Summary of Contents for Ingersoll-Rand GHH RAND SILU CS90

- Page 1 www.ingersollrand.com/ghhrandtransport Operating manual (Translation of the original instructions) SILU CS90 SILU CS580 LITE SILU CS750 LITE...

- Page 2 WICHTIG! Die Betriebsanleitung liegt in Ihrer Landessprache zusammen mit der Montageanleitung (englische und deutsche Ausführung) elektronisch auf der Webseite www.ingersoll.com/ghhrandtransport für den Download bereit. Auf Anfrage senden wir Ihnen auch gerne eine gedruckte Version zu. IMPORTANT! The operating instructions can be downloaded electronically in your language, together with the mount‑ ing instructions (in English and German) from the website www.ingersollrand.com/ghhrandtransport.

- Page 3 TÄRKEÄÄ! Suomenkielisen käyttöohjeen ja (englannin‑ ja saksankielisen) asennusohjeen voi ladata sähköisessä muodossa osoitteesta www.ingersollrand.com/ghhrandtransport. Pyydettäessä lähetämme myös tulos‑ tetun version. ВАЖНА! Электронную версію кіраўніцтва па эксплуатацыі на нацыянальнай мове разам з інструкцыяй па мантажы (на англійскай і нямецкай мовах) можна спампаваць на сайце www.ingersollrand.com/ ghhrandtransport.

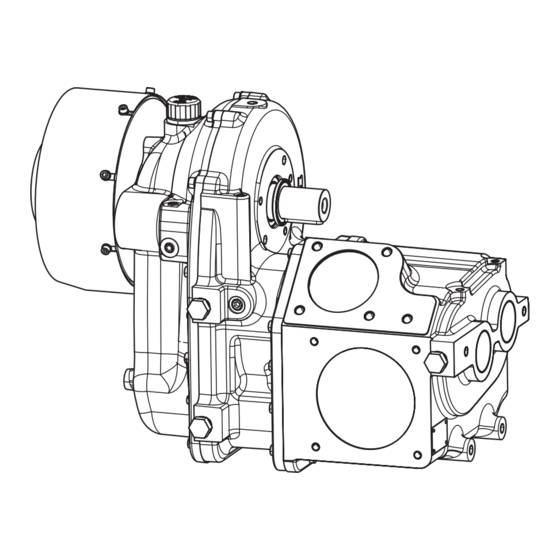

- Page 4 Introduction Before installing and commissioning the SILU CS90 screw compressor or the SILU CS580/750 LITE com‑ pressor kit, please read through these operating instructions carefully (the additional designation SILU is not used in the rest of these operating instructions). The operating manual contains important instructions which must be strictly followed if trouble‑free operation and a long service life are to be ensured.

-

Page 5: Table Of Contents

Contents GENERAL ............................ 7 Application ............................7 Manufacturer's address .......................7 Identification ..........................7 Information for enquiries and orders ..................7 Service & Support .........................7 Technical data CS90 screw compressor ..................8 Technical data CS580/750 LITE compressor kit................9 Operating the compressor at high altitudes ................10 Lubricant .............................10 1.10 Screw compressor type plate .....................11... - Page 6 FAULTS, CAUSE AND INSTRUCTIONS FOR TROUBLESHOOTING ..........28 47757784 A...

-

Page 7: General

General 1 General Application GHH RAND builds and delivers the CS90 screw compressor and the CS580/750 LITE compressor kit, a kit for installation on silo vehicles for the connection‑ready unit (compressor unit). Because of their oil‑free compression of atmospheric air and their power‑to‑weight ratio for installation on silo vehicles, the compressor unit is used to pneumatically convey bulk goods, such as flour, sugar, salt, animal feed, powdered chemicals, dry granulate, soda, cement, sand, lime, plaster, etc. -

Page 8: Technical Data Cs90 Screw Compressor

General Technical data CS90 screw compressor Dimensions & weight …L1x/ …L2x/ Speed range CS90... CS90... Length (approx.) min. rpm 1450 1350 Width (approx.) max. rpm 1800 1800 Height (approx.) Weight (approx.) 114/113 110/109 Maximum operating pressure Oil filling quantity max. 2.5 bar approx. 3.9 litres Maximum intake negative pressure Minimum oil pressure max. -

