Table of Contents

Advertisement

Quick Links

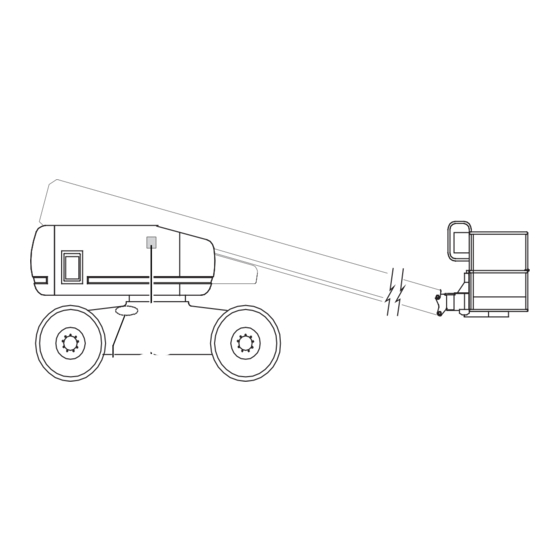

Service and Repair Manual

S

-60 XC

®

S

-65 XC

®

S

-60 TraX

®

S

-65 TraX

®

Serial Number Range

™

™

™

™

from S65XCM-101

from S60XCH-45010

from S65XCH-45001

This manual includes:

Repair procedures

Fault Codes

Electrical and

Hydraulic Schematics

For detailed maintenance

procedures, refer to the

appropriate Maintenance

Manual for your machine.

Part No. 1288652GT

Rev C1

March 2019

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Terex S65XCM-101

- Page 1 Service and Repair Manual Serial Number Range -60 XC ® ™ from S65XCM-101 This manual includes: from S60XCH-45010 Repair procedures from S65XCH-45001 -65 XC ® ™ Fault Codes Electrical and -60 TraX ® ™ Hydraulic Schematics -65 TraX ® ™...

-

Page 2: Find A Manual For This Model

Copyright © 2015 by Terex Corporation 1288652GT Rev C, January 2019 First Edition, Third Printing Genie and "S" are registered trademarks of Terex South Dakota, Inc. in the U.S.A. and many other countries. "XC" and "TRAX" are trademarks of Terex South Dakota, Inc. - Page 3 March 2019 Service and Repair Manual Introduction Revision History Revision Date Section Procedure / Page / Description 7/2018 New Release 9/2018 Specifications Oscillate valve relief pressure Repair Display menu Schematics Update hydraulic and electrical schematics 1/2019 Added ANSI version 1-5 Joystick Threshold Setting 3/2019 Repair Reference Examples:...

-

Page 4: Serial Number Legend

Service and Repair Manual March 2019 Introduction Serial Number Legend 1 Model 1 Serial label (located under cover) 2 Facility code 2 Serial number (stamped on drive chassis) 3 Sequence number ® ™ ® ™ ® ™ ® ™ -60 XC •... -

Page 5: Safety Rules

March 2019 Service and Repair Manual Safety Rules Section 1 Safety R ules Danger Failure to obey the instructions and safety rules in this manual and the appropriate Operator's Manual on your machine will result in death or serious injury. Many of the hazards identified in the operator's manual are also safety hazards when maintenance and repair procedures are performed. - Page 6 Service and Repair Manual March 2019 Safety Rules Personal Safety Workplace Safety Any person working on or around a machine must Any person working on or around a machine must be aware of all known safety hazards. Personal be aware of all known safety hazards. Personal safety and the continued safe operation of the safety and the continued safe operation of the machine should be your top priority.

-

Page 7: Table Of Contents

March 2019 Table of Contents Introduction Introduction ......................ii Important Information ..................... ii Find a Manual for this Model .................. ii Revision History..................... iii Serial Number Legend ..................iv Section 1 Safety Rules ......................v General Safety Rules ..................... v Section 2 Specifications ....................... - Page 8 March 2019 Table of Contents Section 3 Repair Procedures ....................22 Introduction ......................22 Control System ....................24 1-1 ALC-600 Platform Control Module ..............24 1-2 ALC-600 Service Mode .................. 25 1-3 How to Use the Recovery Mode ..............26 1-4 Full Machine Calibration .................

- Page 9 March 2019 Table of Contents Jib Boom Components ..................48 3-1 Jib Boom ......................48 3-2 Jib Boom Lift Cylinder ..................49 Boom Components .................... 50 4-1 Cable Track ....................50 How to Remove the Cable Track, S-60 XC and S-60 TraX ......50 How to Remove the Cable Track, S-65 XC and S-65 TraX ......

- Page 10 March 2019 Table of Contents Engines ........................ 71 5-1 RPM Adjustment - Ford and Deutz Models ............ 71 5-2 RPM Adjustment - Perkins 404D-22 Models ..........71 5-3 Flex Plate - Removal ..................71 How to Install a Type "A" Flex Plate ..............73 How to Install a Type "B"...

- Page 11 March 2019 Table of Contents Turntable Rotation Components ..............98 8-1 Turntable Rotation Assembly ................. 98 How to Adjust the Turntable Rotation Gear Backlash ........99 How to Calibrate the Turntable Tilt Sensor ........... 100 Axle Components ..................... 102 9-1 Oscillating Axle Cylinders ................102 Track Components ...................

- Page 12 Electrical Schematic, Perkins 404D-22 Models ..........162 Electrical Schematic, Ford MSG425 Models ............164 Electrical Schematic, Generators ............... 165 Hydraulic Schematics ..................167 Hydraulic Schematic, from SN S60XCH-45010, S65XCH-45001 ...... 168 Hydraulic Schematic, from SN S65XCM-101 ............. 169 ® ™ ® ™...

-

Page 13: Specifications

March 2019 Service and Repair Manual Specifications Section 2 Specific ati ons Performance Specifications Machine Specifications Boom function speeds, maximum from platform Tires and wheels, S-60 XC, S-65 XC controls Tire size (Rough terrain) 355/55D625 Jib boom up (S-65 XC models) 48 to 53 seconds Tire weight, new foam-filled (minimum) 426 lbs... -

Page 14: Hydraulic Oil Specifications

Service and Repair Manual March 2019 Specifications Hydraulic Oil Specifications Do not top off with incompatible hydraulic fluids. Hydraulic fluids may be incompatible due to the Hydraulic Fluid Specifications differences in base additive Genie specifications require hydraulic oils which are chemistry. - Page 15 March 2019 Service and Repair Manual Specifications Chevron Rando HD Premium Oil Chevron 5606A Hydraulic Oil MV Fluid Properties Fluid Properties ISO Grade ISO Grade Viscosity index Viscosity index Kinematic Viscosity Kinematic Viscosity cSt @ 200°F / 100°C cSt @ 200°F / 100°C cSt @ 104°F / 40°C 33.5 cSt @ 104°F / 40°C...

- Page 16 Service and Repair Manual March 2019 Specifications Petro-Canada Environ MV 46 UCON Hydrolube HP-5046 Fluid Fluid Properties Properties ISO Grade Viscosity index ISO Grade Kinematic Viscosity Viscosity index cSt @ 200°F / 100°C Kinematic Viscosity cSt @ 104°F / 40°C 44.4 cSt @ 149°F / 65°C Flash point...

