to 150° F COP = Coeffi cient Of Performance Standard Voltage on AHP025 & AHP060 models - 208/230 V, 1-phase, 60Hz Standard Voltage on AHP090 - AHP250 models - 208/230 V, 3-phase, 60Hz Other power options are available upon request LOCATION OF THE HEATED WATER CONNECTIONS COULD VARY BY UNIT, SEE MANUFACTURER DOCUMENTS FOR EACH INDIVIDUAL UNIT. -

Page 12: Installation Requirements

INSTALLATION REQUIREMENTS AIR TEMPERATURE Read all installation requirements in this manual before installation begins. The installation must conform to these ENTERING AIR TEMPERATURE instructions and all local and national code authority having The return (entering) air temperature range of operation for jurisdiction. -

Page 13: Conditioned Space

TABLE 2 - VOLTAGE & AMPERAGE RATINGS Compressor Fan Motor Blower Motor Pump Fan HPWH Blower HPWH Model Volts/Phase/HZ 208-230/1/60 16.0 25.0 0.17 6.50 1.40 AHP025 208-230/3/60 14.0 0.17 4.00 1.40 440-480/3/60 0.17 2.00 1.40 575/3/60 0.50 1.20 1.40 208-230/1/60 28.2... -

Page 14: Minimum Wire Size

MINIMUM WIRE SIZE Allowable Ampacities of Insulated Conductors Single-phase heat pump water heaters are two wire circuits. Three-phase heaters are three wire circuits. In addition to the foregoing, a grounded conductor is required. Not more than three conductors in raceway, cable, or earth (directly buried), based on ambient temperature of 30°C (86°F) TABLE 3 +The load current rating and the over current protection for these conductors shall not exceed 15 amperes for 14 AWG. -

Page 15: Water Piping

Water Flow Rate Connection Size expansion. Contact a local plumbing service agency to have a Unit (GPM) (Inches) thermal expansion tank installed on all closed water systems . AHP025 ¾ ” MIXING VALVES AHP0060 1” AHP090 1 ½ ” AHP125 1 ½... -

Page 16: Condensate Removal

should be installed upstream from the building fi xtures or at the hot water taps to further reduce system water temperature. Mixing valves are available at plumbing supply stores. Consult a Qualifi ed Installer or Service Agency. Follow the mixing valve manufacturer’s instructions for installation of the valves. -

Page 17: Contaminated Air

Before using any solar tank in this application, contact your • When using a forklift to raise the HPWH unit ensure the forks are positioned correctly between the runners on the representative or call the toll free technical support number on the back cover of this manual for further assistance. -

Page 18: Installation

INSTALLATION REQUIRED ABILITY SERVICE TOOLS See Qualifications on page 3 regarding regulations and Installation and service of the HPWH unit requires ability certifi cations required under Section 608 of the Clean Air Act equivalent to that of a qualifi ed agency in the fi eld involved. before servicing the refrigeration circuit. -

Page 19: Pad Mounting

TRANSFORMER CONFIGURATION 208 VAC MODELS See Piping Diagram on page 34. AHP025 & AHP060 Only A T&P valve must be installed in the designated opening on the storage tank per the tank manufacturer’ s requirements. -

Page 20: Single Tank Configuration

10. For optimal performance minimize the equivalent length the peak water fl ow rates through the water heating system. See of water piping between the HPWH and storage tank. Piping Diagrams on page 34 for detailed piping diagrams. 11. Building hot water recirculation loop should be connected to the inlet of the backup water heater on two tank preheat confi gurations or to the storage tank on single tank confi gurations. -

Page 21: Temperature Sensor Installation

TEMPERATURE SENSOR INSTALLATION DUCT SIZING The HPWH unit is shipped from the factory with a Digital Tank Supply and return air ducting must be sized properly to insure adequate airflow. Table 6 & Table 7 on page 18 provide Thermostat that includes a Temperature Sensor: requirements for the total equivalent supply and return Secure the Temperature Sensor inside a Sensor or Thermal duct lengths allowed. -

Page 22: When To Install Ducting

• All ductwork and plenums shall be field supplied or outdoor atmosphere. In these circumstances do not fabricated. duct supply air to another location for spot cooling. TABLE 6 AHP025 AHP060 AHP090 AHP125 AHP185 AHP250 TABLE 7... -

Page 23: Return Air Ducting

• Ducting supply air only to an alternate location, such as INSTALLATION CHECKLIST the outdoors, may cause excessive negative air pressure inside the building envelope. The list below represents some of the most critical installation • Provision must be made to prevent a negative pressure requirements that, when overlooked, often result in operational in the installed space or building envelope. -

Page 24: Condensate Drain

12. Ensure the cold water supply is not connected directly 25. Ensure all electrical connections in the HPWH control to or Tee fi tted to the inlet water line on the HPWH. See panel are securely tightened. the Service and Installation Notes for Inlet & Outlet Water 26. -

