Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Miller XMS 425 MPa CE

- Page 1 OM-274462C 2017-02 Processes Multiprocess Welding Description Arc Welding Power Source XMS 425 MPa File: MULTIPROCESS For product information, Own- er’s Manual translations, and more, visit www.MillerWelds.com...

- Page 2 From Miller to You Thank you and congratulations on choosing Miller. Now you can get the job done and get it done right. We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING ....... . . 1-1. - Page 5 DECLARATION OF CONFORMITY for European Community (CE marked) products. ITW Welding Italy S.r.l Via Privata Iseo 6/E, 20098 San Giuliano M.se, (MI) Italy declares that the prod- uct(s) identified in this declaration conform to the essential requirements and provisions of the stat- ed Council Directive(s) and Standard(s).

- Page 6 1 cm 1 cm 1 cm Distance where all occupational ELV Exposure Indices fall below 0.20 (20%) 9 cm Distance where all general public ELV Exposure Indices fall below 1.00 (100%) 185 cm Tested by: Miller Milan Date tested: 2016−03−03 XXXXXX‐A...

-

Page 7: Section 1 − Safety Precautions - Read Before Using

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING som 2015−09 Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! − Indicates a hazardous situation which, if Indicates special instructions. - Page 8 D Remove stick electrode from holder or cut off welding wire at con- FUMES AND GASES can be hazardous. tact tip when not in use. D Wear body protection made from durable, flame−resistant material Welding produces fumes and gases. Breathing (leather, heavy cotton, wool).

-

Page 9: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance FIRE OR EXPLOSION hazard. MOVING PARTS can injure. D Do not install or place unit on, over, or near D Keep away from moving parts such as fans. combustible surfaces. D Keep all doors, panels, covers, and guards D Do not install unit near flammables. -

Page 10: California Proposition 65 Warnings

1-4. California Proposition 65 Warnings Welding or cutting equipment produces fumes or gases This product contains chemicals, including lead, known to which contain chemicals known to the State of California to the state of California to cause cancer, birth defects, or other cause birth defects and, in some cases, cancer. -

Page 11: Section 2 − Definitions

SECTION 2 − DEFINITIONS 2-1. Additional Safety Symbols And Definitions Warning! Watch Out! There are possible hazards as shown by the symbols. Safe1 2012−05 Wear dry insulating gloves. Do not touch electrode with bare hand. Do not wear wet or damaged gloves. Safe2 2012−05 Protect yourself from electric shock by insulating yourself from work and ground. - Page 12 When power is applied failed parts can explode or cause other parts to explode. Safe26 2012−05 Always wear long sleeves and button your collar when servicing unit. Safe28 2012−05 After taking proper precautions as shown, connect power to unit. Safe29 2012−05 Do not use one handle to lift or support unit.

-

Page 13: Miscellaneous Symbols And Definitions

2-2. Miscellaneous Symbols And Definitions Circuit Breaker Amperage Three Phase Alternating Gas Metal Arc Positive Current (AC) Welding (GMAW) Voltage Constant Voltage Remote Negative Primary Voltage Voltage Input Temperature Degree Of Protec- tion Protective Earth MMA Welding (Ground) Maximum Effective Supply 1eff Current Tungsten Inert... -

Page 14: Section 3 − Specifications

SECTION 3 − SPECIFICATIONS 3-1. Serial Number And Rating Label Location The serial number and rating information for this product is located on the rear panel. Use rating label to determine input power requirements and/or rated output. For future reference, write serial number in space provided on back cover of this manual. 3-2. -

Page 15: Environmental Specifications

3-4. Environmental Specifications A. IP Rating IP Rating IP23S This equipment is designed for outdoor use. It may be stored, but is not intended to be used for welding outside during precipitation unless sheltered. IP23S 2014−06 B. Temperature Specifications Operating Temperature Range Storage Temperature Range 14 to 104°F (−10 to 40°C) −4 to 131°F (−20 to 55°C) -

Page 16: Duty Cycle And Overheating

3-5. Duty Cycle And Overheating Duty Cycle is percentage of 10 min- utes that unit can weld at rated load without overheating. If unit overheats, output stops, a Help message is displayed and cooling fan runs. Wait fifteen min- utes for unit to cool. Reduce amper- age or voltage, or duty cycle before welding. -

