Table of Contents

Advertisement

Quick Links

Instructions for Set-up, Operation, Maintenance & Storage

PETROL HOT WATER/STEAM PRESSURE WASHER – 3000 PSI/15.14 LPM (4 GPM)

This pressure washer produces both cold and hot water high pressure spray as well as steam spray. Cleaning

chemicals may be incorporated into the spray if desired. The pressure pump for this equipment is powered by

a petrol internal combustion engine and the water is heated by a kerosene/fuel-oil fired, open flame burner.

READ and UNDERSTAND this Owner's Manual and the Engine Owner's Manual

completely before attempting to set up and use the pressure washer! Failure to properly set

up, operate, and maintain this pressure washer could result in serious injury or death to operator

or bystanders.

CO Poisoning

Skin/Eye

Injury

Burns

Slips/Falls

Flying Debris

Fire/

Explosion

Chemical

Exposure

Electric shock

A summary of important safety information is provided at the end of the manual.

Owner's Manual

Portable Outdoor-Use Only

WARNING – READ THIS MANUAL

WARNING – SPECIAL HAZARDS

•

Exhaust from both the engine and burner contains carbon monoxide, a

poisonous gas that can cause carbon monoxide poisoning and possible

death if inhaled. ONLY run pressure washer OUTDOORS and at least 6m

(20 feet) from the home, away from windows, vents and air intakes, to

allow proper ventilation. If you start to feel sick, dizzy, or weak while

using the pressure washer, shut off the engine and get to fresh air RIGHT

AWAY.

•

High-pressure spray can cause serious skin or eye injury, including injection injury

if fluid pierces the skin. Injection injury can result in blood poisoning and/or

severe tissue damage.

•

Hot spray can scald and burn skin.

•

Hot surfaces of wand, engine and burner, as well as hot exhaust from both

the engine and burner can cause burns.

•

Spray discharge can cause puddles and slippery surfaces.

•

Spray-gun kickback can cause operator loss of balance and falls.

•

High-pressure spray can cause surface damage and flying debris.

•

Engine and burner sparking can ignite fuel or other flammable liquids or

vapors in the vicinity.

•

Hot exhaust from engine and burner can ignite combustible materials.

•

Cleaning chemical vapors or contact with skin may be hazardous.

•

Spray contact with electrical sources can cause electric shock.

Any Questions, Comments, Problems, or Parts Orders

Call Kincrome Tools & Equipment 1300 657 528

MNS157310A

ITEM NUMBER: NS157310

SERIAL NUMBER: _____________

1

Advertisement

Table of Contents

Summary of Contents for North Star NS157310

- Page 1 MNS157310A ITEM NUMBER: NS157310 SERIAL NUMBER: _____________ Owner's Manual Instructions for Set-up, Operation, Maintenance & Storage PETROL HOT WATER/STEAM PRESSURE WASHER – 3000 PSI/15.14 LPM (4 GPM) Portable Outdoor-Use Only This pressure washer produces both cold and hot water high pressure spray as well as steam spray. Cleaning chemicals may be incorporated into the spray if desired.

- Page 2 Hazard Signal Word Definitions This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. DANGER (red) indicates a hazardous situation, which if not avoided, will result in death or serious injury.

-

Page 3: Table Of Contents

Table of Contents About Your Pressure Washer ........................ 4 Specifications ............................5 Component Identification ........................6 Safety Labeling ............................7 Special Equipment Safety Features ....................... 8 Assembly and Initial Set-Up ........................9 Step 1. Unpacking & Delivery Inspection ..................9 Step 2. -

Page 4: About Your Pressure Washer

About Your Pressure Washer Thank you for purchasing a NorthStar hot water pressure washer! Your machine is designed for long life, dependability, and the top performance you demand. This pressure washer is designed to: 1) Produce a high-pressure steam spray or water spray (heated or unheated) – up to 15.14 lpm (4 gpm) at 3000 psi. -

Page 5: Specifications

Specifications MODEL Model # NS157310 FLOW OUTPUT Pressure Rating 3000 psi Flow Rate 15.14 lpm (4 gpm) Maximum Temperature 121°C (250° F) DIMENSIONS / COMPONENTS Length 162.5cm (64") Width 83.8cm (33") Height 111.7cm (44") 252kg (557 lbs.) – dry Weight 322kg (710 lbs.) –... -

