Advertisement

Advertisement

Table of Contents

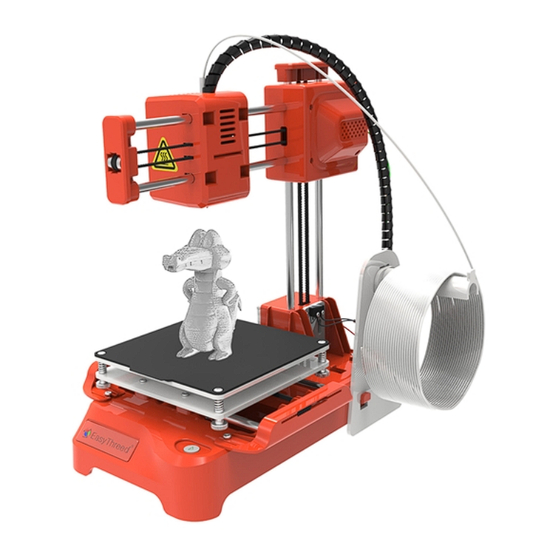

Summary of Contents for EasyThreed K7

- Page 1 USER'S MANUAL Operation video inside the TF card...

-

Page 2: Printer Specifications

1,Printer Specifications 1.1 Main Part... - Page 3 1.2 Basic Parameter Print Basic Parameter Operation Environment Working Temperature: Nozzle Diameter Print material 0.4mm PLA,TPU 1.75mm 5℃~35℃ Relative Humidity: 30%~ Extrude Recommend 180-230℃ PLA:180℃ temperature Temperature Print speed Layer thickness 10~40MM/S 0.05~0.3mm Electrical Parameter Building size Machine size 100X100X100mm 175*235*270mm Power Input :100~240V Compatible...

-

Page 4: Install The Printer

2.2 Install the Printer... - Page 5 3 , Power on Insert power cable to power port, the light inside button is on。(Precaution: the USB port is for firmware updated , If printing finished or no need to use for quite a long time, take off the power cable ) Do not move the XYZ axis by hand when the power is on 4,...

- Page 6 c) Adjust the screw nut at the bottom of the platform (as shown in the figure below ,loosen the nut, the platform rises, tighten the nut, and the platform falls). Adjust the height of the platform through the nut so that the gap between the nozzle and the platform is just one sheet of paper When the paper is gently pulled, there is obvious friction thickness (about 0.1mm).

- Page 7 go further, and press the filament with a little force to keep it. ●Then use another hand to shift the gear (at the side of printer control box base)to” FEED "gear(As shown in the figure ), the light of the print button will blinking.

-

Page 8: Safety Warning

High quality filament which is preferred to be used. Various of filament are available on the market , and quality is much different too. poor quality filament may cause broken or nozzle jam, Pls choose Easythreed high quality filament. Safety Warning Burning , keep your fingers away from the NOZZLE and BLACK INSULATOR when the printer is working as temperature in this area reaches over 200 Celsius degree . - Page 9 7. FAQ Q1: Why is the printing model not adhesive to the printing bed? A1: The nozzle is too far away from the bed, the proper distance between the nozzle and bed is the thickness of a piece of A4 paper . Q2: Why the filament do not come out from the nozzle? A1: Check the filament feeder.If it’s external gearfeeder, then to observe whether gear rotates or not.

- Page 10 A4 paper. A4, The inappropriate printing filament With the maturity of 3d printing , various of filaments are available on the market , but the compatibility for filament and printers are particularly important. www.easythreed.com info@easythreed.com...

Need help?

Do you have a question about the K7 and is the answer not in the manual?

Questions and answers

My K7 Easy Thread will thread the spool forward and retract it but after I start printing a model after for a few minutes it stops feeding the thread.

The EasyThreed K7 could stop feeding filament after a few minutes of printing due to the following reasons:

1. The front end of the filament is not straight.

2. The user did not keep pressing the filament with slight force during the feeding process.

3. The gear was not shifted back to the middle "PRINT POSITION" after feeding.

4. Poor quality construction, such as broken parts or weak filament holder, may also contribute to feeding issues.

These issues can interrupt proper filament feeding during printing.

This answer is automatically generated

Easythreed k7 cover came off of the print head while printing and 2 wires came unplugged. I can see 2 places to plug them back in but which one goes where?