Advertisement

Quick Links

C H A P T E R O V E R V I E W

Operating Instructions

............................................................................................................................................................

Spare Parts Lists

..........................................................................................................................

Options (if equipped)

Attachment

....................................................................................................................................

Manufacturer in terms of 2014/68/EU

The full name and address of the manufacturer is:

Lenhardt & Wagner GmbH

An der Tuchbleiche 39

68623 Hüttenfeld / Germany

Phone: +49 (0) 62 56 - 85 88 0 - 0

Fax: +49 (0) 62 56 - 85 88 0 - 14

E-Mail: service@lw-compressors.com

Internet: www.lw-compressors.com

...............................................................................................................

.................................................................................................................

A

B

C

D

E

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for L&W Compressors LW 230 E II Compact

- Page 1 C H A P T E R O V E R V I E W Operating Instructions ......................................................Spare Parts Lists .......................... Options (if equipped) ......................... Attachment ............................ Manufacturer in terms of 2014/68/EU The full name and address of the manufacturer is: Lenhardt &...

- Page 2 S E R V I C E I N F O R M A T I O N / W A R R A N T Y Compressor information Type designation Serial number Date of construction Purchase information Purchase date First commissioned on Warranty period Dealer's stamp...

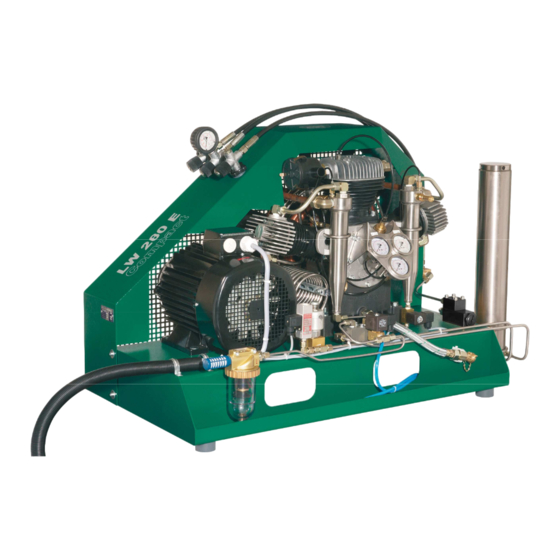

- Page 3 Operating Instructions Breathing Air Compressor LW 230 E II Compact LW 280 E II Compact LW 320 E II Compact Version: 20.05.2023...

- Page 4 Compressor lubrication ........................45 Oil change ............................46 Oil sieve change ..........................47 Manual condensation dump system ....................48 LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 2 Version: 20.05.2023...

- Page 5 Conservation / storage of the compressor / De-conservation, commissioning ......... 69 Transportation instructions / Disposal ..................... 70 LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 3 Version: 20.05.2023...

- Page 6 Note Indicates additional information on how to use the unit. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 4 Version: 20.05.2023...

- Page 7 • Power cable and plug gauges • Special voltages / frequencies on request • Oil pressure monitoring c/w auto shut down LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 5 Version: 20.05.2023...

- Page 8 900 at +20°/ 900 at +20°/ Breathing air treatment capacity [m3]: 72 Hours 46 Hours 54 Hours LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 6 Version: 20.05.2023...

- Page 9 Designation Filling valve Filling pressure gauge Filling hose Filter housing Pressure maintaining / non return valve LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 7 Version: 20.05.2023...

- Page 10 D E S C R I P T I O N Switchboard Designation ON button OFF button Emergency shut-off switch Motor protection warning light Hour counter LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 8 Version: 20.05.2023...

- Page 11 3. Verdichterstufe / 3rd Pressure Stage Flaschenanschluss / Tank Connector Sicherheitsventil 3. Stufe / Safety Valve 3rd Stage Wärmetauscher / Heat Exchanger LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 9 Version: 20.05.2023...

- Page 12 S A F E T Y P R E C A U T I O N S...

- Page 13 Work on the electrical equipment on / with the machine / unit may only be carried out by qualified electricians. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 11...

- Page 14 Importance of notes and warning signs that are affixed to the compressor according to the application or its equipment. Warning Note High voltage! Ensure correct direction of rotation! LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 12 Version: 20.05.2023...

- Page 15 An explosion might be the result if certain conditions apply. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 13 Version: 20.05.2023...

- Page 16 • When handling with fats, oils and other chemical agents, observe the note for the product- related safety. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 14 Version: 20.05.2023...

- Page 17 • Only personnel with particular knowledge and experience in gas equipment may carry out work on gas equipment. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 15 Version: 20.05.2023...

- Page 18 No guarantees whatsoever are valid for damage caused or favoured by the non-consideration of these directions for use. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 16...

- Page 19 I N S T A L L A T I O N...

