Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Pentair Aurora Edwards 150

- Page 1 Edwards Model 150 / 160 / 300 Pump Maintenance Manual...

-

Page 3: Table Of Contents

Contents Installation Safety Inspection ..... . 3-1 General Precautions ....iii Unpacking . -

Page 5: Safety

Safety General Precautions The following are general safety precautions not related to any specific procedure. Per- sonnel must understand and apply these precautions during both operation and main- tenance of the pump. Do Not Operate Pump Without Ear Protection. The pump has heat-treated steel timing gears, which can be very noisy when operated above 900 rpm. -

Page 6: Cautions

Edwards Model 150-348 Pump Do not order parts using this manual if the model number on the pump is not 150-348 or the serial number is not ________________. Using parts ordered from the wrong manual could result in pump failure or personal injury. Cautions Do not hammer on pump endcase. -

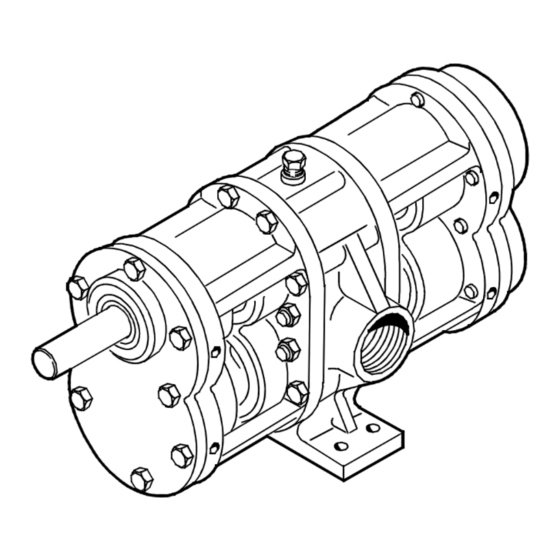

Page 7: General

General Introduction The Edwards Model 150, Model 160 and Model 300 pumps (Figure 1-1) are standard-duty high-speed gear-driven positive-displacement rotary pumps with gear-type rotors. The pumps are self-priming. Edwards rotary pumps are available in many configurations. While they may look alike, there may be significant differences from one pump to another. Differences include construction material, sealing method, rotor type, etc Figure 1-1. -

Page 8: Maintenance

150-348 and the serial number is ________________. If the numbers do not match, contact Edwards - Pentair Water. Most pump repairs can be performed by maintenance personnel using normally avail- able tools. -

Page 9: Lubrication

Model 150 / 160 / 300 Pumps Table 2-1. Consumable Materials (Continued) Item Nomenclature Specification Common Name General Purpose Grease MIL-G-18709 Chevron Ulti-Plex, Shell Retina LC NLGI #2 Lapping Compound D51804, 180 Grit Felpro “Clover” Silicon Carbide Brand Lubrication Zerk fittings do not have check balls. -

Page 10: Removal

Maintenance Table 2-3. Troubleshooting (Continued) Trouble Probable Cause Remedial Action 2c. Worn or damaged 2c. Repair or replace pump. bearing(s). Excessive 3a. Loose or misaligned 3a. Tighten, align, or replace vibration coupling. coupling. 3b. Cavitation. 3b. Check suction piping with a vacuum gauge. -

Page 11: Disassembly

Model 150 / 160 / 300 Pumps Disassembly General Practice 1. Keep work area as clean as possible to avoid contamination of internal parts. 2. Replace gaskets, packings, and seals removed during repair. Replace all keys, spring washers, and like items during assembly. 3. - Page 12 Maintenance UPPER DRIVE SUCTION DISCHARGE DISCHARGE PORT PORT PORT LEFT HAND RIGHT HAND ROTATION ROTATION LOWER DRIVE SUCTION SUCTION DISCHARGE PORT PORT PORT LEFT HAND RIGHT HAND ROTATION ROTATION 1070_0002a.cdr NOTE: ALL ROTATIONS ARE VIEWED FROM PUMP SHAFT END. Edwards USES THE FOLLOWING NOTATION FOR PUMP IDENTIFICATION: UR = UPPER SHAFT –...