-

Page 17: Hydraulic Component Specifications

March 2019 Service and Repair Manual Specifications Hydraulic Component Auxiliary pump Specifications Type: gear, fixed displacement Displacement 1.75 gpm Drive pump 2.8 L/min Type: bi-directional, variable displacement piston pump Function manifold Flow rate @ 2500 rpm 30.3 gpm System relief valve pressure 3000 psi 115 L/min 207 bar... - Page 18 Service and Repair Manual March 2019 Specifications Hydraulic filters 糎 High pressure filter Beta 5 High pressure filter bypass 100 psi pressure 6.89 bar 糎 Medium pressure filter Beta 6 Medium pressure filter bypass 51 psi pressure 3.5 bar Hydraulic return filter 10 micron with 25 psi / 1.7 bar bypass Manifold Component Specifications...

-

Page 19: Ford Msg-425 Efi Engine Specifications

March 2019 Service and Repair Manual Specifications Ford MSG-425 EFI Engine Fuel requirement For fuel requirements, refer to the engine Operator's Displacement 153 cu in Manual on your machine. 2.5 liters Ignition system Number of cylinders Spark plug type Motorcraft AYFS-32Y-R Bore &... -

Page 20: Deutz D2011 L03I Engine Specifications

Service and Repair Manual March 2019 Specifications Deutz D2011 L03i Engine Lubrication system Oil pressure 40 to 60 psi Displacement 142 cu in 1.4 to 3 bar 2.33 liters Oil capacity 9.5 quarts Number of cylinders (including filter) 9 liters Bore and Stroke 3.7 x 4.4 inches Oil viscosity requirements... - Page 21 March 2019 Service and Repair Manual Specifications Deutz D2011 L03i Engine, continued Fuel injection system Injection pump make Bosch Injection pump pressure, 15000 psi maximum 1034 bar Injector opening pressure 3046 psi 210 bar Fuel requirement For fuel requirements, refer to the engine Operator Manual for your engine.

-

Page 22: Deutz Td2011L04I Engine Specifications

Service and Repair Manual March 2019 Specifications Deutz TD2011L04i Engine Lubrication system 40 to 60 psi Oil pressure, hot(at 2000 rpm) Displacement 220.9 cu in 2.8 to 4.1 bar 3.62 liters Oil capacity(including filter) 12.8 quarts Number of cylinders 12.1 liters Bore and stroke 3.78 x 4.92 inches Oil viscosity requirements 96 x 125 mm -22°F to 86°F / -30°C to 30°C... - Page 23 March 2019 Service and Repair Manual Specifications Deutz TD2011L04i Engine, continued Fuel injection system Injection pump make Motorpal Injection pump pressure, maximum 15,000 psi 1034 bar Injector opening pressure 3046 psi 210 bar Fuel requirement For fuel requirements, refer to the engine Operator's Manual on your machine.

-

Page 24: Deutz D 2.9 L4 Engine Specifications

Service and Repair Manual March 2019 Specifications Deutz D 2.9 L4 Engine Oil viscosity requirements -22° F to 86° F/ -30° C to 30° C 5W-30 (synthetic) Displacement 177 cu in -4° F to 90° F / -20° C to 32° C 10W-40 2.9 liters Above 23°... - Page 25 March 2019 Service and Repair Manual Specifications Deutz D 2.9 L4 Engine, continued Starter motor Current draw, normal load 250A to 400A Brush length, new 0.72 in 18.5 mm Brush length, minimum 0.27 in 7 mm Battery Type 12V DC Quantity Cold cranking ampere 1000A...

-

Page 26: Deutz Td 2.9 Engine Specifications

Service and Repair Manual March 2019 Specifications Deutz TD 2.9 Engine Oil Temperature sender Installation torque 8 - 18 ft-lbs Displacement 177 cu. in 11 - 24 Nm 2.9 liters Oil Pressure sender Number of cylinders Installation torque 8 - 18 ft-lbs Bore and Stroke 3.6 x 4.3 inches 11 - 24 Nm... -

Page 27: Perkins 404D-22 Engine Specifications

March 2019 Service and Repair Manual Specifications Perkins 404D-22 Engine Oil pressure sending unit Oil pressure switch point 14.2 psi Displacement 134 cu in 1 bar 2.2 liters Fuel injection system Number of cylinders Injection pump make Zexel Bore and Stroke 3.31 x 3.94 inches Injection pressure 2133 psi... -

Page 28: Perkins 404F-E22T Engine Specifications

Service and Repair Manual March 2019 Specifications Perkins 404F-E22T Engine Lubrication system Oil pressure (@ 2000 rpm) 40 to 60 psi Displacement 134 cu in 1.4 to 3 bar 2.2 liters Oil capacity 9.4 - 11.2 quarts Number of cylinders (including filter) 8.9 - 10.6 liters Bore and Stroke... - Page 29 March 2019 Service and Repair Manual Specifications Perkins 404F-22 Engine, continued Battery Type 12V DC Quantity Cold cranking ampere 1000A Reserve capacity @ 25A rate 200 minutes Engine coolant Capacity 7.7 quarts 7.3 liters Coolant temperature switch Temperature switch point 221°...

-

Page 30: Machine Torque Specifications

Service and Repair Manual March 2019 Specifications Machine Torque Specifications TRAX Torque Specifications Platform rotator Sprocket to hub adapter fasteners 1-8 center bolt, GR 5 500 ft-lbs 3/4 -10 nuts, GR 8, dry 317 ft-lbs 678 Nm 430 Nm 1/2 -13 bolts, GR 8 90 ft-lbs 3/4 -10 nuts, GR 8, lubricated 281 ft-lbs... -

Page 31: Hydraulic Hose And Fitting Torque Specifications

March 2019 Service and Repair Manual Specifications Hydraulic Hose and Fitting SAE O-ring Boss Port Torque Specifications (tube fitting - installed into Aluminum) (all types) Your machine is equipped with Parker Seal-Lok™ SAE Dash Size Torque ORFS or 37° JIC fittings and hose ends. Genie 14 ft-lbs / 19 Nm specifications require that fittings and hose ends be torqued to specification when they are removed and... -

Page 32: Torque Procedure

Service and Repair Manual March 2019 Specifications Torque Procedure JIC 37° fittings Seal-Lok™ fittings Align the tube flare (hex nut) against the nose of the fitting body (body hex fitting) and tighten Replace the O-ring. The O-ring must be the hex nut to the body hex fitting to hand tight, replaced anytime the seal has been broken. - Page 33 March 2019 Service and Repair Manual Specifications Working clockwise on the body hex fitting, make a second mark with a permanent ink marker to indicate the proper tightening position. Refer to Illustration 2. Note: Use the JIC 37° Fitting table in this section to determine the correct number of flats, for the proper tightening position.

-

Page 34: Repair Procedures

Service and Repair Manual March 2019 Repair Procedures Section 3 Repair Pr oc edures Machine Configuration: Unless otherwise specified, perform each repair procedure with the machine in the following configuration: · Machine parked on a firm, level surface · Key switch in the off position with the key Observe and Obey: removed ·... - Page 35 March 2019 Service and Repair Manual Repair Procedures About This Section Most of the procedures in this section should only be performed by trained service professional in a suitably equipped workshop. Select the appropriate repair procedure after troubleshooting the problem. Perform disassembly procedures to the point where repairs can be completed.