- Page 20 Diameter of Intake Hose [mm] ≤ 03 Ø 30 ≤ 10 Ø 80 ≤ 15 Ø 100 ≤ 20 Ø 120 LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 18 Version: 20.05.2023...

- Page 21 I N S T A L L A T I O N Dimensions 1200 Fig. Dimensions LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 19 Version: 20.05.2023...

- Page 22 Front side min. 1500 mm, sides min. 500 mm, rear side min. 500 mm. Avoid anything in this area which can restrict the cooling air flow. 1500 Fig. Minimum distances LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 20 Version: 20.05.2023...

- Page 23 • The fan capacity for fresh air and warm air must meet at least the required cooling air flow. The fans must have the same capacity. Fig. Ventilation through facade Fig. Ventilation via ventilation stack LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 21 Version: 20.05.2023...

- Page 24 Fig. Compressor name plate Designation Circuit diagram number Compressor type Power supply Frequency Motor current consumption Nominal motor power LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 22 Version: 20.05.2023...

- Page 25 Fusing start A Connection in mm² [kw] Direct Star/Delta Contactor supply Motor S/D 14.8 19.6 26.4 18.5 LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 23 Version: 20.05.2023...

- Page 26 O P E R A T I O N...

- Page 27 Ensure that all persons handling the compressor are familiar with function and operation of the unit. Wear hearing protection When working on a running machine, always wear hearing protection. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 25 Version: 20.05.2023...

- Page 28 - If correct, air escapes Stop the compressor by pushing the OFF button. 10. Open all filling valves carefully to vent. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 26 Version: 20.05.2023...

- Page 29 Operation after running in Electric motors 50Hz 500 N 400 N Electric motors 60Hz 400 N 300 N LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 27 Version: 20.05.2023...

- Page 30 Furthermore, cooling air flow will not be sufficient. Rotation direction arrow LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 28 Version: 20.05.2023...

- Page 31 • Check if filter cartridge is in place / observe filter cartridge life! • Ensure toxic-free, pure intake air. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 29...

- Page 32 Close and vent all filling valves. Disconnect all compressed air cylinders from filling valves. 10. Open condensate drain valves manually. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 30 Version: 20.05.2023...

- Page 33 (only in case of emergency!). Note After switching off, open condensate drain valves manually to vent the unit. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 31 Version: 20.05.2023...

- Page 34 R E M E D Y I N G F A U L T S...

- Page 35 Tension V-belt See chapter "Final pressure can not be reached" See chapter "Final pressure can not be reached" LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 33 Version: 20.05.2023...

- Page 36 Use prescribed oil quality Filter cartridge unsuitable Use prescribed filter type Cylinder(s), piston(s) or piston ring(s) defective Replace LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 34 Version: 20.05.2023...

- Page 37 Valid only for E models regulations Emergency stop switch has tripped Unlock emergency stop switch, close compressor housing door correctly LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 35 Version: 20.05.2023...

- Page 38 Oil leak at the compressor block Tighten corresponding mounting screws, if necessary replace corresponding paper sealing / o-ring / shaft seal LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 36 Version: 20.05.2023...

- Page 39 M A I N T E N A N C E A N D S E R V I C E...

- Page 40 Warning Risk of burns! Carry out maintenance or service work when the unit has cooled down. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 38 Version: 20.05.2023...

- Page 41 Type Quantity Order No. Check automatic condensate drain, open manual condensate taps Check/Retorque all connections and bolts LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 39 Version: 20.05.2023...

- Page 42 * Note Article is part of our 1000h and 2000h service kits. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 40 Version: 20.05.2023...

- Page 43 All stated quantities are parts of our 1000h and 2000h service kits. You can find an overview on page Service Kits. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 41...

- Page 44 All stated quantities are parts of our 2000h service kits. You can find an overview on page Service Kits. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 42...

- Page 45 LW 320 E II Compact 2000 h 003920 Note V-belts are not included in our 1000h and 2000h service kits. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 43 Version: 20.05.2023...

- Page 46 Operation after running in Electric motors 50Hz 500 N 400 N Electric motors 60Hz 400 N 300 N LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 44 Version: 20.05.2023...

- Page 47 Refill new compressor oil at least when the oil level reached the middle of the indicated area. Oil sight glass LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 45 Version: 20.05.2023...

- Page 48 Approx. 1800 ml synthetic compressor oil is necessary for one oil change. Only use synthetic compressor oil which is recommended as suitable from L&W. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 46...

- Page 49 • Service Kit oil pump (002569). Consists of: 000798 - Oil sieve + 000672 - oil pump cover gasket Correct oil sieve mounting direction LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 47...

- Page 50 All oil / water separators have an integrated sinter filter which Fig. 3 - Condensate drain valve has to be replaced every 1,000 operating hours. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 48 Version: 20.05.2023...