Page 17: Volt-Ampere Curves

3-6. Volt-Ampere Curves Volt-ampere curves show minimum A. CC Mode and maximum voltage and amper- age output capabilities of welding power source. Curves of other set- tings fall between curves shown. SMAW GTAW SMAW GTAW CONTROL 100% AMPERAGE B. CV Mode 5 00 AMPERAGE 217 836-A / 217 837-B... -

Page 18: Section 4 − Installation

SECTION 4 − INSTALLATION 4-1. Selecting A Location Movement Do not move or operate unit where it could tip. Location And Airflow Special installation may be required where gasoline or volatile liquids are present − see NEC Article 511 or CEC Section 20. -

Page 19: Selecting Cable Sizes

4-2. Selecting Cable Sizes* NOTICE − The Total Cable Length in Weld Circuit (see table below) is the combined length of both weld cables. For example, if the power source is 30 m (100 ft) from the workpiece, the total cable length in the weld circuit is 60 m (2 cables x 30 m). Use the 60 m (200 ft) column to determine cable size. -

Page 20: Remote 14 Receptacle Information

4-4. Remote 14 Receptacle Information Socket* Socket Information 24 volts AC. Protected by supplementary protect- 24 VOLTS AC or CB2. C L N Contact closure to A completes 24 volts AC con- tactor control circuit. Output to remote control; 0 to +10 volts DC, +10 volts DC in MIG mode. -

Page 21: Optional Gas Valve Operation And Shielding Gas Connection

4-6. Optional Gas Valve Operation And Shielding Gas Connection Obtain gas cylinder and chain to running gear, wall, or other station- ary support so cylinder cannot fall and break off valve. Cylinder Regulator/Flowmeter Install so face is vertical. Gas Hose Connection Fitting has 5/8-18 right-hand... -

Page 22: Cooler Connections

4-7. Cooler Connections 115 V, 10 Amp AC Receptacle 115 VAC Cord Provides 115 VAC to power cooler. 7-Pin Cord (See Section 4-8) Provides 23 VAC to activate the cooler, checks the presence of the liquid flow, and checks the pres- ence of the cooler. -

Page 23: Wire Feeder Connections

4-9. Wire Feeder Connections Gas Cylinder (See Section 4-6) Gas Fitting (See Section 4-6) Wire Feeder Welding power source can only be used with XMS 425 wire feed- 6-Pin Cord (See Section 4-10) Provides 23 VAC to power wire feed- er and CAN bus signal communica- tion to feeder. -

Page 24: Tig Connections

4-11. TIG Connections Positive Weld Output Terminal Connect work lead to positive weld output terminal. Negative Weld Output Terminal Connect TIG torch to negative weld Tools Needed: output terminal. Gas Out Connection 17 mm Connect torch gas hose to gas out fitting. -

Page 25: Stick Connections

4-12. Stick Connections Positive Weld Output Terminal Connect electrode holder to posi- tive weld output terminal. Negative Weld Output Terminal Connect work lead to negative weld output terminal. Remote 14 Receptacle If desired, connect remote control to Remote 14 receptacle (see Sec- tion 4-4). -

Page 26: Mig Connections

4-13. MIG Connections Cooler Welding Power Source Wire Feeder Gas Cylinder Gas Hose Connect to gas fitting on back of wire feeder. Wire Feeder Cable See Section 4-9. Welding Gun Connect to welding torch connector on wire feeder. Work Lead Connect work lead to negative weld output terminal. -

Page 27: Electrical Service Guide

4-14. Electrical Service Guide Elec Serv 2017−01 NOTICE − INCORRECT INPUT POWER can damage this welding power source. Phase to ground voltage shall not exceed +10% of rated input voltage. NOTICE − Actual input voltage should not be 10% less than minimum and/or 10% more than maximum input voltages listed in table. If actual input voltage is outside this range, output may not be be available. -

Page 28: Connecting 3-Phase Input Power

4-15. Connecting 3-Phase Input Power = GND/PE Earth Ground Tools Needed: Input2 2012−05 − Ref. 956172246_1-A OM-274462 Page 22... - Page 29 4-15. Connecting 3-Phase Input Power (Continued) voltage available at site. This unit can be con- Input Conductors (L1, L2 And L3) Installation must meet all National and nected to any input power between 208 and Local Codes − have only qualified per- Disconnect Device Line Terminals 575 VAC without removing cover to relink the sons make this installation.