-

Page 36: Control System

Service and Repair Manual March 2019 Control System ALC-600 Control Module Platform Controls The platform control box contains the ALC-600 platform Control Module. The platform Control Module receives all signals from the platform switches, joysticks and foot switch, and provides operator feedback through an Indicator Module. -

Page 37: Service Mode

March 2019 Service and Repair Manual Control System The Control System on this machine allows access to calibrations through the Service Mode. The How to Enter ALC-600 Service procedures that follow may require the operator to Mode already be in the Service Mode. The Service Mode can only be entered at machine start up and requires a special code. -

Page 38: How To Use The Recovery Mode

Service and Repair Manual March 2019 Control System While pressing the ground function enable button, push and hold the recovery toggle How to Use the Recovery Mode switch in the recovery position. Result: The auxiliary power unit will turn on Recovery is only to be used as a last attempt to and the boom will begin the following recovery lower the platform when the operator in the platform... -

Page 39: Full Machine Calibration

March 2019 Service and Repair Manual Control System Full Machine Calibration Machine Functions How to Adj ust the Mac hine M axi mum Speed Setti ng Full machine calibration must be completed in the How to Adjust the Joystick proper sequence when the ALC-600 controller Maximum Speed Setting (TCON) in the ground control box has been replaced. -

Page 40: How To Adjust The Joystick Ramp Rate Setting

Service and Repair Manual March 2019 Control System How to Adj ust the Joystic k Ramp R ate Setting Start a timer and activate the machine function How to Adjust the Joystick Ramp that needs to be adjusted. Using the ground Rate Setting control functions is the same as asking for full joystick deflection at the platform. -

Page 41: How To Adjust The Joystick Threshold Setting

March 2019 Service and Repair Manual Control System How to Adj ust the Joystic k Thr eshol d Setting Scroll and press OK. The change is effective How to Adjust the Joystick immediately. Threshold Setting Start the engine from the ground controls. The threshold setting of a joystick is the minimum Start a timer and activate the machine function output at which a function proportional valve can... -

Page 42: How To Enter Alc600 Software Update Mode

Service and Repair Manual March 2019 Control System Browse and select the desired software. Follow the on-screen guidance to How to Enter ALC600 Software start the update procedure. Update Mode When complete, turn off machine. Remove USB flash drive, re-install the Display Go to the Genie website Controller door and close the GBOX (ground http://firmware.genielift.com, select your... - Page 43 March 2019 Service and Repair Manual Control System Display Module Menus Screen or Menu Item Default Display Settings Backlight 0 - 100% Contrast 0 - 100% Display Inversion On / Off Item Selections Default Screen or Menu Models & Options Model S80XC / S85XC / S60XC / S65XC <select model>...

- Page 44 Service and Repair Manual March 2019 Control System Screen or Menu Item Default Sensor Calibrations Universal Tilt Sensor Calibrate Load Sense Calibrate Boom Angle Sensor Calibrate Boom Length Sensor Calibrate Screen or Menu Item Default Auto Threshold Boom Up / Down Threshold select OK to Calibrate Calibration Screen or Menu...

- Page 45 March 2019 Service and Repair Manual Control System Screen or Menu Item Default Perkins 404D Threshold default = 2350 rpm Anti-Stall Drive Minimum default = 50% Range default = 125 rpm Hysteresis default = 100 rpm Screen or Menu Item Default Perkins 404F Threshold...

- Page 46 Service and Repair Manual March 2019 Control System Screen or Menu Item Default Primary Lift Ramps Extend Accelerating Rate 5000 ms max, 1000 ms min, 2500 ms (default) Extend Decelerating Rate 5000 ms max, 250 ms min, 1000 ms (default) Retract Accelerating Rate 5000 ms max, 1000 ms min, 2500 ms (default) Retract Decelerating Rate...

- Page 47 March 2019 Service and Repair Manual Control System Screen or Menu Item Default Jib Boom and Jib Up Threshold max 133% / min 50% / default 105% Platform Speeds Jib Down Threshold max 133% / min 50% / default 105% Platform Level Up Threshold max 127% / min 50% / default 100% Platform Level Down...

-

Page 48: How To Replace The Display Controller (Discon) Module

Service and Repair Manual March 2019 Control System Open the ground box lid (1) and disconnect the wire harness going to the display controller How to Replace the Display (DISCON). Controller (DISCON) Module Remove the DISCON door from the back by loosening the four Torx head screws (8) and Push in the red Emergency Stop button to the remove the two ribbon cables (6) connecting... -

Page 49: How To Replace The Ground Control Overlay

March 2019 Service and Repair Manual Control System Evenly tighten the nuts, beginning with the lower center nut, working out and then up. How to Replace the Ground Box Install the new ribbon cables, connecting the Control Overlay ground box overlay to the DISCON and reinstall the DISCON door, using the Torx Push in the red Emergency Stop button to the head screws removed in step 4. - Page 50 Service and Repair Manual March 2019 Control System Unscrew the nut holding the buttons and key Remove the DISCON door (4) and disconnect switch and remove the key switch and buttons. the ribbon cables (3) from the Display Note the orientation of the key switch so it can Controller (DISCON) (2).

-

Page 51: Platform Components

March 2019 Service and Repair Manual Platform Components 13 Reinstall the DISCON door using the Torx head screws. Tighten, but do not overtighten. Platform Leveling Slave Cylinder 14 Reinstall the ground box door to the ground box, using the fasteners removed in step 7. The slave cylinder and the rotator pivot are thetwo Tighten the fasteners securely. -

Page 52: Platform Rotator

Service and Repair Manual March 2019 Platform Components Remove the pin retaining fastener from the slave cylinder rod-end pivot pin. Use a soft Platform Rotator metal drift to drive the rod-end pivot pin out. The platform rotator is a hydraulically activated Crushing hazard. - Page 53 March 2019 Service and Repair Manual Platform Components S-60 XC: Tag, disconnect and plug the hydraulic hoses from the platform rotator manifold. Cap the Support the rod end of the platform leveling fittings on the rotator. slave cylinder. Protect the cylinder rod from Tag, disconnect and plug the hydraulic hoses damage.

- Page 54 Service and Repair Manual March 2019 Platform Components How to Bleed the Platform Rotator S-65 XC: 11 Remove the pin retaining fasteners from the jib Note: This procedure will require two people. Do not boom and jib boom leveling arms to platform start the engine.

-

Page 55: Platform Overload System

March 2019 Service and Repair Manual Platform Components Open the bottom bleed screw on the rotator, but do not remove it. Platform Overload System Bodily injury hazard. Spraying hydraulic oil can penetrate and Proper calibration of the platform overload system burn skin. - Page 56 Service and Repair Manual March 2019 Platform Components 10 Place a 1,000 lb / 454 kg test weight on the 17 Test all machine functions from the ground platform floor using a suitable lifting device. controls. Place the weight near the center entry point of Result: All ground control functions should not the platform, as far away from the operator operate.

-

Page 57: How To Perform Zero Load Platform Overload Calibration

March 2019 Service and Repair Manual Platform Components How to R eplac e the Platfor m Overload Load C ell How to Perform Zero Load How to Replace the Load Cell Platform Calibration Sensor Perform this procedure when the required weight Note: The preload adjustment should only be for full load calibration is not available. -

Page 58: Platform

Service and Repair Manual March 2019 Platform Components Install the new Load Cell Sensor 12 Place a 1,000 lb / 454 kg test weight on the platform floor using a suitable lifting device. Screw the foot with jam nut into the top of the Place the weight near the center entry point of load cell sensor until the foot bolt extends out the platform, farthest away from the operator... - Page 59 March 2019 Service and Repair Manual Platform Components Support and secure the platform to an appropriate lifting device. Platform Remove the platform mounting fasteners and remove the platform from the machine. How to Remove the Platform Crushing hazard. The platform Remove the cable clamp from the top of the could become unstable and fall platform mounting weldment.

