Table of Contents

Advertisement

Quick Links

Instructions – Parts List

Parts

55 Gallon, 80:1 Premier

Module Supply Units

4800 psi (331 bar) Maximum Working Pressure

Read warnings and instructions.

See page 2 for table of contents and

list of models.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2000, Graco Inc. is registered to I.S. EN ISO 9001

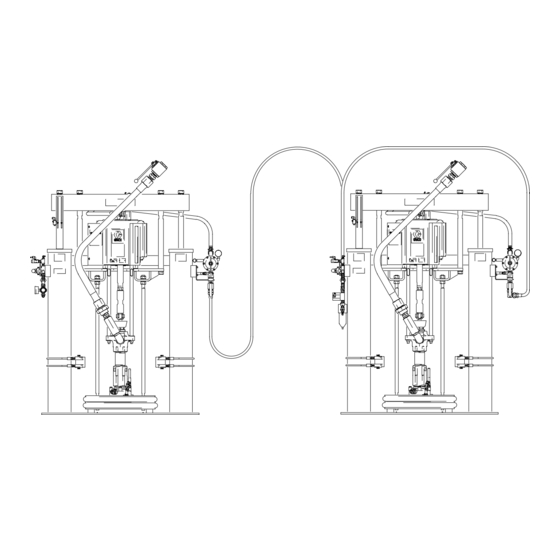

Model 970185 Tandem Shown

310561 Rev.B

TI0794

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Graco 970185

- Page 1 4800 psi (331 bar) Maximum Working Pressure Read warnings and instructions. See page 2 for table of contents and list of models. TI0794 Model 970185 Tandem Shown GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 Copyright 2000, Graco Inc. is registered to I.S. EN ISO 9001...

-

Page 2: Table Of Contents

........Graco Phone Number ...... -

Page 3: Warnings

D This equipment is for professional use only. D Read all instruction manuals, warnings, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco distributor. - Page 4 WARNING INJECTION HAZARD Spray from the spray gun, hose leaks, or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the skin can also cause serious injury. D Fluid injected into the skin might look like just a cut, but it is a serious injury.

- Page 5 WARNING MOVING PARTS HAZARD Moving parts, such as the ram follower plate/pump inlet can pinch fingers. D Do not operate the equipment with the guard removed. D Keep clear of all moving parts when starting or operating the equipment. D Keep hands and fingers away from the priming piston during operation and whenever the pump is charged with air.

-

Page 6: System Information

(Refer to the preceding WARNING ). When closed, System 970185 includes a dual supply unit with pneu- the valve bleeds off all air in the ram and pump, and matic crossover for continuous material supply. -

Page 7: Component Identification And Function

Component Identification and Function Pump Pump Air Bleed Valve Ram Air Regulator Ram (two used on 970185 and one used (required, for pump) Ram Director Valve on 970187) Air Line Filter Air Release Valve Ram Plate Bleed-Type Air Valve W Air Line Drain Valve... -

Page 8: System Setup

(Y) into slot in lug (Z) and accessories. Contact your Graco distributor for help in tighten locknut securely. Connect other end of wire designing a system to suit your particular needs. - Page 9 4–way piloted air valve (3). As the valve stops air to one ram, it starts air to the other ram. This allows constant material flow and changing out of material drums. Pneumatic Crossover Setup (Model 970185) Ball Valves (2) Regulator (2) 4–Way Piloted Air Valve...

- Page 10 System Setup Low–Level Shutoff Setup (Model 970187) NOTE: The position of the air limit valve (2) on the ram determines when the ram air motor is turned on Setup the low–level shutoff as shown in Fig. 4. and off. During operation, this position can be adjusted During system operation, as the ram approaches the as desired.

-

Page 11: Operation

3. Select drum of solvent that dissolves, cleans, and eliminates factory-test oil from system. If neces- 5. Lock the gun/valve trigger safety. sary, check with Graco Distributor or material sup- plier for recommended solvent. 6. Set the ram director valve (U) to the UP position 4. - Page 12 Operation Model 970187 Tandem Ram Shown TI0799 Fig. 5 310561...

- Page 13 Operation Starting and Adjusting System Rams CAUTION To help avoid damage to equipment, do not use WARNING drums that have side bungs or large dents with this ram. Rough bung openings or large dents will dam- PRESSURIZED EQUIPMENT HAZARD age the wipers or stop the ram plate, resulting in a To reduce risk of injury or equipment runaway pump.

- Page 14 Operation Changing Drums 6. Inspect wiper plate and, if necessary, remove any remaining material or material build–up. WARNING Place full drum on ram base. MOVING PARTS HAZARD 8. Lubricate wipers. Moving parts can pinch or amputate your fingers. When the pump is operating and 9.

-

Page 15: Part No

Parts Model 970185 Tandem with Pneumatic Crossover, 80:1 Ratio Premier Pump Includes items 1–6 Fluid Supply Hoses Include Items 4–6 2 REF TI0797 Part Part Description Description 918316 PUMP, ram–mounted 200 liter (55 gal.) C12433 . HOSE See 310524 for parts C20649 . - Page 16 Parts Model 970187 Supply Unit with Pneumatic Low Level Shut–Off, 80:1 Ratio Premier Pump Includes items 1–6 Fluid Supply Hose Includes Items 4–6 TI0800 Part Part Description Description 918316 PUMP, ram–mounted 200 liter (55 gal.) C12433 . HOSE See 310524 for parts C20649 .

- Page 17 Ram Mounted Pump Clearance Dimensions Model 970187 Ram Shown 14.2 mm (0.56 in.) Diameter Holes TI0801 Model (Raised) (Lowered) 2578 mm 1575 mm 533 mm 635 mm 965 mm 1067 mm 1111 mm (108.2 in.) (68.2 in.) (21 in.) (25 in.) (42 in.) (48 in.) (49.74 in.)

-

Page 18: Premiert Checkmatet 1000

Technical Data Displacement Maximum Fluid Maximum Pump Model Pump Model Pump Model Ratio Working Pressure Air Input Pressure 970185 Premiert CheckMatet 1000 80:1 331 bar, 33.1 MPa 4.1 bar, 0.4 MPa (4800 psi) (60 psi) 970187 Premiert CheckMatet 1000 80:1 331 bar, 33.1 MPa... - Page 19 Schematic 8889A Pneumatic Crossover Schematic Diagram (Model 970185 only) Fig. 6 310561...

- Page 20 With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the 970185 and is the answer not in the manual?

Questions and answers