Table of Contents

Advertisement

Quick Links

Installation, Operating &

Maintenance Instructions

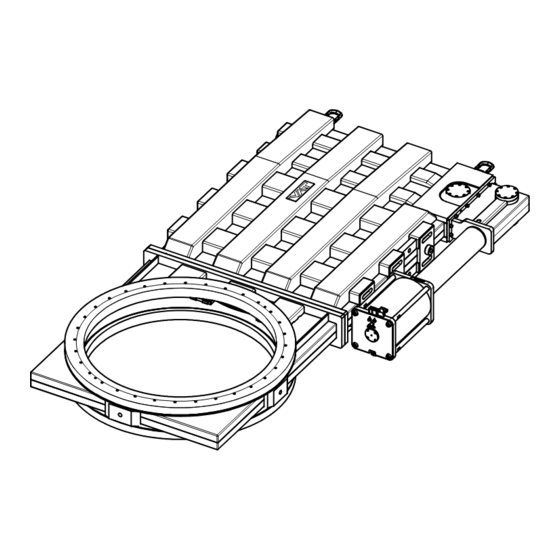

Large HV / UHV gate valve

with double acting pneumatic actuator

Series 191 / 192

DN 900 – 1250 mm (I. D. 36" – 50")

This manual is valid for the following product ordering numbers:

19159- . E14 / 24 / 34 / 44

19160- . E14 / 24 / 34 / 44

19162- . E14 / 24 / 34 / 44

19259- . E14 / 24 / 34 / 44

19260- . E14 / 24 / 34 / 44

19262- . E14 / 24 / 34 / 44

1 Sealing surface

Sample picture

600246EA

Edition 2018-08-22

Advertisement

Table of Contents

Summary of Contents for VAT 192 Series

- Page 1 Installation, Operating & Maintenance Instructions Large HV / UHV gate valve with double acting pneumatic actuator Series 191 / 192 DN 900 – 1250 mm (I. D. 36" – 50") This manual is valid for the following product ordering numbers: 19159- .

- Page 2 VAT. Offenders are liable to pay damages. The original VAT firmware and updated state of the art versions of the VAT firmware are intended for use with VAT products. The VAT firmware contains a limited, time unlimited user license.

-

Page 3: Table Of Contents

Series 191 / 192 Contents Description of product ................ 4 Identification of product ..................4 Use of product ..................... 4 Related documents ..................... 4 Important information ..................4 Technical data ..................... 4 Safety ....................5 Compulsory reading material ................5 Danger levels ...................... -

Page 4: Description Of Product

• Dimensional drawing Important information This symbol points to a very important statement that requires particular attention. Example: VAT disclaims any liability for damages resulting from inappropriate packaging. Technical data See product data sheet and dimensional drawing. 4/26 Edition 2018-08-22... -

Page 5: Safety

Series 191 / 192 SAFETY Safety Compulsory reading material Read this chapter prior to performing any work with or on the product. It contains important information that is significant for your own personal safety. This chapter must have been read and understood by all persons who perform any kind of work with or on the product during any stage of its serviceable life. -

Page 6: Personnel Qualifications

SAFETY Series 191 / 192 Personnel qualifications WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the described work. Safety labels Label Part No. Location on valve T-9001-156 Protective cover Table 2-1 6/26 Edition 2018-08-22... -

Page 7: Design And Function

Series 191 / 192 DESIGN AND FUNCTION Design and Function Design Sealing surface Body lower part Body upper part Actuator Figure 3-1 Function The valve features the VATLOCK sealing technology. This means, the valve is mechani- cally locked in the closed position. In the open position, the mechanism is not locked. Leaf springs hold gate and counter plate against the carriage with the ball retainers. -

Page 8: Installation

• Make sure that the supplied products are in accordance with your order. • Inspect the quality of the supplied products visually. If it does not meet your requirements, please contact VAT immediately. • Store the original packaging material. It may be useful if products must be returned to VAT. -

Page 9: Installation Into The System

Series 191 / 192 INSTALLATION 1 Load rings for valve lifting Figure 4-1 d) Make sure that the valve is in the closed position and locked e) Lift the valve out of the wooden case. Important: Air cylinder is under pressure for transport protection. First, air has to be released from the cylinder by opening the air valve fitting Pos.73. - Page 10 NOTICE Too long screws Valve body may get deformed and / or malfunctions may occur. Use only screws recommended by VAT. Remove protective covers from body flanges. Clean sealing surfaces and seals of both flanges; see (1) and (2) according to «Figure 4-2» on page 11.

