Kärcher HD 3.5/35 G Operator's Manual

Hide thumbs

Also See for HD 3.5/35 G:

- Service manual (28 pages) ,

- Operator's manual (28 pages) ,

- Operator's manual (21 pages)

Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

MODEL #

HD 3.0/27 G

HD3.0/27 GB

HD 3.5/35 G

HD 3.5/35 GB

HD 4.0/40 G

HD 4.0/40 GB

HD 4.0/40 Ge

HD 4.0/40 GeB

HD 5/30 G

HD 3.5/35 G CAL

HD 3.5/35 GB CAL

HD 4.0/40 G CAL

HD 4.0/40 GB CAL

HD 4.0/40 GeB CAL

HD 4.0/40 Ge CAL

KNA, Inc.4555 Airport Way Denver, CO 80239

ORDER #

1.107-270.0

1.107-271.0

1.107-272.0

1.107-273.0

1.107-274.0

1.107-275.0

1.107-276.0

1.107-277.0

1.107-412.0

1.107-421.0

1.107-422.0

1.107-429.0

1.107-430.0

1.107-434.0

1.107-435.0

9.801-759.0 - B

(08/05/21)

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Kärcher HD 3.5/35 G

- Page 1 HD 4.0/40 GB 1.107-275.0 HD 4.0/40 Ge 1.107-276.0 HD 4.0/40 GeB 1.107-277.0 HD 5/30 G 1.107-412.0 HD 3.5/35 G CAL 1.107-421.0 HD 3.5/35 GB CAL 1.107-422.0 HD 4.0/40 G CAL 1.107-429.0 HD 4.0/40 GB CAL 1.107-430.0 HD 4.0/40 GeB CAL 1.107-434.0...

-

Page 3: Table Of Contents

Detergent and General Operating Techniques ........11 Shut Down and Clean-Up ..............12 Storage ....................12 Troubleshooting (Models: HD 3.0/27 G, HD 3.5/35 G, HD 4.0/40 G, HD 4.0/40Ge) ................13-14 Preventive Maintenance (Models: HD 3.0/27 G, HD 3.5/35 G, HD 4.0/40 G, HD 4.0/40Ge) .............. 15 Troubleshooting (Models: HD3.0/27 GB, HD 3.5/35 GB,... -

Page 4: Important Safety Information

INTRODUCTION & IMPORTANT SAFETY INFORMATION 2. Know how to stop the machine and bleed pressure Thank you for purchasing this Pressure Washer. quickly. Be thoroughly familiar with the controls. We reserve the right to make changes at any time 3. Stay alert — watch what you are doing. without incurring any obligation. - Page 5 IMPORTANT SAFETY INFORMATION WARNING: Grip cleaning wand securely with both hands before starting. Failure to do this could WARNING: Do not use gasoline crankcase draining result in injury from a whipping wand. or oil containing gasoline, solvents or alcohol. Do- ing so will result in fire and/or explosion.

- Page 6 IMPORTANT SAFETY INFORMATION or any other relatively unstable location. The clean- ing area should have adequate slopes and drainage to reduce the possibility of a fall due to slippery surfaces. 19. Do not allow acids, caustic or abrasive fluids to pass through the pump.

-

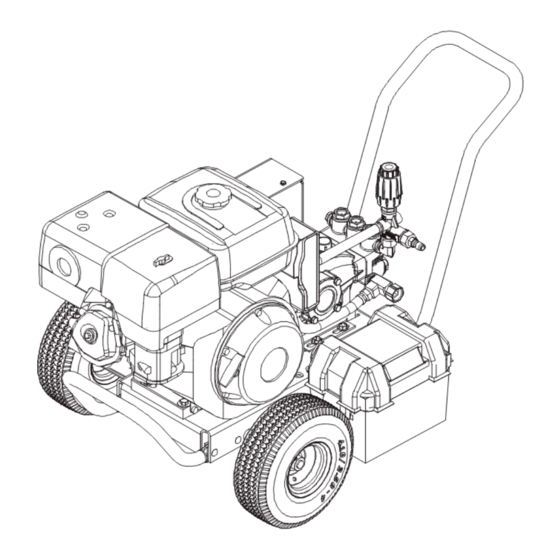

Page 7: Component Identification

COMPONENT IDENTIFICATION Pressure Nozzle Straight Through Wand Detergent Spray Gun Bucket (not included) Trigger ENGINE Inlet High Pressure Screen Hose Unloader Garden Hose (not included) Hose Detergent Pump protector Detergent Starter Grip Injector Pump Pump Pump — Develops high pressure. High Pressure Hose —... -

Page 8: Assembly Instructions

ASSEMBLY INSTRUCTIONS Spray Spray Pressure Gun/Wand Nozzle Safety Wand Latch Wand Coupler High Pressure Hose STEP 1: Attach the high pressure STEP 2: Attach wand to spray gun STEP 3: Pull spring-loaded collar hose to the spray gun using teflon using teflon tape on wand threads. -

Page 9: Operating Instructions

OPERATING INSTRUCTIONS Dipstick Oil Dipstick Oil Window STEP 1: Check engine oil level. Oil level should be level with the bottom STEP 2: Remove shipping cap and of the oil filler neck. Be sure the machine is level when checking the oil install oil dipstick. - Page 10 OPERATING INSTRUCTIONS On-Off Switch STEP 8: Turn the engine switch to "On" position. STEP 9: Pull the starter grip. If the engine fails to start after 2 pulls, squeeze the trigger gun to release pres- sure and repeat step. Return starter gently. After the engine warms up enough to run smoothly, move choke to run position and throttle to fast position.