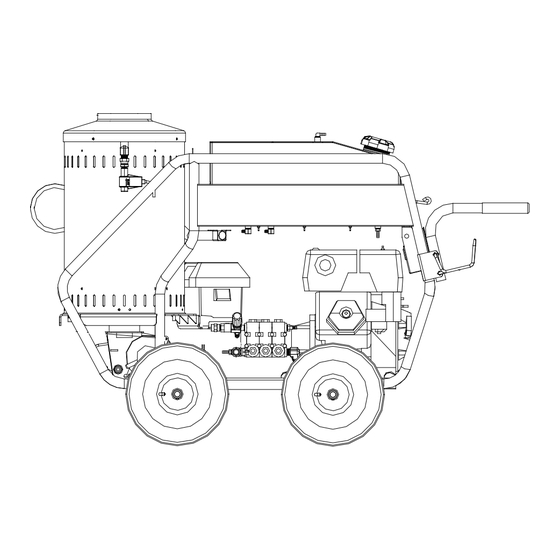

Page 6: Component Identification

Component Identification Ref # Description Ref # Description Exhaust Vent Control Panel Pump Engine Battery Box Burner Fuel Filter/Water Separator High Pressure Water Outlet Petrol Cap Engine ON/OFF Key Switch Petrol Tank Pump Oil Sight Glass Fuel Cap Hose Hook Fuel Tank Gun Hook REFERENCE GUIDE... -

Page 7: Safety Labeling

Safety Labeling DANGER IMPORTANT! FOR OUTDOOR USE ONLY ! Using this pressure washer indoors CAN KILL YOU IN MINUTES. TURN HEAT SWITCH TO OFF POSITION Engine exhaust and burner exhaust contain carbon monoxide. This is a poison you cannot see or smell. WHEN NOT IN USE. -

Page 8: Special Equipment Safety Features

Special Equipment Safety Features High Pressure WARNING-If the high-pressure safety device ever discharges water, Safety Device turn the engine off and do not use the machine. The device will no longer (Rupture Disc) function properly. See a dealer or call Kincrome Tools & Equipment on 1300 657 528. -

Page 9: Assembly And Initial Set-Up

Assembly and Initial Set-Up Steps for Assembly / Initial Set-Up Step 1. Unpacking & Delivery Inspection Step 2. Assembly Step 3. Initial Pump & Engine Preparation Step 4. Battery Installation Each of these steps is discussed in the below: Step 1. Unpacking & Delivery Inspection Find and separate the components identified in Figure 2- Overview of Pressure Washer Components and Figure 3- Hardware Bag. - Page 10 Assembly and Initial Set-Up Grommet Qty 6 Nozzle Qty 6 Honda Manual Owner’s Manual Qty: 1 Qty: 1 Hose Hook Wheel Retainer QTY 1 QTY 4 M8 Nylock Nut 5/16” Nut 5/16” Washer QTY 2 QTY 2 QTY 8 4 ft. Braided Hose 5/16”...

-

Page 11: Step 2. Assembly

Assembly and Initial Set-Up Step 2. Assembly You must assemble your pressure washer before it can be used. See below: Lift back of unit by handles to install rear wheels, then lift front of unit to install front wheels. Fasten wheel with retainer. NOTE: It is recommended that two people lift this unit while a third slides the wheels onto the axles. -

Page 12: Step 3. Initial Pump & Engine Preparation

Assembly and Initial Set-Up a. Rear Wheels Have two people lift the back of the pressure washer by the handles while a third person slides the wheels onto the Rear Axle. Fasten each wheel with a wheel retainer using a hex wrench. -

Page 13: Step 4. Battery Installation

Assembly and Initial Set-Up Step 4. Battery Installation Install a 12-volt standard lawn and garden battery (Group U1) with a minimum 18 amp- hour rating. The engine will run, but the burner will not fire unless a battery is installed. The battery is supplied with the product and should be installed in the protective battery compartment located near the engine. -

Page 14: Moving And Handling

Moving and Handling WARNING The pressures washer is heavy. It can crush and cause serious injury if it rolls out of control or tips over. Follow the instructions below for safely moving the pressure washer. Moving and Handling Lift Here Handles Breaks Figure 7... -

