Summary of Contents for Toshiba RAV-RM1601BTP-E

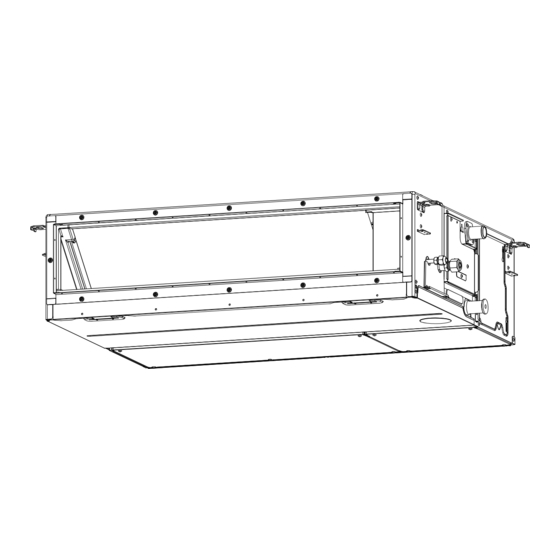

- Page 1 R32 or R410A AIR CONDITIONER (SPLIT TYPE) Installation Manual Indoor Unit For commercial use Model name: Concealed Duct Type RAV-RM 1BTP-E English...

-

Page 2: Table Of Contents

9 Applicable controls ........... 16 work on the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such matters by an individual or individuals who have been trained and is thus thoroughly 10 Test run . - Page 3 Warning indications on the air conditioner unit Definition of Protective Gear When the air conditioner is to be transported, installed, maintained, repaired or removed, wear protective gloves and ‘safety’ work clothing. Warning indication Description In addition to such normal protective gear, wear the protective gear described below when undertaking the special work detailed in the following table.

-

Page 4: Precautions For Safety

– 3 – Precautions for safety • Only a qualifi ed installer(*1) or qualifi ed service person(*1) is allowed to undertake work at heights using a stand of 50 The manufacturer shall not assume any liability for the damage cm or more or to remove the intake grille of the indoor unit to caused by not observing the description of this manual. - Page 5 • The air conditioner must be transported in stable condition. If • Appliance and pipe-work shall be installed, operated and stored any part of the product is broken, contact the dealer. in a room with a fl oor area larger than A •...

- Page 6 – 5 – • Helmet must be worn to protect your head from falling objects. • To connect the electrical wires, repair the electrical parts Especially, when you work under an inspection opening, helmet or undertake other electrical jobs, wear gloves to provide must be worn to protect your head from falling objects from the protection for electricians, insulating shoes and clothing to opening.

- Page 7 Test run Relocation • Before operating the air conditioner after having completed the • Only a qualifi ed installer(*1) or qualifi ed service person(*1) is work, check that the electrical control box cover of the indoor allowed to relocate the air conditioner. It is dangerous for the air unit and service panel of the outdoor unit are closed, and set conditioner to be relocated by an unqualifi...

-

Page 8: Accessory Parts

– 7 – Accessory parts Selection of installation place Avoid installing in the following places Accessory parts Select a location for the indoor unit where the cool or warm air will circulate evenly. Avoid installation in the following kinds of locations. Saline area (coastal area) ’... -

Page 9: Installation

Installation 3. Installation to a place where inside of the ceiling is used for pathway to intake the fresh air 4. Installation to a kitchen In the above cases, additionally attach the heat insulator to all positions of the air conditioner, which come to CAUTION contact with the high-humidity atmosphere. - Page 10 – 9 – Installation of hanging bolt Installation of indoor unit Mounting filter rails and filters Consider the piping / wiring after the unit is hung to Mount the filter rail so that the hooks fit into the corresponding holes. Treatment of ceiling determine the location of the indoor unit installation (Note that the upper and lower filter rails are not identical.)

-

Page 11: Drain Piping

Drain piping Gravitational drainage Reattach the drain cap. CAUTION * For gravitational drainage, remove the white connector (CN504) on the upper left of the circuit board in the Following the Installation Manual, perform the drain piping work so that water is properly drained. Apply a heat electrical control box. - Page 12 – 11 – Check the draining Heat insulating process In the test run, check that water drain is properly performed and water does not leak from the connecting part of • As shown in the figure, cover the flexible hose and hose band with the attached heat insulator up to the bottom the pipes.