- Page 51 Fig. 2 - Remove sinter filter holder Fig. 3 - Change sinter filter Fig. 4 - Change o-ring LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 49 Version: 20.05.2023...

- Page 52 • 54 hours for LW 280 E II Compact • 46 hours for LW 320 E II Compact LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 50 Version: 20.05.2023...

- Page 53 Ensure that the old filter cartridge is disposed correctly at an approved waste point. Fig. 3 - Pull the cartridge out of the housing. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 51 Version: 20.05.2023...

- Page 54 Fig. 3 - Loosen pipe connections and Fig. 4 - Change o-ring and back-up rings nuts rings LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 52 Version: 20.05.2023...

- Page 55 The inlet filter cartridge change is now completed. (Fig.1) Loose nut (Fig.3) Mount the intake filter (Fig.2) Remove cover and replace filter cartridge LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 53 Version: 20.05.2023...

- Page 56 Special tools are not necessary for dismounting inlet and outlet valves but make work easier. Order number: 006847 Special tool LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 54 Version: 20.05.2023...

- Page 57 Install Inlet / Outlet Valve - see following page Fig. 2 - Pull out inlet and outlet valve Fig. 3 - Copper valve ring LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 55 Version: 20.05.2023...

- Page 58 Inlet and outlet valves change 1st stage is now completed. Fig. 5 - Screw valve head screws in Fig. 6 - Connect pipe connections and tighten LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 56 Version: 20.05.2023...

- Page 59 Fig. 4 - Remove inlet and outlet valve Fig. 5 - Ensure correct mounting position of the upper valve gasket LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 57 Version: 20.05.2023...

- Page 60 Note Replace defective safety valves immediately! Safety valve 3rd stage LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 58 Version: 20.05.2023...

- Page 61 When opening pressure is reached, the pressure gauge value increases within a few seconds. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 59 Version: 20.05.2023...

- Page 62 The safety valve test is now completed. Note After switching off, open condensate drain valves manually to vent the unit. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 60 Version: 20.05.2023...

- Page 63 The leak test is now completed. Note After switching off, open condensate drain valves manually to vent the unit. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 61 Version: 20.05.2023...

- Page 64 In addition, a water pressure test is carried out at 1.5 times of the permissible vessel operating pressure. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 62 Version: 20.05.2023...

- Page 65 M A I N T E N A N C E R E C O R D S...

- Page 66 (TRG, DGRL, BetrSichV, GSG, GSGV). LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 64...

- Page 67 M A I N T E N A N C E R E C O R D S Top up oil, oil change Date Operating hours Oil quantity [l] Name LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 65 Version: 20.05.2023...

- Page 68 M A I N T E N A N C E R E C O R D S Cartridge change Date Operating hours Difference Name LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 66 Version: 20.05.2023...

- Page 69 M A I N T E N A N C E R E C O R D S Maintenance work Description Date, signature LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 67 Version: 20.05.2023...

- Page 70 M A I N T E N A N C E R E C O R D S Replaced Parts Designation Part number Date, signature LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 68 Version: 20.05.2023...

- Page 71 Check all connections and pipe work for leaks. Once all above steps are completed, compressor unit is now ready for use. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 69...

- Page 72 The device can be returned to L&W. Please do not hesitate to contact us if you have any further questions on this issue. LW 230 E II Compact / LW 280 E II Compact / LW 320 E II Compact Page A - 70...

- Page 73 E R S A T Z T E I L L I S T E N / S PA R E PA R T S L I S T S D E TA I L A N S I C H T E N / D E TA I L E D V I E W S...

- Page 74 I n h a l t s v e r z e i c h n i s Schalttafel - Control Board ......................1 Kompressorblock & Ölpumpe Suntec - Compressor Block & Suntec ........... 4 Kurbelwelle - Crankshaft ......................8 Lagerflansch - Bearing Flange ....................

- Page 75 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Schalttafel / Control Board Best.-Nr. / Order No. Benennung Description 002089 Betriebsstunderzähler 230V Hour Counter 230V...

- Page 76 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Schalttafel / Control Board LW 230 E II - LW 230 ES II LW 280 E II - LW 280 ES II LW 320 E II -...

- Page 77 LW 280 E II Compact LW 320 E II Compact - LW 320 E Nautic 002942 002089 006925 LW 230 E II Compact - Option 006859 LW 230 E II Compact - Option 004701 003121 LW 230 E II Compact - Option Version: 20.05 2023...

- Page 78 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Kompressorblock mit Ölpumpe SUNTEC Assembly : Compressor Block with Oilpump SUNTEC Best.-Nr.

- Page 79 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Kompressorblock mit Ölpumpe SUNTEC Assembly : Compressor Block with Oilpump SUNTEC Best.-Nr. / Order No. Benennung Description 002107...