-

Page 60: Jib Boom Components

Service and Repair Manual March 2019 Jib Boom Components Attach a lifting strap from an overhead crane to the jib boom assembly. Jib Boom Place blocks under the platform leveling cylinder for support. Protect the cylinder rod How to Remove the Jib Boom from damage. -

Page 61: Jib Boom Lift Cylinder

March 2019 Service and Repair Manual Jib Boom Components Use a soft metal drift to tap the jib boom lift cylinder rod-end pivot pin half way out. Then Jib Boom Lift Cylinder lower one of the leveling arms to the ground. Tap the pin the other direction and lower the opposite leveling arm. -

Page 62: Boom Components

Service and Repair Manual March 2019 Boom Components Tag, disconnect and plug the platform leveling slave cylinder hydraulic hoses from the Cable Track bulkhead fittings on the side of the primary boom. Cap the bulkhead fittings. The primary boom cable track guides the cables Bodily injury hazard. -

Page 63: How To Remove The Cable Track, S-65 Xc And S-65 Trax

March 2019 Service and Repair Manual Boom Components How to R emove the C able Trac k, S-65 XC and S-65 XC TR AX How to Remove the Cable Track, 14 Place blocks in between the upper and lower cable tracks and secure the upper and lower S-65 XC and S-65 TraX tracks together. - Page 64 Service and Repair Manual March 2019 Boom Components Bodily injury hazard. Spraying 17 Remove the cable track pull tube guide hydraulic oil can penetrate and fasteners from the cable track guide at the burn skin. Loosen hydraulic platform end of the boom. Remove the cable connections very slowly to allow track guide from the boom.

-

Page 65: How To Repair The Cable Track

March 2019 Service and Repair Manual Boom Components How to R epair the C abl e Tr ac k Lift up the hoses and cables and carefully How to Repair the Cable Track insert the new 4 link section of cable track. Component damage hazard. - Page 66 Service and Repair Manual March 2019 Boom Components Boom components 1 short link arm to boom pivot pin 2 boom 3 boom lift cylinder rod-end pivot pin 4 boom lift cylinder 5 long link arm (ground controls side) 6 long link arm (engine side) 7 long link arm to turntable pivot pin 8 master cylinder cam 9 master cylinder cam link...

-

Page 67: Boom

March 2019 Service and Repair Manual Boom Components Boom How to R emove the Boom Remove the jib boom. Refer to Repair Procedure, How to Remove the Jib Boom. How to Remove the Boom Remove the cable track. Refer to Repair Procedure, How to Remove the Cable Track. - Page 68 Service and Repair Manual March 2019 Repair Procedures 15 Remove the hose and cable guide fasteners at Slowly operate the overhead crane to apply the primary boom pivot pin. Remove the hose tension to the lifting straps. Do not attempt to and cable guide.

- Page 69 March 2019 Service and Repair Manual Repair Procedures 19 Using auxiliary power, activate the boom down 25 Support the platform leveling master cylinder. function so the cylinder will retract. Retract the Remove the master cylinder rod-end pivot pin cylinder just enough until the rod end of the retaining fasteners.

-

Page 70: Boom Lift Cylinder

Service and Repair Manual March 2019 Repair Procedures Support and secure both ends of the boom lift cylinder to a second overhead crane or similar Boom Lift Cylinder lifting device. The boom lift cylinder raises and lowers the boom. Remove the pin retaining fastener from the The boom lift cylinder is equipped with boom lift cylinder rod-end pivot pin. -

Page 71: Boom Extension Cylinder

March 2019 Service and Repair Manual Repair Procedures Use a slide hammer to remove the barrel-end pivot pins. Boom Extension Cylinder Crushing hazard. The lift cylinder The boom extension cylinder is located inside the could become unbalanced and boom assembly and incorporates cables and fall if not properly supported and pulleys that are responsible for extending the secured to the lifting device. - Page 72 Service and Repair Manual March 2019 Repair Procedures Remove the boom end cover from the pivot end of the boom while guiding the small cable from the string potentiometer out of the slot of the cover. Rest the cover and string potentiometer on the counterweight.

- Page 73 March 2019 Service and Repair Manual Repair Procedures 11 Remove the fasteners from the retaining 17 Remove the lower extend cable bracket blocks from the extension cylinder saddle. mounting fasteners and pull back on the Remove the blocks. bracket to release it from the number 3 boom tube.

-

Page 74: Boom Extend/Retract Cables

Service and Repair Manual March 2019 Repair Procedures 24 Lift the boom extension cylinder with the crane until it clears the cylinder saddle inside the Boom Extend/Retract Cables number 2 boom tube. 25 Carefully support and slide the extension How to Adjust the Boom cylinder out of the boom. - Page 75 March 2019 Service and Repair Manual Repair Procedures Adjust the extend cable adjustment nuts until 12 Visually inspect the cable break limit switch approximately 1.5 inches / 4 cm of threads are arm to be sure the wheel of the limit switch arm visible past the nylock nut.

- Page 76 Service and Repair Manual March 2019 Repair Procedures How to Replace the Boom Boom retract cables: Extend/Retract Cables 10 Remove the cotter pins and clevis pins from the boom retract cables at the platform end of Note: The cable pulleys must also be replaced the boom.

-

Page 77: Platform Leveling Master Cylinder

March 2019 Service and Repair Manual Repair Procedures 18 At the pivot end of the boom, carefully pull the rope with the new retract cable attached. Platform Leveling Master Cylinder 19 Pull the new cable towards the pivot end of the The master cylinder acts as a pump for the slave boom until the end of the cable is at the end of cylinder. -

Page 78: Primary Boom Angle Sensor Calibration

Service and Repair Manual March 2019 Repair Procedures Place a 2 x 4 x 48 inches / 5 x 10 x 120 cm block of wood across the turntable covers. Primary Boom Angle Sensor Position the block under the master cylinder. The primary boom angle sensor is used to limit the Remove the pin retaining fastener from the angle of the primary boom relative to the angle of... -

Page 79: Primary Boom Angle Sensor Replacement

March 2019 Service and Repair Manual Repair Procedures Press OK on the display to continue with the procedure to capture the maximum angle How to Replace the Primary point. Boom Angle Sensor Operate the boom up function until the boom reaches its maximum angle. - Page 80 Service and Repair Manual March 2019 Repair Procedures Referring to Illustration 2, locate the sensor Remove any old blue thread locker, dirt or oils carrier plate (7) and remove the three phillips from the threaded holes in the sensor carrier head screws (8) securing the bracket.

-

Page 81: Boom Length Sensor Calibration

March 2019 Service and Repair Manual Repair Procedures 13 Apply blue thread locker into the sensor carrier plate threaded holes. Attach the provided Boom Length Sensor sensor onto the sensor carrier plate. Used the provided 14 mm screws (illustration 2, item 5). Securely tighten the fasteners. - Page 82 Service and Repair Manual March 2019 Repair Procedures Press the function enable and boom extend buttons until the boom reaches its maximum extension. Continue holding the buttons for several seconds after the boom reaches its maximum extension until the display indicates the calibration point has been captured.