-

Page 30: Section 5 − Operation

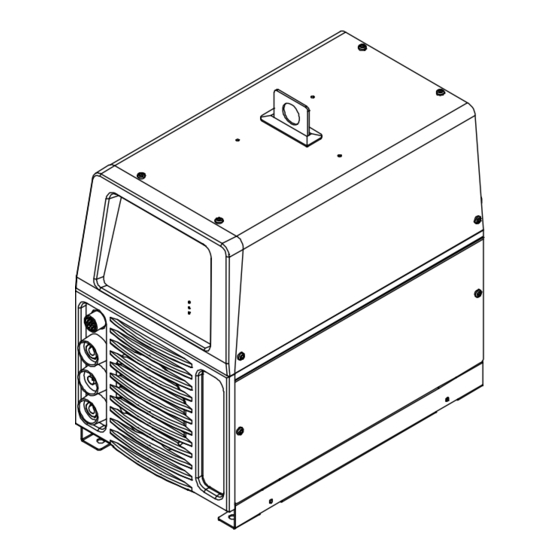

SECTION 5 − OPERATION 5-1. Front Panel Controls Front Of Machine Back Of Machine 956172246_14-A Power Switch See Section 4-10. 12 Negative Weld Output Terminal Use switch to turn unit On/Off. MIG Positive Weld Output Terminal 13 Weld Output Indicator Light (Blue LED) Circuit Breaker CB1 Gas In Fitting Is lit when output power is On. -

Page 31: Lift-Arc Trigger Hold Tig

5-2. Lift-Arc Trigger Hold TIG TIG Electrode Workpiece Procedure requires: control Start sequence: • Touch tungsten electrode to workpiece at weld start point. • Momentarily depress output switch. • Slowly lift electrode. An arc will 1 − 2 form when electrode is lifted. “Touch”... -

Page 32: Section 6 − Maintenance & Troubleshooting

SECTION 6 − MAINTENANCE & TROUBLESHOOTING 6-1. Routine Maintenance Disconnect power Maintain more often before maintaining. during severe conditions. 3 Months Repair Or Replace Replace Cracked Replace Damaged Or Torch Body Cracked Unreadable Cables Labels Repair Or Replace Cracked Cables And Cords Clean Tighten Weld... -

Page 33: Troubleshooting

6-3. Troubleshooting Trouble Remedy No weld output; unit completely inop- Place line disconnect switch in On position (see Section 4-15). erative. Check and replace line fuse(s), if necessary, or reset circuit breaker (see Section 4-15). Check for proper input power connections (see Section 4-15). No weld output;... -

Page 34: Section 7 − Electrical Diagram

SECTION 7 − ELECTRICAL DIAGRAM Figure 7-1. Circuit Diagram OM-274462 Page 28... - Page 35 956172195-B OM-274462 Page 29...

-

Page 36: Section 8 − Parts List

SECTION 8 − PARTS LIST 956172246_15-B Figure 8.1. Parts Assembly OM-274462 Page 30... - Page 37 Item Dia. Part Mkgs. Description Quantity Figure 8.1. Parts Assembly ....213073 Seal, Lift Eye ...........

- Page 38 Item Dia. Part Mkgs. Description Quantity Figure 8.1. Parts Assembly (Continued) ....261556 Kit, Input/Pre−Regulator And Inverter Module (Includes) ....

- Page 39 Effective January 1, 2017 (Equipment with a serial number preface of MH or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other guarantees or warranties expressed or implied. LIMITED WARRANTY − Subject to the terms and conditions 90 Days —...

- Page 40 File a claim for loss or damage during Phone: 39 (0) 2982901 Fax: 39 (0) 298290-203 shipment. email: miller@itw−welding.it For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © ORIGINAL INSTRUCTIONS − PRINTED IN USA 2017 Miller Electric Mfg. Co. 2017−01...

Need help?

Do you have a question about the XMS 425 MPa CE and is the answer not in the manual?

Questions and answers