- Page 80 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Kompressorblock mit Ölpumpe SUNTEC Assembly : Compressor Block with Oilpump SUNTEC Version: 03.04.2023 LW 230 - 280 - 320 E II Compact C - 6...

- Page 81 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Kompressorblock mit Ölpumpe SUNTEC Assembly : Compressor Block with Oilpump SUNTEC Version: 03.04.2023 LW 230 - 280 - 320 E II Compact C - 7...

- Page 82 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Kurbelwelle / Assembly: Crankshaft Best.-Nr. / Order No. Benennung Description 001209 Passfeder Woodruff Key...

- Page 83 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Kurbelwelle / Assembly: Crankshaft Version: 28.03.2023 LW 230 - 280 - 320 E II Compact C - 9...

- Page 84 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Lagerflansch / Assembly: Bearing Flange Best.-Nr. / Order No. Benennung Description 000428 Hauptlager (Kugellager)

- Page 85 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Lagerflansch / Assembly: Bearing Flange Version: 28.03.2023 LW 230 - 280 - 320 E II Compact C - 11...

- Page 86 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Kolben 1. Stufe / Assembly: Piston 1st Stage Best.-Nr. / Order No. Benennung Description 000265...

- Page 87 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Kolben 1. Stufe / Assembly: Piston 1st Stage Version: 25.05.2023 LW 230 - 280 - 320 E II Compact C - 13...

- Page 88 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Kolben 2. Stufe / Assembly: Piston 2nd Stage Best.-Nr. / Order No. Benennung Description 001353...

- Page 89 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Kolben 2. Stufe / Assembly: Piston 2nd Stage Version: 25.05.2023 LW 230 - 280 - 320 E II Compact C - 15...

- Page 90 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Kolben 3. Stufe / Assembly: Piston 3rd Stage Best.-Nr. / Order No. Benennung Description 001353...

- Page 91 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Kolben 3. Stufe / Assembly: Piston 3rd Stage Version: 25.05.2023 LW 230 - 280 - 320 E II Compact C - 17...

- Page 92 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Saug und Druckventil 1. Stufe / Assembly: In and outlet valve 1st stage Best.-Nr.

- Page 93 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Saug und Druckventile 2. und 3. Stufe / Assembly: In and outlet valves 2nd and 3rd stage Best.-Nr.

- Page 94 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Wasserabscheider 1. und 2. Stufe Assembly: Water Separator 1st and 2nd Stage Best.-Nr.

- Page 95 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Wasserabscheider 1. und 2. Stufe Assembly: Water Separator 1st and 2nd Stage Version: 28.05.2013 LW 230 - 280 - 320 E II Compact C - 21...

- Page 96 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Filtergehäuse 1,7 l / Assembly: Filter housing 1.7 ltr Best.-Nr. / Order No. Benennung Description 000002...

- Page 97 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Filtergehäuse 1,7 l / Assembly: Filter housing 1.7 ltr Version: 31.05.2023 LW 230 - 280 - 320 E II Compact C - 23...

- Page 98 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Kühlrohre / Assembly: Cooling Pipes Best.-Nr. / Order No. Benennung Description 000498 U-Scheibe A6...

- Page 99 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Kühlrohre / Assembly: Cooling Pipes Version: 14.05.2018 LW 230 - 280 - 320 E II Compact C - 25...

- Page 100 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Druckhalteventil / Pressure Maintaining Valve Best.-Nr. / Order No. Benennung Description 000169 Druckhalterückschlagventil, schwarz Pressure Maint.

- Page 101 D E T A I L A N S I C H T / D E T A I L E D V I E W Druckhalteventil / Pressure Maintaining Valve Reparatursatz 003548: Bestehend aus: Gelbmarkierte Bestellnummern Repair kit 003548: Consists of: Yellow marked P/N´s...

- Page 102 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Sicherheitsventil / Assembly: Safety Valve Best.-Nr. / Order No. Benennung Description 000165 Gehäuse Rückschlagventil...

- Page 103 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Sicherheitsventil / Assembly: Safety Valve Version: 28.05.2013 LW 230 - 280 - 320 E II Compact C - 29...

- Page 104 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Ansaugfilter / Intake Filter Best.-Nr. / Order No. Benennung Description 000170 Ansaugfilterpatrone Air Intake Filter Cartridge...

- Page 105 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Ansaugfilter / Intake Filter Version: 08.02.2017 LW 230 - 280 - 320 E II Compact C - 31...

- Page 106 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Ölpumpe „Suntec“ / Assembly: Oil Pump „Suntec“ Best.-Nr. / Order No. Benennung Description 000204...

- Page 107 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Ölpumpe „Suntec“ / Assembly: Oil Pump „Suntec“ Version: 13.01.2023 LW 230 - 280 - 320 E II Compact C - 33...