-

Page 83: Engines

March 2019 Service and Repair Manual Engines Flex Plate RPM Adjustment - Ford and Deutz Models The flex plate acts as a coupler between the engine and the pump. It is bolted to the engine flywheel and Refer to Maintenance Procedure in the appropriate has a splined center to drive the pump. - Page 84 Service and Repair Manual March 2019 Engines Remove the engine mounting plate to bell housing fasteners. How to Remove the Flex Plate Raise the engine slightly using the overhead Deutz models: crane and place a block of wood under the oil pan for support.

-

Page 85: How To Install A Type "A" Flex Plate

March 2019 Service and Repair Manual Engines How to Ins tall a T ype " A" Flex Plate Install the pump coupler onto the pump shaft with the set screw toward the pump. Leave the How to Install a Type "A" Flex appropriate gap between coupler and pump Plate end plate for your engine. -

Page 86: How To Install A Type "B" Flex Plate

Service and Repair Manual March 2019 Engines How to Ins tall a T ype " B" Flex Plate How to Install a Type "B" Flex Plate Install the flex plate onto the engine flywheel with the rubber vibration isolators towards the pump. -

Page 87: How To Install The Pump And Bell Housing Assembly

March 2019 Service and Repair Manual Engines How to i nstall the Pump and Bell H ousing Ass embl y How to Install the Pump and Bell Housing Assembly Install the pump and bell housing assembly. Deutz models: Torque the bell housing mounting bolts labeled "C"... -

Page 88: Ford Msg-425 Engine Fault Codes

Service and Repair Manual March 2019 Engines Ford MSG-425 Engine Fault Codes How to Retrieve Engine Fault Codes The ECM constantly monitors the engine by the use of sensors on the engine. The ECM also uses signals from the sensors to initiate sequential fuel injection and make constant and instantaneous changes to ignition timing, fuel delivery and throttle position to maintain the engine's running condition... -

Page 89: Engine Fault Codes - Deutz D 2.9 L4 And Perkins 404-22 Models

March 2019 Service and Repair Manual Engines Engine Fault Codes - Deutz D 2.9 L4, D436 L3i and Perkins 404F-22 Models How to Retrieve Engine Fault Codes The ECM constantly monitors the engine by the use of sensors on the engine. The ECM also uses signals from the sensors to initiate sequential fuel injection and make constant and instantaneous changes to ignition timing, fuel delivery and throttle... -

Page 90: Hydraulic Pump

Service and Repair Manual March 2019 Hydraulic Pump Tag, disconnect and plug the function pump hydraulic hoses. Cap the fittings on the pum Function Pump Bodily injury hazard. Spraying hydraulic oil can penetrate and How to Remove the Function burn skin. Loosen hydraulic Pump connections very slowly to allow the oil pressure to dissipate... -

Page 91: Drive Pump

March 2019 Service and Repair Manual Hydraulic Pump Locate the two hydraulic tank valves at the hydraulic tank through the access hole Drive Pump underneath the turntable. Close the valves. The drive pump is a bi-directional variable Component damage hazard. displacement piston pump. - Page 92 Service and Repair Manual March 2019 Hydraulic Pump Carefully pull the drive pump out until the pump Ford models: Close the valve on the LPG coupler separates from the flex plate. tank then disconnect the hose from the tank. Then move the fuel select switch to the LPG Remove the drive pump from the machine.

- Page 93 March 2019 Service and Repair Manual This page intentionally left blank. ® ™ ® ™ ® ™ ® ™ Part No. 1288652GT -60 XC • S -65 XC -60 TraX -65 TraX...

-

Page 94: Manifolds

Service and Repair Manual March 2019 Manifolds 7-1 Function Manifold Components The function manifold is located underneath the ground controls side turntable cover. Index Schematic Description Function Torque Item Solenoid valve, 2 position 2 way Boom up 33-37 ft-lbs / 45-50 Nm Solenoid valve, 2 position 2 way Boom down 33-37 ft-lbs / 45-50 Nm... - Page 95 March 2019 Service and Repair Manual Manifolds ® ™ ® ™ ® ™ ® ™ Part No. 1288652GT -60 XC • S -65 XC -60 TraX -65 TraX...

- Page 96 Service and Repair Manual March 2019 Manifolds Function Manifold Components, continued Index Schematic Description Function Torque Item Check valve, 30 psi / 2 bar Platform rotate tank line 20-25 ft-lbs / 27-34 Proportional directional valve, 4 way, Platform level up/down 33-37 ft-lbs / 45-50 3 position Check valve...

- Page 97 March 2019 Service and Repair Manual Manifolds ® ™ ® ™ ® ™ ® ™ Part No. 1288652GT -60 XC • S -65 XC -60 TraX -65 TraX...

-

Page 98: Valve Adjustments - Function Manifold

Service and Repair Manual March 2019 Manifolds How to Adj ust the Boom Extend R elief Val ve 7-2 Valve Adjustments - Function How to Adjust the Boom Extend Manifold Relief Valve Note: Perform this procedure with the boom in the stowed position. -

Page 99: Jib Boom / Platform Rotate Manifold Components

March 2019 Service and Repair Manual Manifolds Jib Boom / Platform Rotate Manifold Components The jib boom / platform rotate manifold is mounted to the platform support. Index Schematic Description Function Torque Item Solenoid valve, 2 position 3 way Platform rotate/jib boom select 20-25 ft-lbs / 27-34 Nm ®... -

Page 100: Turntable Rotation Manifold Components

Service and Repair Manual March 2019 Manifolds Turntable Rotation Manifold Componentss The turntable rotation manifold is mounted to the turntable rotation motor. Index Schematic Description Function Torque Item Counterbalance valve Turntable rotate right 35-40 ft-lbs / 47-54 Nm Counterbalance valve Turntable rotate left 35-40 ft-lbs / 47-54 Nm Shuttle valve, 2 position 3 way... -

Page 101: How To Set Up The Oscillate Directional Valve

March 2019 Service and Repair Manual Manifolds 7-6 H ow to Set U p the Oscillate Directi onal Val ve 7-6 How to Set Up the Oscillate Adjust the heim joint until the hole lines up with the retaining fastener hole in the axle. Directional Valve 10 Install the heim joint to the axle and tighten the Note: Adjustment of the oscillate directional valve... -

Page 102: Valve Adjustments - Oscillate Relief Valve

Service and Repair Manual March 2019 Manifolds From S65XCM-101 Valve Adjustments - Oscillate Remove the drive chassis cover from the non-steer end of the machine. Relief Valve Connect a 0 to 2000 psi / 0 to 150 bar pressure gauge to the diagnostic nipple How to Adjust the Oscillate Relief located near the oscillate directional valve. - Page 103 March 2019 Service and Repair Manual This page intentionally left blank. ® ™ ® ™ ® ™ ® ™ Part No. 1288652GT -60 XC • S -65 XC -60 TraX -65 TraX...

-

Page 104: Traction Manifold Components, 4Wd

Service and Repair Manual March 2019 Manifolds Traction Manifold Components, 4WD The traction manifold is mounted inside the drive chassis at the non-steer end. Index Schematic Description Function Torque Item Flow divider/combiner valve Divides flow between diagonal pairs of 80-90 ft-lbs / 108-122 motors Check valve, 5 psi Prevents cavitation in LF motor... - Page 105 March 2019 Service and Repair Manual Manifolds ® ™ ® ™ ® ™ ® ™ Part No. 1288652GT -60 XC • S -65 XC -60 TraX -65 TraX...