- Page 11 DETERGENT AND GENERAL CLEANING TECHNIQUES THERMAL PUMP PROTECTION WARNING: Some detergents WARNING may be harmful if inhaled or If you run the engine on your pressure washer for ingested, causing severe nau- 1-2 minutes without pressing the trigger on the spray sea, fainting or poisoning.

-

Page 12: Storage

SHUTTING DOWN AND CLEAN-UP On-Off Switch STEP 1: Remove detergent suc- STEP 2: Turn off the engine. STEP 3: Turn off water tion tube from container and insert supply. into one gallon of fresh water. Slide nozzle forward for low pressure or to connect black detergent nozzle. -

Page 13: Troubleshooting (Models: Hd 3.0/27 G, Hd 3.5/35 G, Hd 4.0/40 G, Hd 4.0/40Ge)

TROUBLESHOOTING For Models: HD 3.0/27 G, HD 3.5/35 G, HD 4.0/40 G, HD 4.0/40Ge PROBLEM POSSIBLE CAUSE SOLUTION LOW OPERATING Insufficient water supply. Closed Use larger garden hose; clean inlet water PRESSURE faucet. Inlet hose kinked screen. Open faucet. Clogged inlet hose strainer Check plumbing system for leaks. -

Page 14: Troubleshooting (Models: Hd3.0/27 Gb, Hd 3.5/35 Gb, Hd 4.0/40 Gb, Hd 4.0/40 Geb, Hd 5.0/30 Gb)

TROUBLESHOOTING For Models: HD 3.0/27 G, HD 3.5/35 G, HD 4.0/40 G, HD 4.0/40Ge PROBLEM POSSIBLE CAUSE SOLUTION ENGINE OPERATES Not enough gas or engine oil Fill tank with gas. Check oil level. FOR 15 MINUTES Vapor lock developed by heat of day Keep gas tank full to avoid vapor locking. -

Page 15: Preventive Maintenance

PREVENTATIVE MAINTENANCE For Models: HD 3.0/27 G, HD 3.5/35 G, HD 4.0/40 G, HD 4.0/40Ge This pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventa- tive maintenance procedures will assist in preserving the performance of your equipment. - Page 16 TROUBLESHOOTING For Models: HD3.0/27 GB, HD 3.5/35 GB, HD 4.0/40 GB HD 4.0/40 GeB, HD 5.0/30 GB PROBLEM POSSIBLE CAUSE SOLUTION LOW OPERATING Faulty pressure gauge Install new gauge. PRESSURE Use larger supply hose; clean filter at water Insufficient water supply inlet.

- Page 17 TROUBLESHOOTING For Models: HD3.0/27 GB, HD 3.5/35 GB, HD 4.0/40 GB HD 4.0/40 GeB, HD 5.0/30 GB PROBLEM POSSIBLE CAUSE SOLUTION WATER OR OIL A small amount of leaking is If excessive leaking occurs, call local LEAKING FROM normal distributor. BOTTOM OF PUMP PRESENCE OF Water sprayed at machine...

- Page 18 TROUBLESHOOTING For Models: HD3.0/27 GB, HD 3.3/35 GB, HD 4.0/40 GB HD 4.0/40 GeB, HD 5.0/30 GB PROBLEM POSSIBLE CAUSE SOLUTION SPRAY WAND Spray wand not properly attached Slide the spray wand into the gun. Turn the LEAKS wand collar clockwise onto the spray gun threads until tight.

- Page 19 Wand 30" Zinc Plated, Handle & Coupler (HD 3.0/27 G, HD 3.0/27 GB) 8.783-040.0 Wand 44" Zinc Plated, Handle & Coupler (HD 3.5/35 G, HD 4.0/40 G, HD 4.0/40Ge, HD 3.5/35 GB, HD 4.0/40 GB, HD 4.0/40 GeB) Quick Connect Nozzle Kit (3.5) (HD 3.0/27 G, HD 3.5/35 G and HD 3.5/35 GB) ▲...

-

Page 20: Oil Change Record

OIL CHANGE RECORD Check pump oil and engine oil level before first use of your new pressure washer. Estimated Operating Estimated Operating Date Oil Changed Hours Since Last Date Oil Changed Hours Since Last Month/Day/Year Oil Change Month/Day/Year Oil Change 9.801-759.0 - B - Operator's Manual, Catch Up... - Page 21 KNA, Inc.4555 Airport Way Denver, CO 80239 Form #9.801-759.0 • Revised 08/21 • Printed in U.S.A. or Mexico...

Need help?

Do you have a question about the HD 3.5/35 G and is the answer not in the manual?

Questions and answers