Page 9: Technical Data Cs580/750 Lite Compressor Kit

General Code key type designation Compressor stage type R = clockwise L = anti‑clockwise 1 = with oil cooler 2 = without oil cooler H = wheel set 1 L = wheel set 2 CS90 R 1 H Technical data CS580/750 LITE compressor kit Dimensions & weight* Rotational speed range... -

Page 10: Operating The Compressor At High Altitudes

General Operating the compressor at high altitudes If operating the compressor at high altitudes, make sure that, depending on the existing ambient pres‑ sure, the operating overpressure must be reduced in order to prevent temperature damage to the com‑ pressor. This should be carried out in accordance with the following table: Installation height h [m] 1000... -

Page 11: Screw Compressor Type Plate

General 1.10 Screw compressor type plate The type plate is attached to the side of the screw compressor. It contains the following information: · Type · Serial number · Rotational speed range · Max. volume flow · At max. operating pressure ·... -

Page 12: Safety

Safety 2 Safety General This operating manual contains basic instructions to be followed during operation and maintenance/ repair. Therefore, this operating manual must be read by the responsible technical staff/operator prior to commissioning and it must always be available at the place of use for the screw compressor. Authorised personnel, training and qualification Work carried out on the compressor, such as operation and maintenance/repair, must only be carried out by persons with the appropriate authorisation, training and qualifications, who are familiar with the... -

Page 13: Unauthorised Conversions And Spare Parts

Safety Unauthorised conversions and spare parts Conversions and modifications to the screw compressor and screw compressor unit are not permitted. Damage to the seal will void any warranty claims. Original replacement parts and accessories that are authorised by the manufacturer represent safety factors. The use of non‑original or unauthorised re‑ placement and accessory parts may void the liability for resulting consequences. -

Page 14: Operation

Operation 3 Operation Safety during operation NOTE Also observe the safety instructions in chapter 2 on page 12. DANGER RISK OF EXPLOSION! For the conveyance of combustible, dust‑like materials, the temperature of the compressed air at the measurement point directly before contact with the material to be conveyed may not exceed the maximum value of 120°C. -

Page 15: Installation

Operation Installation ‣ Park the vehicle in as level a position as possible. ‣ Observe the permitted inclination. Permitted inclination NOTICE INSUFFICIENT LUBRICATION! Excessive inclination results in irregular level of lubricant in the housing. ‣ Observe the maximum permitted inclination of the screw compressor during operation: ·... -

Page 16: Monitoring Operation

Operation Monitoring operation 3.5.1 CS90/external installation The manufacturer installs a gauge (measurement position in the following pipeline) pneumatic system to monitor the compression pressure. The system manufacturer or external installer must also install displays that monitor the intake negative pressure and the oil pressure of the compressor stage. For the operation and control of the operating displays, only the instructions from the manufacturer are appli‑... - Page 17 Operation Maintenance indicator variant 1 The negative pressure in the compressor is displayed on the maintenance indicator (1). The negative pressure must not exceed 65 mbar (red area on the maintenance indicator). NOTICE PERMITTED NEGATIVE PRESSURE EXCEEDED! Excessive negative pressure (> 65 mbar) can result in overheating and damage to the com‑ pressor.

-

Page 18: External Oil Cooler For Compressor (Optional)

Operation External oil cooler for compressor (optional) To ensure that the compressor has an optimum service life even under extreme conditions, an external oil cooler can be connected as an option. Function control of external oil cooler fan A sheet of paper held in front of the radiator of a running fan must be sucked towards it. NOTICE DAMAGE TO THE COMPRESSOR! The compressor can be damaged if the fan is defective. -

Page 19: Maintenance/Repair

Maintenance/repair 4 Maintenance/repair Safety NOTE Also observe the safety instructions in chapter 2 on page 12. WARNING COMPRESSED AIR IN THE SYSTEM! There is a risk of injury due to pressurized components and lines. ‣ All checks and maintenance tasks must only be performed with the compressor switched off and depressurised. -