Page 15: Before Each Use

Before Each Use Follow the steps below prior to each use of the pressure washer. Steps to Follow Before Each Use Step 1. Check Equipment Step 2. Add Fuel(s) Step 3. Select Suitable Worksite Step 1. Check Equipment Check/add pump oil. Check/add Caution: Never run the pump without sufficient lubrication! pump oil... -

Page 16: Step 2. Add Fuel(S)

Before Each Use 1) Check hoses, fittings, wand, trigger gun and connections for signs of wear, cracks, looseness, or leaks. Replace as required. 2) Check and clean the nozzle orifice. 3) Clean inlet filter. (See Maintenance instructions) Inspect fuel Always inspect (engine and burner) fuel systems & check for leaks system BEFORE starting pressure washer. - Page 17 Before Each Use Note: A running or still-hot engine or burner is hot enough to ignite fuel. 2) Fill fuel tank OUTDOORS – never indoors. Fuel vapors can ignite if they collect inside an enclosure and explosion can result. 3) Stay away from all sources of heat, sparks, and flames. Do not smoke. 4) Never pump fuel directly into the petrol tank or burner at a petrol station –...

-

Page 18: Step 3. Select A Suitable Worksite

Before Each Use Step 3. Select Suitable Outdoor Worksite Before using the pressure washer, you must understand the criteria for selecting a suitable location for operation. Note that this pressure washer is for OUTDOOR USE only. WARNING You must choose a suitable site for operating your pressure washer to avoid equipment damage and/or injury and possible death from carbon monoxide poisoning, fire/explosion, uncontrolled equipment movement/tip over, or slips and falls. - Page 19 Before Each Use WARNING Never attempt to attach ductwork to the engine muffler or burner exhaust to allow for installation inside an enclosure. This could cause hot air deflection, heat build-up, and increased exhaust backpressure, resulting in possible exhaust leakage or overheating and damage to the pressure washer.

-

Page 20: Operation

Operation After you have checked and fueled the equipment and positioned it in a suitable worksite, it is time to start your pressure washer. The following are the procedures necessary for safe, successful operation of your pressure washer. WARNING Carefully read and make sure you understand all instructions and safety information before using the pressure washer. - Page 21 Operation Attach garden Acquire a suitable garden hose and attach to the water supply. hose to water 1. Acquire a suitable garden hose: supply a. The water supply garden hose must have an inside diameter of at least 16mm (5/8"). If the hose is more than 30mt (100 ft.) long, the diameter must be at least 19mm (3/4").

- Page 22 Operation 4. Release the collar, making sure it springs back and re-seats to its original (non-retracted) position. (Figure 8b). Check the connection by pulling on the hose to ensure a positive connection. Correct Insertion Not Fully Inserted Figure 8b Collar Seated Collar NOT Seated Select spray Your pressure washer is equipped with five high-pressure nozzles and one...

-

Page 23: Step 2. Set Up For Chemical Spray (If Desired)

Operation 1. Make sure the engine is OFF and the hose line depressurized. 2. To install the nozzle, pull the collar back and twist the nozzle firmly into the coupler on the end of the wand. (Figure 9a) Lance Coupler Nozzle Collar Figure 9a... - Page 24 Operation cause pump damage if introduced upstream through the pump's water inlet. • It mixes the cleaning chemical into a low-pressure spray. Cleaning chemicals applied under low pressure adhere better to the surface being cleaned, allowing the formula time to react and remove dirt more effectively.

-

Page 25: Step 3. Spraying

Operation Step 3. Spraying Safety rules Before starting the pressure washer, review the following general safety for operation rules for operation: Conditions for Use Know how to stop. Be thoroughly familiar with proper use of the equipment and all controls and connections. Know how to stop the pressure washer and depressurize system quickly if needed (see "Step 6. - Page 26 Operation the locked position when not spraying. Leaving unattended. Always turn OFF the pressure washer and relieve system pressure before leaving the sprayer unattended. Prompt Emergency Response Seek medical aid for suspected injection injury. If injured by high-pressure fluid, no matter how small the wound is, see a doctor at once.

- Page 27 Operation by rotating it to the locked position. 3. Follow the instructions in the Engine Manual for starting the engine. - If the engine doesn't start on the first try, pressure may build up in the pump. Relieve pressure by squeezing the spray gun trigger before attempting to start engine again.