-

Page 13: Cleaning

Model 150 / 160 / 300 Pumps 9/16’’ HOLES 1/2’’ x 2-1/2’’ NC GRADE 8 (2 PLACES) CAP SCREWS (2 PLACES) 2-3/4’’ 3/4’’ 6’’ 2’’ 1070_0003a.cdr Figure 2-2. Timing-Gear Puller Fabrication Diagram 13. Remove timing gear endcase (15) and pump body gasket (20). Discard gasket. Never hammer directly on pump drive shaft. -

Page 14: Inspection

Maintenance 5. Place ball or roller bearings in basket and suspend in container of “dry” cleaning Always replace solvent overnight. If necessary, use soft-bristled brush to remove caked grease and bearings whenever chips. Avoid rotating bearing before solid particles are removed to prevent damag- possible. -

Page 15: Assembly

Model 150 / 160 / 300 Pumps Assembly General Practice 1. Remove any protective coatings from new parts. 2. Lubricate bearings with same type of lubricant normally used in pump or as directed in specific repair procedure. 3. Lubricate lip of oil seals with lubricant specified in specific procedure. Install oil seals, with lip facing out, by applying an even force to outer edge of seal. - Page 16 Figure 2-4. We recommend using with two lips must face toward pump an arbor press to seat the seals. Installation tools are available from Edwards-Pentair Water. body as shown in 3. Pre-lubricate grease seals (14) with approved grease (7, Table 2-1).

- Page 17 Model 150 / 160 / 300 Pumps 3. Check that seals (19) have been installed in endcase (15) before proceeding with Seals must be endcase installation. installed in end- cases before install- Make sure liners fit into counterbore on endcase, and that they can be fully ing endcases.

- Page 18 Maintenance Do not overtighten bearing adjusting nut setscrews. Excessive bearing preload may result, causing bearing damage. 6. Tighten the setscrews (11) enough to secure the bearing adjusting nuts (12) in end- case (15). 7. Repeat steps 2 through 6 for drive rotor assembly (22) bearings. USE NUT AND BOLT ENDCASE TO SUPPORT DIAL INDICATOR...

-

Page 19: Replacement

Model 150 / 160 / 300 Pumps 8. Remove shim stock and rotate drive rotor (22). The drive rotor should rotate idler rotor (23) freely with no contact between rotors. Install End Covers 1. Apply light coat of approved grease (7, Table 2-1) to rubber surface of new front cover seal (7, Figure 4-1). -

Page 20: Inspection

2. Check for shipment shortages against the bill of lading. 3. Report shortages to the carrier and note them on the bill of lading. 4. Notify Edwards- Pentair Water of damage to contents not a fault of the carrier, or in the event of short- ages. -

Page 21: Clean Pump

Model 150 / 160 / 300 Pumps 3. Leave plastic or gasket-type port covers in place. 4. If pump comes wrapped with protective material, rewrap pump. 5. Store in clean, dry location. Installation The pump can be installed wherever adequate space exists to connect piping and per- form maintenance. - Page 22 Installation...

-

Page 23: Prepare Foundation

Model 150 / 160 / 300 Pumps Prepare Foundation The foundation absorbs any vibration, strains, or shock, while providing a permanent, rigid support for the pump skid. 1. Construct a foundation form that is 4 to 6 inches longer and wider than the skid base. -

Page 24: Level Pump Skid

Installation PUT WASTE 1/2’’ AROUND BOLT TEMPLATE BEFORE POURING CONCRETE LEAVE SURFACE ROUGH TO ANCHOR GROUT SLEEVE 5’’ 1.5’’ WASHER 1/4’’ 2’’ 3’’ 1070_0011a.cdr Figure 3-5. Typical Foundation Bolt Configuration Level Pump Skid 1. Before pump skid is set on foundation, clean underside of skid base and top of foun- dation. -

Page 25: Check Driver Rotation

Model 150 / 160 / 300 Pumps 3. Wet top of foundation prior to grouting. 4. Pour grout between frame and skid base. 5. Puddle grout as poured, working as much as possible under skid base and into sleeves around foundation bolts. Ideally, complete space under skid base should be filled to height of grout around skid base. -

Page 26: Align Couplings

Installation 4. Start and stop the driver while observing driver shaft rotation. Driver rotation must be same as pump rotation. For applications Align Couplings where pumps are operated at elevated The alignment of the pump and motor or engine driver must be checked before startup. temperatures, final Maximum angular offset in the two coupling halves is 1 degree;... - Page 27 Model 150 / 160 / 300 Pumps FEELER GAUGE 1070_0014a.cdr Figure 3-8. Checking for Angular Coupling Misalignment Checking for Parallel Misalignment. To check parallel misalignment: 1. Attach dial indicator as shown in Figure 3-9. 2. With dial indicator secured to pump or driver shaft, rotate both shafts together, noting dial indicator readings through one complete revolution.