- Page 108 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Mitnehmerwelle „Suntec“ Assembly: Drive shaft „Suntec“ Best.-Nr. / Order No. Benennung Description 001030...

- Page 109 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Mitnehmerwelle „Suntec“ Assembly: Drive shaft „Suntec“ Version: 03.04.2023 LW 230 - 280 - 320 E II Compact C - 35...

- Page 110 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Ölablassschlauch / Assembly: Oil Drainage Tube Best.-Nr. / Order No. Benennung Description 000817...

- Page 111 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Ölablassschlauch / Assembly: Oil Drainage Tube Version: 02.03.2017 LW 230 - 280 - 320 E II Compact C - 37...

- Page 112 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: E-Motor / Assembly: E-Motor Best.-Nr. / Order No. Benennung Description 000148 Keilriemen V-Belt...

- Page 113 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: E-Motor / Assembly: E-Motor Version: 20.05.2023 LW 230 - 280 - 320 E II Compact C - 39...

- Page 114 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Lüfterrad / Assembly: Fan Wheel Best.-Nr. / Order No. Benennung Description 000498 U-Scheibe A6...

- Page 115 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Lüfterrad / Assembly: Fan Wheel Version: 28.05.2013 LW 230 - 280 - 320 E II Compact C - 41...

- Page 116 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Verteilerleiste mit Füllschlauch Assembly: Distributor Block c/w Filling Hose Best.-Nr. / Order No. Benennung Description 000761...

- Page 117 D E T A I L A N S I C H T / D E T A I L E D V I E W Baugruppe: Verteilerleiste mit Füllschlauch Assembly: Distributor Block c/w Filling Hose Version: 28.05.2013 LW 230 - 280 - 320 E II Compact C - 43...

- Page 118 E R S A T Z T E I L L I S T E / S P A R E P A R T L I S T Baugruppe: Kreuzventil / Assembly: Cross Design Valve Best.-Nr. / Order No. Benennung Description 000213...

- Page 119 000665 Andere verfügbare Füllanschlüsse (Other available filling connectors) Benennung (Description) Best.-Nr. (Order No.) CGA 346 - 200bar 008394 CGA 347 - 300bar 006842 INT / Yoke - 200/232 bar 002307 LW 230 - 280 - 320 E II Compact C - 45...

- Page 120 O P T I O N S...

- Page 121 I n h a l t s v e r z e i c h n i s Auto Shut Down .......................... 1 Automatic Condensation Drain ....................6 Auto Start Function ........................19 Oil Pressure Display ........................24 Oil Pressure Monitoring ......................27 Oil Temperature Monitoring .....................

- Page 122 A U T O S H U T D O W N LW 230 - 280 - 320 E II Compact - UK D - 1...

- Page 123 A U T O S H U T D O W N Final pressure switch The pressure switch shuts off the compressor automatically when the selected final pressure is reached. The final pres- sure switch is already adjusted to the corresponding cut-out pressure.

- Page 124 A U T O S H U T D O W N Safety valve test Note Do not fill any tank during test phase! Safety valve test as follows: • Disconnect compressor from the electrical power supply and protect against unexpected restart. •...

- Page 125 A U T O S H U T D O W N Druckschalter / Pressure Switch Best.-Nr. / Order No. Benennung Description 000203 Druckschalter 50-350 bar Pressure Switch 50-350 bar 000749 Verschraubung, mit fester Mutter Connection with fixed nut 000764 Winkelverschraubung Elbow connection Version: 24.04.2018...

- Page 126 A U T O S H U T D O W N Sicherheitsventil / Safety Valve Best.-Nr. / Order No. Benennung Description 000751 T-Verschraubung 8L T-connection 8L The safety valve in option Auto-Stop is different to the standard one. A T-connection is instal- led at the outlet of the safety valve! Version: 24.04.2018 LW 230 - 280 - 320 E II Compact - UK...

- Page 127 A U T O M A T I C C O N D E N S A T I O N D R A I N LW 230 - 280 - 320 E II Compact - UK D - 6...

- Page 128 A U T O M A T I C C O N D E N S A T I O N D R A I N Automatic condensation dump system Note The collected condensate can contain oil and has to be disposed according to regulations.

- Page 129 A U T O M A T I C C O N D E N S A T I O N D R A I N Leak test Note Do not fill any tank during test phase! Leak test as follows: •...

- Page 130 A U T O M A T I C C O N D E N S A T I O N D R A I N Condensate stop valve - maintenance Note Clean all parts thoroughly before assembly. Change/clean condensate stop valve as follows: •...

- Page 131 A U T O M A T I C C O N D E N S A T I O N D R A I N Pneumatic condensate valve - maintenance Note Clean all parts thoroughly before assembly. Pneumatic condensate valve change as follows: •...