-

Page 11: Admissible Forces And Bending Moments

2200 1274 1000 9800 2200 1372 1015 1250 9800 2200 1470 1090 If a combination of both forces («FA» and «M») occurs, the values mentioned above are invalid. Please contact VAT for more information. Table 4-1 600246EA Edition 2018-08-22 11/26... -

Page 12: Compressed Air Connection

INSTALLATION Series 191 / 192 Compressed air connection WARNING Valve in open position Risk of injury when compressed air is connected to the valve. Connect compressed air only when: – valve is installed in the vacuum system – moving parts cannot be touched Use clean, dry or slightly oiled air only. -

Page 13: Operation

Series 191 / 192 OPERATION Operation WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the described work. WARNING Movable parts Human body parts may get jammed and severely injured. Do not operate before product is installed completely into the vacuum system. - Page 14 OPERATION Series 191 / 192 Standard solenoid valve To close the valve: Turn the slotted screw (1) counter-clockwise to its stop. To open the valve: Turn the slotted screw (1) clockwise to its stop. 1 Slotted screw Figure 5-1 For remote operation make sure that the slotted screw is turned counter-clockwise to its stop.

-

Page 15: Trouble Shooting

/ mechanism unit» replace bonnet seal Bellows all right? Contact VAT www.vatvalve.com Table 5-1 If you need any further information, please contact one of our service centers. You will find the addresses on our website www.vatvalve.com. 600246EA... -

Page 16: Maintenance

Maintenance intervals Under clean operating conditions the valve does not require any maintenance during 10 000 cycles; see product data sheet. After these cycles, VAT recommends replacing the mechanism unit; see chapter «6.3 Replacement of valve gate / mechanism unit». -

Page 17: Replacement Of Valve Gate / Mechanism Unit

Series 191 / 192 MAINTENANCE Replacement of valve gate / mechanism unit WARNING Loaded spring steel sheet Human body parts may get jammed and severely injured. Do not put human body parts between valve gate and spring steel sheet. NOTICE Contamination Product may get contaminated. - Page 18 MAINTENANCE Series 191 / 192 10. Tighten the screws (3) from the body cover (7) according the sealing technology with the correct tightening torque. 11. Connect electrical power supply. 12. Connect compressed air supply. 13. Close the valve. 1 Lifting ropes 2 Load ring 3 Screws / Pins 4 Bonnet seal...

-

Page 19: Repairs

Repairs may only be carried out by the VAT service staff. In exceptional cases, the customer is allowed to carry out the repairs, but only with the prior consent of VAT. Please contact one of our service centers. You will find the addresses on our website www.vatvalve.com. -

Page 20: Dismounting And Storage

DISMOUNTING AND STORAGE Series 191 / 192 Dismounting and Storage WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the described work. WARNING Heavy weight Physical overstraining. Use a crane to lift the product. WARNING Hazardous components Human body parts may get jammed and severely injured. -

Page 21: Dismounting

Series 191 / 192 DISMOUNTING AND STORAGE Dismounting NOTICE Valve in open position Valve mechanism may get damaged if valve is in open position. Close valve before dismounting the valve from the system. Close valve. Carry out the steps according to chapter «4 Installation» in reverse order. Pay attention to the safety instructions! Storage NOTICE... -

Page 22: Packaging And Transport

• If products are radioactively contaminated, the VAT form «Contamination and Radiation Report» must be filled out. Please contact VAT in advance. • If products are sent to VAT in contaminated condition, VAT will carry out the decontamination procedure at the customer's expense. -

Page 23: Packaging

Valve mechanism may get damaged if valve is in open position. Make sure that the valve is closed. Cover all valve openings with a protective foil. Pack valve appropriately, by using the original packaging material. VAT disclaims any liability for damages resulting from inappropriate packaging. Transport NOTICE Inappropriate packaging Product may get damaged if inappropriate packaging material is used. -

Page 24: Disposal

DISPOSAL Series 191 / 192 Disposal WARNING Harmful substances Environmental pollution. Discard products and parts according to the local regulations. 24/26 Edition 2018-08-22 600246EA... -

Page 25: Spare Parts

«1.1 Identification of product». This is to ensure that the appropriate spare parts are supplied. • VAT makes a difference between spare parts that may be replaced by the customer and those that need to be replaced by the VAT service staff. - Page 26 SPARE PARTS Series 191 / 192 26/26 Edition 2018-08-22 600246EA...

Need help?

Do you have a question about the 192 Series and is the answer not in the manual?

Questions and answers