-

Page 106: Valve Adjustments, 4Wd Traction Manifold

Service and Repair Manual March 2019 Manifolds Hold the charge pressure relief valve and remove the cap (item DI). Valve Adjustments, 4WD Traction Adjust the internal hex socket until the Manifold pressure reading on the gauge is 30 psi / 2 bar less than the pressure reading on the pump. -

Page 107: Generator Manifold Components

March 2019 Service and Repair Manual Manifolds 7-10 12 Kw Generator Manifold The generator manifold is mounted on the turntable tray by the fuel tank. Index Schematic Description Function Torque Item Relief valve Generator relief valve 50 ft-lbs / 67 Nm Solenoid Valve Charge pressure circuit 60-65 ft lbs / 81-88 Nm... -

Page 108: Valve Coils

Service and Repair Manual March 2019 Manifolds 7-11 Valve Coil Resistance Valve Coils Specification How to Test a Coil Note: The following coil resistance specifications are at an ambient temperature of 68°F / 20°C. As A properly functioning coil provides an valve coil resistance is sensitive to changes in air electromotive force which operates the solenoid temperature, the coil resistance will typically... -

Page 109: How To Test A Coil Diode

March 2019 Service and Repair Manual Manifolds How to T est a Coil Di ode How to Test a Coil Diode Genie incorporates spike suppressing diodes in all of its directional valve coils except proportional valves and those coils with a metal case. Properly functioning coil diodes protect the electrical circuit by suppressing voltage spikes. -

Page 110: Turntable Rotation Components

Service and Repair Manual March 2019 Turntable Rotation Components Loosen the backlash pivot plate and adjustment bolts. Turntable Rotation Assembly How to Remove the Turntable Rotation Assembly Note: When removing a hose assembly or fitting, the O-ring (if equipped) on the fitting and/or hose end must be replaced. -

Page 111: How To Adjust The Turntable Rotation Gear Backlash

March 2019 Service and Repair Manual Turntable Rotation Components How to Adj ust the Tur ntabl e R otati on Gear Bac klas h How to Adjust the Turntable Remove the backlash pivot plate mounting bolts. Carefully remove the drive hub assembly Rotation Gear Backlash from the machine. -

Page 112: How To Calibrate The Turntable Tilt Sensor

Service and Repair Manual March 2019 Turntable Rotation Components How to Calibrate the Turntable Tilt Push the backlash pivot plate towards the turntable as far as possible (this will push the Sensor rotation gear into the turntable bearing ring Note: Perform this procedure with the boom fully gear). - Page 113 March 2019 Service and Repair Manual Turntable Rotation Components A graphic of the machine pitch will now be 13 A graphic of the machine roll will now be shown on the display. By pressing the UP or shown on the display. By pressing the UP and DOWN buttons, the graphic will change to DOWN buttons, the graphic will change to show the counterweight being uphill or...

-

Page 114: Axle Components

Service and Repair Manual March 2019 Axle Components Tag, disconnect and plug the oscillating axle cylinder hydraulic hoses. Cap the fittings on Oscillating Axle Cylinders the cylinder. The oscillating axle cylinders extend and retract Bodily injury hazard. Spraying between the drive chassis and the axle to maintain hydraulic oil can penetrate and a level chassis while driving over uneven terrain. -

Page 115: Track Components

March 2019 Service and Repair Manual Track Components How to R eplac e a Tr ac k 10-1 How to Replace a Track Assembly Track Assembly, S-60 TraX and S-65 TraX Note: Perform this procedure on firm, level surface with the boom in the stowed position. How to Remove a Track Assembly Remove the track assembly from the machine. - Page 116 Service and Repair Manual March 2019 Track Components Install the new track onto the undercarriage. Rotate the sprocket half until the split tooth of the sprocket is lower than the other side. Attach a lifting strap from an overhead crane to the center-point of the track, above the sprocket.

- Page 117 March 2019 Service and Repair Manual Track Components 14 Using the pry bars, lift the sprocket half into 19 Pump grease into the grease zerk fitting until position. Install the 2 sprocket retaining grease, free from air, comes out of the grease fasteners and torque to specification.

- Page 118 Service and Repair Manual March 2019 Track Components 21 Continue to pump grease into the cylinder until the track has proper tension. Component damage hazard. Do not over tighten the track. Overtightening the track will cause the machine to lose power during operation.

-

Page 119: Fault Codes

March 2019 Service and Repair Manual Fault Codes Section 4 Faul t Codes Before Troubleshooting: Read, understand and obey the safety rules and operating instructions in the appropriate operator's manual on your machine. Be sure that all necessary tools and test equipment are available and ready for use. -

Page 120: Control System Fault Codes

Service and Repair Manual March 2019 Control System Fault Codes How to R etrieve Contr ol System F ault Codes Control System How to Retrieve Control System Fault Codes The machine control system contains two different types of fault codes Active Faults: These faults have been detected in the current operating session. -

Page 121: Control System Fault Codes

March 2019 Service and Repair Manual Control System Fault Codes Control System F ault C odes Component ID Name Cause Effect Solution Keyswitch 19 Fault Signals Machine will not Verify with a voltmeter that signals switch C134PLT be functional. properly. * With the keyswitch in the Ground C174GND position, C174GND (WH, TCON J5-12) - Page 122 Service and Repair Manual March 2019 Control System Fault Codes Component Name Cause Effect Solution or timeout detected as that C24FS (WH, PCON J12-2) is LOW occurred. HIGH at when foot switch is released and 12 V start-up, or when held down. footswitch was held for too long and...

- Page 123 March 2019 Service and Repair Manual Control System Fault Codes Component ID Name Cause Effect Solution at 2. 5V +/- 0.2 V at startup and does not 15 Joystick Circuit go above 4.5 V or below 0.5 V when fully voltage too C164PUD is stroked in each direction.

- Page 124 Service and Repair Manual March 2019 Control System Fault Codes Component Name Cause Effect Solution 17 Invalid Sensor has been Run the boom angle calibration process calibration replaced and and verify fault is no longer active. requires calibration, or calibration in memory has been erased.

- Page 125 March 2019 Service and Repair Manual Control System Fault Codes Component ID Name Cause Effect Solution are shorted on the with the stuck * If problem persists, open ground control ground control button will box and open the Display Controller panel.

- Page 126 Service and Repair Manual March 2019 Control System Fault Codes Component Name Cause Effect Solution Drive Enable 19 Stuck ON at Toggle switch Drive Enable Verify with a voltmeter that the Drive Switch power up. input was switch will Enable Toggle Switch (TS15) is operating detected as HIGH not operate, properly.

- Page 127 March 2019 Service and Repair Manual Control System Fault Codes Component ID Name Cause Effect Solution Drive 12 Circuit TCON detected Drive * With a voltmeter, measure Y6. Proper Forward shorted to that C30FWD Forward, resistance should be between 5 - 60 ohms. Valve circuit is shorted Brake...

- Page 128 Service and Repair Manual March 2019 Control System Fault Codes Component Name Cause Effect Solution voltage range of * Replace joystick if voltage check fails. 2.5 V +/- 0.2 V. Safety 21 Out of The system has All functions Use Auxiliary Power and the boom retract range Envelope determined that...

- Page 129 March 2019 Service and Repair Manual Control System Fault Codes Component ID Name Cause Effect Solution circuit between these pins indicates a harness or cable fault. 22 ESTOP TCON detected * Using a voltmeter and with the system Source that ESTOP 1 is turned OFF, check the resistance between circuit is at 12 V but...

- Page 130 Service and Repair Manual March 2019 Control System Fault Codes Component Name Cause Effect Solution consistently detected as less than -220 lbs. 17 Invalid The platform load * Run the platform overload calibration calibration sensor has no process and verify fault is no longer active. valid calibration data, either because the...