- Page 132 A U T O M A T I C C O N D E N S A T I O N D R A I N Kondensat-Stopp-Ventil Gehäuse - Housing Condensate-Stop-Valve Best.-Nr. / Order No. Benennung Description 000739 Verschraubung Connection 000741 Verschraubung Connection...

- Page 133 A U T O M A T I C C O N D E N S A T I O N D R A I N Kondensat-Stopp-Ventil Gehäuse - Housing Condensate-Stop-Valve Version: 17.04.2023 LW 230 - 280 - 320 E II Compact - UK D - 12...

- Page 134 A U T O M A T I C C O N D E N S A T I O N D R A I N Kondensat-Stopp-Ventil - Condensate-Stop-Valve Best.-Nr. / Order No. Benennung Description 000498 U-Scheibe A6 Washer A6 001156 Stoppmutter M6, verzinkt Lock Nut M6, zinc plated...

- Page 135 A U T O M A T I C C O N D E N S A T I O N D R A I N Kondensat-Stopp-Ventil - Condensate-Stop-Valve Version: 17.04.2023 LW 230 - 280 - 320 E II Compact - UK D - 14...

- Page 136 A U T O M A T I C C O N D E N S A T I O N D R A I N Pneum. Kondensat-Ablassventil / Pneumatic Condensate Valve Best.-Nr. / Order No. Benennung Description 000188 Sinterfilter Sintered Filter 000190 O-Ring, 10 x 2,5 NBR90...

- Page 137 A U T O M A T I C C O N D E N S A T I O N D R A I N Pneum. Kondensat-Ablassventil / Pneumatic Condensate Valve Version: 17.04.2023 LW 230 - 280 - 320 E II Compact - UK D - 16...

- Page 138 A U T O M A T I C C O N D E N S A T I O N D R A I N Baugruppe: Magnetventil / Assembly: Solenoid Best.-Nr. / Order No. Benennung Description 000892 Doppelnippel Double Nipple 001546 Aludichtring für Magnetventile G1/4"...

- Page 139 A U T O M A T I C C O N D E N S A T I O N D R A I N Switch box with condensate drain test switch Best.-Nr. / Order No. Benennung Description 002089 Betriebsstundenzähler Hour counter 002502...

- Page 140 A U T O S T A R T F U N C T I O N LW 230 - 280 - 320 E II Compact - UK D - 19...

- Page 141 A U T O S T A R T F U N C T I O N Auto Start Function The auto start function allows operating the compressor optionally in automatic or semi-automatic mode by turning the selector switch. Semi-automatic operation: Start the compressor by pushing the Start button.

- Page 142 A U T O S T A R T F U N C T I O N Filling procedure semi-automatic operation Caution! Only fill cylinders which: - are marked with the test mark and the test stamp of the expert. - have been hydro static tested (check last test date).

- Page 143 A U T O S T A R T F U N C T I O N Filling procedure automatic operation Caution! Only fill cylinders which: - are marked with the test mark and the test stamp of the expert. - have been hydro static tested (check last test date).

- Page 144 A U T O S T A R T F U N C T I O N Spare part lists Best.-Nr. / Order No. Benennung Description 000203 Druckschalter Pressure Switch 000751 T-Verschraubung 8L T-Piece 8L 000765 Schneidring 8L Olive Seal 8L 000766 Schneidring 8L Olive Seal 8L...

- Page 145 O I L P R E S S U R E D I S P L A Y LW 230 - 280 - 320 E II Compact - UK D - 24...

- Page 146 O I L P R E S S U R E D I S P L A Y Oil pressure display The oil pressure gauge shows the compressor oil pressure during operation. Oil pressure values should remain between: • min. + 0.5 bar •...

- Page 147 O I L P R E S S U R E D I S P L A Y Spare part lists Best.-Nr. / Order No. Benennung Description 000721 Winkelverschraubung WE06LRCFX Ellbow Connection WE06LRCFX 000769 Verschraubung MAVE06LRCRF Connection MAVE06LRCRF 000777 Dichtring für Seal Ring for Pressure Gauge 005226 Öldruckmanometer 0-6 bar,...

- Page 148 O I L P R E S S U R E M O N I T O R I N G LW 230 - 280 - 320 E II Compact - UK D - 27...

- Page 149 O I L P R E S S U R E M O N I T O R I N G Oil pressure monitoring The oil pressure is maintained by a pressure switch during operation. The compressor automatically shuts off when oil pressure decreases below the minimum pressure of +0.5 bar.

- Page 150 O I L P R E S S U R E M O N I T O R I N G Spare part lists Best.-Nr. / Order No. Benennung Description 000716 Verschraubung TE G1/8" / 6L Connection w/o nut& olive seal 000732 Überwurfmutter M06LCFX Union Nut 06L...