-

Page 13: Duct Design

Duct design Fan characteristics RM160 Arrangement (Unit: mm) Referring to the following dimensions, manufacture duct at the local site. Standard air volume: 2100 m Lower limit of external static pressure (120 Pa) Upper limit of RM160 external static High pressure (120 Pa) (120 Pa) High <Under air intake>... -

Page 14: Refrigerant Piping

– 13 – Refrigerant piping Evacuation * In case of flaring with the conventional flare tool, pull it out approx. 0.5 mm more than that for R22 to adjust to the specified flare size. The copper pipe Perform vacuuming from the charge port of valve of the Connecting refrigerant piping gauge is useful for adjusting projection margin size. -

Page 15: Electrical Connection

Electrical connection Heat insulation process Apply heat insulation for the pipes separately at liquid side and gas side. • For the heat insulation to the pipes at gas side, be sure to use the material with heat-resisting temperature WARNING 120 °C or higher. •... - Page 16 – 15 – Wiring between indoor unit and outdoor unit Wire connection 1. Figure below shows the wiring connections between the indoor and outdoor units and between the indoor units REQUIREMENT and remote controller. The wires indicated by the broken lines or dot-and-dash lines are provided at the locally. •...

-

Page 17: Applicable Controls

Applicable controls External static pressure Each time button is pushed, indoor unit numbers in the control group change settings cyclically. Select the indoor unit to change Basic procedure for changing REQUIREMENT settings for. Set up a tap change based upon the external static settings The fan of the selected unit runs and the louvers •... - Page 18 – 17 – External static pressure Filter sign setting Power saving mode When using the wireless remote controller According to the installation condition, the filter sign Performing settings of the power saving term (Notification of filter cleaning) can be changed. To set up the external static pressure, use the DIP switch on the circuit board of the wireless reception part.

- Page 19 Remote controller switch Group control Push button to return to the normal display. monitoring function Simultaneous twin, triple or double twin system Indoor unit data This function is available to call the service monitor A combination with an outdoor unit allows simultaneous ON/OFF operation of the indoor units. The following CODE No.

- Page 20 – 19 – Group control for system of multiple units [Procedure example] One remote controller can control maximum 8 indoor units as a group. Manual address setup procedure 1. Specify CODE No. [12] with TEMP. buttons. While the operation stops, change the setup. ▼...

- Page 21 To recognize the position of the After check of the changed contents, push After confirmation, push button to return button. (Setup is determined.) When corresponding indoor unit though the to the normal mode. 1. Specify CODE No. [14] TEMP. buttons. button is pushed, the display disappears indoor UNIT No.

-

Page 22: Test Run

– 21 – Test run 8 °C Operation Pre-heating operation can be set for cold regions where room temperature drops to below zero. Before test run Wired remote controller Push buttons simultaneously for 4 seconds or more when the air 2, 4 Before turning on the power supply, carry out the conditioner is not working. -

Page 23: Maintenance

Maintenance Wireless remote controller When a test run is not performed properly When TEMPORARY button is pushed for 10 seconds or more, “Pi!” sound is heard and <Daily maintenance> the operation changes to test run. After • When a test run is not performed properly, refer to ▼... -

Page 24: Troubleshooting

– 23 – Troubleshooting ▼ Periodic Maintenance For environmental conservation, it is strongly recommended that the indoor and outdoor units of the air conditioner in use be cleaned and maintained regularly to ensure efficient operation of the air conditioner. When the air conditioner is operated for a long time, periodic maintenance (once a year) is recommended. Confirmation and check Confirmation of error log Furthermore, regularly check the outdoor unit for rust and scratches, and remove them or apply rustproof... - Page 25 Error codes and parts to be checked Wired Wireless remote controller remote Sensor block display of controller receiving unit Judging display Main defective parts Parts to be checked / error description conditioner Wired Wireless remote controller device status remote Operation Timer Sensor block display of controller Ready...

- Page 26 – 25 – Wired Wireless remote controller remote Sensor block display of controller receiving unit display Judging Main defective parts Parts to be checked / error description conditioner device status Operation Timer Indication Ready Flashing GR GR OR Abnormal operation of the indoor fan motor, indoor The fan error of the P.C.

-

Page 27: Appendix

Appendix Work instructions 5. When a commercially available dryer is attached to the Existing pipes: Cannot be used. existing pipes. Are there scratches or dents on the existing pipes? The existing R22 and R410A piping can be reused for Use new pipes. There is the possibility that copper green rust has inverter R32 product installations. - Page 28 144 / 9 Moo 5, Bangkadi Industrial Park, Tivanon Road, Tambol Bangkadi, Amphur Muang, Pathumthani 12000, Thailand 1116950193...

Need help?

Do you have a question about the RAV-RM1601BTP-E and is the answer not in the manual?

Questions and answers