- Page 131 March 2019 Service and Repair Manual Control System Fault Codes Component ID Name Cause Effect Solution bus. Display 13 Not TCON has not Controls from * Verify DISCON is operating by checking Controller detected detected the the ground that the display on the front is operating (DISCON) properly.

- Page 132 Service and Repair Manual March 2019 Control System Fault Codes Component Name Cause Effect Solution on the telematics option. Turntable Tilt 13 Not The tilt sensors Boom Up, * Verify S8O is receiving power. Sensor detected (S8O and/or S8S) Extend and Disconnect sensor connector and verify have not been Drive...

- Page 133 March 2019 Service and Repair Manual Control System Fault Codes Component ID Name Cause Effect Solution the Length functions will Unplug the sensor and verify 12 V across Sensor. not operate. pins 1 (+) and 2 (-) on the harness connector.

- Page 134 Service and Repair Manual March 2019 Control System Fault Codes Component Name Cause Effect Solution to GND. 101 Platform 12 Circuit PCON detected Platform * With a voltmeter, measure Y19. Proper Level Down shorted to that V15PLD Level Down resistance should be between 5 - 60 ohms. Valve circuit is shorted and possibly...

- Page 135 March 2019 Service and Repair Manual Control System Fault Codes Component ID Name Cause Effect Solution * Verify wiring for C9PEF (BK/RD, TCON 15 Circuit TCON detected J4-5) and check for open or short circuits. shorted to that C9PEF circuit is shorted to * Verify resistance between Recovery GND.

- Page 136 Service and Repair Manual March 2019 Control System Fault Codes Component Name Cause Effect Solution 241 Sensor 12 Circuit TCON detected Boom Up * Turn on machine and verify sensor power Power shorted to that P109PWR and Extend P109PWR (GR/WH, TCON J7-7) is at 12 P109PWR circuit is shorted functions will...

-

Page 137: Engine Fault Codes

March 2019 Service and Repair Manual Control System Fault Codes Engine F ault C odes Engine Fault Codes Some engine options have their own Electronic Control Module that contains more detailed fault information that is specific to the engine. This system can be accessed by using the engine's dedicated service tool. -

Page 138: Deutz D 2.9 L4 Engine Fault Codes

Service and Repair Manual March 2019 Deutz D 2.9 L4 Engine Fault Codes SPN FMI Description SPN = Suspect Parameter Number 1231 Actuator error EGR-Valve; Power FMI = Failure Mode Identifier stage over temp due to high KWP = Keyword Protocol current SPN FMI Description... - Page 139 March 2019 Service and Repair Manual Deutz D 2.9 L4 Engine Fault Codes SPN = Suspect Parameter Number SPN FMI Description FMI = Failure Mode Identifier 1180 Physical range check high for KWP = Keyword Protocol battery voltage SPN FMI Description 1181 Physical range check low for...

- Page 140 Service and Repair Manual March 2019 Deutz D 2.9 L4 Engine Fault Codes SPN = Suspect Parameter Number SPN FMI Description FMI = Failure Mode Identifier 1007 Sensor error EGR cooler KWP = Keyword Protocol downstream temperature; signal range check high SPN FMI Description 1008...

- Page 141 March 2019 Service and Repair Manual Deutz D 2.9 L4 Engine Fault Codes SPN = Suspect Parameter Number SPN FMI Description FMI = Failure Mode Identifier 1109 2 Engine shut off demand ignored KWP = Keyword Protocol 1136 0 1398 Physikal range check high for SPN FMI Description...

- Page 142 Service and Repair Manual March 2019 Deutz D 2.9 L4 Engine Fault Codes SPN = Suspect Parameter Number SPN FMI Description FMI = Failure Mode Identifier 2659 2 1527 AGS sensor temperature exhaust KWP = Keyword Protocol gas mass flow; plausibility error SPN FMI Description 2659 12...

- Page 143 March 2019 Service and Repair Manual Deutz D 2.9 L4 Engine Fault Codes SPN = Suspect Parameter Number FMI KWP Description FMI = Failure Mode Identifier 523212 Timeout Error of KWP = Keyword Protocol CAN-Receive-Frame ComEngPrt; Engine Protection FMI KWP Description 523216 Timeout Error of 4766...

- Page 144 Service and Repair Manual March 2019 Deutz D 2.9 L4 Engine Fault Codes SPN = Suspect Parameter Number FMI KWP Description FMI = Failure Mode Identifier 523612 Internal ECU monitoring KWP = Keyword Protocol detection reported error FMI KWP Description 523612 1170 Internal software error ECU 523605...

- Page 145 March 2019 Service and Repair Manual Deutz D 2.9 L4 Engine Fault Codes SPN = Suspect Parameter Number FMI KWP Description FMI = Failure Mode Identifier 523788 Timeout Error of KWP = Keyword Protocol CAN-Transmit-Frame TrbCH; Status Wastegate FMI KWP Description 523793 Timeout Error of 523717...

- Page 146 Service and Repair Manual March 2019 Deutz D 2.9 L4 Engine Fault Codes SPN = Suspect Parameter Number FMI KWP Description FMI = Failure Mode Identifier 523946 1164 Zero fuel calibration injector 1 (in KWP = Keyword Protocol firing order); minimum value FMI KWP Description exceeded 523922...

- Page 147 March 2019 Service and Repair Manual Deutz D 2.9 L4 Engine Fault Codes SPN = Suspect Parameter Number FMI KWP Description FMI = Failure Mode Identifier 524032 1442 EGR actuator; status message KWP = Keyword Protocol EGRCust is missing FMI KWP Description 524033 1443 EGR actuator;...

- Page 148 Service and Repair Manual March 2019 Deutz D 2.9 L4 Engine Fault Codes SPN = Suspect Parameter Number KWP Description FMI = Failure Mode Identifier 524114 9 1659 Timeout error of KWP = Keyword Protocol CAN-Transmit-Frame A1DOC KWP Description 524115 9 1660 Timeout error of 524102 9 1674 Timeout error of...

-

Page 149: Perkins 404-22 Engine Fault Codes

March 2019 Service and Repair Manual Perkins 404-22 Engine Fault Codes Description SPN = Suspect Parameter Number Engine Speed Sensor #2: Voltage FMI = Failure Mode Identifier Above Normal Description Engine Speed Sensor #2: Voltage Accelerator Pedal Position 2: Voltage Below Normal Above Normal Engine Speed Sensor#2: Abnormal... - Page 150 Service and Repair Manual March 2019 Perkins 404-22 Engine Fault Codes SPN = Suspect Parameter Number Description FMI = Failure Mode Identifier 4201 Engine Speed Sensor #1: Voltage Description Below Normal 3251 Particulate Trap Differential Pressure: 4201 Engine Speed Sensor #1: Abnormal Voltage Above Normal Frequency, Pulse \Nidth, or Period 3251...

-

Page 151: Ford Msg-425 Engine Fault Codes

March 2019 Service and Repair Manual Ford MSG-425 Engine Fault Codes How to R etrieve For d M SG-425 Engine F ault C odes How to Retrieve Ford Engine Note: Before the fault codes are displayed, the check engine light will blink a code 1-6-5-4 three Fault Codes times. - Page 152 Service and Repair Manual March 2019 Ford MSG-425 Engine Fault Codes IAT high voltage Code Description ECT higher than expected 1 TIP Low Voltage ECT/CHT Low Voltage TIP High Voltage ECT/CHT High Voltage Injector Loop Open or Low-side short to Ground TPS1 lower than TPS2 Injector Coil Shorted...