- Page 151 O I L P R E S S U R E M O N I T O R I N G Spare part lists Best.-Nr. / Order No. Benennung Description 004701 Warnlampe Warning Lamp 004703 Schild Label 004704 Relais für Warnlampe Relais for warning lamp 006859 Schildträger...

- Page 152 O I L T E M P E R A T U R E M O N I T O R I N G LW 230 - 280 - 320 E II Compact - UK D - 31...

- Page 153 O I L T E M P E R A T U R E M O N I T O R I N G Oil temperature monitoring Oil temperature monitoring The oil temperature is maintained by a temperature sensor inside the compressor block during operation. The compressor automatically shuts off when oil tempera- ture exceeds the maximum pressure of +120 °C.

- Page 154 O I L T E M P E R A T U R E M O N I T O R I N G Spare part lists Best.-Nr. / Order No. Benennung Description 004342 Display Display 004730 Display und Sensor Display and Sensor 004342 004730...

- Page 155 C Y L I N D E R H E A D T E M P E R A T U R E M O N I T O R I N G LW 230 - 280 - 320 E II Compact - UK D - 34...

- Page 156 C Y L I N D E R H E A D T E M P E R A T U R E M O N I T O R I N G Cylinder head temperature monitoring The cylinder head temperature is maintained by a temperature sensor at the cylinder head of the high pressure stage during operation.

- Page 157 C Y L I N D E R H E A D T E M P E R A T U R E M O N I T O R I N G Spare part lists Best.-Nr. / Order No. Benennung Description 004726...

- Page 158 I N T E R S T A G E P R E S S U R E G A U G E LW 230 - 280 - 320 E II Compact - UK D - 37...

- Page 159 I N T E R S T A G E P R E S S U R E G A U G E Interstage pressure gauge Each of the 3 pressure stages is monitored by a single pressure gauge. This is serviceable for troubleshooting and allows detecting faults at an early stage.

- Page 160 I N T E R S T A G E P R E S S U R E G A U G E Spare part lists Best.-Nr. / Order No. Benennung Description 000645 Manometer, glyzeringefüllt Pressure Gauge, glycerine 000648 Manometer, glyzeringefüllt Edelstahl Press.Gauge,glycer.stain.steel 000710 Verschraubung...

- Page 161 2 0 0 / 3 0 0 B A R P A R A L L E L F I L L I N G P R E S S U R E O P E R A T I O N LW 230 - 280 - 320 E II Compact - UK D - 40...

- Page 162 2 0 0 / 3 0 0 BA R PA RAL L EL F IL L IN G P RES S U R E O PE RA T ION 200 bar / 300 bar parallel filling pressure operation This option allows the filling of 200 bar and 300 bar at the same time.

- Page 163 2 0 0 / 3 0 0 BA R PA RAL L EL F IL L IN G P RES S U R E O PE RA T ION Verrohrung 2 Druckbereiche / Spare Part List: Piping 2 Pressure Ranges Best.-Nr.

- Page 164 2 0 0 / 3 0 0 BA R PA RAL L EL F IL L IN G P RES S U R E O PE RA T ION Verrohrung 2 Druckbereiche / Spare Part List: Piping 2 Pressure Ranges 000566 000797 000796...

- Page 165 A I R C O O L E R C O N N E C T I O N K I T LW 230 - 280 - 320 E II Compact - UK D - 44...

- Page 166 A I R C O O L E R C O N N E C T I O N K I T Air cooler connection kit The Air Cooler Connection Kit provides an easy connection and a simple and time-saving installation or backfitting.

- Page 167 A I R C O O L E R C O N N E C T I O N K I T Spare part lists Best.-Nr. / Order No. Benennung Description 000793 T-Verschraubung 10L T-Connection 10L 000796 Winkelverschraubung 10L Elbow Connection 10L Standard Version (Air Cooler) Option c/w Auto-Stop (Air Cooler) Version: 27.09.2013...

- Page 168 C O N D E N S A T E T A N K 6 0 L T R . LW 230 - 280 - 320 E II Compact - UK D - 47...

- Page 169 C O N D E N S A T E T A N K 6 0 L T R . The 60 ltr. tank is equipped with an active carbon filter to collect condensate odourlessly and quietly. The condensate can be easily transported in the collecting tank and disposed environmentally sound.

- Page 170 C O N D E N S A T E T A N K 6 0 L T R . Maintenance and service How to change the activated carbon and the metal filter insert • Shut down the unit • Plug out the condensate hoses •...

- Page 171 C O N D E N S A T E T A N K 6 0 L T R . Spare part lists Best.-Nr. / Order No. Benennung Description 003091 Kondensatbehälter 60 Liter Condensate Tank 60L 004056 Kondensatschläuche Set of condensate hoses, 3 stages Kondensatbehälter 60L, für 3- 004057 Kondensatschläuche...