-

Page 28: Piping

Installation USE DIAL SECURE BRACKET INDICATOR TO COUPLING HALF FOR PARALLEL ALIGNMENT USE INSIDE MICROMETER FOR ANGULAR ALIGNMENT 1070_0016a.cdr Figure 3-10. Checking for Spacer Coupling Misalignment Piping Rotary pumps have close running clearances. Thus, clean piping is a must. Dirt, grit, weld bead or scale, flushed from an unclean piping system, will damage and may stall the pump. -

Page 29: Strainers

Model 150 / 160 / 300 Pumps tem including valves, strainers, and other restrictions, and the elevation of the pump with reference to supply and discharge points. Friction or line losses may be calculated by referring to the manufacturer’s Engineering Manual or the Hydraulic Institute’s Engineering Data Book. -

Page 30: Pre-Startup Checks

Installation RECOMMENDED BYPASS FLOW SUPPLY TANK PRESSURE RELIEF VALVE NOT RECOMMENDED BUSHING PIPE TEE TO SYSTEM SUCTION PORT DISCHARGE PORT ROTARY GEAR PUMP 1070_0005a.cdr Figure 3-11. Pump By-pass Piping Pre-Startup Checks Inspection checks are essential to avoid operational difficulties and ensure trouble-free startup. - Page 32 Check the name plate on the pump to make certain the model number is 150-348 and the serial number is ________________. If the numbers do not match, contact Edwards - Pentair Water. When ordering parts, please provide: 1.

- Page 33 SECTION EDWARDS PAGE 8 EDWARDS DATED JANUARY 2008 Figure 4-1. Edwards Model 150 Pump Exploded View 16 15 1070_0009a.cdr Pentair Water...

- Page 34 644 ** 150-348 Splined Hydraulic 700-0891 644 ** 150-348 Splined Hydraulic 700-0891 644 ** 150-348 Splined 700-0892 644 ** 150-348 Splined 700-0892 644 ** BOLD numbers are recommended spare parts. BOLD numbers are recommended spare parts. Pentair Water Pentair Water...

- Page 35 SECTION EDWARDS PAGE 10 DATED JANUARY 2008 Figure 4-2. Edwards Model 160 Pump Exploded View 16 15 1070_0009b.cdr Pentair Water...

- Page 36 160-338 SD, HD Splined 700-0901 644 ** 160-338 SD, HD Splined 700-0901 644 ** 160-338 XHD 700-0912 644 ** 160-338 XHD 700-0912 644 ** BOLD numbers are recommended spare parts. BOLD numbers are recommended spare parts. Pentair Water Pentair Water...

- Page 37 SECTION EDWARDS PAGE 12 DATED JANUARY 2008 Figure 4-3. Edwards Model 300 Pump Exploded View 16 15 1070_0009a.cdr Pentair Water...

- Page 38 368 SD, HD 496-0117 368 HXD 496-0119 Not used with hydraulic bracket 372 SD, HD 496-0121 372 XHD 496-0123 ** For Duplex SS Shafts, change material code to 388 SD, HD 496-0125 388 XHD BOLD numbers are recommended spare parts. Pentair Water...

- Page 40 WARRANTY: Seller warrants equipment (and its component parts) of its own manufacture against defects in materials and workmanship under normal use and service for one (1) year from the date of installation or start-up, or for eighteen (18) months after the date of shipment, whichever occurs first.

- Page 41 800 Airport Road, North Aurora, IL 60542 phone: 630-859-7000 fax: 630-859-1226 ED11008 (07/08/13) website: www.aurorapump.com...

Need help?

Do you have a question about the Aurora Edwards 150 and is the answer not in the manual?

Questions and answers