- Page 153 March 2019 Service and Repair Manual Ford MSG-425 Engine Fault Codes Code Description Code Description Emissions/catalyst damaging misfire 5VE1 low voltage Emissions/catalyst damaging misfire 5VE1 high voltage Emissions/catalyst damaging misfire MIL open Emissions/catalyst damaging misfire 5VE2 low voltage Emissions/catalyst damaging misfire 5VE2 high voltage Emissions/catalyst damaging misfire Relay Coil Open...

- Page 154 Service and Repair Manual March 2019 Ford MSG-425 Engine Fault Codes Code Description Code Description 1173 Megajector comm lost 1551 AUX DIG1 high 1174 Megajector voltage supply high 1552 AUX DIG1 low 1175 Megajector voltage supply low 1553 AUX DIG2 high 1176 Megajector internal actuator fault detection 1554...

- Page 155 March 2019 Service and Repair Manual Ford MSG-425 Engine Fault Codes Code Description Code Description 1629 J1939 TSC1 message receipt lost 2130 IVS stuck at-idle, FPP1/2 match 1630 J1939 ETC message receipt lost 2131 IVS stuck off-idle, FPP1/2 match 1631 PWM1-Gauge1 open / ground short 2135 TPS1/2 simultaneous voltages out of range...

- Page 156 Service and Repair Manual March 2019 Ford MSG-425 Engine Fault Codes Code Description 2309 Primary Loop Open or Low-side Short to Ground 2310 Primary Coil Shorted 2312 Primary Loop Open or Low-side Short to Ground 2313 Primary Coil Shorted 2315 Primary Loop Open or Low-side Short to Ground 2316...

- Page 157 March 2019 Service and Repair Manual Schematics Section 5 Schematics About This Section There are two groups of schematics in this section. Electrical Schematics Electrocution/burn hazard. Contact with electrically charged Observe and Obey: circuits could result in death or serious injury. Remove all rings, Troubleshooting and repair procedures shall be watches and other jewelry.

- Page 158 Service and Repair Manual March 2019 Electrical Symbol Legend Battery Coil, solenoid or relay Horn or alarm Flashing beacon Gauge Diode Hour meter Fuse with amperage Foot switch T-circuits connect Limit Switch Power relay Coil with suppression Fuel or RPM solenoid T-circuits connect at Circuits crossing no Quick disconnect...

- Page 159 March 2019 Service and Repair Manual Hydraulic Symbols Legend Orifice with size Check valve Shut off valve Brake Pump, bi-directional Motor, 2 speed Pump, fixed displacement Motor, bi-directional variable displacement bi-directional Pump, prime mover (engine Shuttle valve. 2 position, Cylinder, double acting Differential sensing valve or motor) 3 way...

- Page 160 Service and Repair Manual March 2019 Limit Switches and Angle Sensors Types of Limit Switches Numbering Legend There are two types of limit switches, found in Limit Front Circuit Load Operational various locations throughout the machine: Switch Axle Number moment mechanical-type operational/safety switches and Rear Stringpot...

- Page 161 March 2019 Service and Repair Manual Limit Switch Location Legend S-60 XC / S-65 XC 1 S24 1 Rotary Sensor 2 LSB1RS 2 LST3S 3 LSB2S 3 LST1O 4 String Potentiometer 4 UTS Limit Switches and Sensors Platform overload sensor LSB1RS Limit switch boom fully retracted- operational LSB2S...

- Page 162 Service and Repair Manual March 2019 This page intentionally left blank. ® ™ ® ™ ® ™ ® ™ -60 XC • S -65 XC -60 TraX -65 TraX Part No. 1288652GT...

- Page 163 March 2019 Service and Repair Manual Electrical Schematic- TCON...

- Page 164 Service and Repair Manual March 2019 Electrical Schematic- TCON ® ™ ® ™ ® ™ ® ™ -60 XC • S -65 XC -60 TraX -65 TraX Part No. 1288652GT...

- Page 165 March 2019 Service and Repair Manual Electrical Schematic, PCON ® ™ ® ™ ® ™ ® ™ Part No. 1288652GT -60 XC • S -65 XC -60 TraX -65 TraX...

- Page 166 Service and Repair Manual March 2019 Electrical Schematic- PCON...

- Page 167 March 2019 Service and Repair Manual Electrical Schematic- Deutz 2.9L Models...

- Page 168 Service and Repair Manual March 2019 Electrical Schematic- Deutz 2.9L Models ® ™ ® ™ ® ™ ® ™ -60 XC • S -65 XC -60 TraX -65 TraX Part No. 1288652GT...

- Page 169 March 2019 Service and Repair Manual Electrical Schematic- Deutz D2011 Models ® ™ ® ™ ® ™ ® ™ Part No. 1288652GT -60 XC • S -65 XC -60 TraX -65 TraX...

- Page 170 Service and Repair Manual March 2019 Electrical Schematic- Deutz D2011 Models...

- Page 171 March 2019 Service and Repair Manual Electrical Schematic, Perkins 404F-E22T Models...

- Page 172 Service and Repair Manual March 2019 Electrical Schematic- Perkins 404F-E22T Models ® ™ ® ™ ® ™ ® ™ -60 XC • S -65 XC -60 TraX -65 TraX Part No. 1288652GT...

- Page 173 March 2019 Service and Repair Manual Electrical Schematic- Perkins 404D-22 Models ® ™ ® ™ ® ™ ® ™ Part No. 1288652GT -60 XC • S -65 XC -60 TraX -65 TraX...

- Page 174 Service and Repair Manual March 2019 Electrical Schematic, Perkins 404D-22 Models...

- Page 175 March 2019 Service and Repair Manual Electrical Schematic- Ford MSG425 Models...

- Page 176 Service and Repair Manual March 2019 Electrical Schematic- Ford MSG425 Models ® ™ ® ™ ® ™ ® ™ -60 XC • S -65 XC -60 TraX -65 TraX Part No. 1288652GT...

- Page 177 March 2019 Service and Repair Manual Electrical Schematic, Generators ® ™ ® ™ ® ™ ® ™ Part No. 1288652GT -60 XC • S -65 XC -60 TraX -65 TraX...

- Page 178 Service and Repair Manual March 2019 Electrical Schematic- Generators...

- Page 179 March 2019 Service and Repair Manual Hydraulic Schematic- from SN S60XCH-45010, S65XCH-45001...

- Page 180 Service and Repair Manual March 2019 Hydraulic Schematic- from SN S60XCH-45010, S65XCH-45001 ® ™ ® ™ ® ™ ® ™ -60 XC • S -65 XC -60 TraX -65 TraX Part No. 1288652GT...

- Page 181 March 2019 Service and Repair Manual Hydraulic Schematic- from SN S65XCM-101 ® ™ ® ™ ® ™ ® ™ Part No. 1288652GT -60 XC • S -65 XC -60 TraX -65 TraX...

- Page 182 Service and Repair Manual March 2019 Hydraulic Schematic- from S65XCM-101 S®-60 XC™ • S®- 65 XC™ S®- 60 TraX™ S®- 65 TraX™ Part No. 1288652GT Ser vic e and R epair M anual March 2019...

Need help?

Do you have a question about the S65XCM-101 and is the answer not in the manual?

Questions and answers