- Page 172 C O N D E N S A T E T A N K 6 0 L T R . Spare part lists Best.-Nr. / Order No. Benennung Description 000508 USIT-Ring 13,7 x Ø20 x 1,5 Gasket Ring U-Sit 13,7 x Ø20 x 1,5 003866 Filter Nachfüllset für 60 Liter Filter refill set 60 ltr...

- Page 173 A T T A C H M E N T Version: 11/12-E...

- Page 174 OPERATING INSTRUCTION FOR SAFETY VALVE Lenhardt & Wagner GmbH An der Tuchbleiche 39 D-68623 Lampertheim – Hüttenfeld www.lw-compressors.com Operating Instruction Safety valve Typ: SiV2 BKZ TÜV.SV.19-1140.5.G.V.P CE 0091 AlMgSi1 F31 1100* Lenhardt & Wagner Set pressure: see mark (hand wheel on top of valve) Maximum outflow: Set pressure 100-159 bar: 750 l / min...

- Page 175 OPERATING INSTRUCTION FOR SAFETY VALVE In order to prevent manipulation of the set pressure, all safety valves are factory fitted with a seal. A safety valve on which the seal has been removed, must be returned to the manufacturer for repair / adjustment before further use.

- Page 176 OPERATING INSTRUCTION FOR SAFETY VALVE Manufacturer: Lenhardt & Wagner GmbH An der Tuchbleiche 39 D-68623 Lampertheim – Hüttenfeld Contact: E-Mail: service@lw-compressors.com Web: www.lw-compressors.com Tel.: +49 (0) 6256 – 85880 0 Fax: +49 (0) 6256 – 85880 14 Note: Only use safety valves which are in a technically perfect condition, for its intended purpose, safety and danger awareness, in compliance with the operating instructions! Faults which could affect safety must be rectified immediately! Notes:...

- Page 177 INFORMATION ON THE SERVICE LIFE OF L&W HIGH PRESSURE HOSES...

- Page 178 CONTENTS Testing hose lines Testing hose lines ........................... 3 Testing after assembly and before commissioning ................3 Recurring test ............................4 Procedure for hose lines found to be "defective" ................4 Test intervals ............................4 Persons qualified to test hose lines ...................... 5 Maintenance Replacing hose lines ..........................

- Page 179 TESTING HOSE LINES Testing hose lines An essential factor in ensuring operational safety when handling L&W compressors is the proper testing of the hose lines used. Tests are necessary: After assembly and before commissioning the hose line. After accidents, changes (modifications) to the compressor system, longer periods of non- ...

- Page 180 TESTING HOSE LINES Recurring test Since hose lines are subject to influences that cause damage during operation and can lead to dangerous situations, they must be tested recurrently at fixed intervals. The aim of recurring tests is to detect and repair damage in good time. The objective is to ensure that the system remains in a safe condition.

- Page 181 TESTING HOSE LINES Persons qualified to test hose lines A qualified person is a person who, through his or her professional training, professional experience and recent professional activity, has the necessary specialist knowledge required for testing work equipment - in this case for testing hose lines. These requirements are defined in the Technical Rules for Industrial Safety TRBS 1203 "Qualified persons - general requirements"...

- Page 182 MAINTENAN Replacing hose lines As a general rule, even when stored properly and subjected to permissible stress during use, all hose lines are subject to natural aging, which changes the material and composite properties and reduces the performance of the hose lines. This limits the service life of a hose line and the operator must ensure that hose lines are replaced at appropriate intervals.

- Page 183 SERVICE LIFE Service life of L&W high pressure hoses When determining the service life or the replacement interval of the individual hose lines, the concrete specifications and recommendations of the hose line or machine manufacturer must be observed. Furthermore, empirical values resulting from previous tests done under the prevailing operating conditions on site are also relevant.

- Page 184 STORAGE Storing hose lines When storing hose lines, storage conditions must be aimed at minimizing the natural aging that occurs over time and the associated change in material and composite properties. For this purpose, the following information must be provided: ...

- Page 185 ANNEX...

- Page 186 ANNEX SCOPE OF TESTING; TEST CRITERIA Recommended scope of testing "visual inspection" (before initial commissioning or recommissioning) Is all user information required for safe operation of the system available (e.g. flow chart, operating instructions)? Do the hose lines comply with the flow chart or parts list? ...

- Page 187 ANNEX SCOPE OF TESTING; TEST CRITERIA Recommended scope of testing "Functional test" (before initial or recommissioning) Note: Visual inspection must be carried out before the functional test All parts of the system must be tested at least at the maximum working pressure that could be achieved taking into account all intended applications:...

Need help?

Do you have a question about the LW 230 E II Compact and is the answer not in the manual?

Questions and answers