- Page 28 Operation the heat exchanger during operation. Turn the heat switch ON and adjust the thermostat to the desired temperature. (For steam spraying, set the temperature at 100°C (212°F) or higher and use yellow steam nozzle.) WARNING: • NEVER attempt to immediately run or re-light the burner if it doesn't ignite the first time.

- Page 29 Operation ladder or scaffolding, ensure it is firmly anchored from sway or tip-over. Be aware of puddles and slippery surfaces. Ensure there is adequate drainage to prevent pooling of water. • Prevent surface damage & flying debris – Surfaces being sprayed must be strong enough to withstand high-pressure spray or damage may result.

- Page 30 Operation WARNING: Do not attempt to alter the unloader valve's maximum pressure. Excess pressure could cause serious injury from escaping high-pressure fluids and/or pump damage. Any alteration other than turning the adjustment knob will void your warranty. Unloader Figure 11 If temporarily interrupting spraying, rotate trigger safety latch downward to the locked position to guard against accidental trigger release.

-

Page 31: Step 4. Stopping

Operation Step 4. Stopping Stop the engine using the following steps: WARNING: Never disconnect the high-pressure hose from the pump or spray gun while the system is pressurized. Relieve pressure by squeezing the spray gun trigger after the engine is turned OFF. - Page 32 Burner Adjustment Choose a storage Choose a storage location that is: o Clean and dry. location o Away from sources of heat, open flames, sparks, or pilot lights, even if the pressure washer's engine and burner fuel tanks are empty. Residual fuel fumes from tank can ignite.

- Page 33 Burner Adjustment 3. Attach the 30 cm (12”) garden hose piece with the funnel to the pump inlet. Pour antifreeze into the funnel, then turn starter (or pull the recoil) a few times until antifreeze comes out of the pump outlet. Prepare engine for First prepare the engine for long term storage if you will not be using long term storage...

-

Page 34: Burner Adjustment

Burner Adjustment Oil Burner Adjustment (only needed if white exhaust smoke appears) The oil burner is preset and performance tested at the factory [elevation 335m (1100 feet)]. Different altitudes may require a one-time initial burner adjustment. CAUTION: If white smoke appears from the burner exhaust vent during start-up or operation, discontinue use and readjust air bands. - Page 35 Burner Adjustment Tighten the locking screw. 6. Now fine tune the burner air by adjusting the shutter: a. Locate the shutter as shown in Figure 14 below. The shutter is a thin circular metal plate located on the outside of the air band. The shutter adjusts independently from the air band and is used to fine-tune the amount of intake air.

-

Page 36: Maintenance And Repair

Maintenance and Repair Inspect and maintain your pressure washer as specified below in order to keep it in safe and optimal working order. Follow all safety rules and recommended maintenance instructions. WARNING ALWAYS shut OFF water supply, bleed water pressure, turn OFF engine and disconnect the spark plug before cleaning, adjusting, or servicing the pressure washer. - Page 37 Maintenance and Repair repair parts. Replacement parts that do not meet specifications may result in a safety hazard or poor operation of the pressure washer and will void the warranty. Keep pressure Keep pressure washer clean. washer clean If dust or debris accumulates on the pressure washer, clean the pressure washer with a damp cloth or soft bristle brush.

- Page 38 Maintenance and Repair Good Water dripping or spraying, or localized moisture Exposed wire mesh due to wear Figure 15 Clean inlet filter Clean the inlet filter before each use. WARNING: When cleaning filters, check whether dangerous chemicals have been used with the filter and take any precautions that may be recommended by the manufacturer of these chemicals.

- Page 39 Maintenance and Repair Recharge and Inspect, recharge, and maintain battery according to your battery maintain battery manufacturer's instructions. Do not store with battery charger always connected. Batteries that are over- charged can boil themselves dry and produce excessive amounts of hydrogen, an explosive gas.

- Page 40 Maintenance and Repair Maintain burner's Drain water from burner's filter bowl as needed, and replace filter after fuel filter/water every 500 hours of use or as needed. separator 1) After each use of the burner, visually check the filter bowl. If any water has accumulated, drain it via the water drain at the bottom of the bowl.