Page 20: Maintenance Intervals

Maintenance/repair Maintenance Intervals All of the maintenance and repair tasks given on this page are described in detail in the following chap- ter 4.4 on page 20. After the first 2 operating hours Section 4.4.1 Re‑tighten the fastening screws on the discharge silencer. Visually inspect the oil cooler and the lines to/from the oil cooler and compressor for leaks. -

Page 21: Checking The Oil Cooler And Compressor For Leaks

Maintenance/repair ‣ Retighten fastening screws (4) of the holder (3) between the discharge silencer (2) and the com‑ pressor housing (5). Tightening torque (M10 A2-70): 37 Nm 4.4.2 Checking the oil cooler and compressor for leaks ‣ Visually inspect the oil cooler (2) and compressor housing (1) for leaks. -

Page 22: Checking The Oil Level

Maintenance/repair 4.4.3 Checking the oil level ‣ Check that the oil reaches the oil inspection glass (2). ‣ Correct the oil level as needed. If the oil level is too high (oil inspection glass is completely full): ‣ Unscrew and remove the locking screw (1) from the compressor housing. -

Page 23: Cleaning And Replacing The Intake Filter Element

Maintenance/repair 4.4.4 Cleaning and replacing the intake filter element For the maintenance or replacement of the intake filter of a compressor unit based on the CS90 com‑ pressor stage (third‑party manufacturer), only the instructions from the manufacturer are applicable. NOTE Intake filters from diverse manufacturers can be installed. -

Page 24: Check The Safety Valve

Maintenance/repair ‣ Press the dust release valve at the bottom of the air filter housing so that the collected dust/dirt falls out. ‣ Reassemble the parts in reverse order. 4.4.5 Check the safety valve The safety valve is usually installed on the discharge silencer. -

Page 25: Check The Non-Return Valve

Maintenance/repair 4.4.6 Check the non-return valve For the maintenance or replacement of the non-return valves of a compressor unit based on the CS90 compressor stage (third‑party manufacturer), only the instructions from the manufacturer are applicable. NOTE Non‑return valves from diverse manufacturers can be installed. Also observe the instructions from the manufacturer. -

Page 26: Oil Change And Cleaning The Oil Intake Strainer

Maintenance/repair 4.4.8 Oil change and cleaning the oil intake strainer CAUTION ENVIRONMENTAL POLLUTION THROUGH OIL! Very small quantities of oil are sufficient to make significant amounts of potable water unusable. ‣ During the oil change, make sure that no oil is released into the environment. ‣... -

Page 27: Replacing The Overload Coupling Shear Bolts

Maintenance/repair 4.4.9 Replacing the overload coupling shear bolts NOTE Before installing new shear bolts, determine the cause of the shearing, see chapter 5 on page 28. Check the compressor for freedom of movement by turning the drive shaft. The shear bolts (2) of the overload coupling ((3) optional) can shear off if the torque is too high and they must be replaced as follows: ‣... - Page 28 Faults, cause and instructions for troubleshooting 5 Faults, cause and instructions for troubleshooting If in doubt, switch off the compressor! Fault Possible cause Remedy Section 1.6 - 1.8 Air quantity not sufficient Drive speed too low Increase drive speed to the maxi‑ mum permitted speed Intake filter soiled / clogged Clean or replace filter cartridges or 4.4.4 elements as necessary...

- Page 29 Faults, cause and instructions for troubleshooting Fault Possible cause Remedy Section 4.4.3 Oil pressure fluctuates Oil level too low Check oil level and top up as nec‑ essary 4.4.8 Excessive inclination of the com‑ Observe the max. permitted incli‑ pressor nation 4.4.9 Compressor does not work Shear bolts sheared off Replace shear bolts;...

- Page 30 Service & Support www.ingersollrand.com/ghhrandtransport Subject to revision without notice Printed in Fed. Rep. of Germany 12/2022 EN...

Need help?

Do you have a question about the GHH RAND SILU CS90 and is the answer not in the manual?

Questions and answers