Page 25: Single Phase Startup Procedures

• Turn power on. Check and make sure the power at the FIGURE #1 distribution block is the same as the power requirements on the data sticker that is on the electrical panel. • Put an amp meter on one of the legs for the blower/ fan motor. -

Page 26: Initial Start-Up

INITIAL START-UP phasing of the power to L1, L2 and L3. Since there is a 50/50 chance of connecting power in such a way as to cause rotation CAUTION OIL DILUTION! Bearing malfunction! It is important in the reverse direction, it is important to include notices and to ensure that new compressors are not subjected to liquid instructions in appropriate locations on the equipment to ensure abuse. -

Page 27: Setting Lower Limit Control Valve Limit For Single-Pass

Every piping system is diff erent therefore they have exchanger is adequate. Other factors may also aff ect water diff erent head losses in the system. In order for the Lochinvar fl ow rate and temperature rise such as debris or lime scale heat pump to operate effi ciently and meet the supply de- build up inside heat exchanger or water pump operation. -

Page 28: Purging The Condenser On A Plc

Some of the A421 controllers settings are preprogrammed by heater. Set the “lower limit” value to 100 to open the control Lochinvar before shipment. These settings along with param- valve all the way, then press the purge button to run the pump. -

Page 29: Basic Mode

The Anti-Short Cycle Delay indicates the time required for the unit to wait before running again. This parameter is set to 0 min because Lochinvar units come equipped with safety timers already in place. Sensor Failure indicates that the temperature sensor has failed. -

Page 30: Temperature & Setpoints

MASTER SCREENS TEMPERATURE & SETPOINTS MASTER PANEL HOME SCREEN To view and adjust the temperature setpoint, follow these steps. • View the HMI mounted on the electrical panel door. Locate the “High Temp” value on the setup screen. • Touch the box representing the current value. A keypad and cursor will appear. -

Page 31: Master Screen Terminology

MASTER SCREEN TERMINOLOGY CONFIGURATION SCREEN HOME SCREEN “Comp HRS” – Compressor Hours: indicates the compressor run time hours of each unit “LP” – Low Pressure: indicates the suction line pressure on the “Pump %” - Percentage of envelope sent to pump via low side of the system communication connection. -

Page 32: Member Screens

SINGLE UNIT HOME SCREEN DISPLAYING ALARM compressor run hours, alarm status, and unit number. Then the master will call the unit in the fi rst unit in the run order to turn on If the tank temperature does not increase 1°F in 300 seconds than the second unit in the run order will be called to run 4. -

Page 33: Single Unit Ip Address Configuration

SCREEN (FOR USE CONTACT LOCHINVAR) Remote Mode Indicator – indicates if this unit is connected to a master panel via Ethernet, if it isn’t then it will display a start button Alarm Indicator –... -

Page 34: Stop Screen

Unit Number – Only used for custom network confi gurations, cleaning solution and scour the sides of and bottom of the this confi gures your Lochinvar unit to connect to a Master Panel drain pan. Remove all large solid particles that could potentially under a desired number. -

Page 35: Blower Motor

CLEANING INTERNAL INSULATION wheel or bearing failure. The pillow block bearings come pre-lubricated from the factory. Inspect the internal insulation on a yearly basis for any microbial These bearings should be lubricated at least once per year. growth. The insulation never has to be cleaned unless microbial The recommended lubricant is Shell Alvania #2 or S3. -

Page 36: Factory Charge

If the measured temperature rise through the HPWH unit is more than 12°F (7°C) check for restrictions in the inlet and outlet water piping connected between the HPWH unit and the storage tank. TABLE 9 Model Factory Charge R134A AHP025 AHP060 14 # AHP090 21 # AHP125... -

Page 37: Troubleshooting

TROUBLESHOOTING Problem Possible Causes Corrections Sheet Metal fasteners are loose. Tighten Fasteners Operating vibration is transferring to fl oor or Heat Pump is too noisy building structure. Place vibration dampers underneath unit Blower pulley assembly loose or out of Tighten or align pulleys alignment Tubing, valves, or fi... -

Page 42: Limited Warranty

LIMITED WARRANTY Lochinvar Water Heating Systems, the warrantor, extends the following LIMITED WARRANTY to the original owner of this commercial heat pump water heater subject to the terms, conditions and disclaimers stated below: SERVICE REPAIR AND EXPENSE WHAT IS COVERED:... - Page 43 Technical Support: 1-833-447-3201...

-

Page 44: Service Log

Service Log Issue Description Date Servicer... - Page 45 Service Log Issue Description Date Servicer...

- Page 46 Notes...

Need help?

Do you have a question about the AHP025 and is the answer not in the manual?

Questions and answers