- Page 41 Maintenance and Repair cleaning solution. CAUTION: Do not run the burner. 7) Dispose of the cleaning solution where it is not harmful to animals or the environment. 8) Flush with fresh water and clean the inlet strainer when finished. Figure 18 Cleaning Flow Inspect and clean the flow switch as needed Mineral build-up and/or debris within the flow switch can occur and may...

- Page 42 Maintenance and Repair 3) Unthread the removable outlet fitting with the swivel still attached from the flow switch assembly 4) Remove the shuttle 5) Clean the inside of the brass flow switch body and the shuttle with water and a soft brush 6) Insert the shuttle into the brass flow switch in the orientation shown Note: Aligning the male tabs on the shuttle to the female guides inside the brass flow switch body can be difficult since the shuttle is magnetic...

- Page 43 Maintenance and Repair If soot has built up on the exterior of the coil tubing, clean as follows: 1) Wear protective clothing, goggles, and gloves. 2) Disconnect high-pressure hose on inlet side of coil and thermostat on outlet side of coil. 3) Remove the lid and insulation lid from the heating chamber and hoist the coil out.

- Page 44 Maintenance and Repair Electrodes 1/16" 1/8" 5/16" Figure 22 NOTE TO COMMERCIAL USERS: All mechanical equipment, no matter how well designed, will need maintenance and repairs. A Northstar pressure washer is no exception. At times, a Northstar pressure washer may become inoperable because repairs are required. Product Support will assist in these repairs as needed, but if an inoperable pressure washer creates a major expense to your business, then we strongly recommend the following: •...

-

Page 45: Troubleshooting

Troubleshooting Engine Will Not Start Causes Solutions Low Oil Shutdown Fill engine with the adequate amount of oil. Cold Engine Choke engine to start. No Fuel Add petrol to fuel tank, make sure fuel shutoff valve is open. Dead Battery Recharge/Replace battery. -

Page 46: Parts Explosion

Parts Explosion MNS157310 – Rev A... - Page 47 Parts Explosion MNS157310 – Rev A Ref# Part # Description Ref# Part # Description 793846 Outer Frame 778219 ISO-Mount Plate 789546 Decal, Instructions 778228 ISO Support Bar 791574 Fuel Tank (Yellow) 777232 Rear Brake 784769 Sealed Fuel Cap 30747 Handle/Brake Grip 791575 Petrol Tank (Red) 778295...

- Page 48 Pump Explosion – Rev A...

-

Page 49: Wiring Diagrams

Summary of Important Safety Information... -

Page 50: Summary Of Important Safety Information

Summary of Important Safety Information This section provides a summary of the various safety procedures and measures that have been presented throughout the manual. Keep this summary handy and refer to it to refresh your memory about how to safely use your pressure washer. WARNING Carefully read and follow all instructions and safety information for using this pressure washer. - Page 51 Summary of Important Safety Information • Prevent carbon monoxide poisoning – Use outside only! Exhaust fumes from both the engine and the burner contain carbon monoxide (CO), a poisonous gas you cannot see, smell, or taste. The CO generated by the pressure washer can rapidly accumulate, even in areas that appear to be well ventilated, resulting in dangerous and fatal concentrations within minutes.

- Page 52 Summary of Important Safety Information Never run the machine without sufficient lubrication or sufficient water to cool the pump. Never operate unless all safety guards are in place. • Position safely. Place sprayer on firm, level ground to prevent accidental falls and equipment tip-over. •...

- Page 53 Summary of Important Safety Information Always wear protective gloves when handling and cleaning with chemicals. When cleaning filters, check whether dangerous chemicals have been used with the filter and take any precautions that may have been recommended by the supplier of these chemicals.

-

Page 54: Limited Warranty

Kincrome shall warranty any piece of equipment manufactured, or parts of equipment manufactured, to be free from defects in material or workmanship for a period of: Product Warranty Item # Warranty Period NS157310 2 years from date of purchase by user Engine Warranty Item # Warranty Period... - Page 56 Engineered and Assembled by: Northern Tool & Equipment Company, Inc. Burnsville, MN 55306 USA Distributed in Australia by: Kincrome Tools & Equipment Pty Ltd 3 Lakeview Drive, Caribbean Business Park, Scoresby, Victoria, Australia 3179 1300 657 528...

Need help?

Do you have a question about the NS157310 and is the answer not in the manual?

Questions and answers